Test device for measuring and simulating brake hose

A technology of brake hose and test equipment, which is applied in the field of automobiles, can solve the problems of excessively long direction, reduce the assembly efficiency of brake hose, and the pipeline is too short, so as to avoid repeated trial installation and improve the success rate of one-time development , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

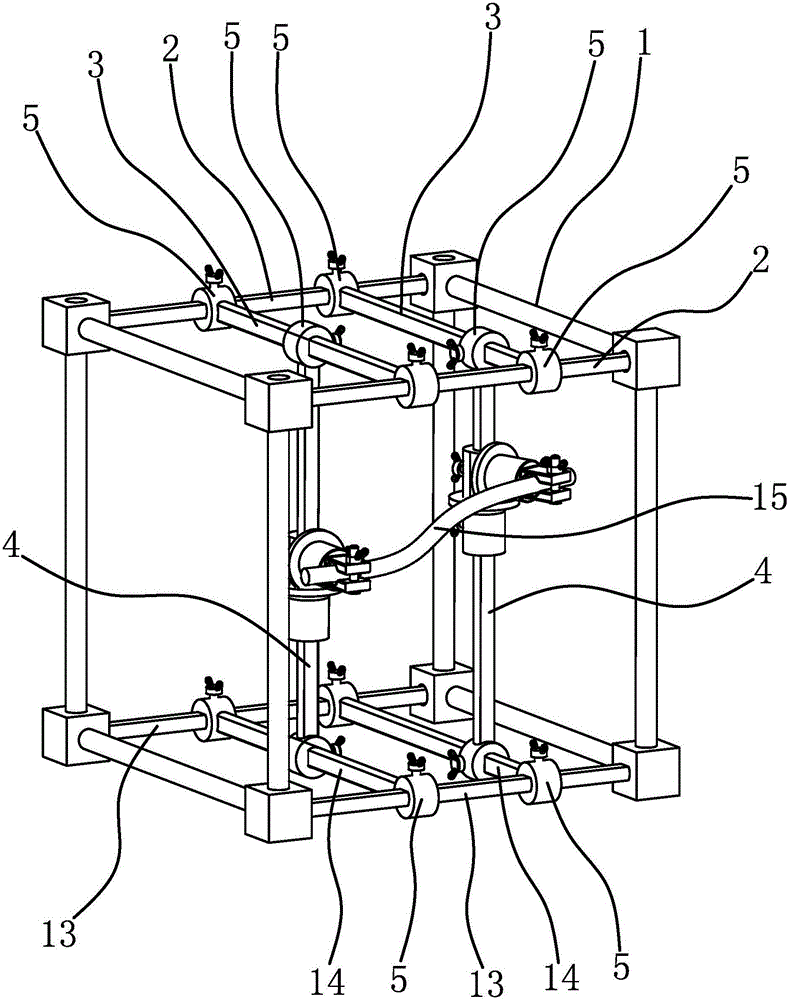

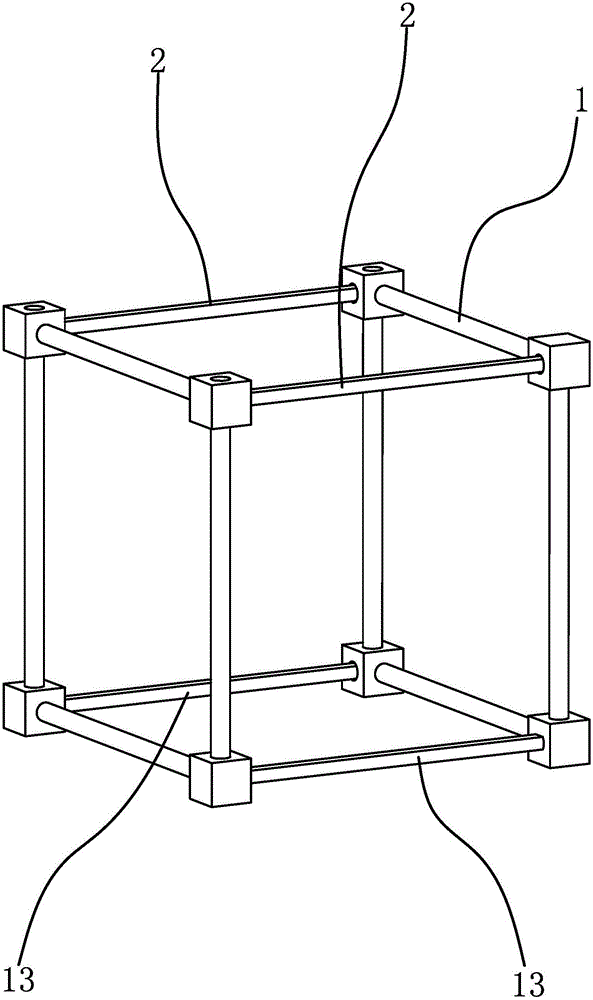

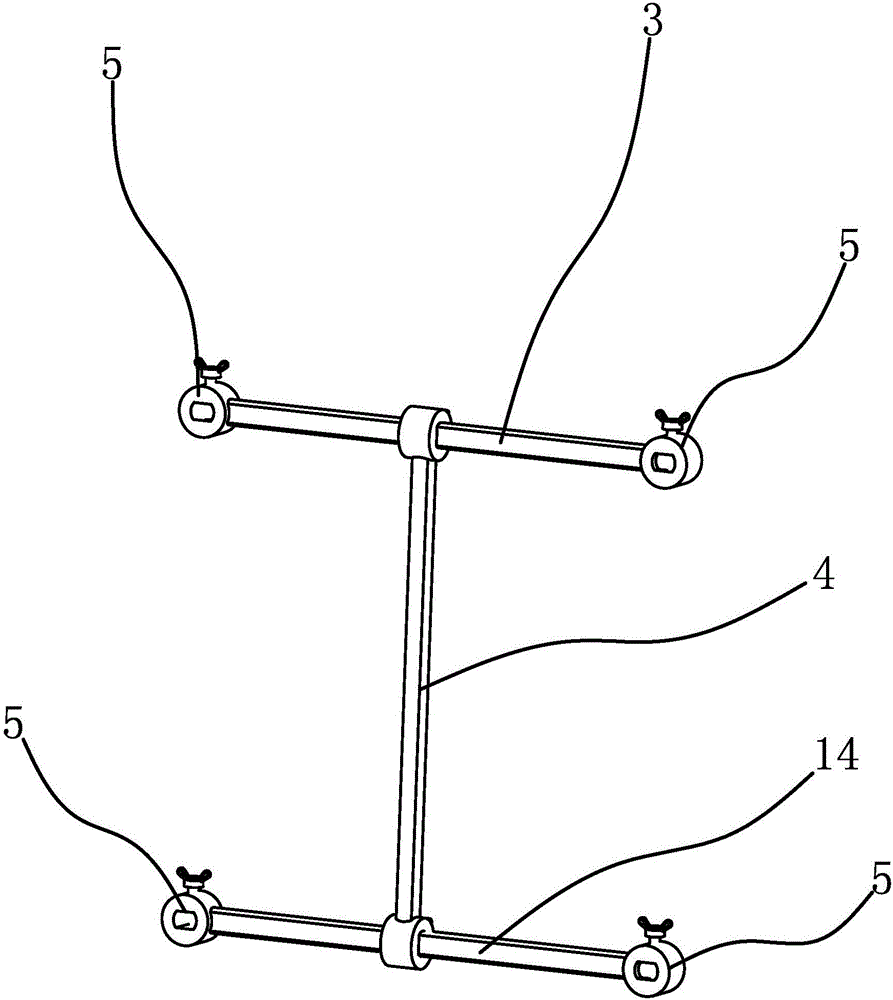

[0030]The test equipment for measuring and simulating the brake hose includes frame body 1, X scale guide rod 2, Y scale guide rod 3, Z scale guide rod 4, cursor 5, sliding sleeve 51, sliding hole 52, through screw hole 53, Adjusting knob 54, horizontal dial 6, rotating sleeve 1 7, vertical dial 8, rotating sleeve 2 9, pipe clamp 10, clamp body 1 10a, clamp body 2 10b, clamping bolt 10c, clamping port 10d, inner cylinder 11. Set screw 12, X scale auxiliary guide rod 13, Y scale auxiliary guide rod 14.

[0031] Specifically, as figure 1 with image 3 As shown, the test equipment includes a rectangular frame-shaped frame body 1, on which two X-scale guide rods 2 parallel to each other and arranged horizontally are fixed, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com