Patents

Literature

130results about How to "Improve combination efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

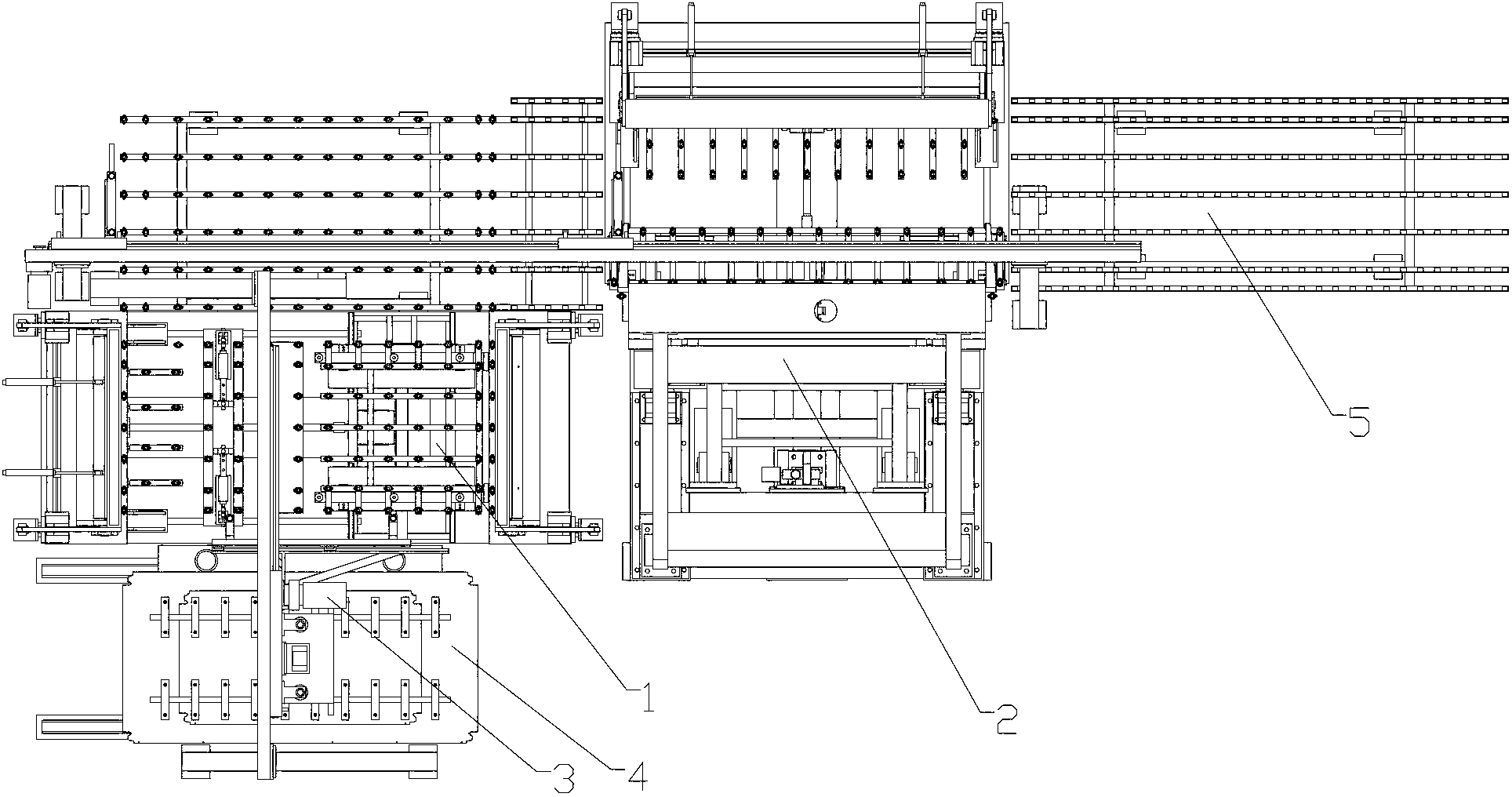

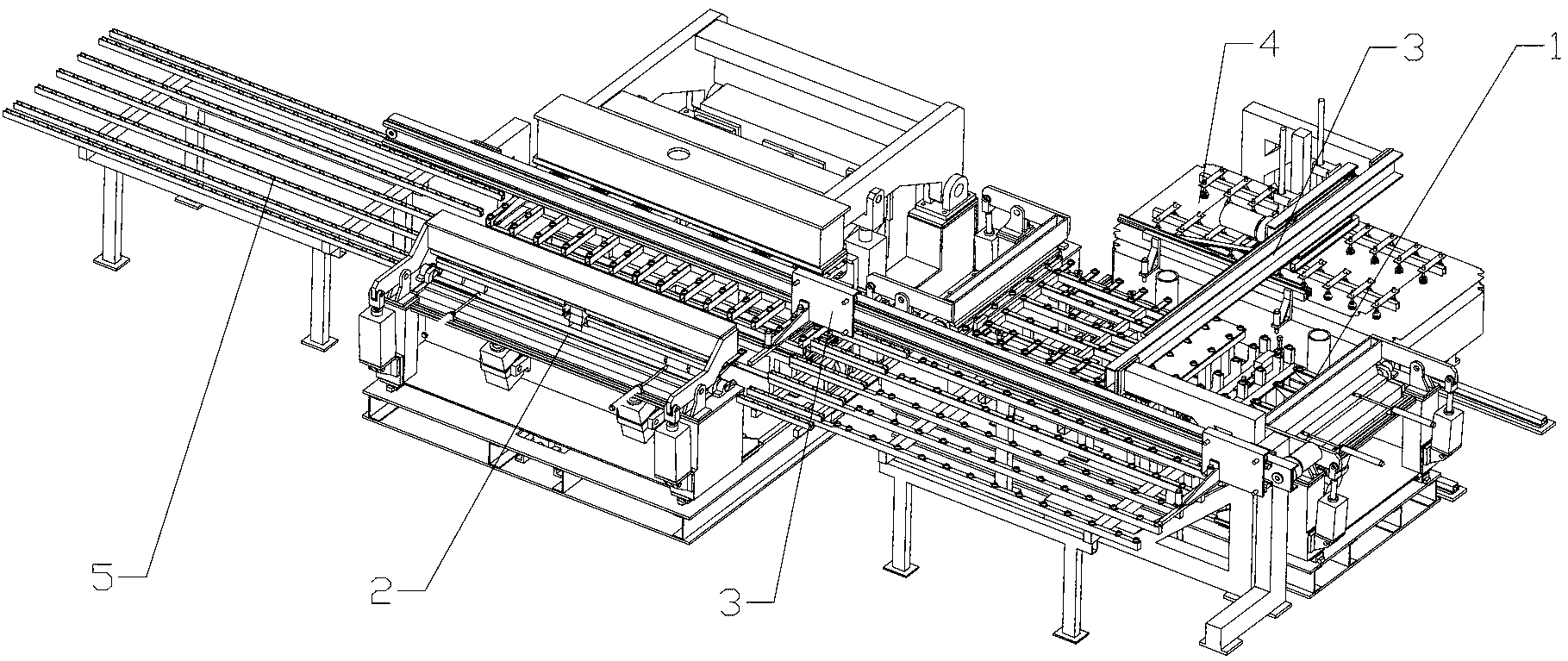

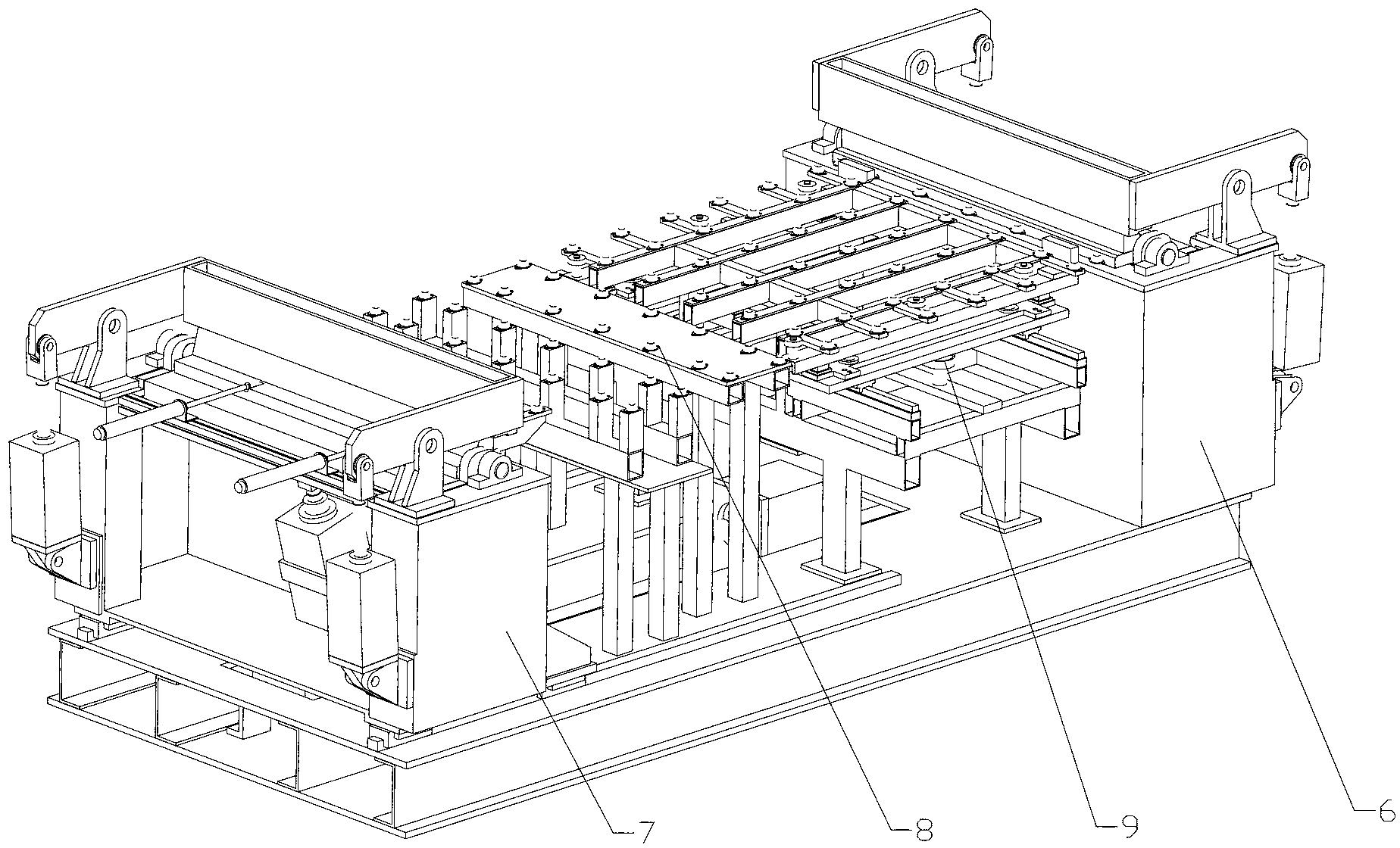

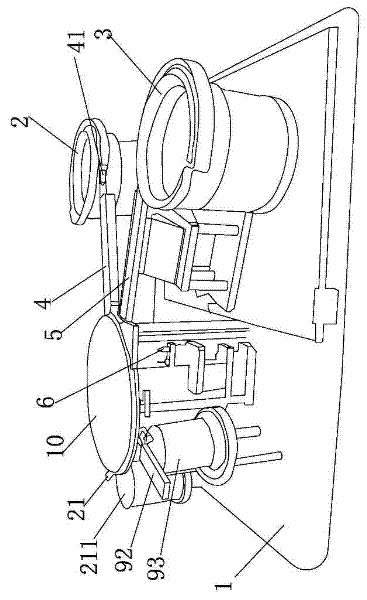

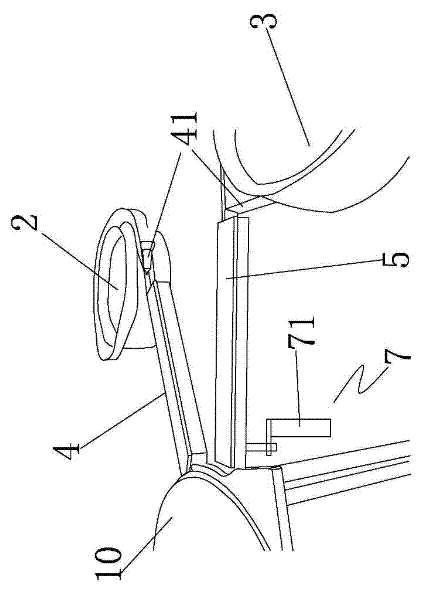

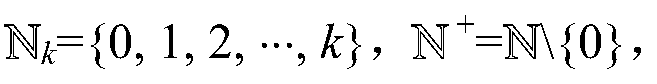

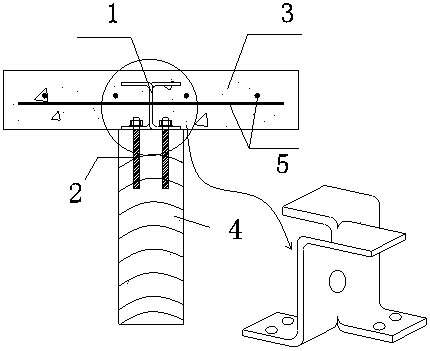

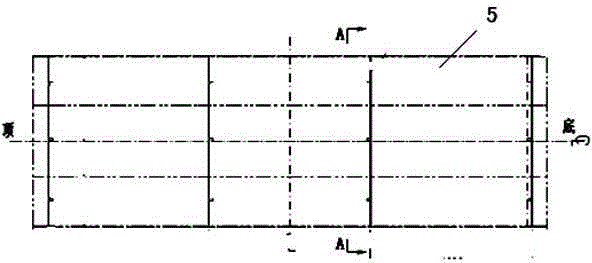

Four-side bending system

ActiveCN102909244AImprove combination efficiencyEasy to arrange for productionMaterial transferPress brake

The invention relates to a four-side bending system comprising a first bending unit, a second bending unit and a material transferring device, wherein the first bending unit is used for completing the bending work of a group of opposite sides of a material to be bent; the second bending unit is used for completing the bending work of the other group of opposite sides of the material to be bent; and the material transferring device is used for shifting the material according to the process. The first bending unit comprises a first static bending machine, a first movable bending machine, a first working table and a first positioning part, wherein the first static bending machine and the first movable bending machine are oppositely placed on a main frame; and the working table and the positioning part are placed between the first static bending machine and the first movable bending machine. The second bending unit comprises a second static bending machine, a second movable bending machine, a second working table and a second positioning part, wherein the second static bending machine and the second movable bending machine are oppositely placed on the main frame; and the second working table and the second positioning part are placed between the second static bending machine and the second movable bending machine. The four-side bending system is relatively high in production efficiency, relatively low in manufacture cost and simple to maintain and is suitable for various productions.

