Design method for optimum speed characteristics of trunk cab damper

A design method and technology of optimal speed, applied in the superstructure, vehicle components, superstructure and other directions of trucks, can solve the problem of not meeting the design requirements of the comfort of the vehicle cab, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

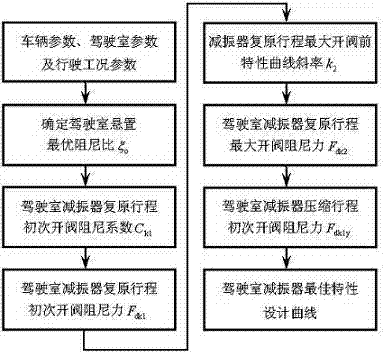

Method used

Image

Examples

Embodiment 1

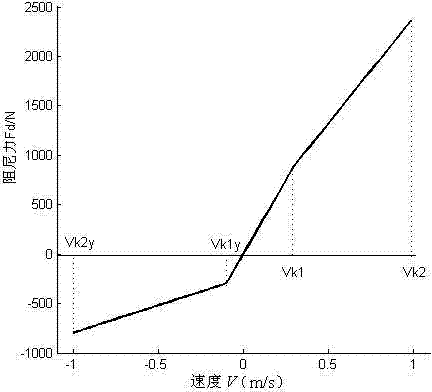

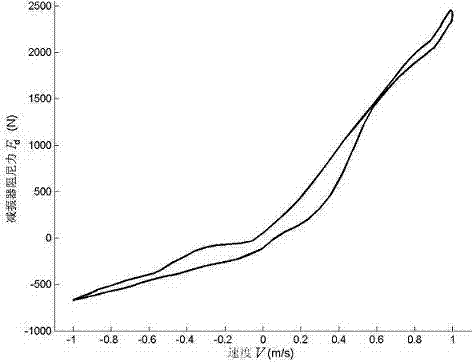

[0054] Embodiment one : One-side suspension mass of a truck full floating cab , the one-sided mount corresponds to the cab mount elastic coefficient ; The weight of the cab is carried by the single point of the front suspension , the single mounting point of the front suspension corresponds to the elastic coefficient of the cab suspension ;Corresponding body mass of a single wheel , that is, the sprung mass, the suspension spring stiffness , suspension damping ; Unsprung tire mass , tire stiffness ; Class C pavement reference spatial frequency The pavement power spectral density value under , the vehicle speed ;shock absorber installation leverage ratio , mounting angle ; Initial valve opening speed of shock absorber recovery stroke , the maximum valve opening speed ;Initial valve opening speed in compression stroke , the maximum valve opening speed ; Safety ratio of shock absorber , two-way ratio .

[0055] The design method of the optim...

Embodiment 2

[0097] Embodiment two : A truck full floating cab rear suspension single point (single shock absorber) bears the weight of the cab , the single rear suspension point corresponds to the cab suspension elastic coefficient ; Other vehicle parameters and shock absorber parameters are the same as in Example 1.

[0098] Adopt the design steps of embodiment one, namely:

[0099] (1) Determine the optimal damping ratio of the cab suspension system :

[0100] According to the quality of the one-side suspension of the cab , one-sided suspension stiffness , the sprung mass corresponding to a single wheel , suspension stiffness , suspension damping N.s / m, unsprung tire mass , tire stiffness ; Class C pavement reference spatial frequency ;reference spatial frequency The pavement power spectral density value under , and the vehicle speed , to determine the optimal damping ratio of the cab suspension system ,which is:

[0101] =0.2701;

[0102] In the formul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com