Commutator overspeed performance simulation calculation method

A technology of simulation calculation and commutator, which is applied in calculation, design optimization/simulation, instruments, etc., to achieve the effects of shortening the development cycle, strong observability, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the present invention will be further described below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

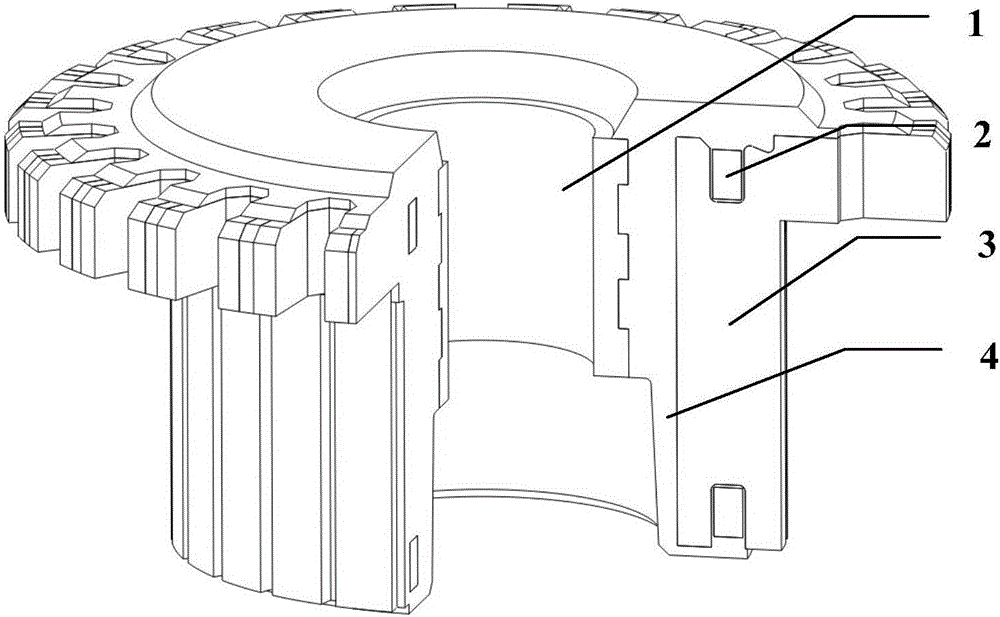

[0038] This embodiment is a simulation calculation method for the overspeed performance of the commutator, aiming at simulating the overspeed damage process of the commutator through finite element software, estimating the overspeed fracture speed of the commutator, and optimizing the design of the commutator. as attached figure 1 As shown, the commutator is composed of a bushing 1, a reinforcement ring 2, a commutator segment 3, and a molding compound 4. During the working process of the commutator, the commutator as a whole bears the centrifugal force and thermal stress, and the commutator segment acts as a The role of conducting current and commutation, the molding compound plays the role of insulation and supporting the commutator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com