Owner:YINDU KITCHEN EQUIP

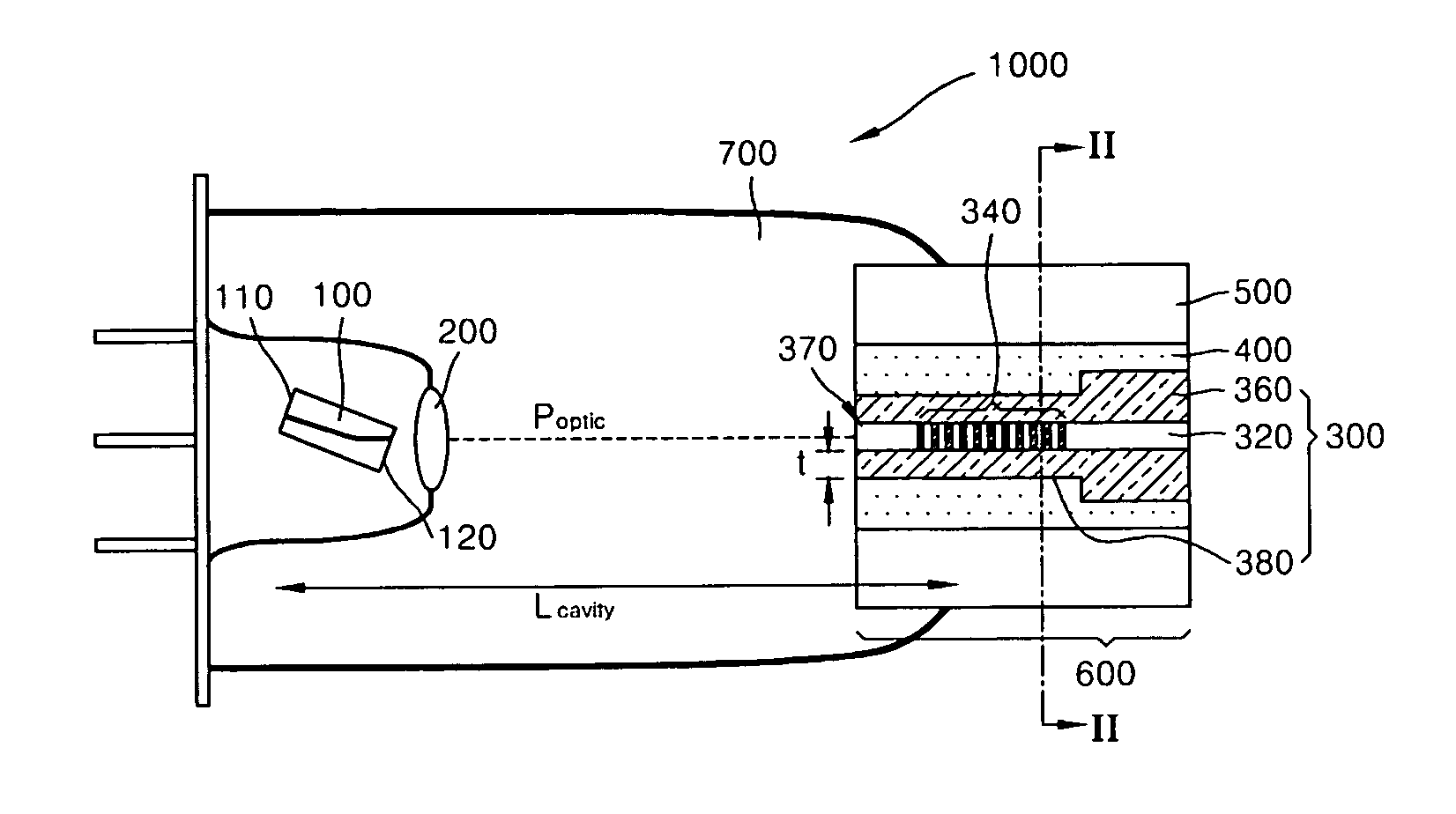

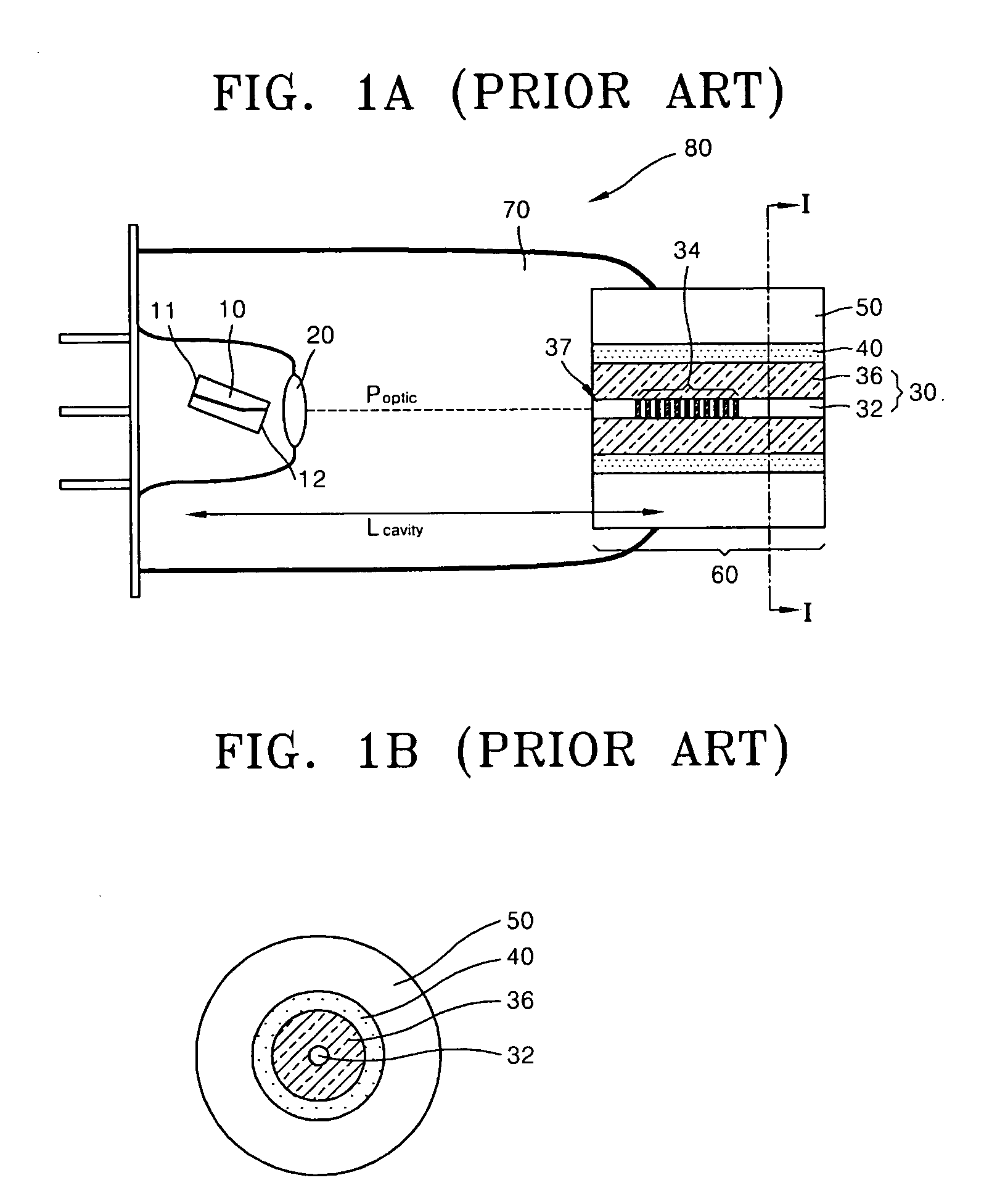

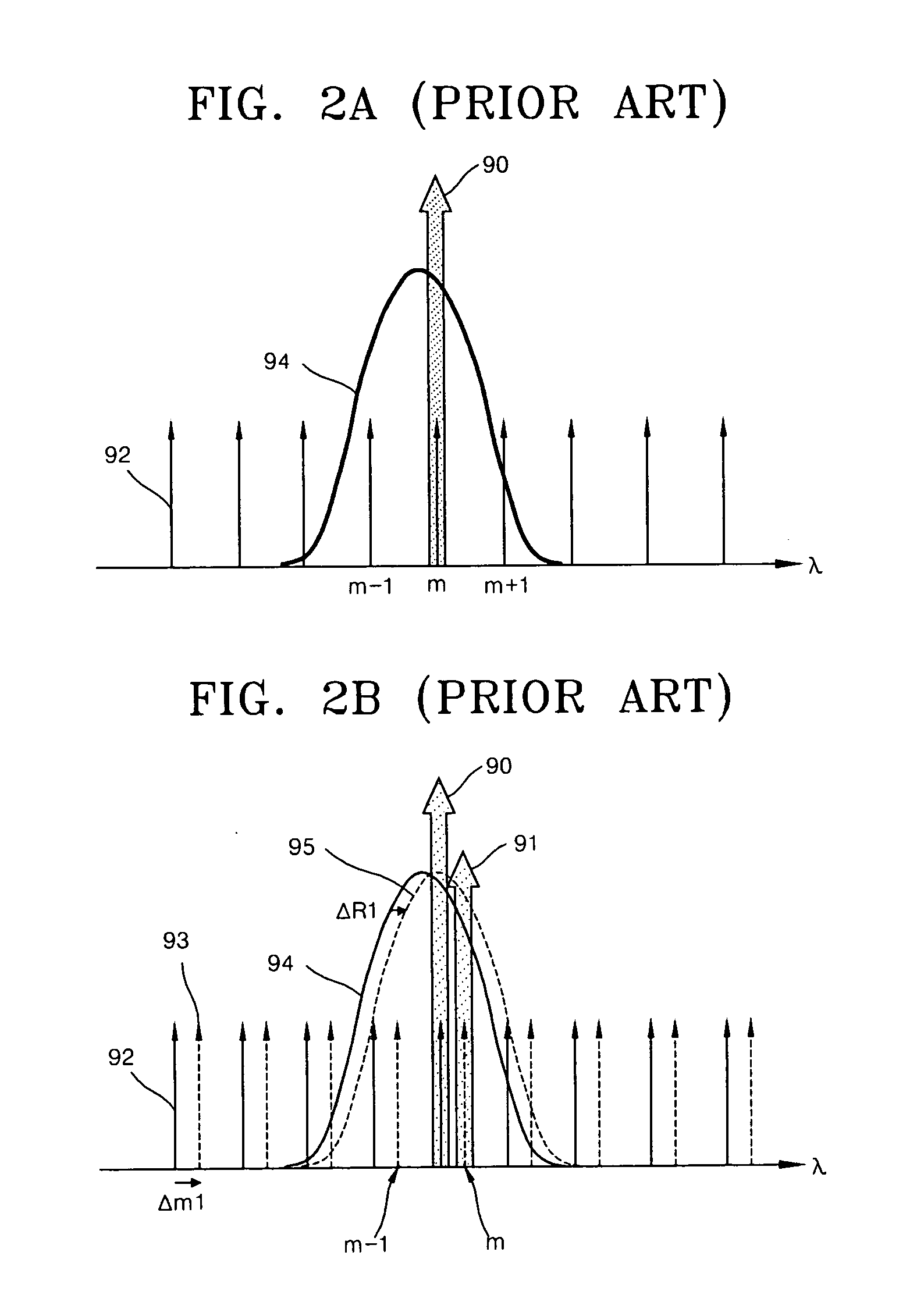

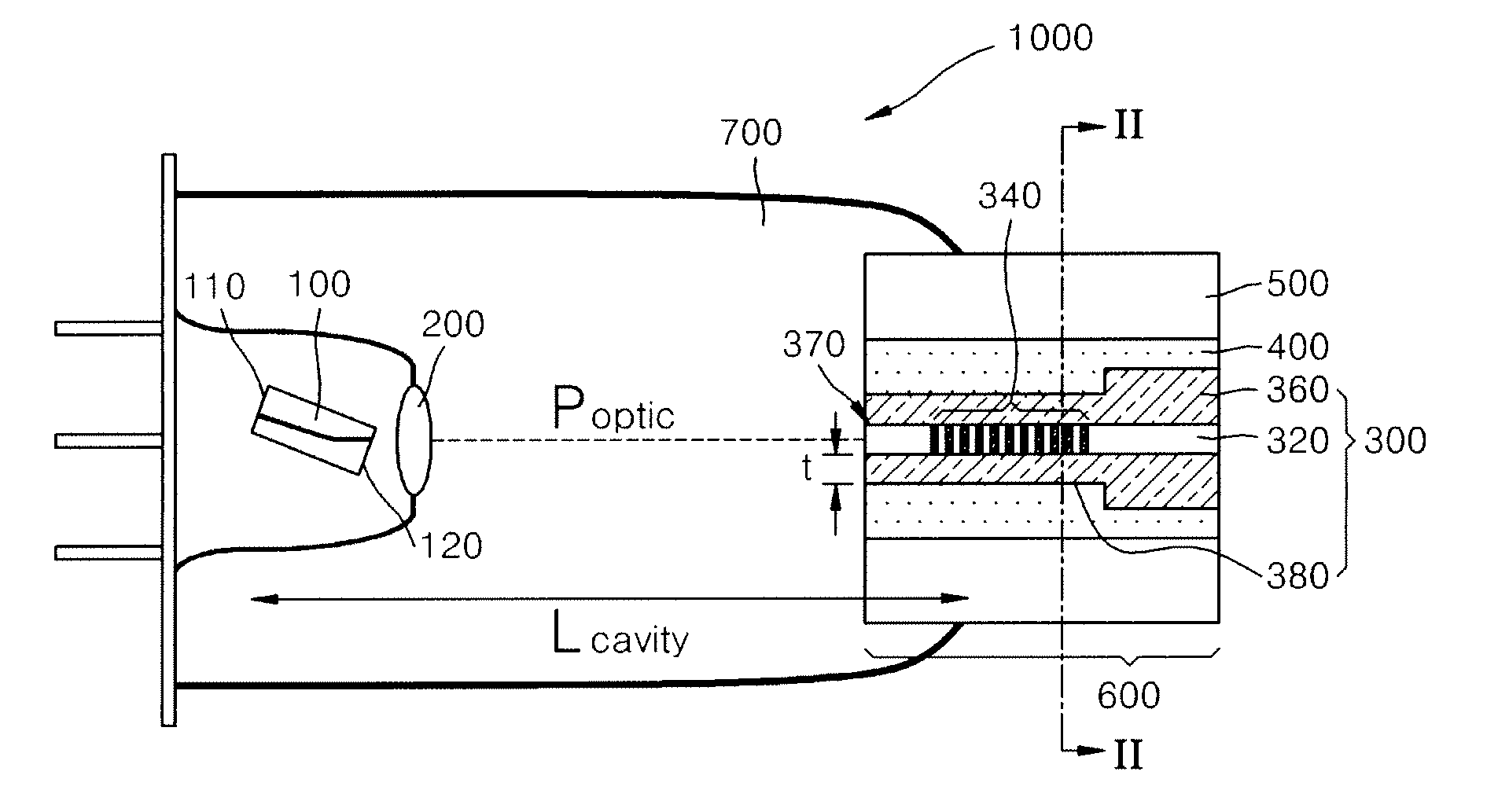

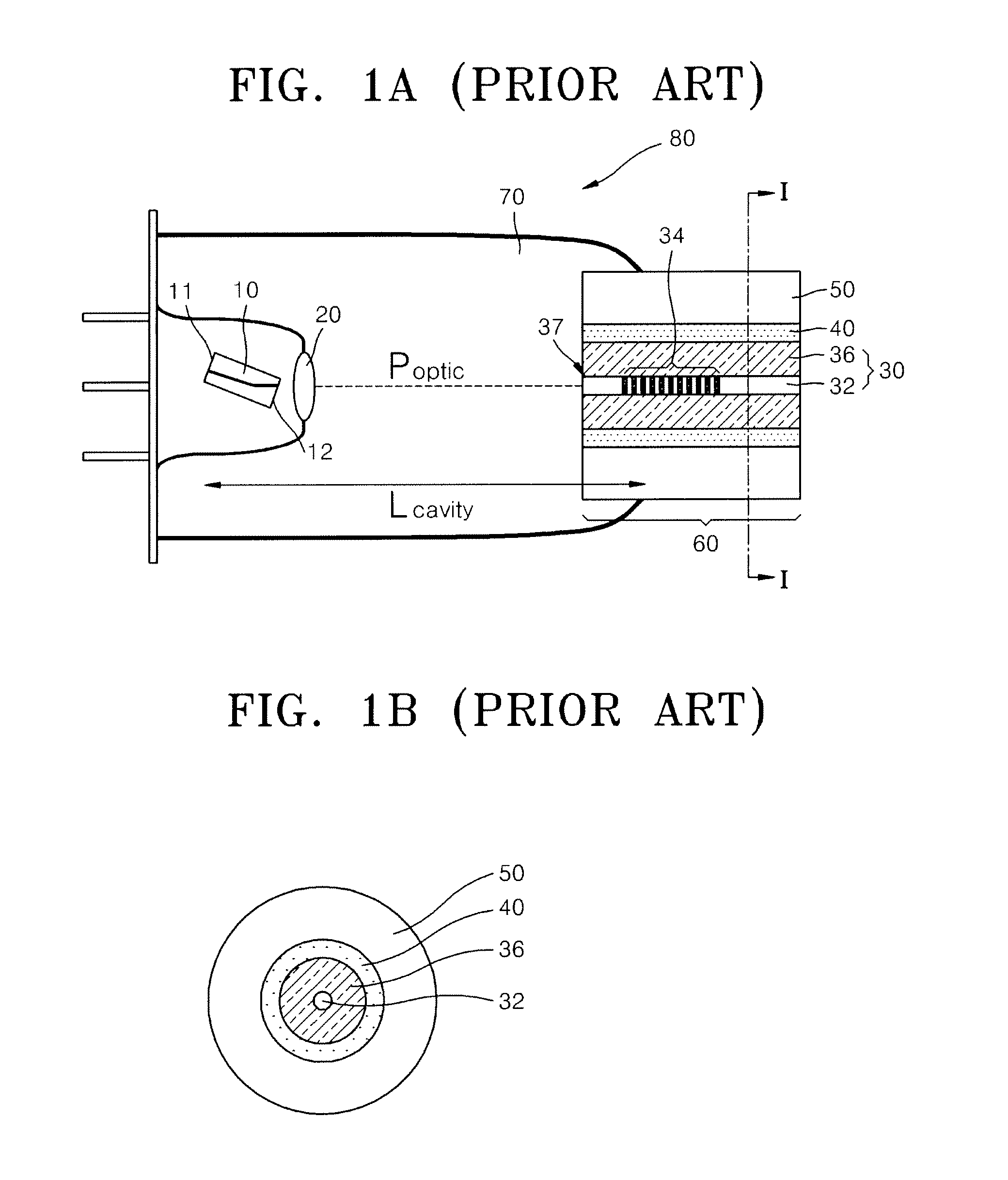

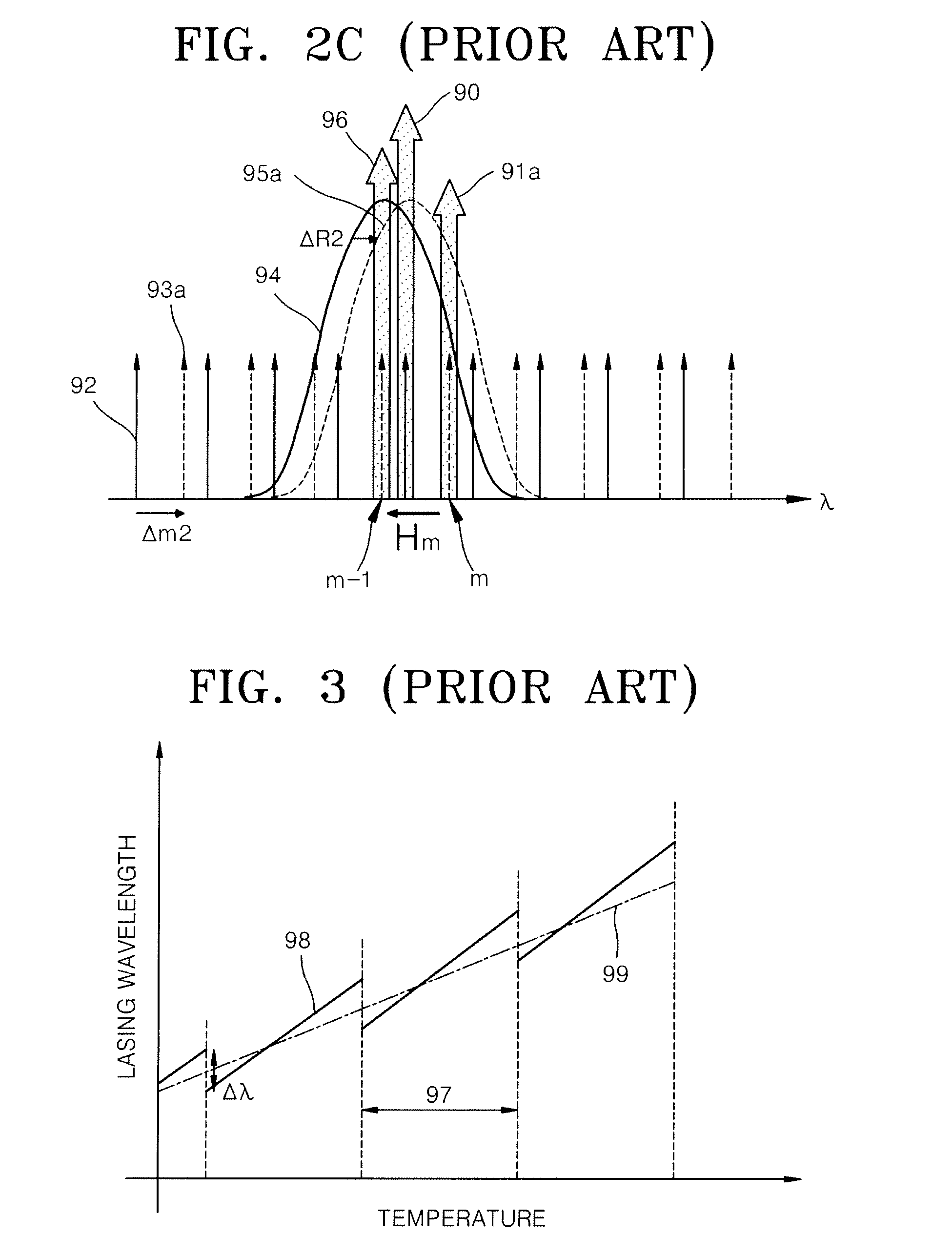

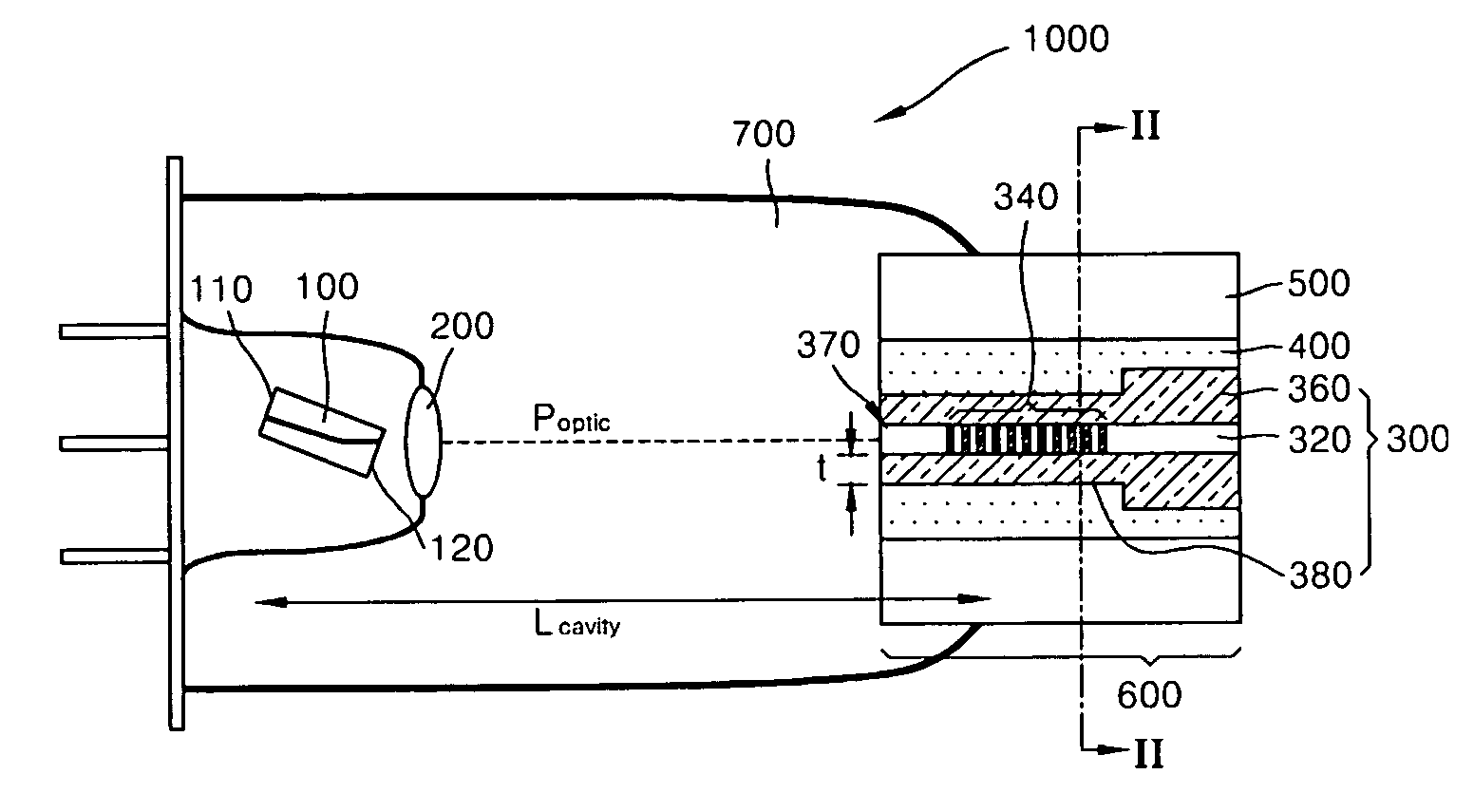

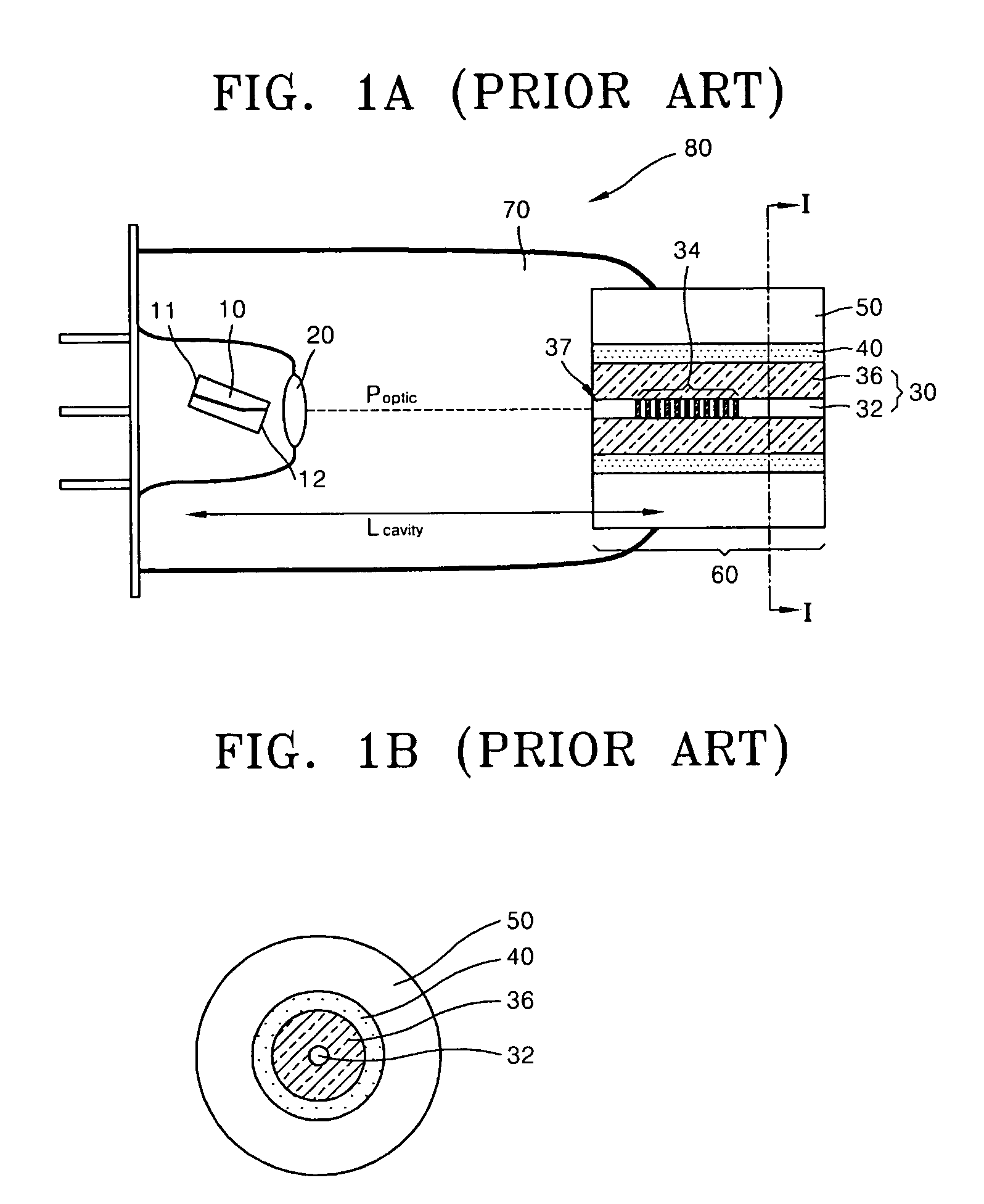

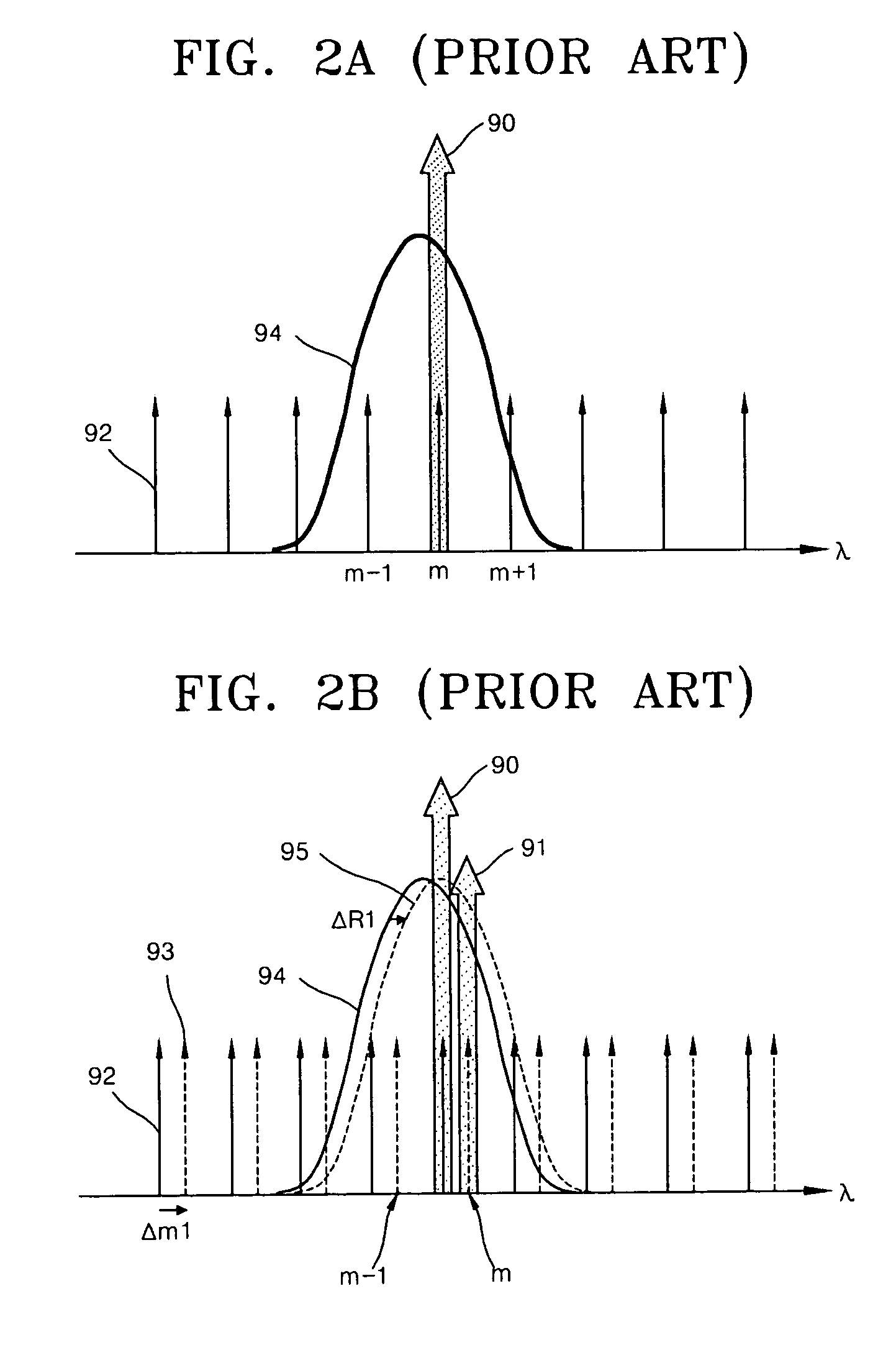

Athermal external cavity laser

ActiveUS20070127538A1Low costReduce manufacturing costLaser using scattering effectsOptical resonator shape and constructionOptical powerLight source

Provided is an athermal external cavity laser (ECL), whose output optical power and output wavelength can be kept regular irrespective of temperature changes without using additional temperature controlling components. The ECL comprises: a semiconductor amplifier; an optical fiber comprising a core in which a Bragg grating is formed and a cladding surrounding the core; and a thermosetting polymer that fixes the optical fiber to a ferrule and has a negative thermooptical coefficient, wherein the thickness of the cladding surrounding the core in which the Bragg grating is formed is smaller than the portion of the cladding surrounding the portion of the core where the Bragg grating is not formed, and the thermosetting polymer the negative thermooptical coefficient surrounds the cladding. The ECL does not need additional temperature controlling components and thus can be manufactured compact and at low cost, and thus can be used as a light source of a dense wavelength division multiplexing (DWDM) system in designing economical WDM passive optical networks (PON).

Owner:ELECTRONICS & TELECOMM RES INST

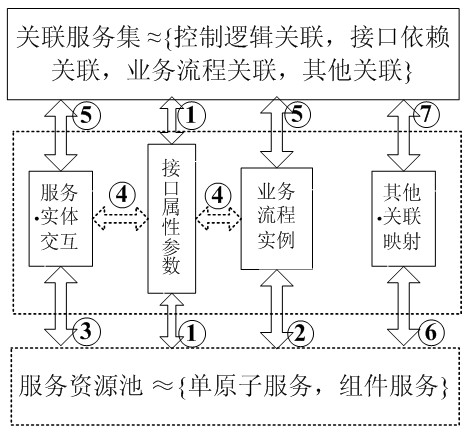

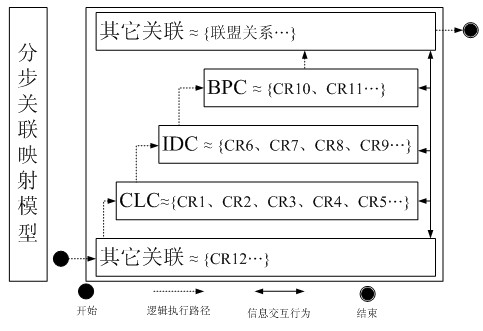

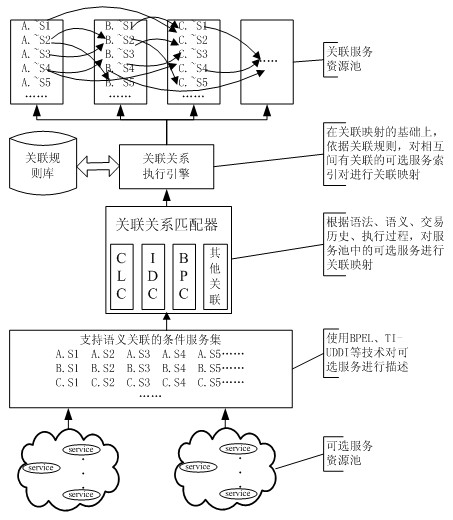

Method for establishing relevance relation among services under opened network

ActiveCN102685242AReduce development difficultyReduce difficultyTransmissionPersonalizationService implementation

The invention provides a method for establishing relevance relation among services under an opened network, which provides a sub-step relevance mapping model aiming at characteristics of dynamics, isomerism, progressive services and the like of an opened network environment, and uses the sub-step relevance mapping model to establish a relevance service resource pool meeting a user individual requirement. According to the scheme provided by the invention, the relevance relation among the services is considered from a plurality of view points; the relevance relation among the services of a combined service in different steps can be comprehensively analyzed according to an executing route of the combined service, a combination process and a service implementation process; and a sub-step relevance mapping mechanism for indexing a relevant service mapping pair list is established. With the adoption of the scheme, the selection of carrying out the services depending on port matching among the services can be expanded; the properties of an executing structure of the combined service, and the interaction property and the limitation property in service implementation can be increased; and a novel model is provided for a research of a relevance mechanism among the services in the opened network environment.

