Design method for rebound valve plate thickness of hydraulic oscillating damper

A hydraulic shock absorber and recovery valve technology, which is applied in the field of hydraulic shock absorbers, can solve problems such as difficulty in mastering shock absorbers, lack of shock absorber design technology, and failure to realize modern CAD design of hydraulic shock absorbers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

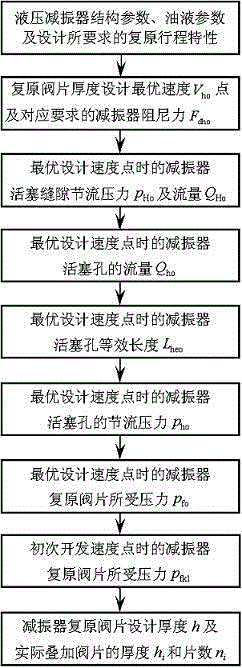

Method used

Image

Examples

Embodiment 1

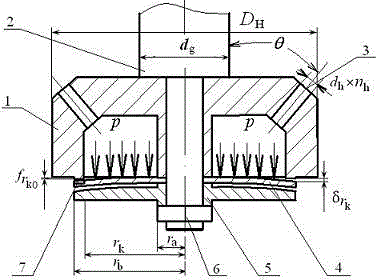

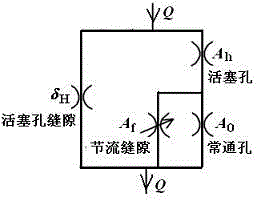

[0049] Embodiment one : The structure of a shock absorber piston assembly and recovery valve is as follows figure 2 As shown, the piston body 1, the piston rod 2, the piston hole 3, the recovery valve plate 4, the limit retaining ring 5, and the fastening nut 6, wherein, in order to prevent the excessive opening of the recovery valve from being too large when the shock absorber moves too fast When the shock absorber breaks down, the limit retaining ring 5 is installed under the recovery valve plate 4, and is fixed with the fastening nut 6; at the same time, in order to increase the service life of the shock absorber, prevent the shock absorber from frequently opening the valve when driving on ordinary roads , The recovery valve is provided with a normally through hole 6. The structural parameters of the shock absorber and the valve body structure and oil parameters are as follows: piston cylinder inner diameter , piston rod diameter d g =20mm, the annular area between t...

Embodiment 2

[0085] Embodiment two : The recovery speed characteristic required by the design of a certain hydraulic shock absorber, such as Figure 6 Shown, the initial valve opening speed , initial valve opening damping force ;Maximum valve opening speed , the maximum valve opening damping force , the structural parameters and oil parameters of the shock absorber are the same as those in Example 1.

[0086] Using the design steps of Embodiment 1, the thickness of the shock absorber recovery valve plate is designed, and the design value of the recovery valve plate thickness obtained h =0.267mm 2 ; The thickness and number of the actual shock absorber recovery superimposed valve slices are:

[0087] ; ; ;

[0088] The equivalent thickness of the actual restored superimposed valve plate is = 0.2674 mm.

[0089] Using the electro-hydraulic servo shock absorber comprehensive performance test bench to carry out the characteristic test on the designed and processed shock ...

Embodiment 3

[0090] Embodiment Three : The recovery speed characteristic curve required for the design of a certain hydraulic shock absorber is the same as that of Embodiment 2; d g =18mm, other structural parameters and oil parameters are exactly the same as those of Example 1.

[0091] Using the design steps of Embodiment 1, the thickness of the shock absorber recovery valve plate is designed, and the design value of the recovery valve plate thickness obtained h =0.243mm 2 ;The thickness and number of the actual restored superimposed valve slices are:

[0092] ; ; ;

[0093] The equivalent thickness of the actual restored superimposed valve plate is = 0.2431 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com