Owner:INST OF BIG DATA RES AT YANCHENG OF NANJING UNIV OF POSTS & TELECOMM

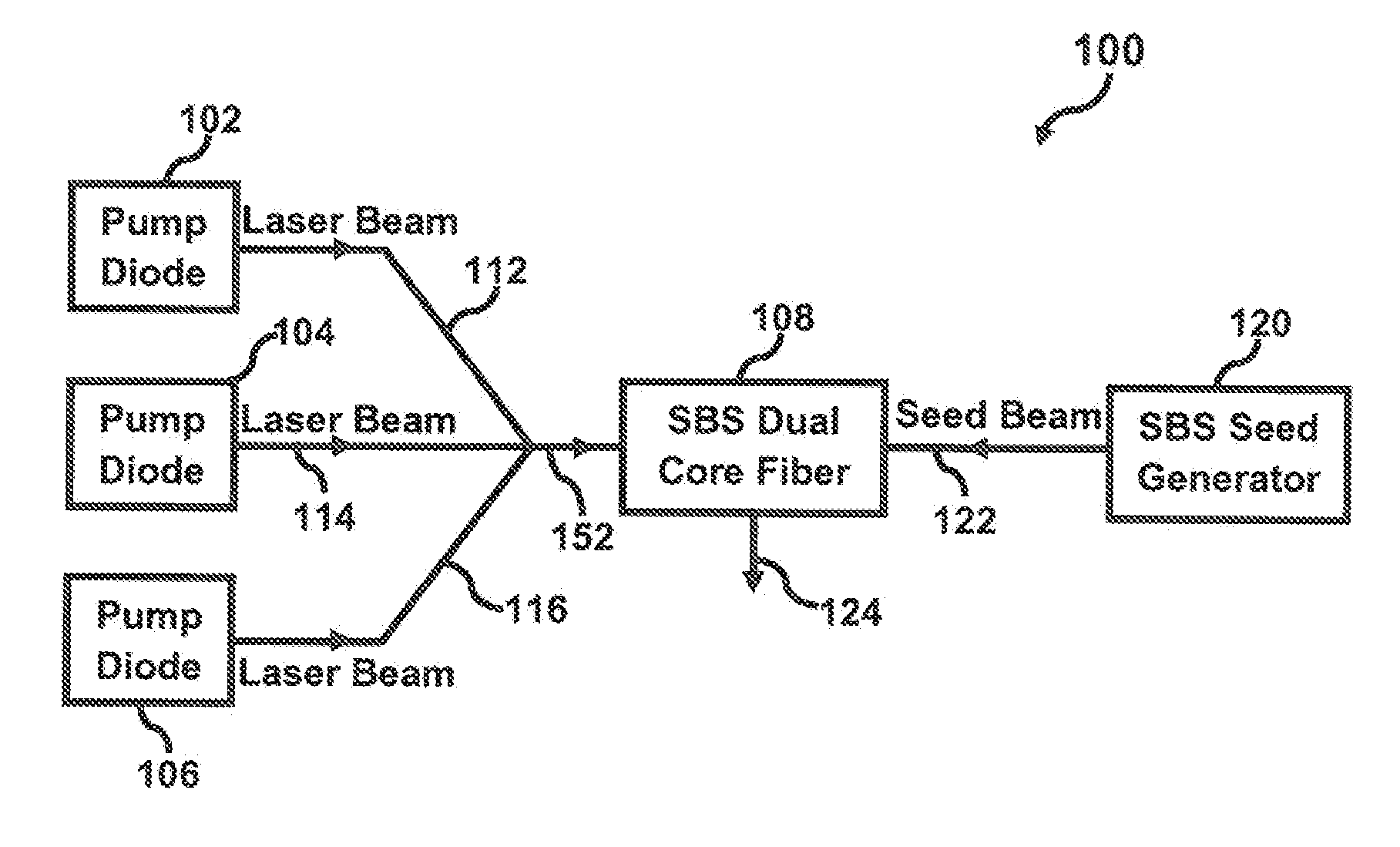

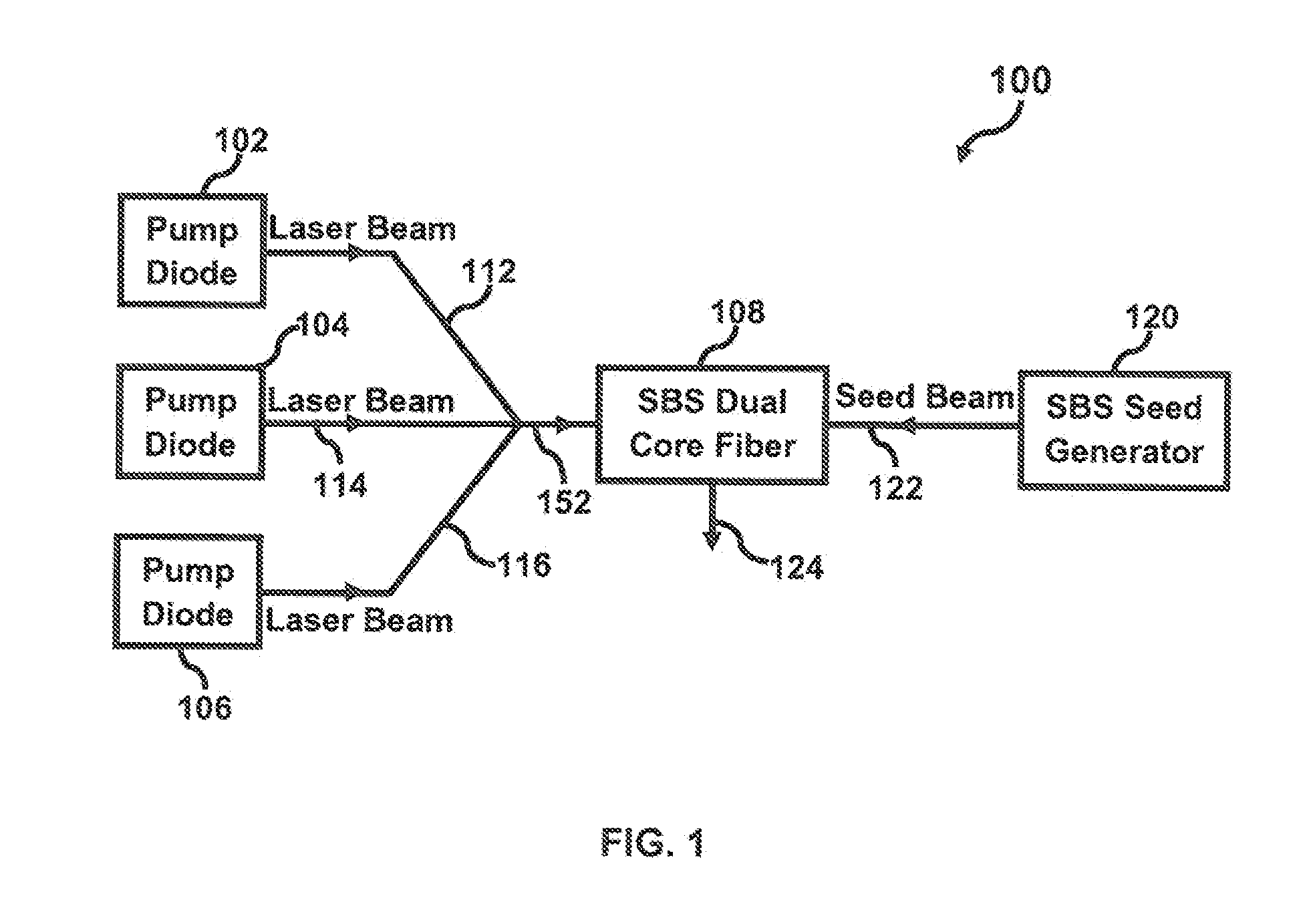

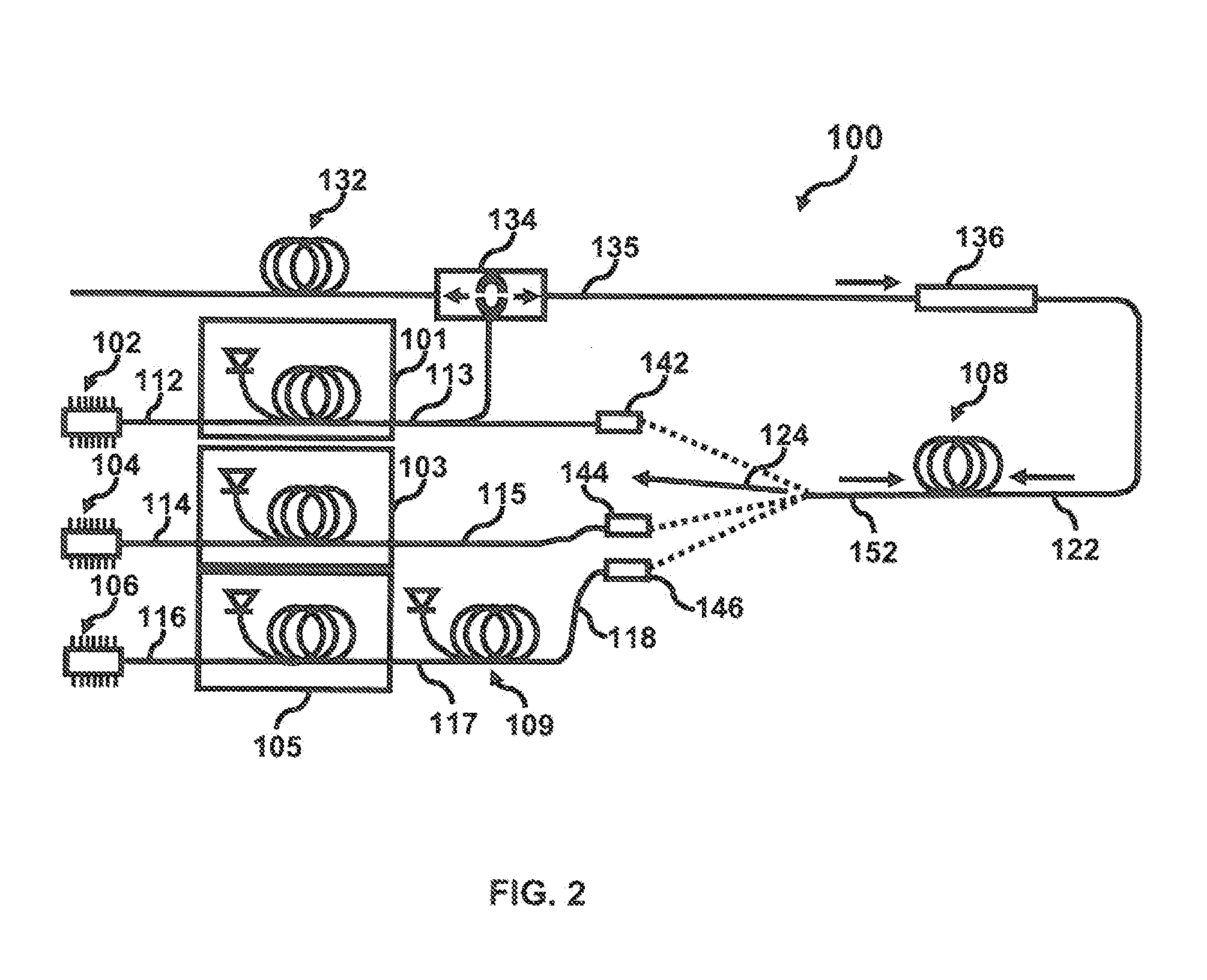

Method for beam combination by seeding stimulated brillouin scattering in optical fiber

ActiveUS20130148673A1Efficient combinationLower the thresholdLaser using scattering effectsSemiconductor lasersFiberDual core

A system and method for efficiently combining multiple laser beams into a single frequency by invoking stimulated Brillouin scattering (SBS) in a dual core optical fiber is disclosed. The method and apparatus essentially becomes a brightness converter for the input laser beams. An SRS seed is generated in a long length of fiber or by a diode and is launched into the back-end of the SBS combining optical fiber. Various single-frequency pump beams are launched into the front-end of the same fiber. The seed acts to lower a threshold for SBS in the fiber, thus invoking the nonlinearity. Provided the various pump beams are close in frequency and seed / pump modes overlap, each acts to amplify the seed through the nonlinear SBS process, providing an output signal which is brighter than the combined pump beams.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

Athermal external cavity laser

InactiveUS20100014545A1Reduce manufacturing costImprove combination efficiencyLaser using scattering effectsOptical resonator shape and constructionExternal cavity laserGrating

Provided is an athermal external cavity laser (ECL), whose output optical power and output wavelength can be kept regular irrespective of temperature changes without using additional temperature controlling components. The ECL comprises: a semiconductor amplifier; an optical fiber comprising a core in which a Bragg grating is formed and a cladding surrounding the core; and a thermosetting polymer that fixes the optical fiber to a ferrule and has a negative thermooptical coefficient, wherein the thickness of the cladding surrounding the core in which the Bragg grating is formed is smaller than the portion of the cladding surrounding the portion of the core where the Bragg grating is not formed, and the thermosetting polymer the negative thermooptical coefficient surrounds the cladding. The ECL does not need additional temperature controlling components and thus can be manufactured compact and at low cost, and thus can be used as a light source of a dense wavelength division multiplexing (DWDM) system in designing economical WDM passive optical networks (PON).

Owner:ELECTRONICS & TELECOMM RES INST

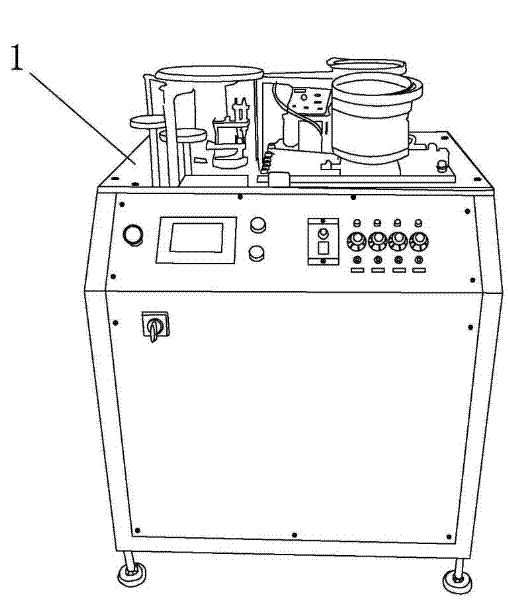

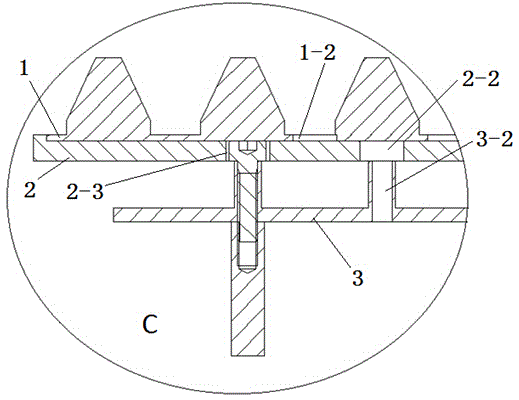

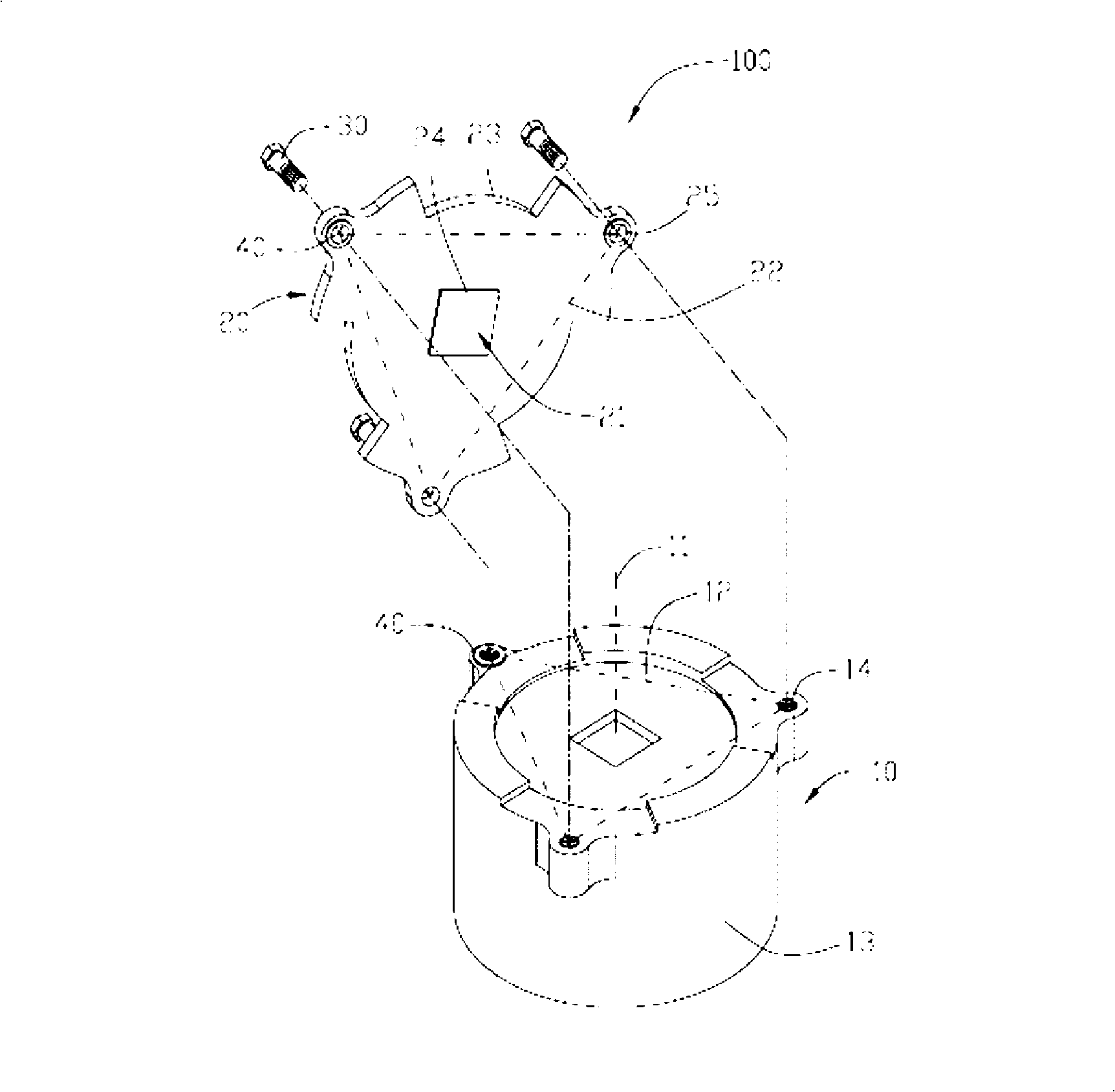

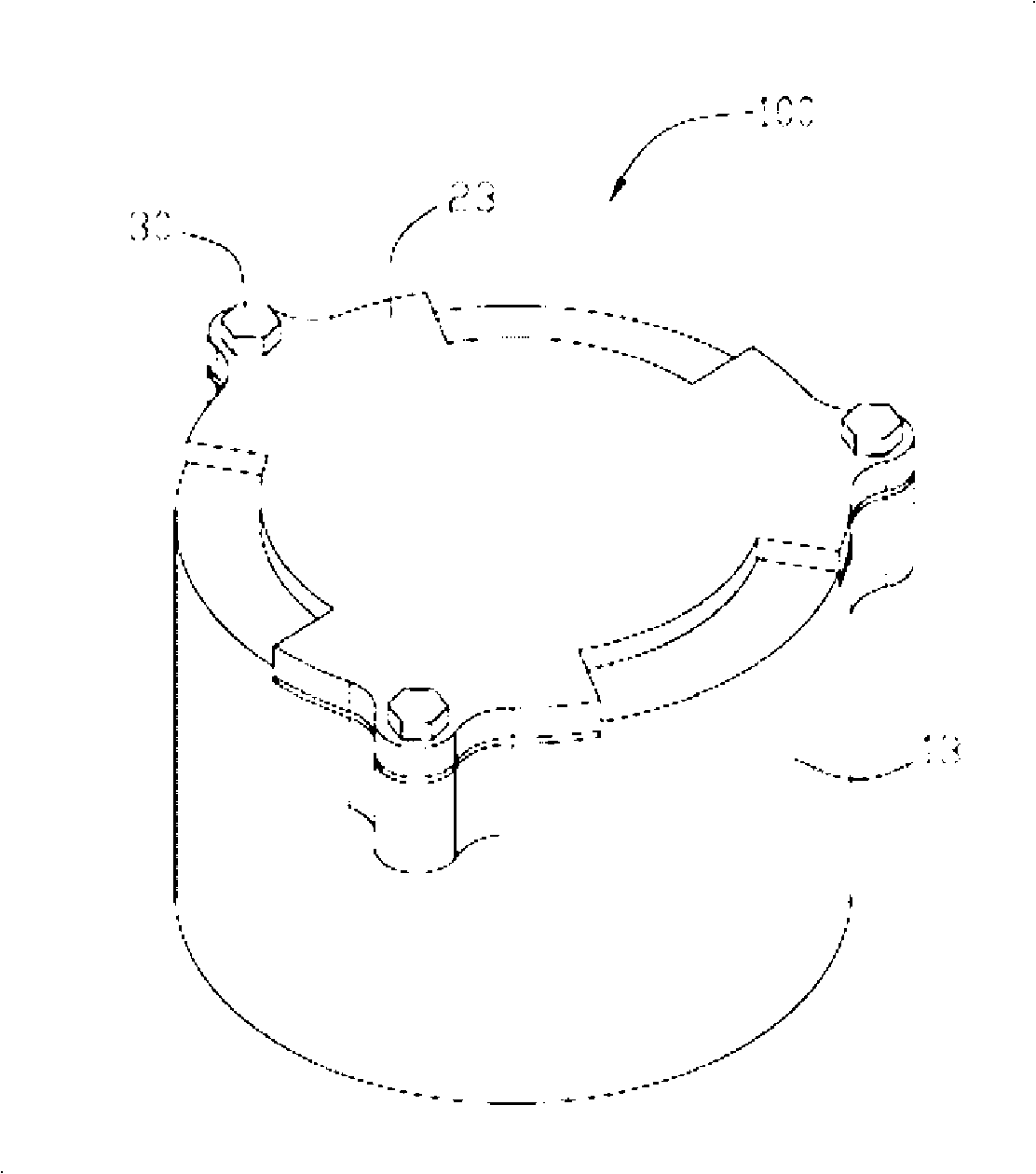

Automatic precision screw and O-shaped rubber ring combination device

InactiveCN102501062AImprove combination efficiencyCombination quality is stableMetal working apparatusRubber ringEngineering

The invention relates to an automatic precision screw and O-shaped rubber ring combination device which comprises a working table. A division rotary disk, a screw vibration disk for successively outputting screws and a rubber ring vibration disk for successively outputting rubber rings are installed on the working table, and the output of the screw vibration disk and the rubber ring vibration disk are respectively communicated with the division disk through a screw conveying rail and a rubber ring conveying rail. A hanging slot for receiving screws is arranged on the periphery of the division disk, and rubber rings at the output of the rubber ring conveying rail can be hang to the ends of the screws in the hanging slot during the rotation process of the division disk. With the automatic precision screw and O-shaped rubber ring combination device designed by the invention, the existing manual mode is improved into the automatic mode using the device, the combination efficiency is high, the combined produce can also meet design requirements, the combination quality is stable, operating workers are reduced, the efficiency is more than ten times of that of the manual mode, and the labor cost is reduced. A sorting mechanism for automatically picking out unqualified products is arranged, so that the unqualified products are ensured to be not confused with qualified products.

Owner:YUEI PRECISION (HUIZHOU) CO LTD

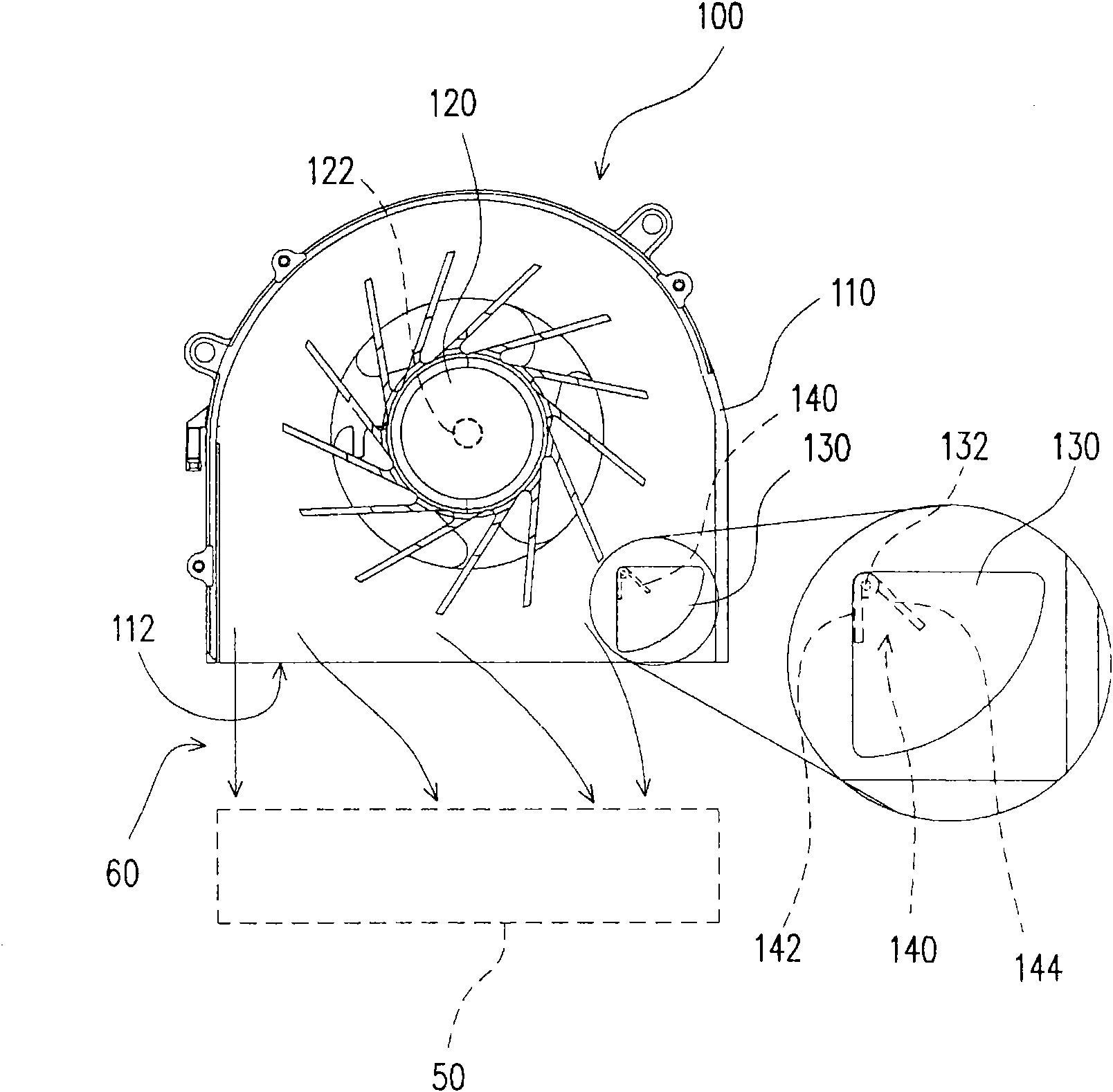

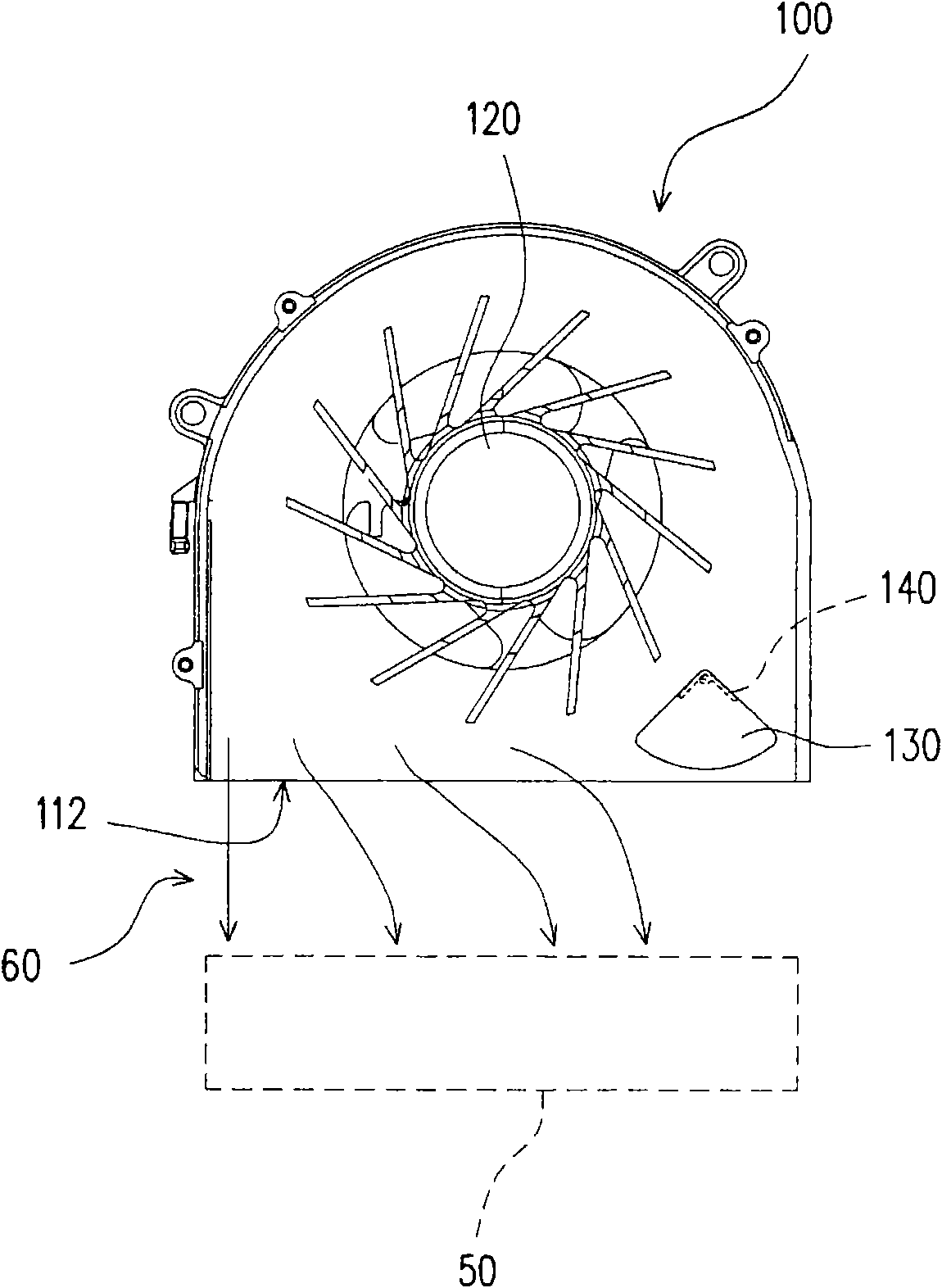

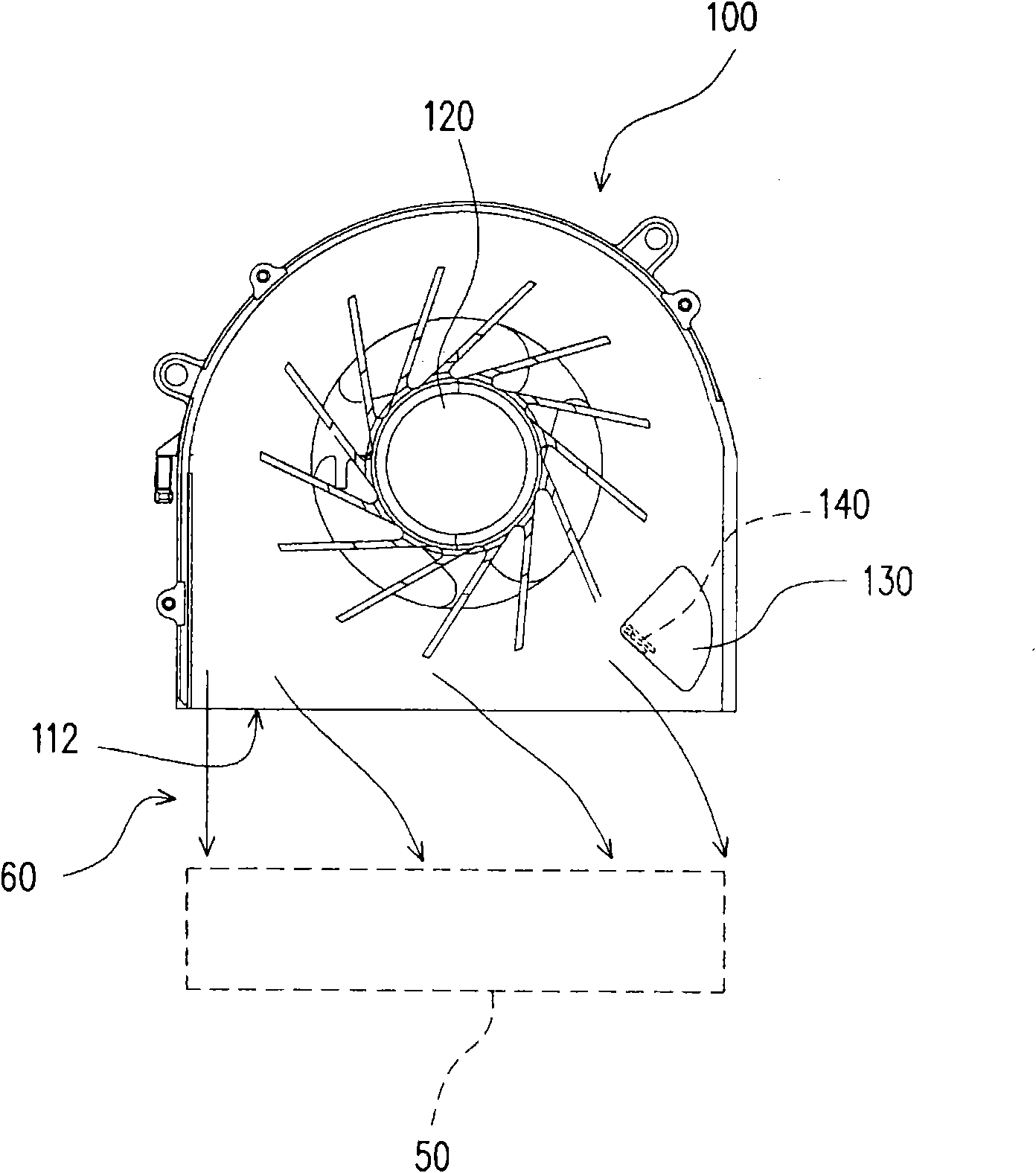

Fan assembly

InactiveCN101649842AImprove combination efficiencyPump componentsDigital data processing detailsControl theoryShuttle valve

The invention discloses a fan assembly applied to an electronic device. The fan assembly comprises a housing, a fan, a throttle valve and a regulator. The housing is provided with an air outlet. The fan is arranged in the housing, and is applicable to providing air current, wherein, the air current produces air flow at the air outlet. The throttle valve is movably arranged in the housing, and located at the air outlet. The regulator is connected to the throttle valve for controlling the motion of the throttle valve to regulate opening size of the air outlet.

Owner:COMPAL ELECTRONICS INC

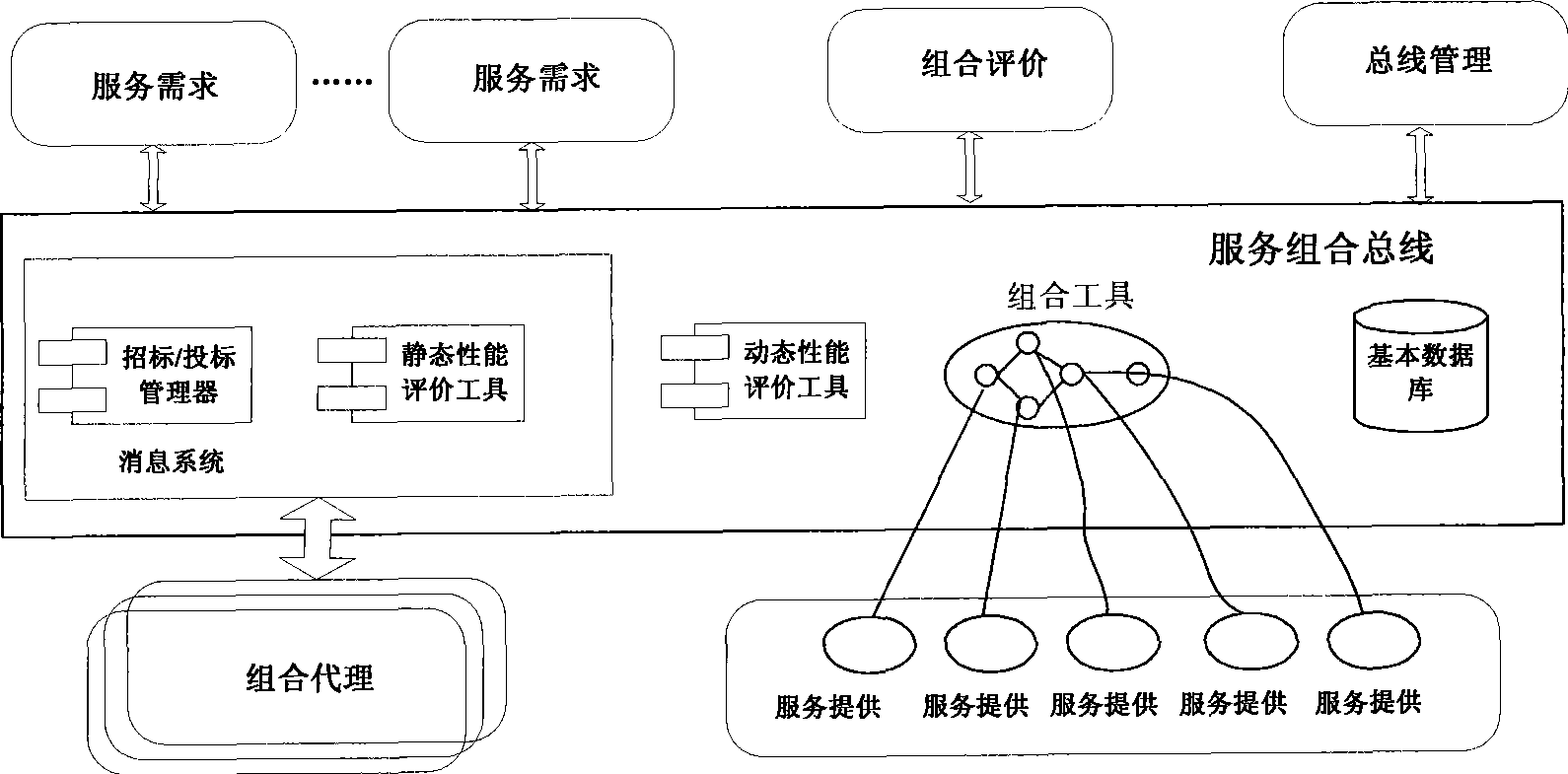

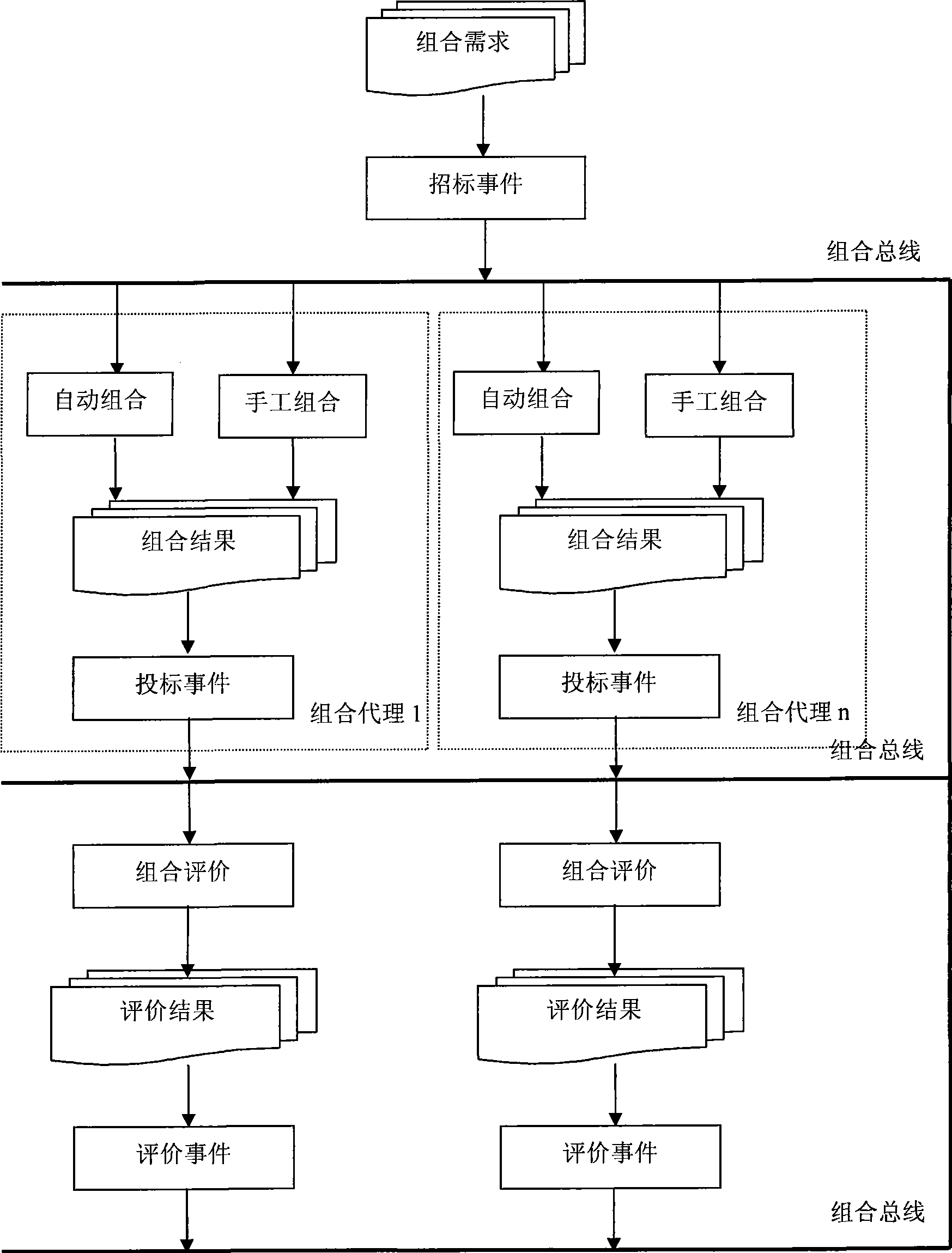

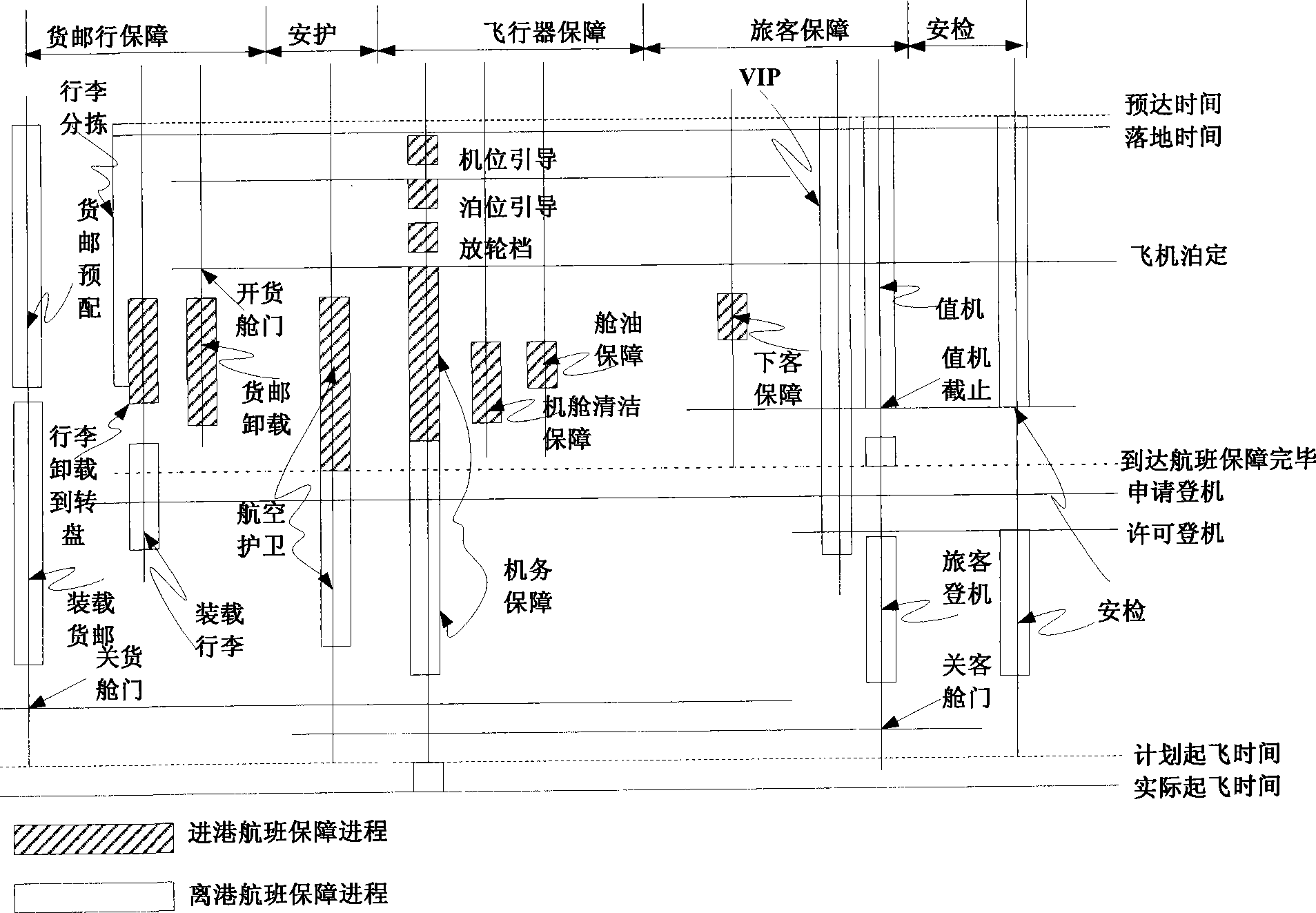

Web service combination system and method

InactiveCN101464887AMeet needsImprove combination efficiencySpecial data processing applicationsService compositionUser needs

The invention provides a Web service combined system. A service combined bus is established in the system; each combined part establishes communications through service combination; each combined part comprises a service demander, a service provider, a combined agent and a combination evaluator; and the service combination bus establishes a two-dimensional theme event matrix and delivers theme events related to the service combination among each combined part on the basis of the two-dimensional theme event matrix through a subscribe / publish mechanism and a request / reply mechanism. The invention further provides a service combined method which ensures that four phases of service combination are completely realized, so that an overall support from user demand to final combination result is realized. The invention is particularly suitable for supporting competitive bidding of a multiple combination agency; each combined party can know problems well in time in the combination; and the mix strategy can be adjusted in time, so as to help to improve the combination quality greatly and obtain a combined service with a highest performance-to-price ratio.

Owner:WUHAN UNIV

Service combining and replacing method based on service cluster

InactiveCN104902018AImprove discovery efficiencyImprove combination efficiencyTransmissionDistributed computingWeb service composition

The invention discloses a service combining and replacing method based on a service cluster. The service cluster is constructed with an existing service clustering method, and a formal description method of services and the service cluster is put forward based on a Petri network; and the input and output parameters of the services are represented in an abstract way, and the input and output parameters of the services are described through a parameter matrix. Through adoption of a service matching method in the invention, universality and individuality can be fully realized among the services in the service cluster, and the service discovery and combining efficiencies are increased by narrowing of a service discovery range. A Web service combining and replacing method is provided through improvements on a service cluster model. Parallel combination and serial combination of the services in the service cluster are described respectively, and rapid service combination is realized in the service cluster, so that efficient service combination and replacement are realized. Through adoption of the service replacing method in the invention, single service replacement in the service cluster can be realized, and service combination and replacement in the service cluster can be realized.

Owner:SHANDONG UNIV OF SCI & TECH

Manufacture method of multi-baffle large-aperture box frame

InactiveCN104209706AReduce processing difficultyImprove the accuracy of frame combinationWelding/cutting auxillary devicesAuxillary welding devicesDisc diameterEngineering

The invention discloses a manufacture method of a multi-baffle large-aperture box frame. The method comprises the steps of firstly, reliably connecting positioning bases and limiting blocks, ensuring that side surfaces of the positioning bases and the limiting blocks are adhered, loading the positioning bases and the limiting blocks into baffle inner holes integrally, then welding the limiting blocks with baffle bearing seats in a spot welding way, secondly, establishing lines on a combined platform to determine positions of all baffles, ensuring that a core shaft penetrates through all the positioning bases, fixing the positions of the positioning bases separately through positioning pins, connecting the positioning bases with the core shaft, thirdly, welding all process supports with inner holes of all the baffles in a spot welding way in weight reduction notch space positions arranged on the positioning bases, fourthly, cutting welding lines of the limiting blocks and the bearing seats, laying the limiting blocks in directions perpendicular to disc diameters of the positioning bases, gradually withdrawing the positioning bases and the core shaft, welding a frame body, welding connecting plates among all the baffles, and fifthly, performing thermal aging on the frame body integrally, and then removing all the process supports. The method improves the frame body combination accuracy and the operating efficiency.

Owner:BAOJI PETROLEUM MASCH CO LTD

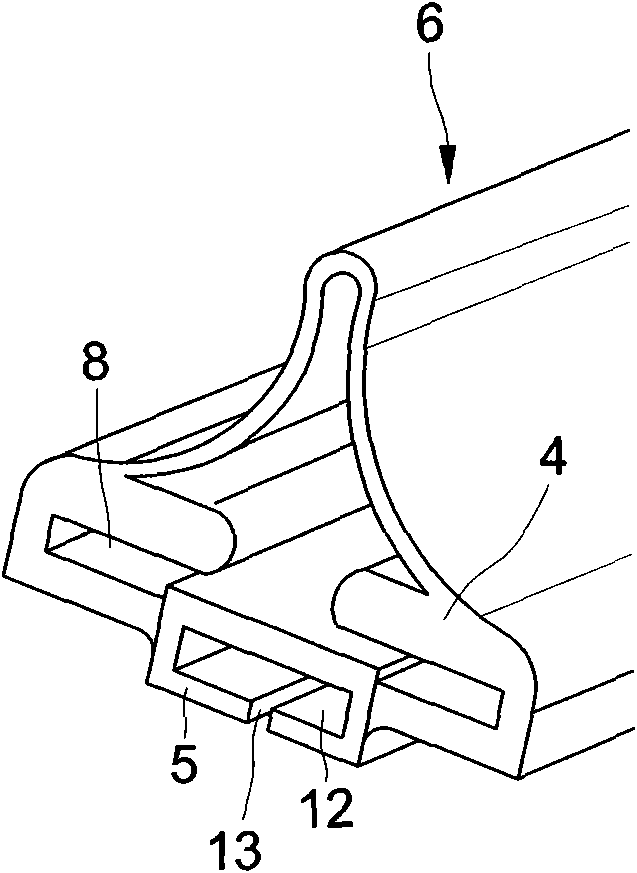

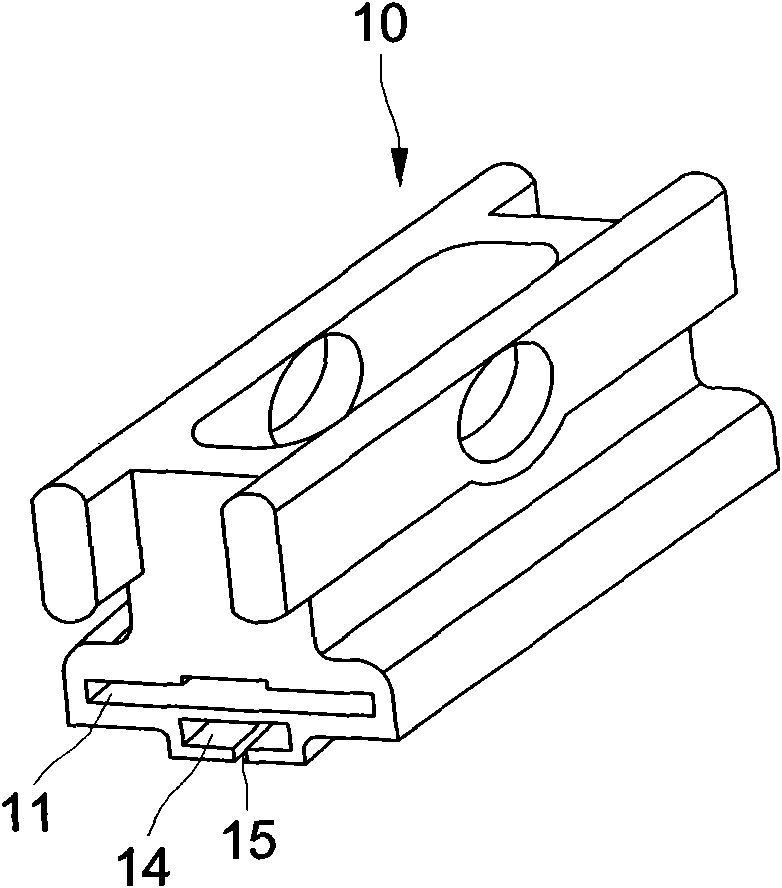

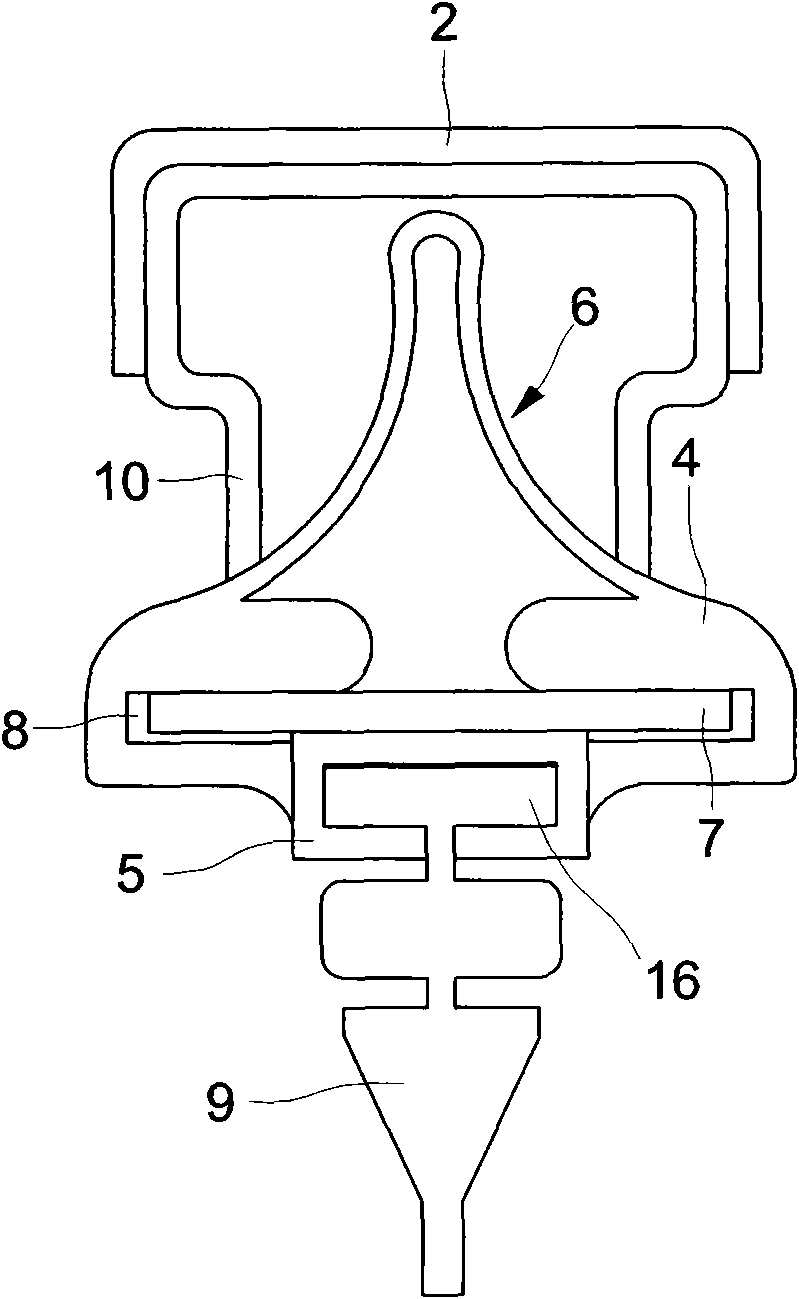

Flat blade wiper

The invention provides a flat blade wiper which includes an elastic metal keelson strip, a saddle bracket for receiving a wiper adapter, two rigid hard clipping sleeve mounts and a pair of end positioning caps. Each clipping sleeve mount and wiper adapter saddle bracket has a first compatible accommodating channel which is flat and wide and a second accommodating channel which is narrow and high respectively so that the elastic metal keelson strip can run through the first accommodating channel while the upper wing section of the elongated scraping blade can run through the second accommodating channel in both the wiper adapter saddle bracket and the clipping sleeve mount. When the wiper swings back and forth, an acting force is directly transmitted to the clipping sleeve mounts by the metal keelson strip without any pause or delay, eliminating jerking so that no noise is incurred to spoil the internal tranquility of the vehicle.

Owner:东莞山多力汽车配件有限公司

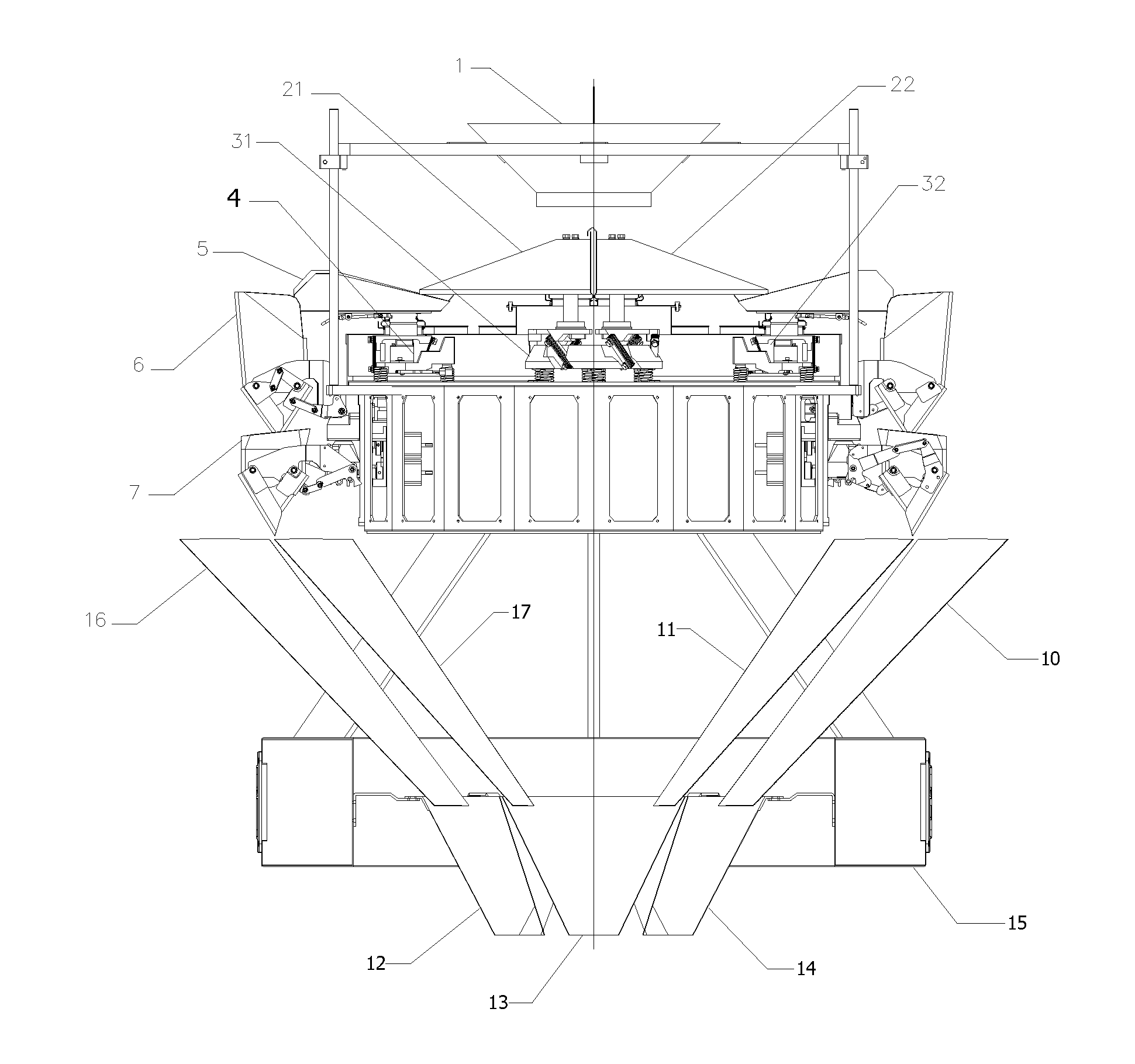

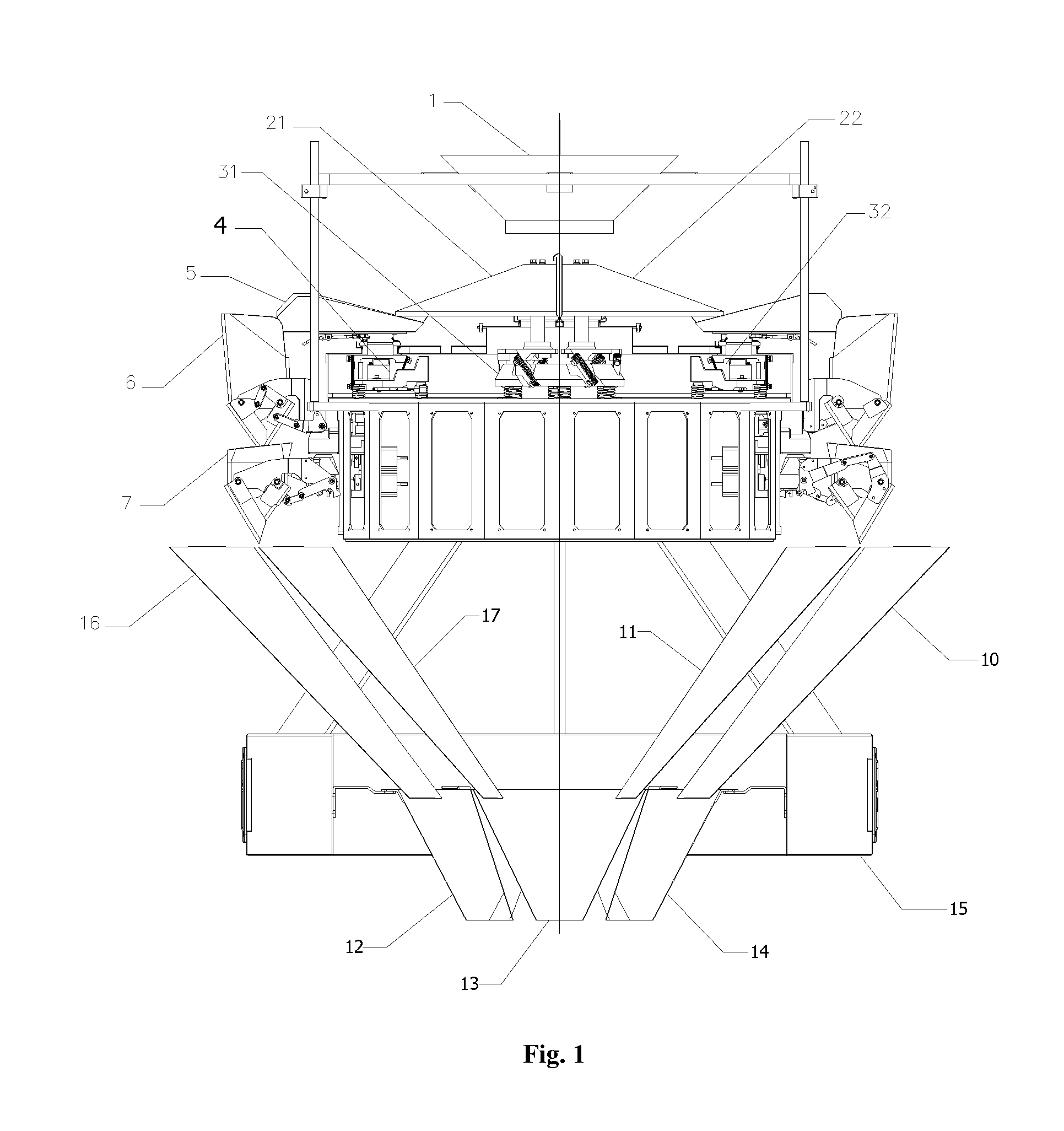

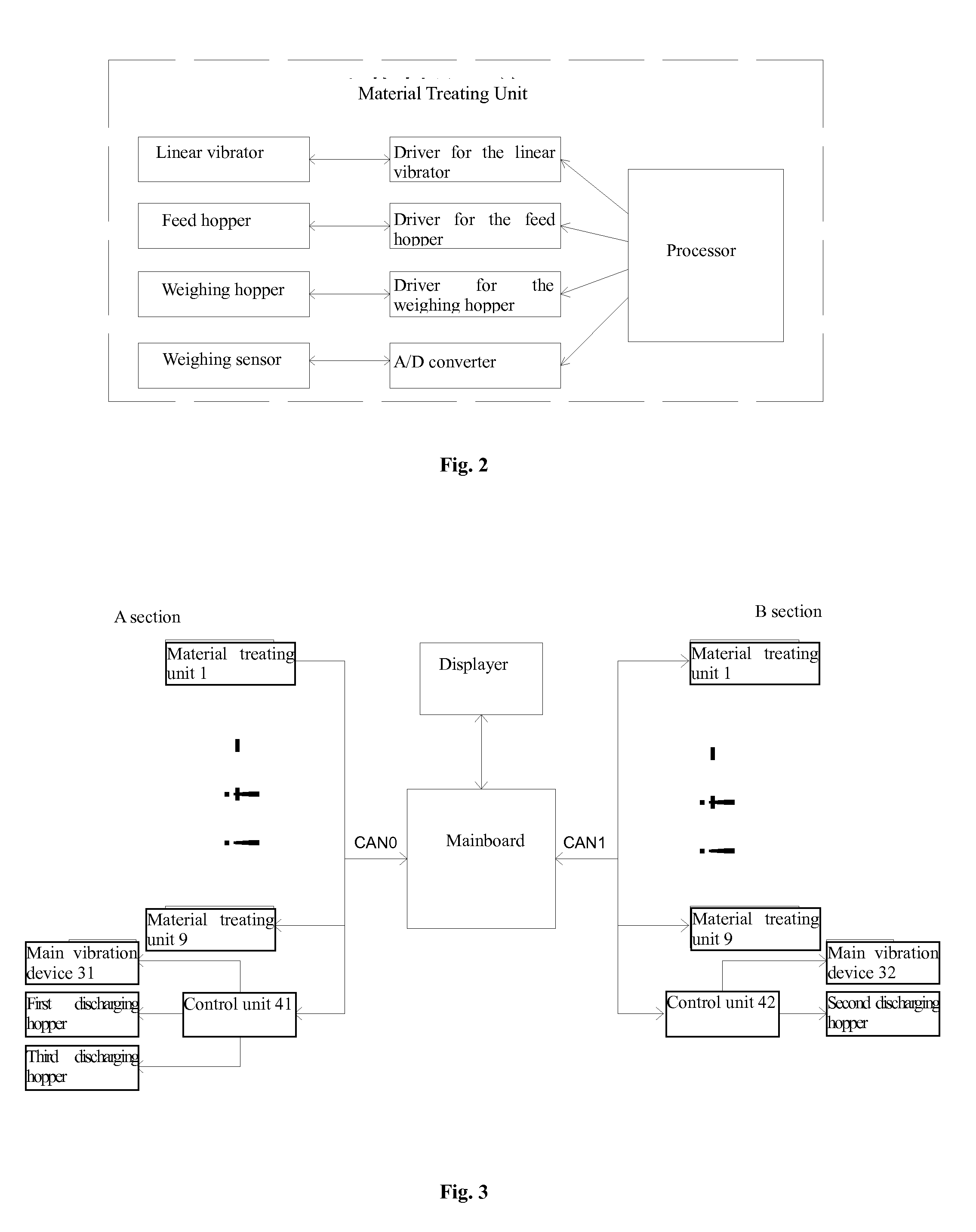

Combination weighing device and operating method thereof

ActiveUS20120103703A1Improve efficiencyData transfer speed is fastSolid materialWeighing apparatus for materials with special property/formControl signalEngineering

A combination weighing device and an operating method thereof are disclosed. The device comprises N material treating units, a mainboard, chutes (10, 11, 16, 17) and discharging hoppers (12, 13, 14), wherein the material treating units are used for receiving materials, outputting the weight value of materials and discharging materials according to the discharging control signal from the mainboard; the mainboard is used for selecting materials by combinatorial calculation based on the present-period weight value during every period and outputting the discharging control signal to weighing hoppers (7); the chutes (10, 11, 16, 17) are used for collecting the materials through a discharging route, discharging the materials to the discharging hoppers (12, 13, 14), after a discharging route is determined; the discharging hoppers (12, 13, 14) are used to separately collect materials discharged from the chutes (10, 11, 16, 17) during the same weighing period and send the materials to a packing machine; each material treating unit comprises a linear vibrator (5), a feed hopper (6), a weighing hoper (7), a weighing sensor used to weigh the materials in the weighing hoper (7), a processor and a A / D converter which is connected with the weighing sensor and the processor, N material treating units are connected with the mainboard signal together by two data receiving and delivering communication converters of the mainboard.

Owner:GUANGODNG HIGH DREAM INTELLECTUALIZED MACHINERY

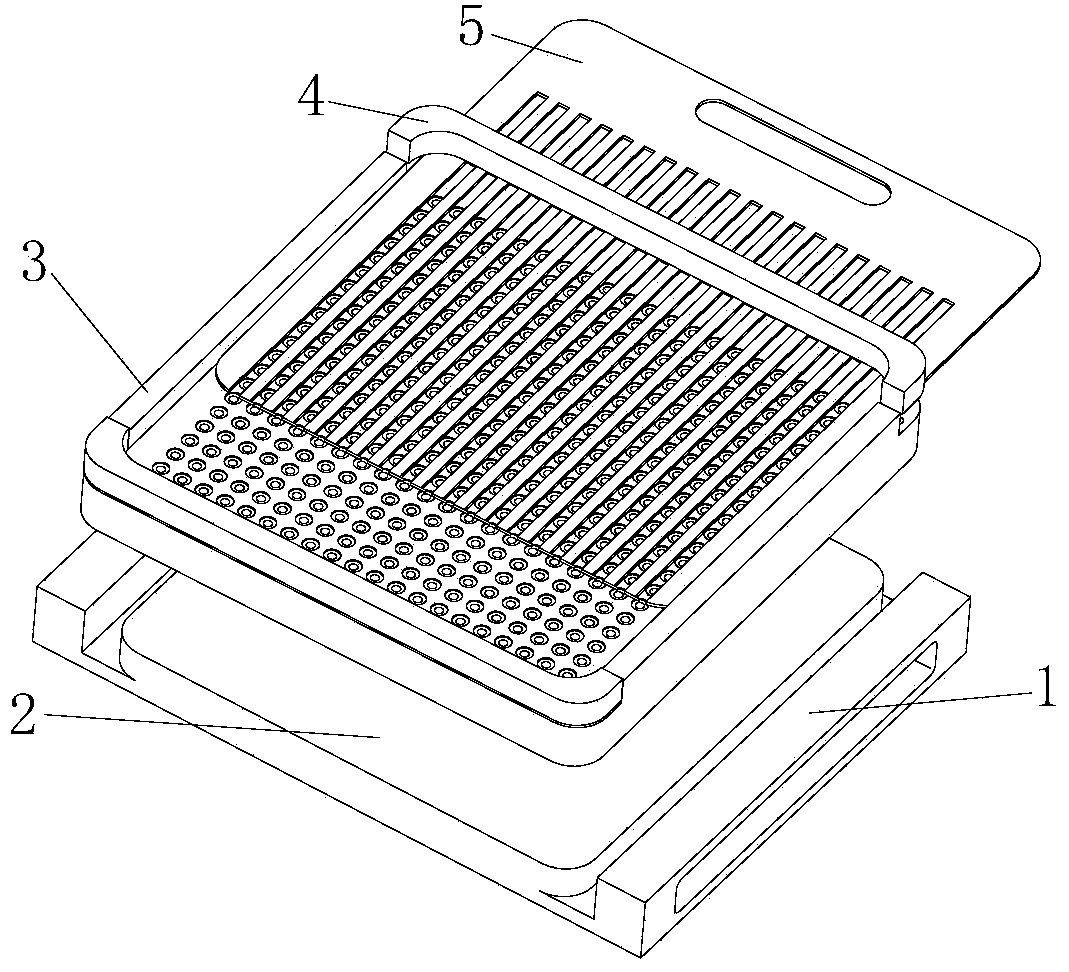

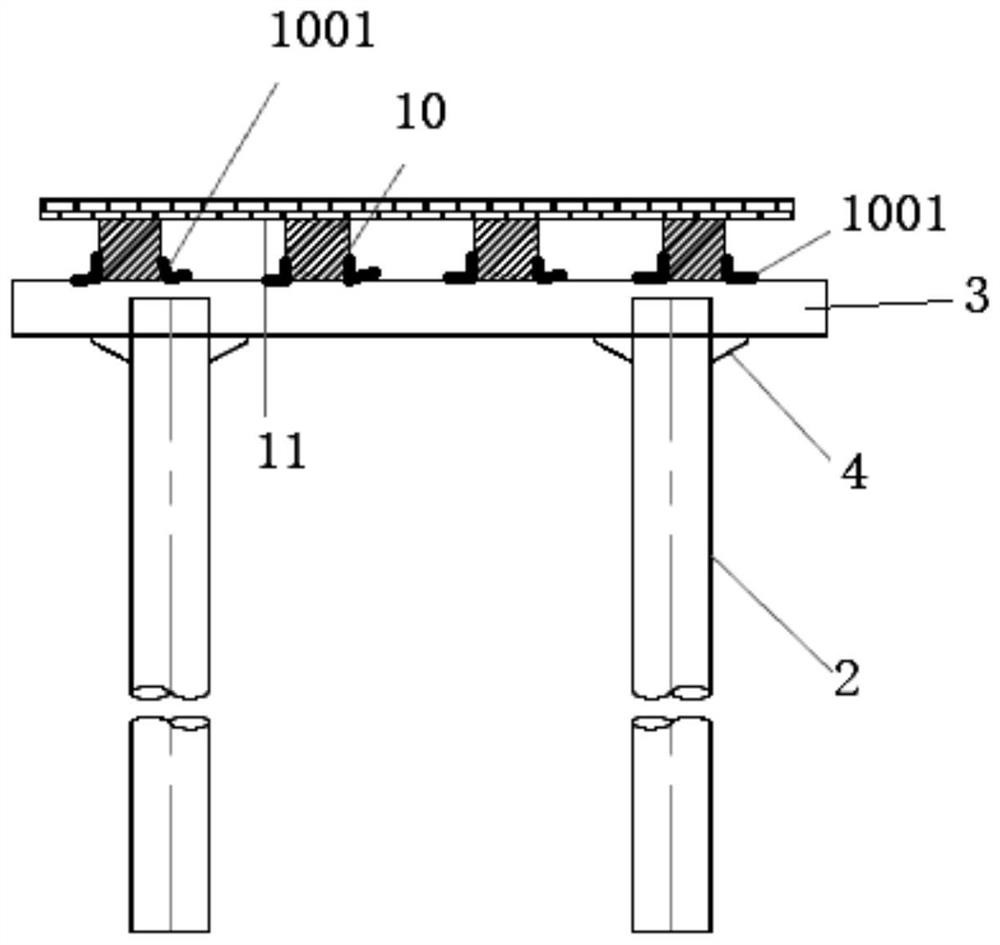

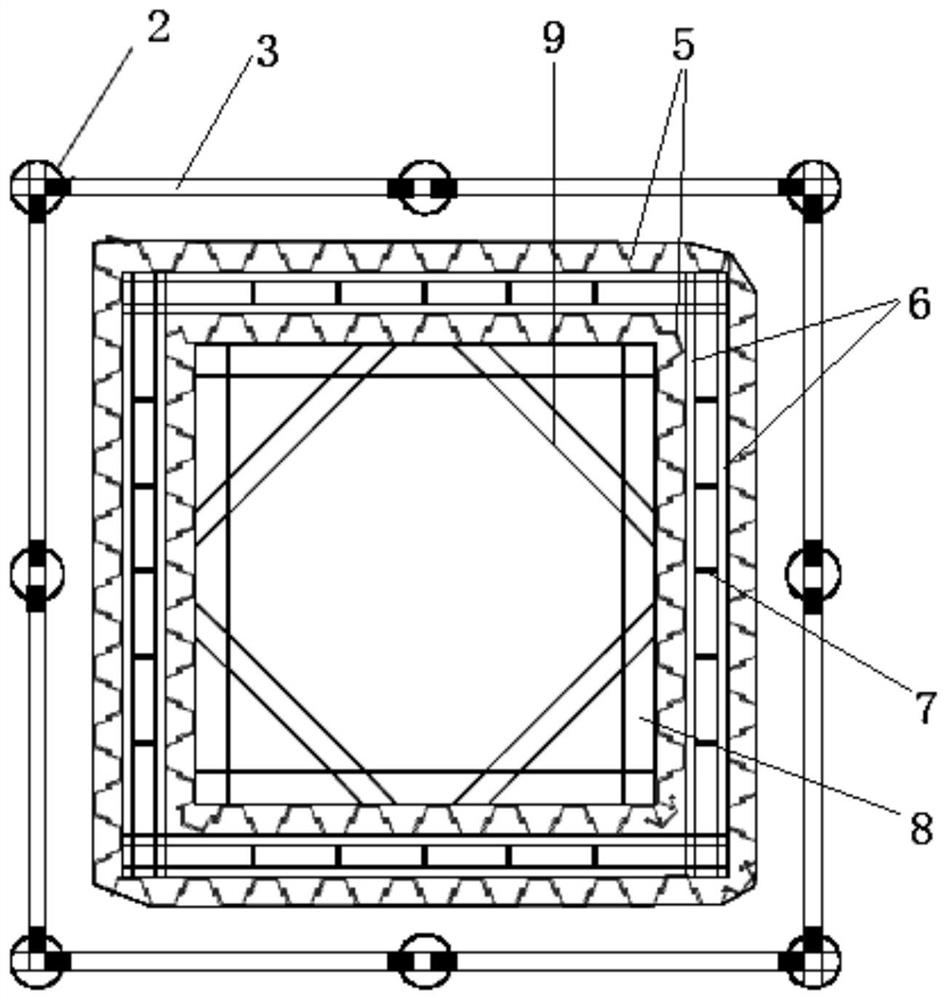

Wood-concrete composite beam shear connector pushing-out testing sample

PendingCN108412049AIncreased shear strengthIncrease stiffnessBridge structural detailsBuilding constructionsSocial benefitsMesh reinforcement

The invention discloses a wood-concrete composite beam shear connector pushing-out testing sample. The wood-concrete composite beam shear connector pushing-out testing sample comprises a wood beam, concrete slabs, a shear connector, anchoring parts and a steel mesh reinforcement. The shear connector is anchored on the upper portion of the wood beam through the anchoring parts, the steel mesh reinforcement is laid on the upper portion of the wood beam through a supported template piece, transverse reinforcements in the steel mesh reinforcement penetrate through through-holes reserved in the shear connector, the concrete slabs are poured into the template piece with the steel mesh reinforcement and the shear connector used as a skeleton, and a wood-concrete composite beam is formed. The wood-concrete composite beam shear connector pushing-out testing sample improves the shear strength and shear stiffness of the shear connector, has good fatigue resistance performance, reduces the shear deformation of the shear connector, and overall deformation of wood-concrete composite beam is reduced; and while resisting relative slip, the raising effect between the concrete slabs and the wood beam can be effectively restrained, and good social benefits and transformation prospects are achieved.

Owner:SUZHOU UNIV OF SCI & TECH

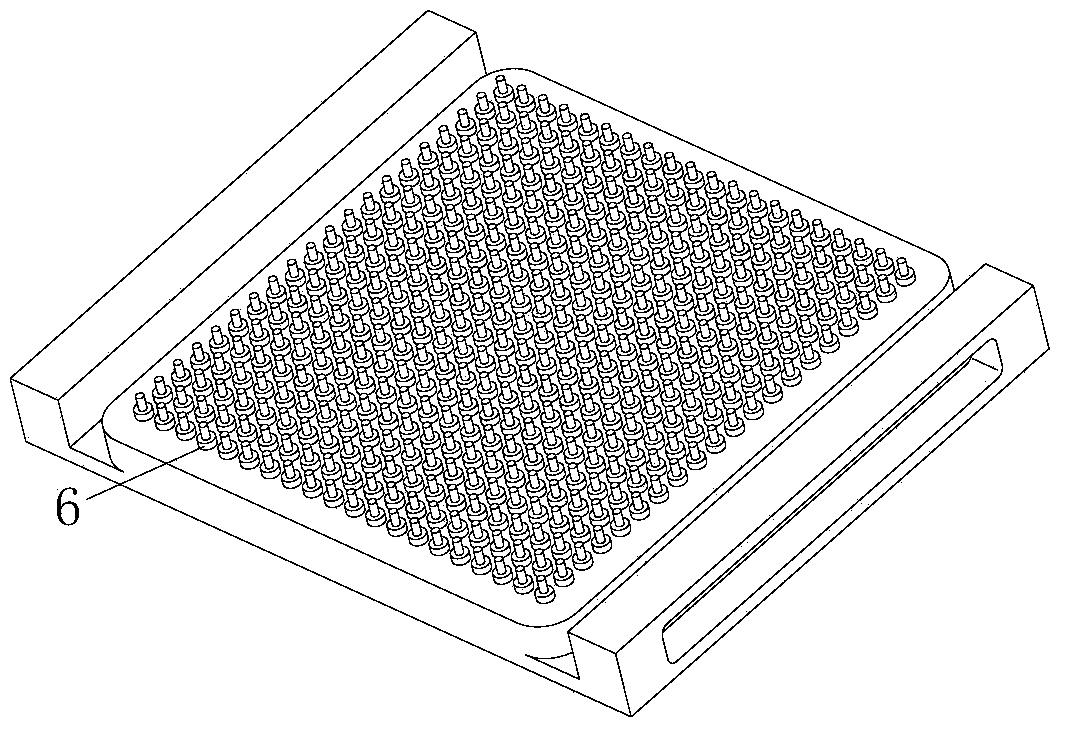

Device and method for arraying and combining screw, spring pad and flat pad

The invention relates to a device for arraying and combining a screw with a spring pad and a flat pad, which is characterized in that a bottom plate is of a concave structure, the appearance of a sieve plate is matched with the concave structure of the bottom plate, and double-sided adhesive cloth is arranged between the sieve plate and the bottom plate; a double-sided hole array formed by a plurality of double-sided holes is arranged on the sieve plate, and a comb plate is positioned above the sieve plate; each double-sided hole adopts a three-section step through hole, the diameter of the middle section of through hole and the diameter of one section of through hole are matched with the size of a screening screw, and the diameter of the other section of through hole is matched with the size of the spring pad and the flat pad. The device and the method for arraying and combining the screw with the spring pad and the flat pad provided by the invention have the benefits that the cost of the device is low, the structure is simple, the screw is arrayed and combined with the spring pad and the flat pad with the adoption of the device and the method, the operation is convenient, and the efficiency of combining the screw with the spring pad and the flat pad is improved by 20 times compared with that of the manual operation.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

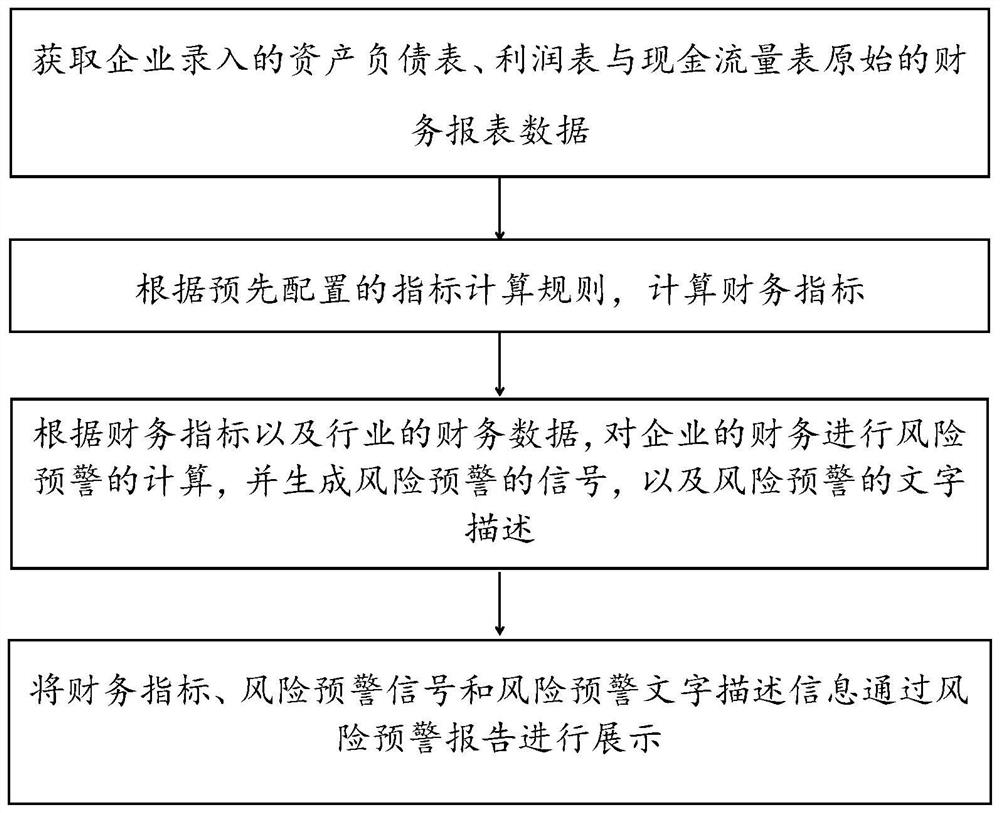

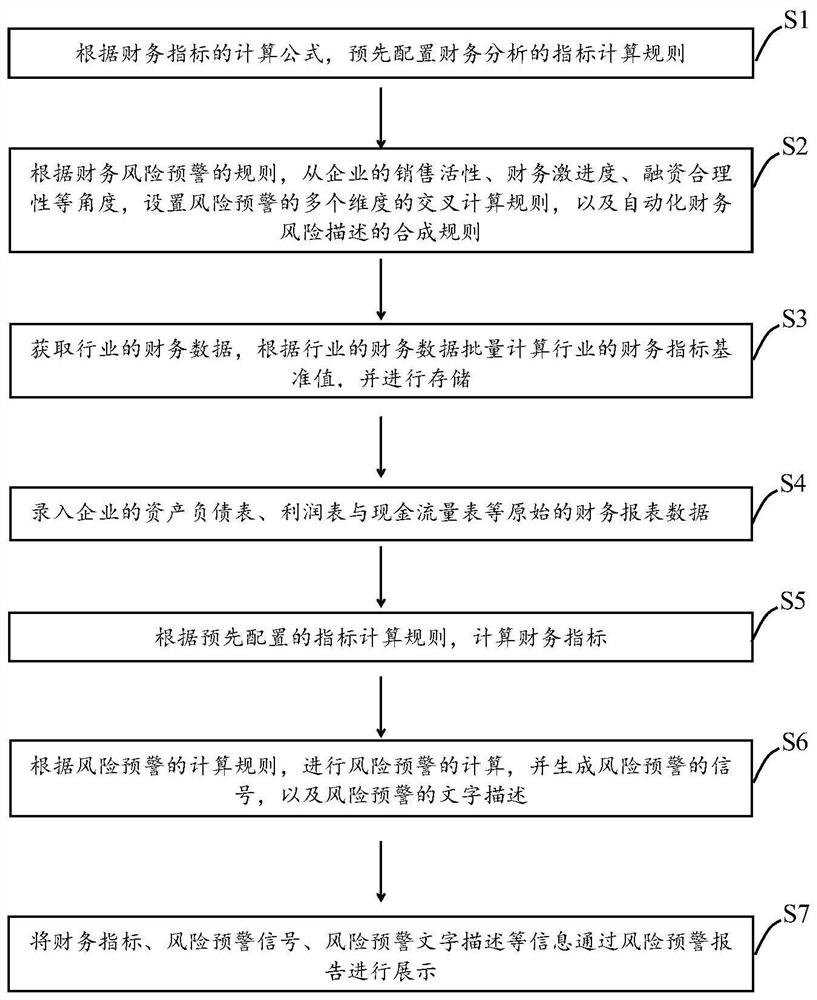

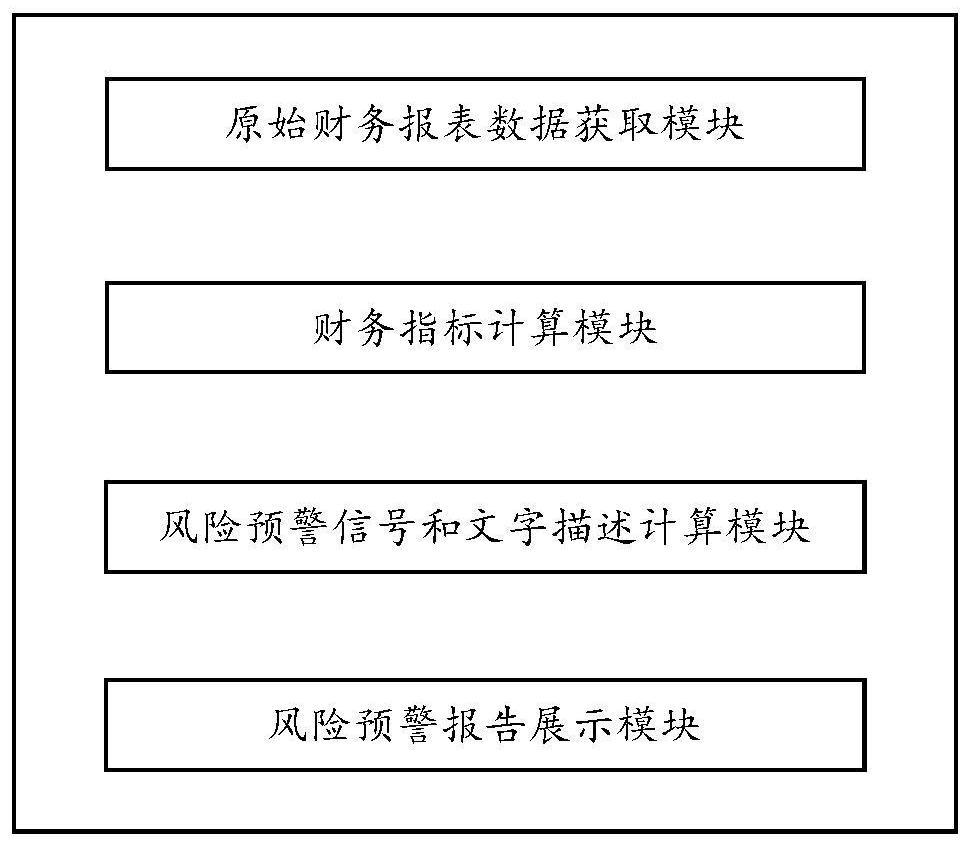

Financial risk early warning analysis method and device

PendingCN111798297AHigh precisionImprove completenessFinanceCharacter and pattern recognitionBusiness enterpriseData acquisition

The invention provides a financial risk early warning analysis method and device. The method comprises steps of obtaining original financial statement data of an asset debt table, a profit table and acash flow table inputted by an enterprise; based on the original financial statement data of the asset debt table, the profit table and the cash flow table of the enterprise, calculating financial indexes according to a pre-configured index calculation rule; according to the financial indexes and the financial data of the industry, risk early warning calculation being carried out on the finance of the enterprise, and a risk early warning signal and risk early warning text description being generated; and displaying the financial indexes, the risk early warning signals and the risk early warning text description information through a risk early warning report. The device comprises an original financial statement data acquisition module, a financial index calculation module, a risk early warning signal and text description calculation module and a risk early warning report display module.

Owner:中国经济信息社有限公司 +1

Athermal external cavity laser

ActiveUS7580441B2Reduce manufacturing costImprove combination efficiencyLaser using scattering effectsOptical resonator shape and constructionGratingExternal cavity laser

Provided is an athermal external cavity laser (ECL), whose output optical power and output wavelength can be kept regular irrespective of temperature changes without using additional temperature controlling components. The ECL comprises: a semiconductor amplifier; an optical fiber comprising a core in which a Bragg grating is formed and a cladding surrounding the core; and a thermosetting polymer that fixes the optical fiber to a ferrule and has a negative thermooptical coefficient, wherein the thickness of the cladding surrounding the core in which the Bragg grating is formed is smaller than the portion of the cladding surrounding the portion of the core where the Bragg grating is not formed, and the thermosetting polymer the negative thermooptical coefficient surrounds the cladding. The ECL does not need additional temperature controlling components and thus can be manufactured compact and at low cost, and thus can be used as a light source of a dense wavelength division multiplexing (DWDM) system in designing economical WDM passive optical networks (PON).

Owner:ELECTRONICS & TELECOMM RES INST

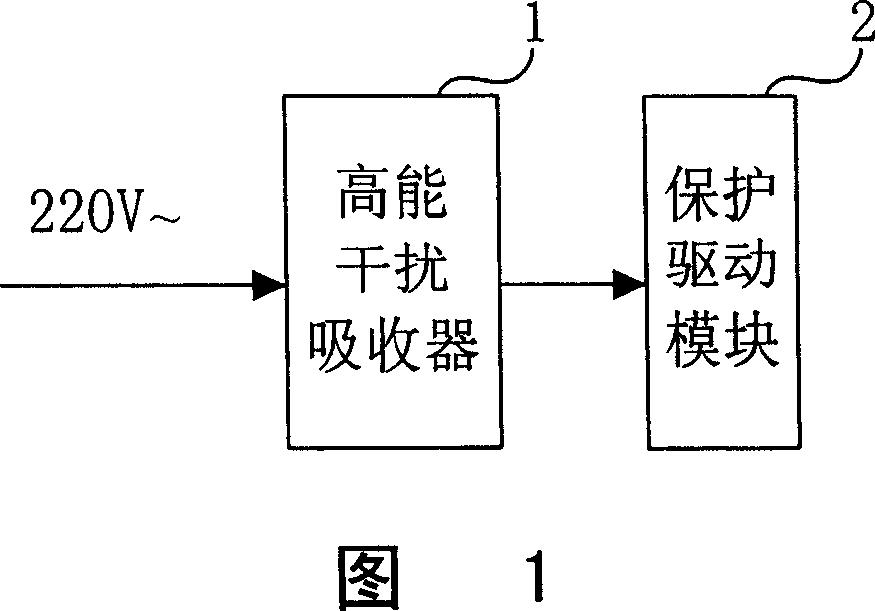

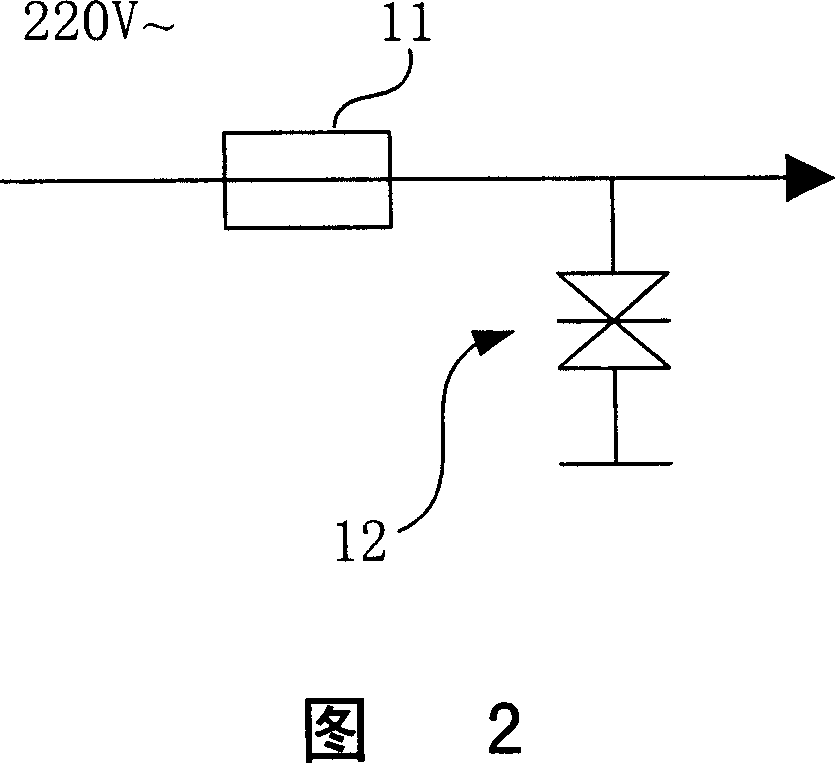

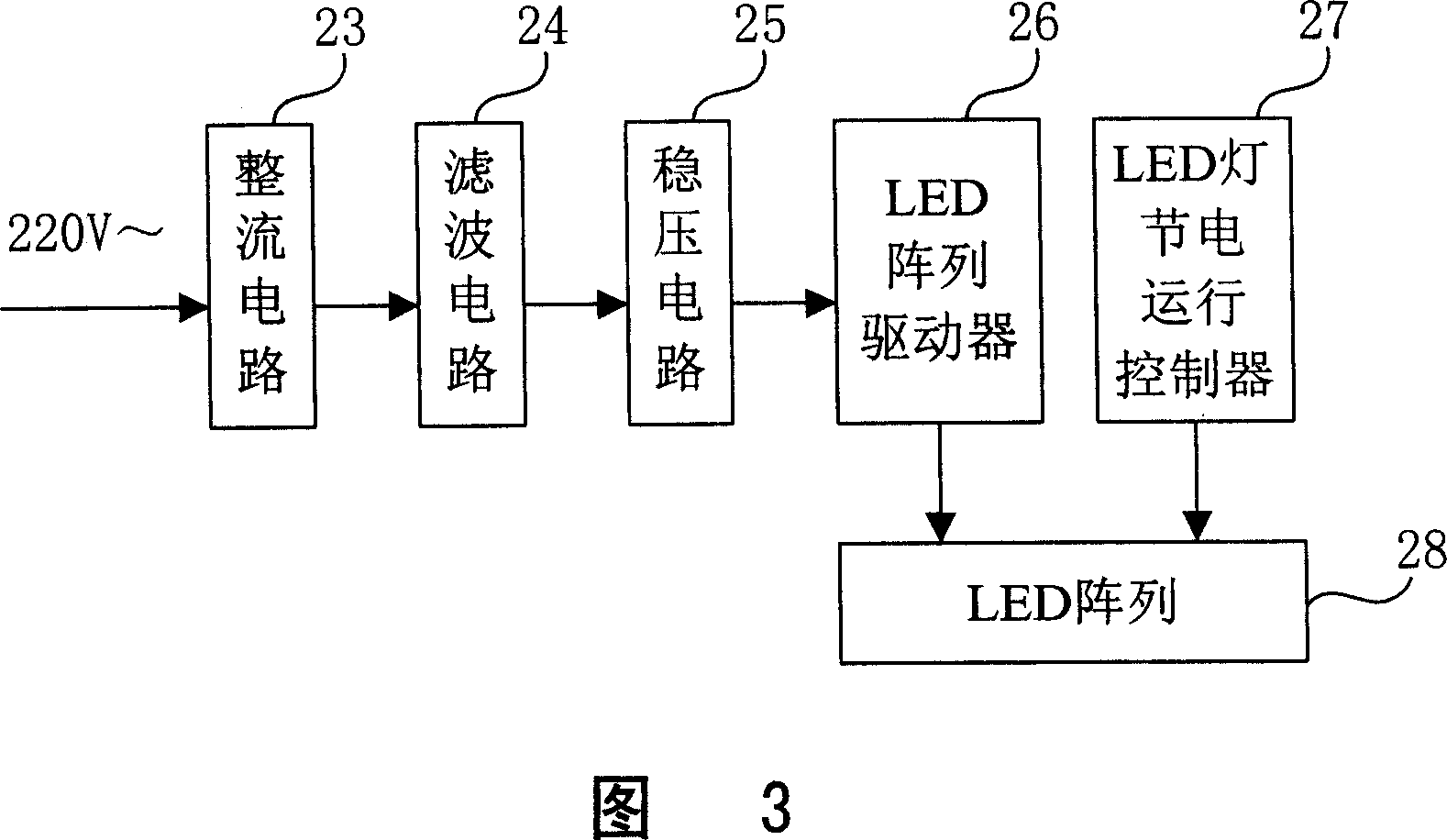

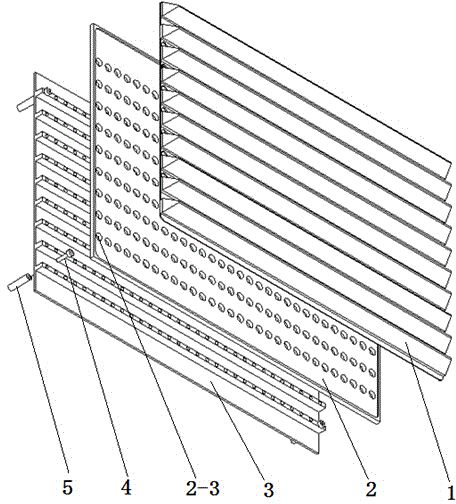

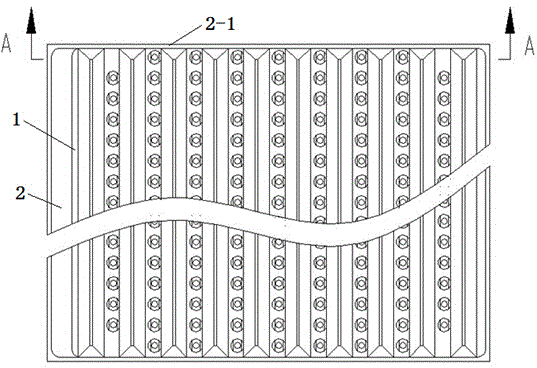

Full combination efficiency LED lamp

InactiveCN101056484AAvoid premature agingSolution to short lifeElectroluminescent light sourcesSemiconductor lamp usageLed arrayEngineering

A full combination efficiency LED light is connected by a super interference absorber and a protective driving module, in which the super interference absorber is used for absorbing super interference signal; protective driving module is used for rectifing, filtering, stabilizing and changing level of the alternating 220V voltage, including rectifing circuit, filter circuit, stabilizer circuit, LED array driver, LED array circuit and energy-saving controller. The invention can limit the electric network super interference in a small range or stop it and separate from the LED array by LED array driver so as to avoid LED premature decay by the effect of interference signal and prolong the LED light service life. Furthermore, the invention gives up the driver level transition made up of micro-electronics element and having decompression element so that the power loss of the LED light is decreased notably and the combination efficiency is improved. Meanwhile, the invention can also avoid the power loss by resistance decompression.

Owner:徐玉琦

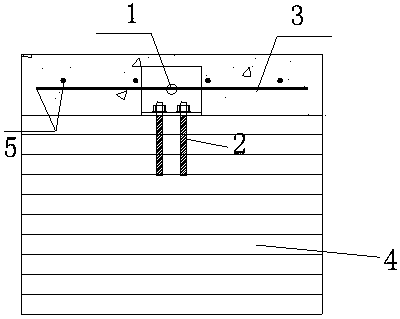

Device for quickly combining washers with screws and method for applying device

ActiveCN104875006AImprove work efficiencyImprove combination efficiencyMetal working apparatusEngineeringMechanical engineering

The invention relates to a device for quickly combining washers with screws and a method for applying the device. The method includes that a washer retaining plate is arranged on a combined screw tray, a washer positioning plate is arranged in four protruded edges on the washer retaining plate, the multiple plain washers are respectively arranged in a plurality of large-diameter holes I of the washer positioning plate, each large-diameter hole I of the washer positioning plate is overlapped on a corresponding large-diameter hole II on a plate surface of the washer retaining plate to form a circular hole, the plain washers can fall into the multiple large-diameter holes II of the washer retaining plate, the multiple spring washers are respectively arranged in the large-diameter holes I of the washer positioning plate and fall in the plain washers in the multiple large-diameter holes II of the washer retaining plate according to processes, the screws penetrate the various spring washers and the plain washers one by one by the aid of fingers of workers, the washer positioning plate and the washer retaining plate are lifted, and the combined screws are retained on the combined screw tray for standby application. The device and the method have the advantages that the work efficiency of the device for combining the washers with the screws is far higher than the work efficiency when washers are manually combined with screws one by one at present, and accordingly the device is high in combining efficiency and low in error rate.

Owner:TIANJIN 712 COMM & BROADCASTING CO LTD

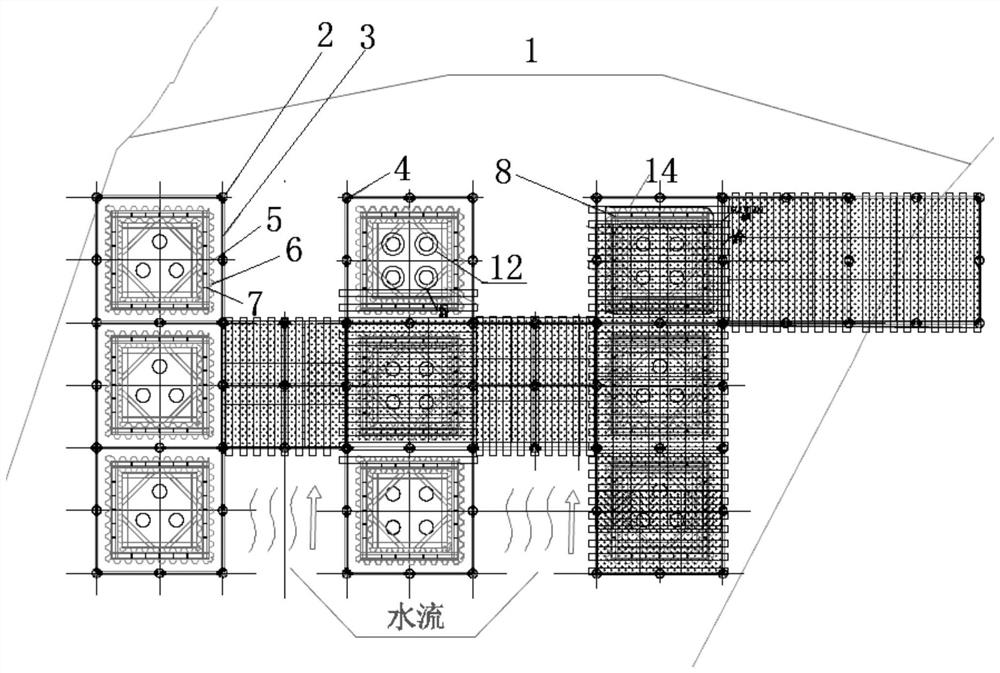

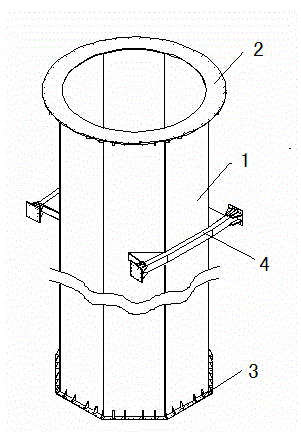

Construction method of underwater pile bearing platform in flood-discharging area of river way

InactiveCN111794256AImprove combination efficiencyHigh turnover rateFoundation engineeringRiver routingCofferdam

The invention discloses a construction method of an underwater pile bearing platform in a flood-discharging area of a river way. The construction method comprises the following steps: 1, the strengthof a construction component is calculated according to the flood drainage requirement of the flood-discharging area of the river way; 2, measurement positioning is conducted, and a steel pipe pile (2)is mounted; 3, shape steel (3) is constructed on the steel pipe pile; 4, a sleeper beam (10) is positioned and mounted on the shape steel; 5, a platform (11) is laid on the sleeper beam; 6, measurement positioning is conducted, and a plurality of steel sheet piles (5) are mounted, the steel sheet piles are located on the inner side of the steel pipe pile, and unit bearing platform cofferdams areformed; 7, underwater engineering piles are constructed in inner areas of the double rows of cofferdams; 8, a bearing platform (13) and an overwater structure are constructed, and one bearing platformcofferdam unit is completed; and 9, steps 1 to 8 are repeated till construction of all bearing platform cofferdam units within the range (1) of the flood-discharging river way is completed. A water-stop cofferdam of a steel pipe pile platform internally connected with a Larsen steel sheet pile can be adopted, and stability of platform construction operation and safety and stability of underwaterconstruction can be guaranteed while flood-discharging navigation of the river way is ensured.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

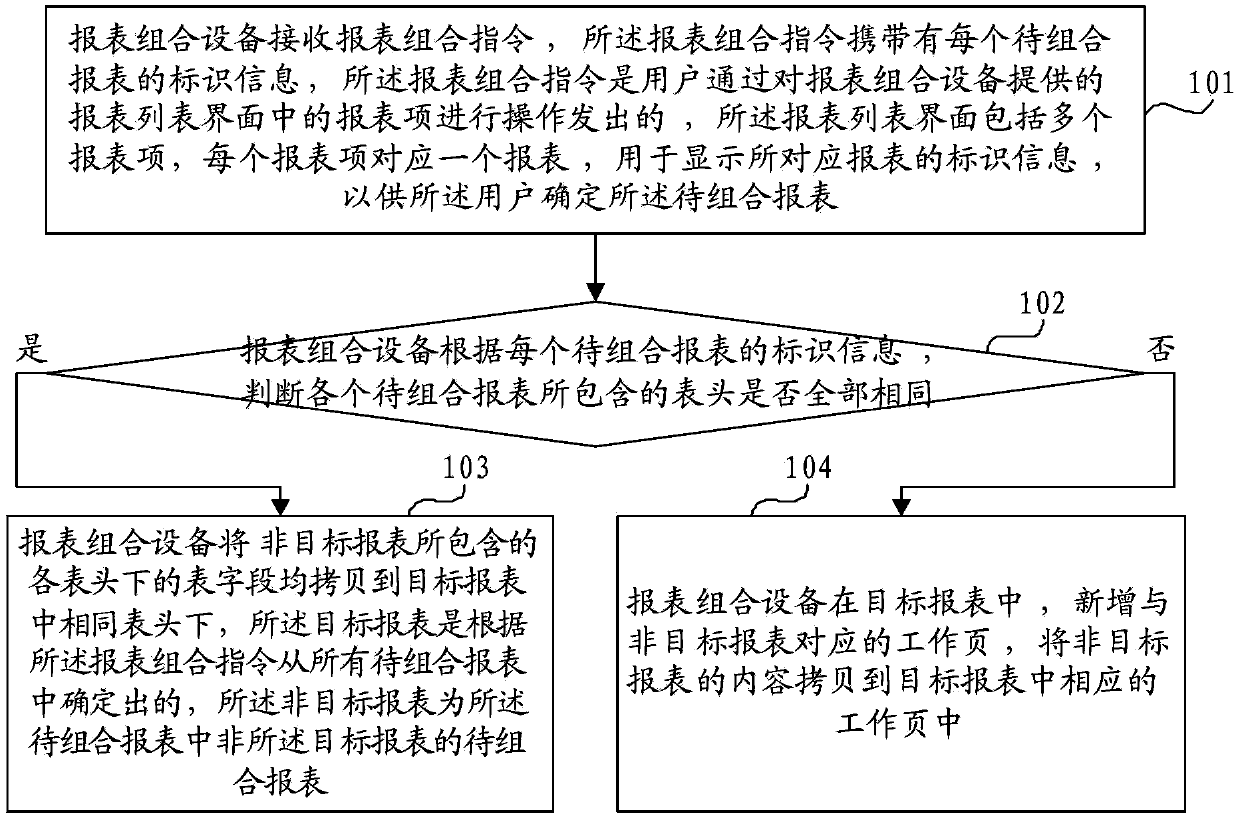

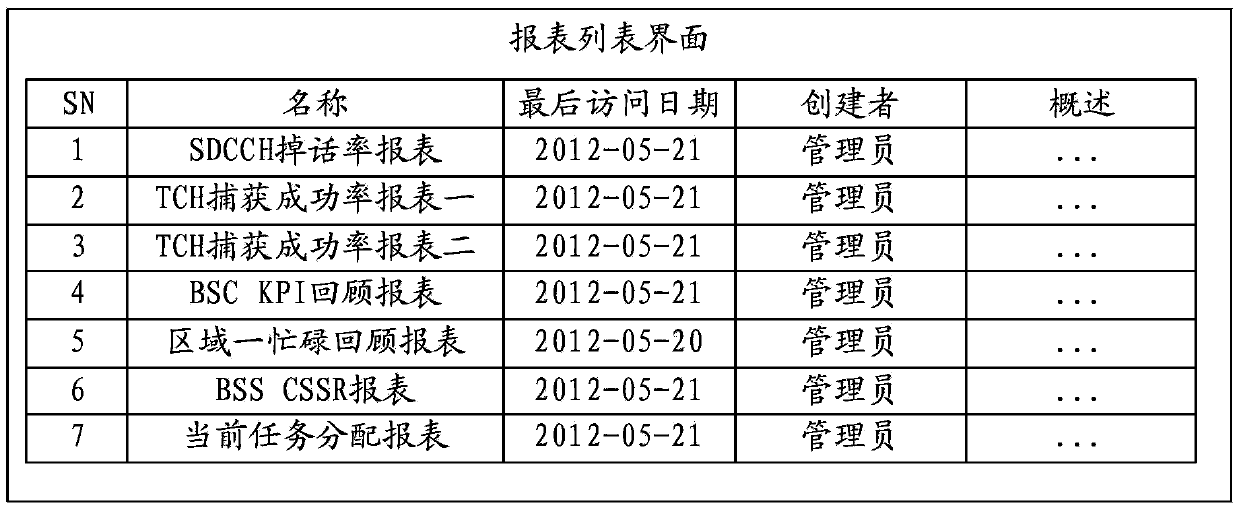

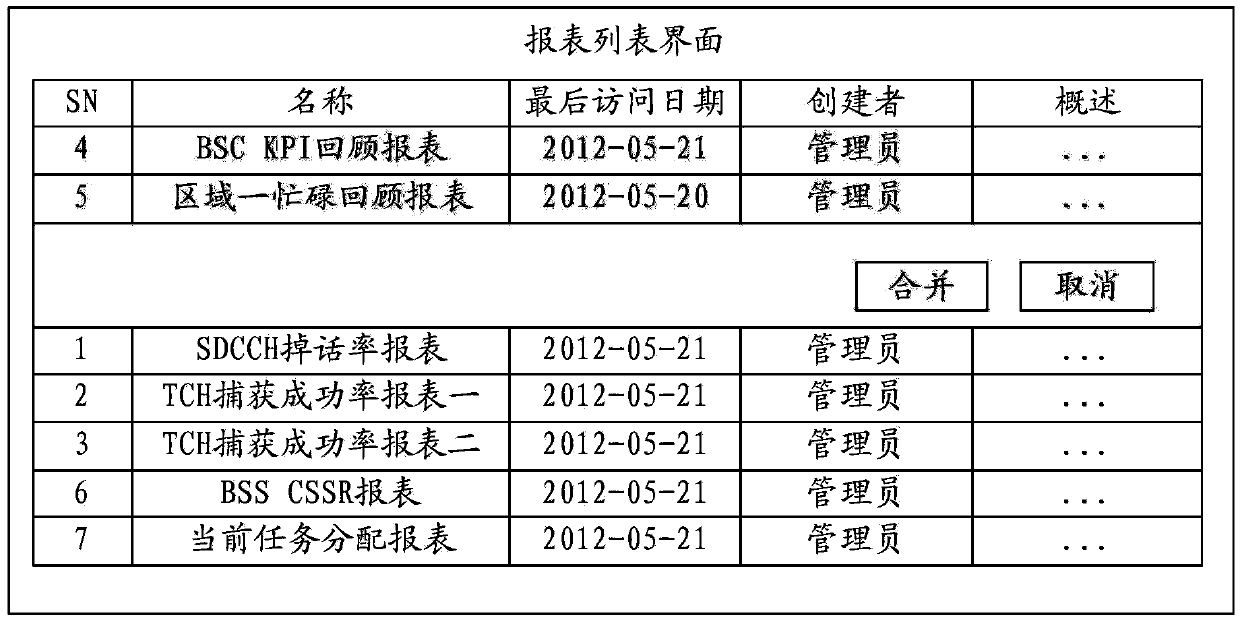

Report combination method and equipment

ActiveCN103970790AImprove combination efficiencyIncrease flexibilityText processingSpecial data processing applicationsSoftware engineeringEngineering

The embodiment of the invention provides a report combination method and report combination equipment. The method comprises the following steps: receiving a report combination instruction by the report combination equipment, wherein the report combination instruction is sent by operating report items in a report list interface by a user and carries identification information of each report to be combined, the report list interface comprises the plurality of report items, and each report item corresponds to a report and is used for displaying the identification information of the corresponding report; judging whether the report headers of the reports to be combined are all the same according to the identification information of the reports to be combined; if so, copying report fields of report headers of non target reports in the reports to be combined to same report headers in target reports in the reports to be combined; if not, appending work pages corresponding to the non target reports to the target reports, and copying the contents of the non target reports to the corresponding work pages in the target reports. According to the technical scheme, the report combination efficiency and flexibility can be improved.

Owner:HUAWEI TECH CO LTD

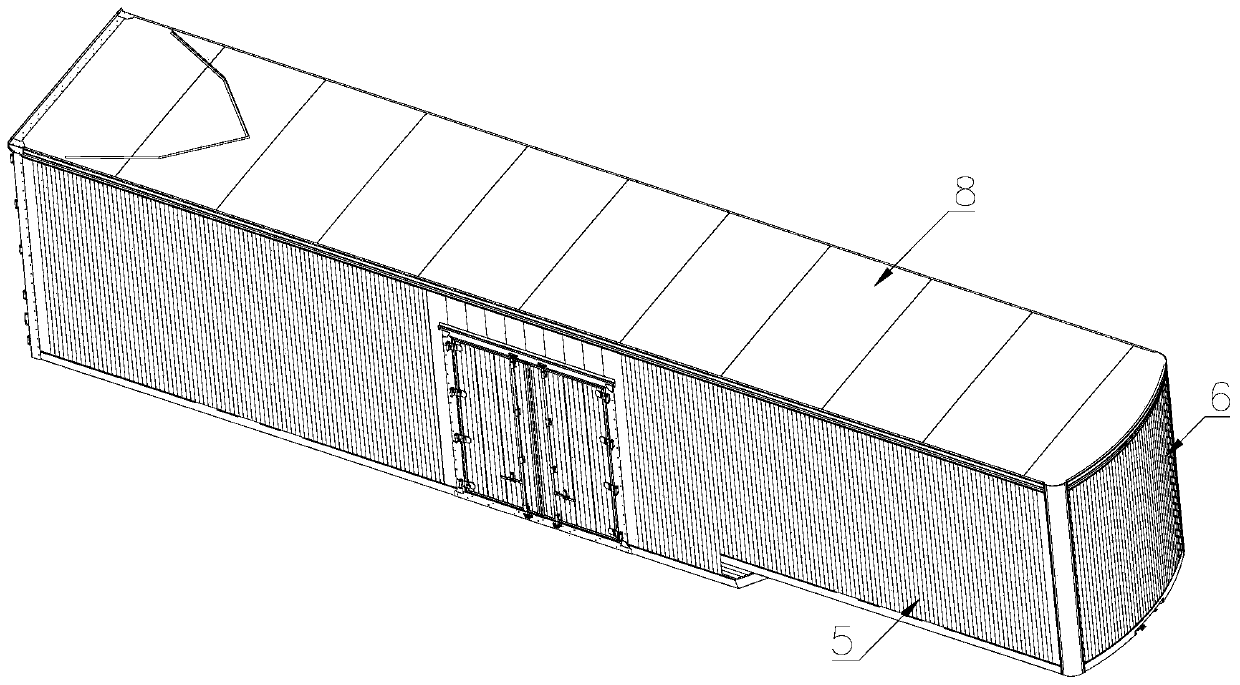

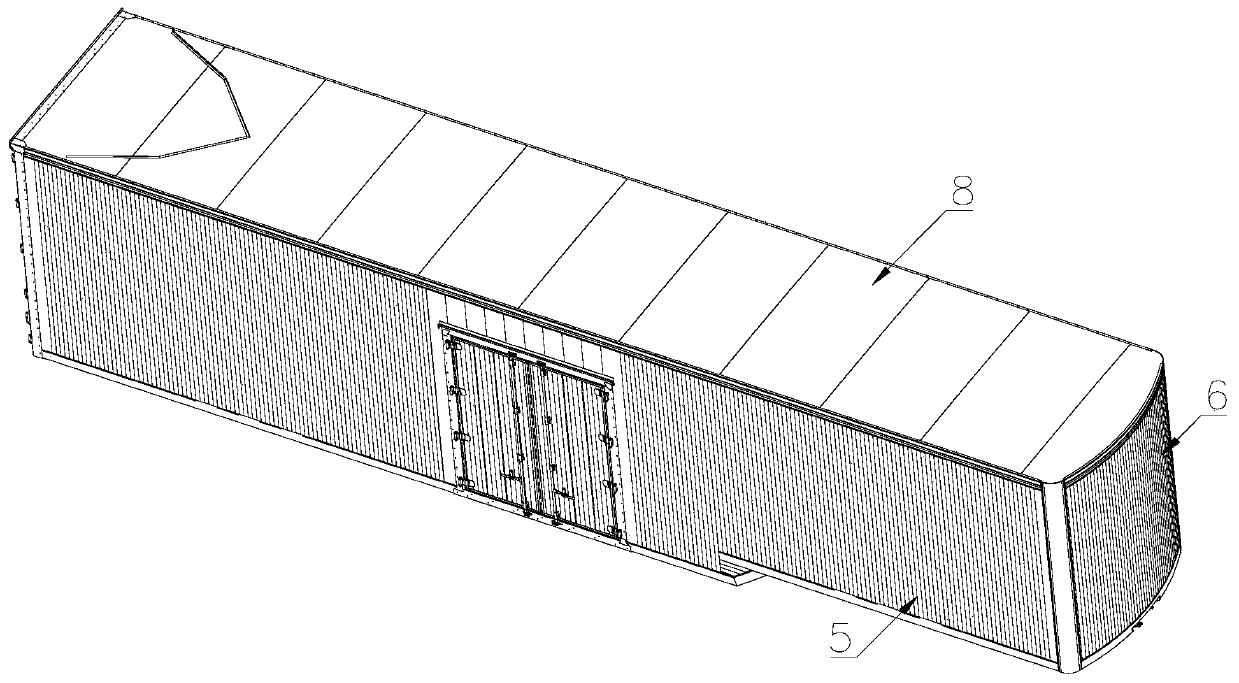

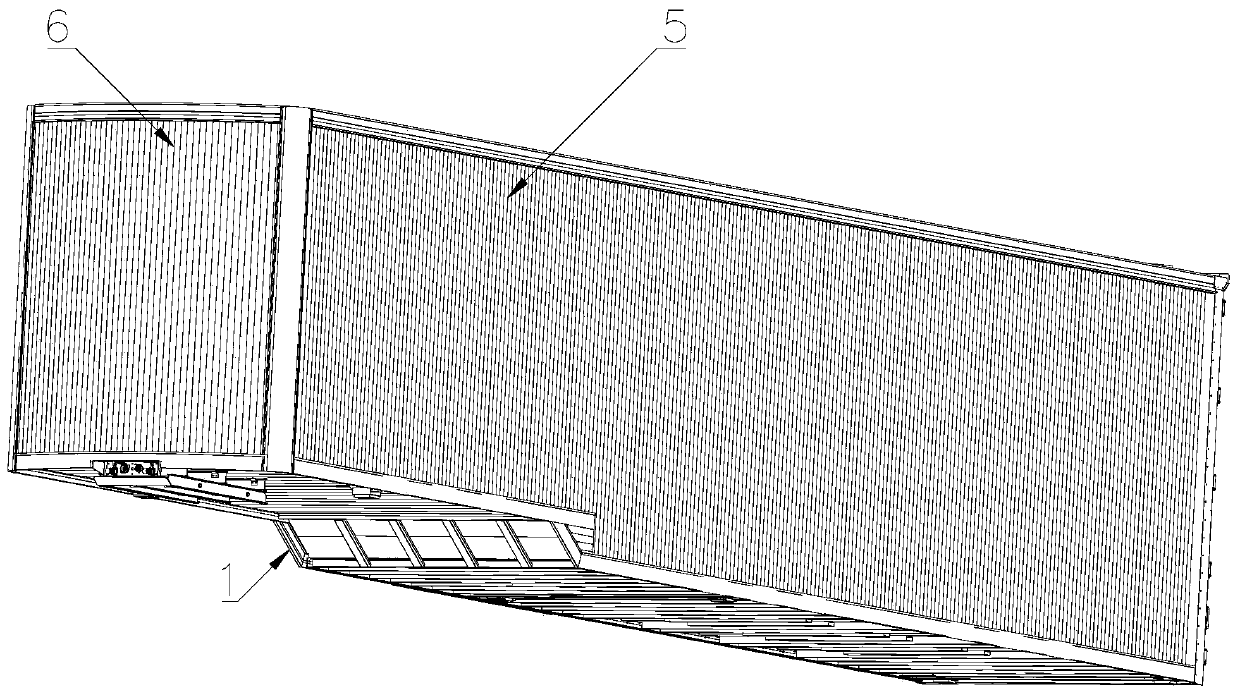

Light-weight aluminum alloy carriage

PendingCN111137364AImprove combination efficiencyExcellent lightweight designLarge containersSuperstructure subunitsLogistics managementCarriage

The invention relates to the field of manufacturing and application of light-weight logistics equipment, in particular to a light-weight aluminum alloy carriage which comprises a bottom plate assembly, and the bottom plate assembly comprises a front end part and a rear end part which are arranged front and back on the axis; the front end portion comprises a transversely-laid aluminum alloy profilebottom plate, and the extrusion direction of the transversely-laid aluminum alloy profile bottom plate is perpendicular to the axis of the bottom plate assembly. The rear end part comprises an aluminum alloy square tube cross beam and a longitudinally-laid aluminum alloy profile bottom plate; and the aluminum alloy square tube cross beam is perpendicular to the axis of the bottom plate assembly.According to the light-weight aluminum alloy carriage provided by the invention, the process difficulty of production and manufacturing is reduced; compared with the prior art, the production cycle isshortened, the carriage combination efficiency is improved, particularly, under the condition that the overall lightweight design effect of the carriage is better and the cargo carrying capacity is equivalent, the carriage is greatly lightened, the logistics transportation efficiency is greatly improved, the loading capacity, deformation resistance and impact resistance of the carriage are improved, and safety is guaranteed while the logistics transportation efficiency is improved.

Owner:FUJIAN MINLU LIGHTWEIGHT AUTOMOBILE MFG CO LTD

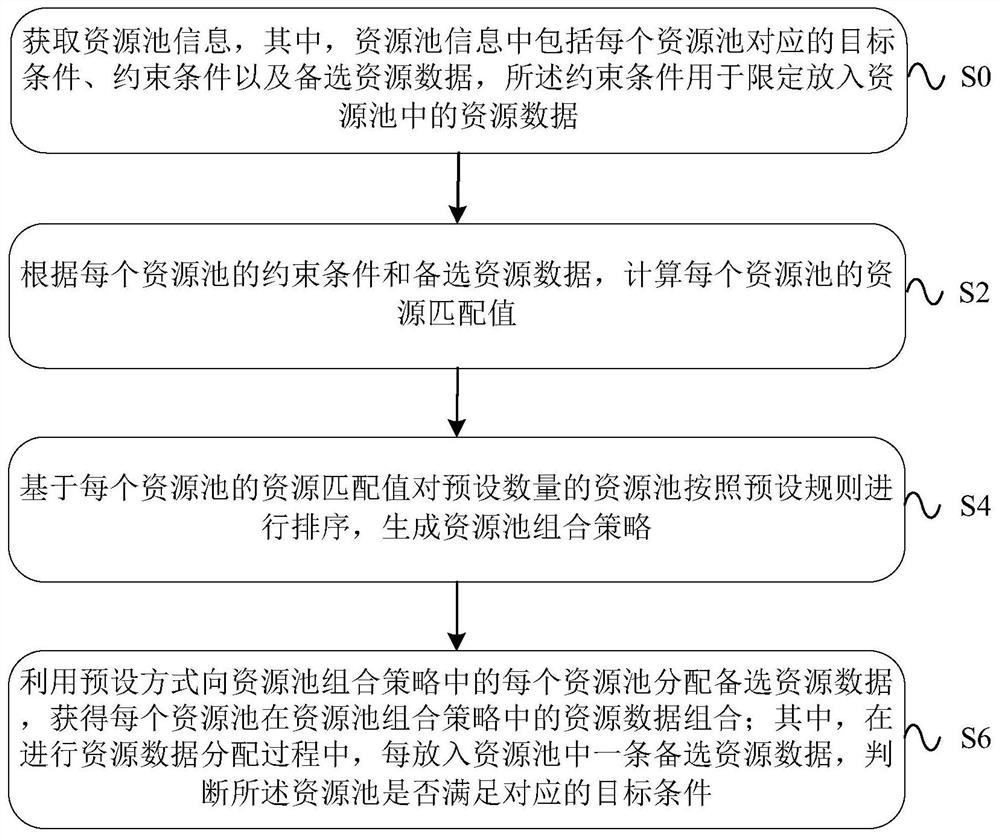

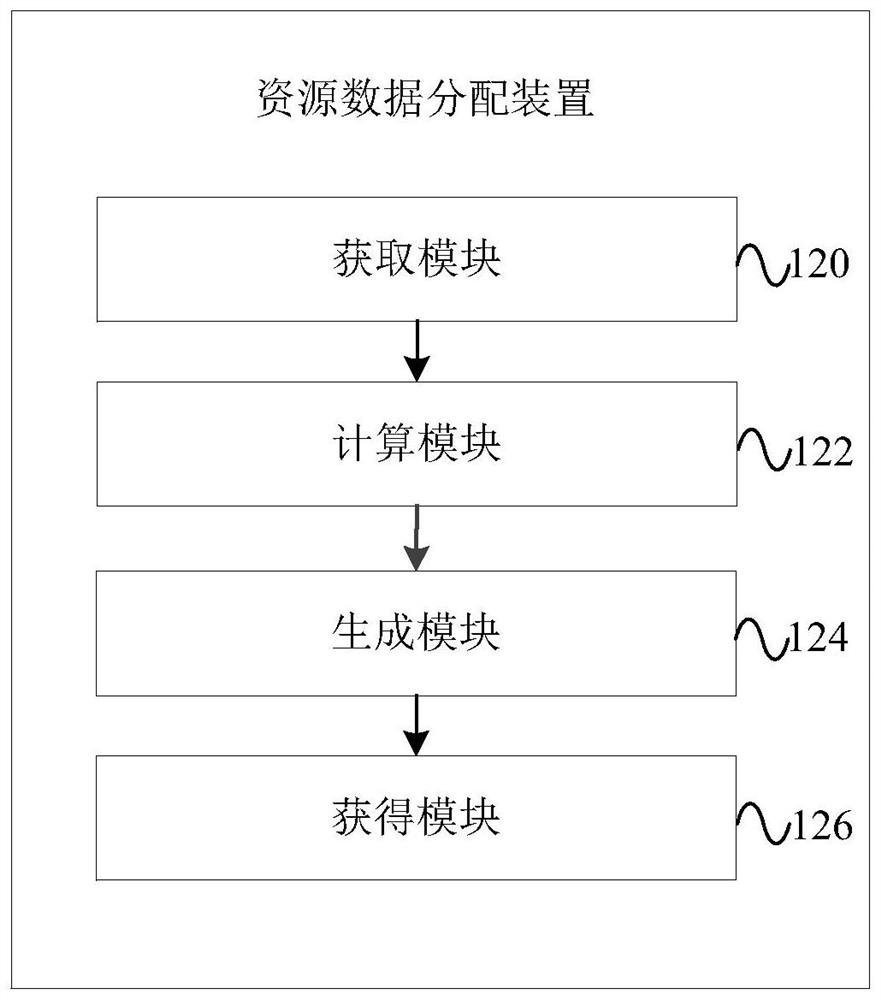

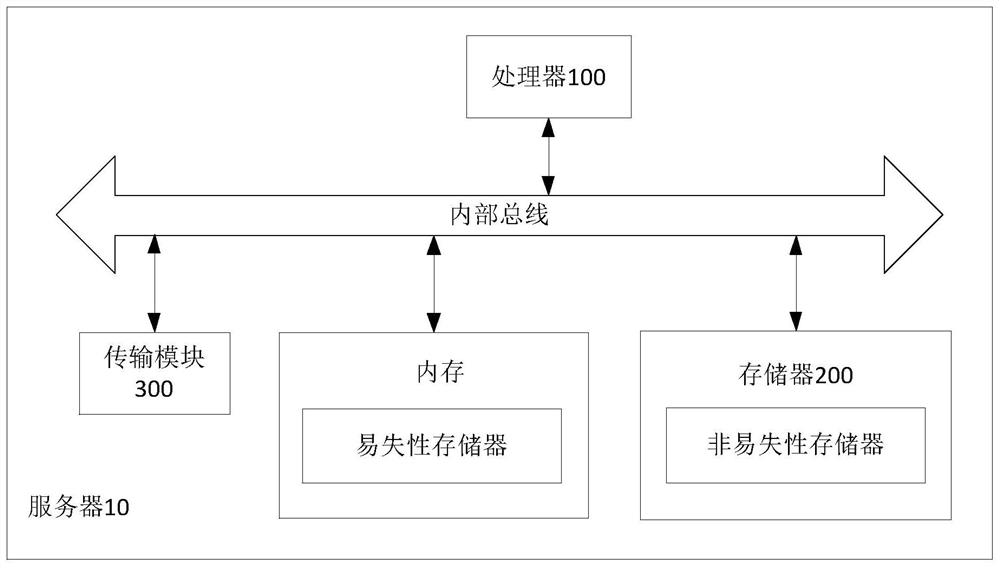

Resource data distribution method, device and equipment

PendingCN112465371ASolving the problem of combinatorial multi-strategy searchImprove liquidityFinanceResourcesDistribution methodResource combination

The embodiment of the invention provides a resource data distribution method, device and equipment. The resource data distribution method, device and equipment can be applied to the financial field orother fields. The method comprises the following steps: acquiring resource pool information; calculating a resource matching value of each resource pool according to the constraint condition of eachresource pool and the alternative resource data; sorting a preset number of resource pools according to a preset rule based on the resource matching value of each resource pool to generate a resourcepool combination strategy; allocating alternative resource data to each resource pool in the resource pool combination strategy in a preset mode to obtain a resource data combination of each resourcepool in the resource pool combination strategy, wherein in the resource data distribution process, whether the resource pool meets the corresponding target condition or not is judged every time when one piece of alternative resource data is put into the resource pool. By utilizing the embodiment of the invention, the problem of resource pool combination multi-strategy search can be solved, and theresource combination efficiency is improved.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

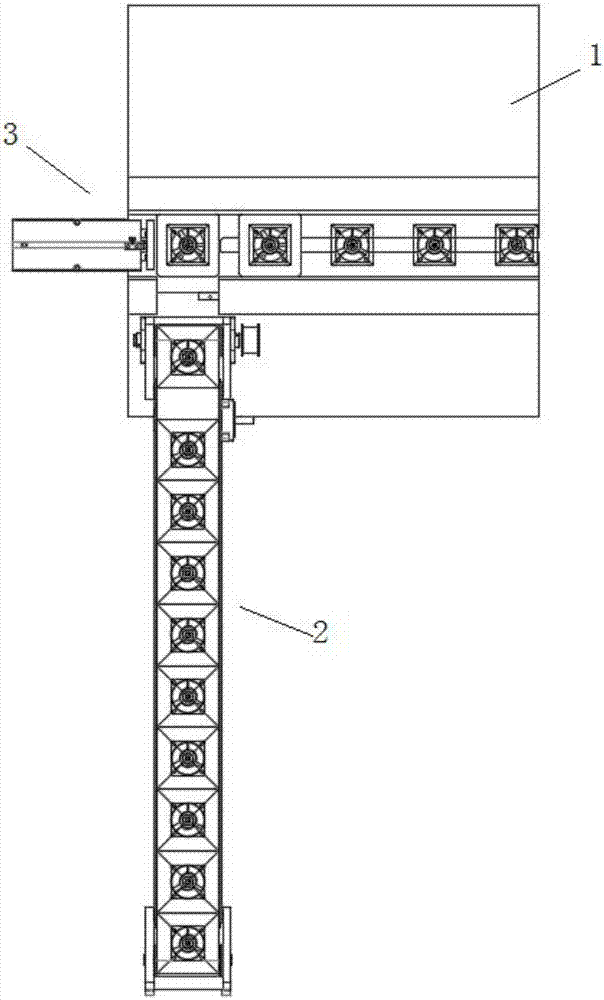

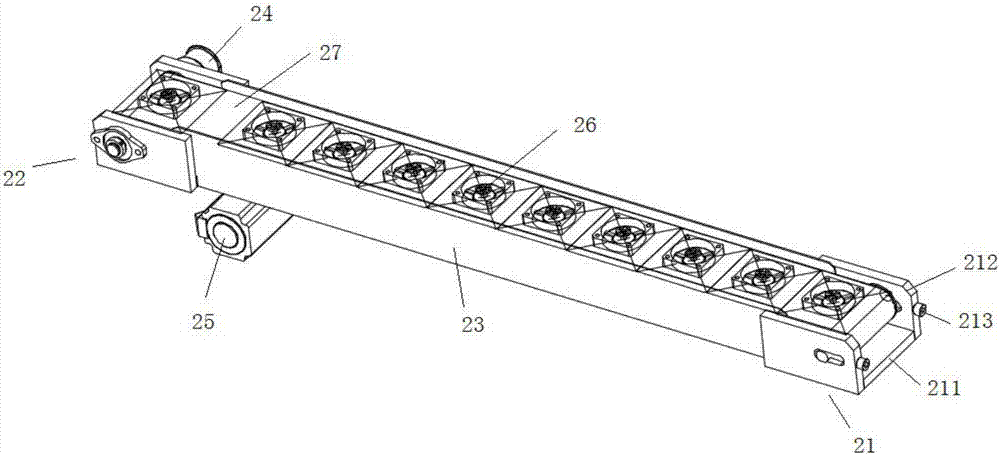

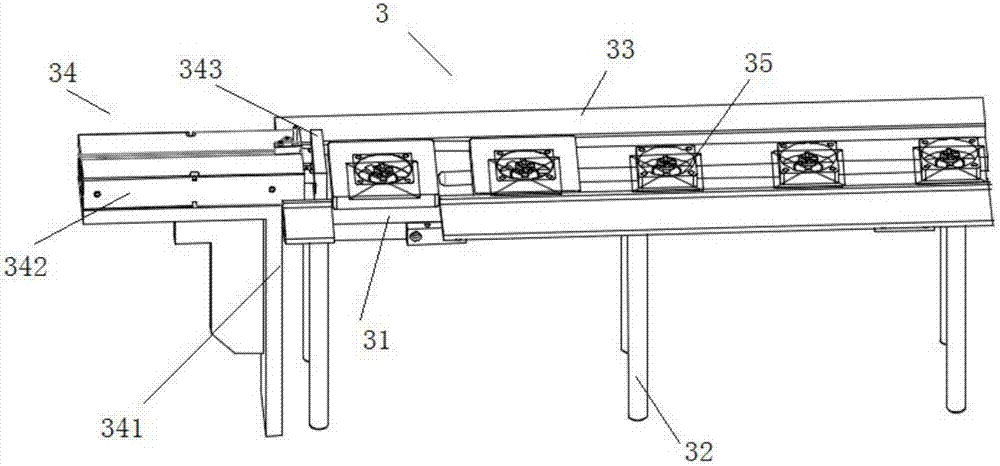

Radiating piece feeding combination equipment

InactiveCN107243564ANovel structureIngenious designMetal-working feeding devicesHeat exchange apparatusAssembly lineEngineering

The invention proposes a combined feeding equipment for heat sinks, which includes a frame and a working platform arranged on the upper end of the frame. Heat sink delivery line at the end. This kind of cooling element feeding combination equipment is used for the combination of heat dissipation shell and fan blade. It has a novel structure and ingenious design. The equipment has the advantages of good stability and high combination efficiency; The transmission line of the heat dissipation shell is vertically set, and the fan blade moves to the heat dissipation shell at the heat dissipation shell transmission line. The heat dissipation shell has a recess, and the fan blade just moves to this position. The combination is accurate and efficient, which is conducive to improving production efficiency.

Owner:嘉善凝辉新型建材有限公司

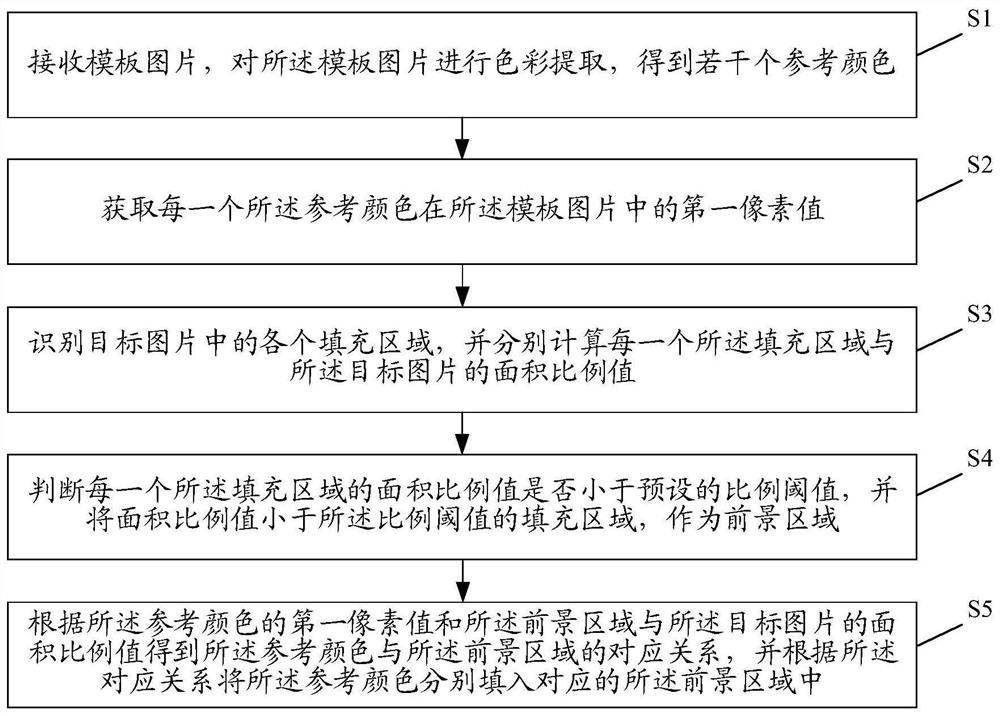

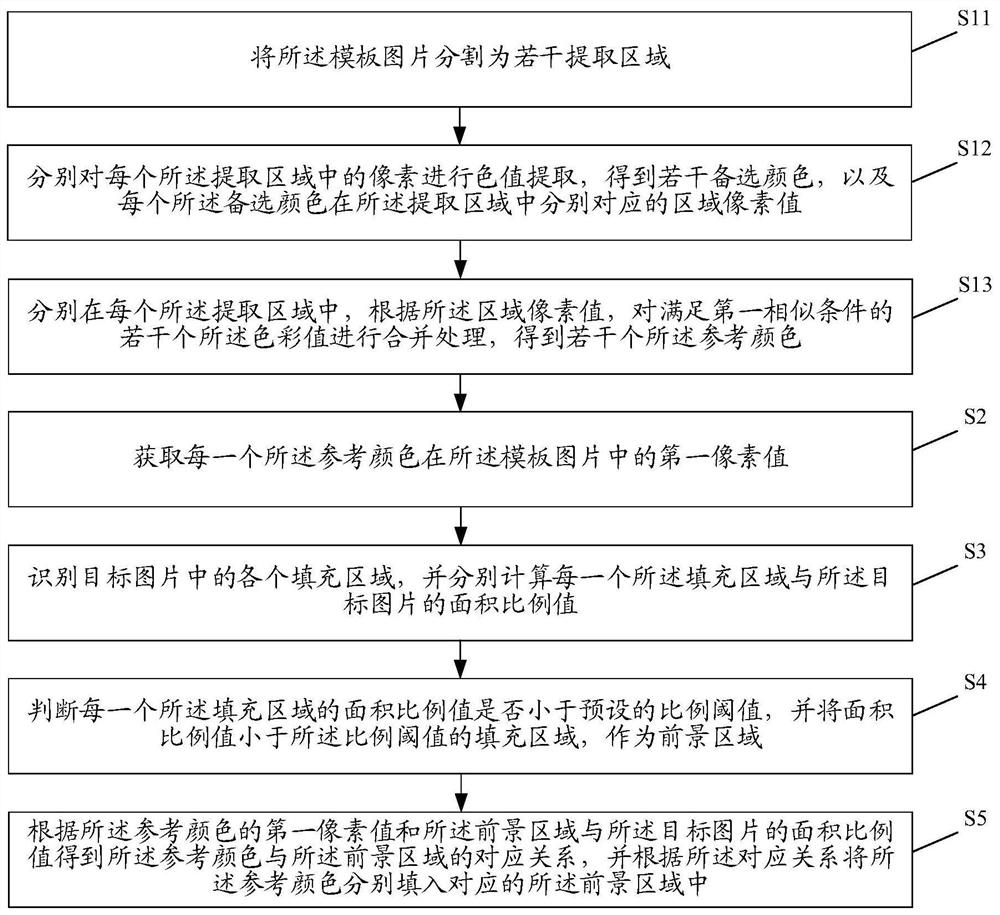

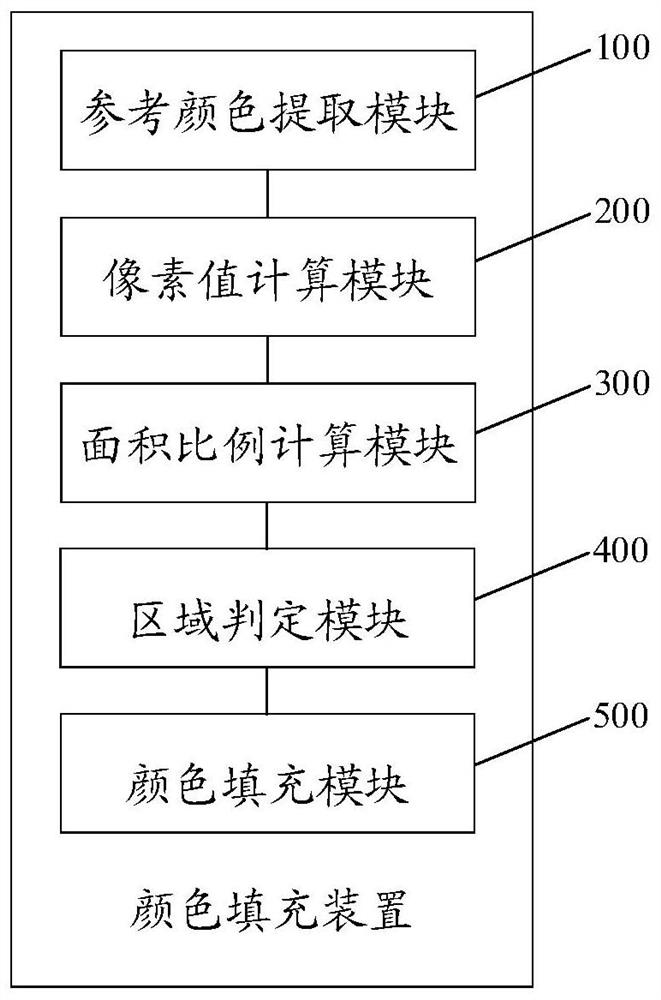

Color filling method and device, equipment and storage medium

PendingCN113808235AImprove combination efficiencyImprove reliabilityFilling planer surface with attributesComputer graphics (images)Engineering

The invention relates to the technical field of artificial intelligence, and discloses a color filling method and device, equipment and a storage medium, and the method comprises the steps: receiving a template picture, and extracting a plurality of reference colors; obtaining a first pixel value of each reference color in the template picture; identifying filling areas in a target picture, and calculating an area ratio value of each filling area to the target picture; judging whether the area proportion value of the filling area is smaller than a preset proportion threshold value or not, wherein the filling area with the area proportion value smaller than the proportion threshold value serves as a foreground area; obtaining a corresponding relation between the reference colors and the foreground areas according to the first pixel values of the reference colors and the area proportion value of the foreground areas and the target picture, and filling the corresponding foreground areas with the reference colors according to the corresponding relation; the automatic selection of the filling color is realized, so that the color matching design efficiency of the picture is improved.

Owner:PINGAN PUHUI ENTERPRISE MANAGEMENT CO LTD

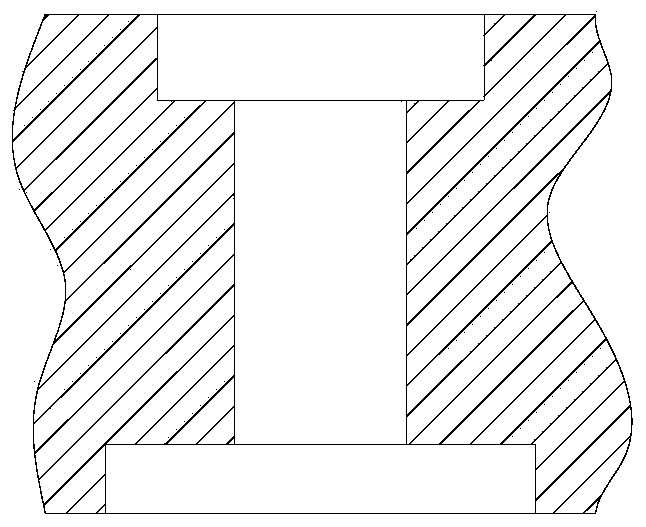

Technology for manufacturing octagonal center driving shaft sleeve of thickener

ActiveCN104646842ASimple processReduce welding difficultyWelding apparatusEngineeringOperation safety

The invention relates to a technology for manufacturing an octagonal center driving shaft sleeve of a thickener. The technology comprises the following steps of manufacturing a regular octagonal barrel body in a flat welding manner; firstly splicing a top surface flange plate and the regular octagonal barrel body integrally; flattening the top surface flange plate, pairwise boring a bottom surface flange plate corresponding to an upper barrel body, and welding pairwise; firstly making a middle supporting truss into a component, and then assembling and welding according to a theoretical size; pairwise assembling the bottom surface flange bottom separately in the process of positively manufacturing and pre-assembling the upper barrel body and a lower barrel body, and welding pairwise. The technology for manufacturing the octagonal center driving shaft sleeve of the thickener has the advantages that the traditional high elevation welding is replaced by flat welding, the welding difficulty is reduced, the welding quality is improved, the overhead operation is greatly reduced, the operation safety coefficient is improved, and the working efficiency is guaranteed.

Owner:南通华川交通装备有限责任公司

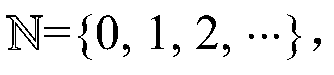

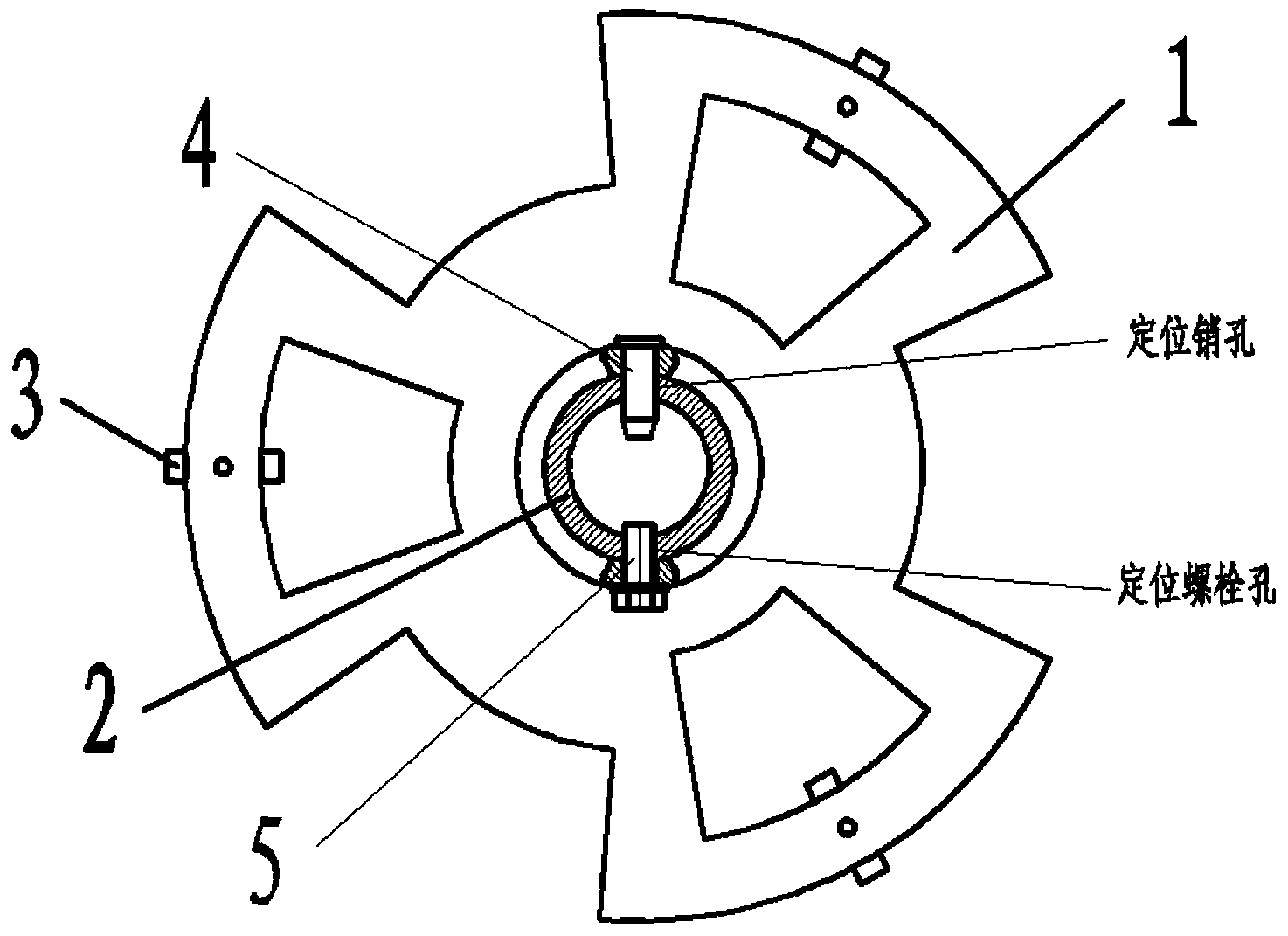

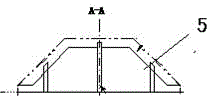

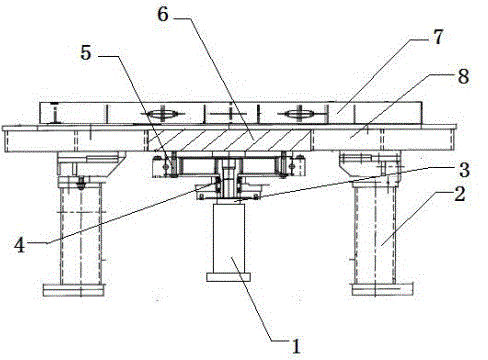

Automatic rotating mechanical worktable

InactiveCN105562629AImprove combination efficiencyGuaranteed rotation angleMould tablesHydraulic cylinderCoupling

An automatic rotating mechanical worktable is characterized by comprising a hydraulic cylinder, supporting stand columns, a hydraulic piston, a coupler, a fixing tool, a rotating disc, a worktable body and a fixing chuck, wherein the fixing chuck is fixed to the supporting stand columns, the worktable body is arranged on the fixing chuck and connected with the rotating disc arranged in the fixing chuck, the lower side of the rotating disc is connected with a driving device, the driving device comprises the hydraulic cylinder, the hydraulic piston and the coupler, the hydraulic piston of the hydraulic cylinder is connected with the coupler, the driving device is connected to the lower side of the rotating disc through the fixing tool, the rotating disc is in a round cake shape, a sliding wheel is arranged on the outer edge of the rotating disc, the fixing chuck is in a ring shape, and a sliding track matched with the sliding wheel of the rotating disc is arranged on the inner ring of the fixing chuck. The automatic rotating mechanical worktable has the advantages that the structure is simple, use is convenient, the combination efficiency of sand cores can be effectively improved, and the labor intensity of workers can be effectively relieved; besides, by adopting a tabletop rotating device, the rotating angle of the sand cores can be guaranteed, the sand cores can be prevented from being damaged, the rate of finished products can be increased, and requirements of modernized production can be met.

Owner:贾雪松

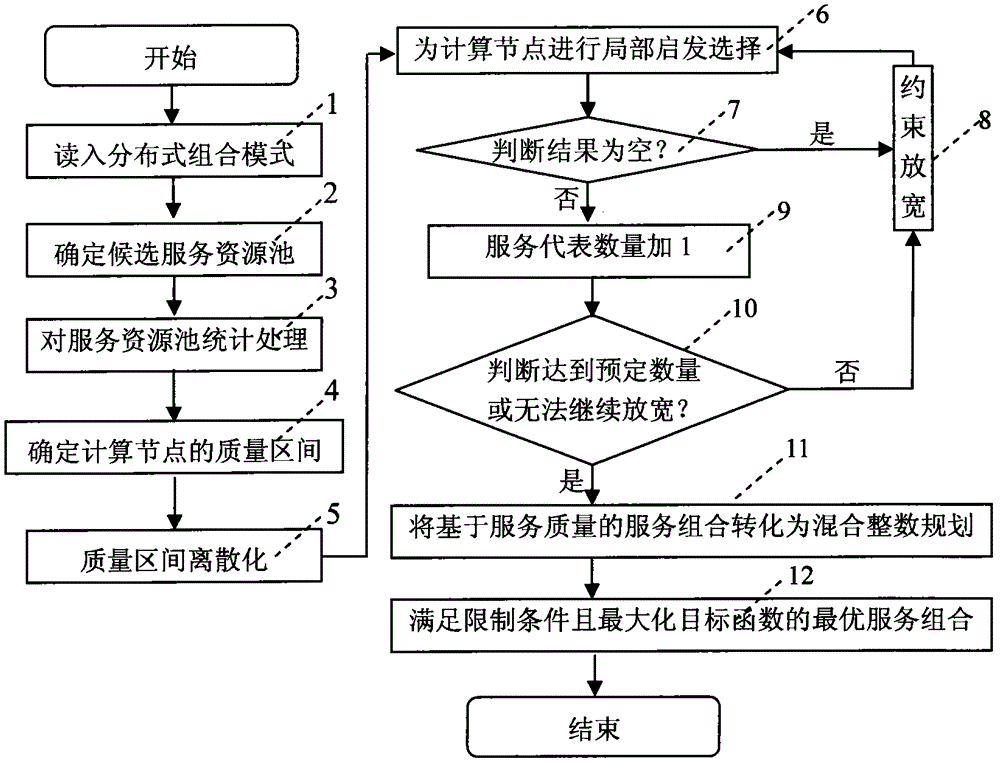

Service combination method based on service quality under service oriented architecture (SOA) in network system

InactiveCN101977213BHigh degree of automationMeet real-time needsTransmissionResource poolService composition

The invention discloses a service combination method based on the service quality under an service oriented architecture (SOA) in a network system, comprising the following steps after saving distributed combination mode data in a computer memory: reading a distributed combination mode description file; determining a candidate web service resource pool matched in function; performing statistical process; building a statistical interval representation; discretizing each continuous quality index statistical interval; performing a local heuristic selection to each distributed computation node under the limitation of the initial mass; obtaining a service representation under the mass limitation, and converting the service combination problem under the SOA into an equivalent MIP problem by using the service representation obtained by each distributed computation node; and obtaining an optimal service combination scheme by solving the MIP problem based on the integer programming technology.In the invention, the optimal selection process of the service combination under the entire SOA is completely realized by the computer automatically, thereby enhancing the automation and the operation efficiency of the service combination.

Owner:NANJING UNIV

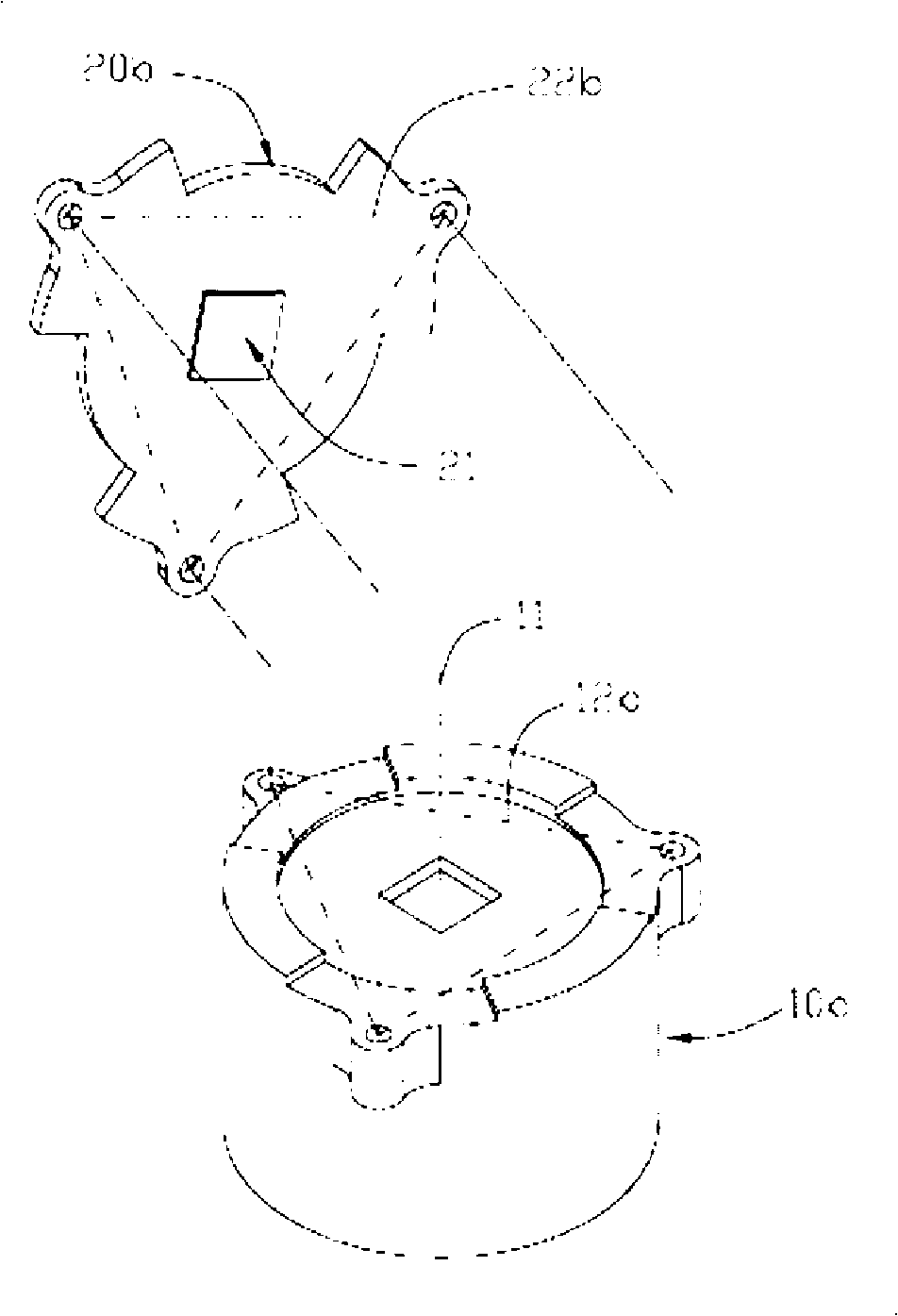

Camera module group combined method and camera module group

InactiveCN101329434AAvoid damageAvoid repeated disassembly and assembly operationsTelevision system detailsProjector focusing arrangementCamera lensOptical axis

The invention provides a combination method of a camera module and the camera module obtained by the method. The combination method of the camera module is used for combining a lens unit and a photographic unit and comprises the steps as follows: whether the locking adhesion surface of the lens unit is vertical to an optical axis thereof or not is detected; if not vertical, the locking adhesion surface is corrected till the locking adhesion surface is vertical to the optical axis; whether the assembly surface of the photographic unit is parallel to a photosurface or not is detected; if not parallel, the assembly surface is corrected till the assembly surface is parallel to the photosurface; and the assembly surface which is vertical to the optical axis is locked and adhered to the locking adhesion surface which is parallel to the photosurface. The combination method of the camera module respectively detects and corrects the lens unit and the photographic unit and further combines the lens unit and the photographic unit after the correction, thereby avoiding the possible splitting action from damaging elements after the combination. In addition, the combination method can avoid the repeated demolition and rotation operations and enhance the combination efficiency. The lens unit and the photographic unit which are obtained by utilizing the combination method of the camera module have great universality.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

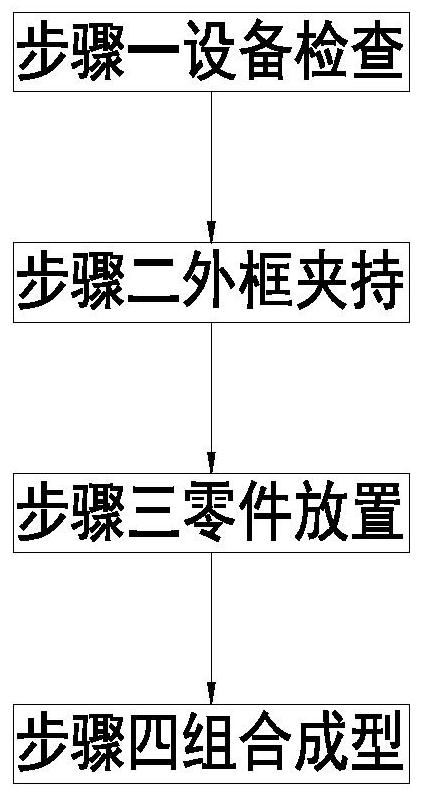

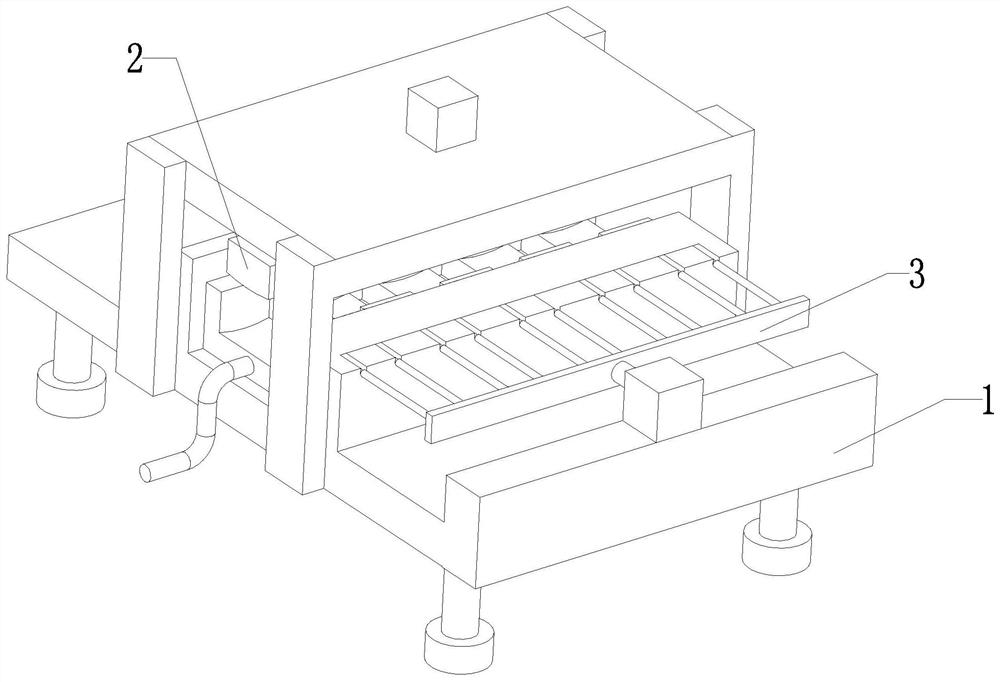

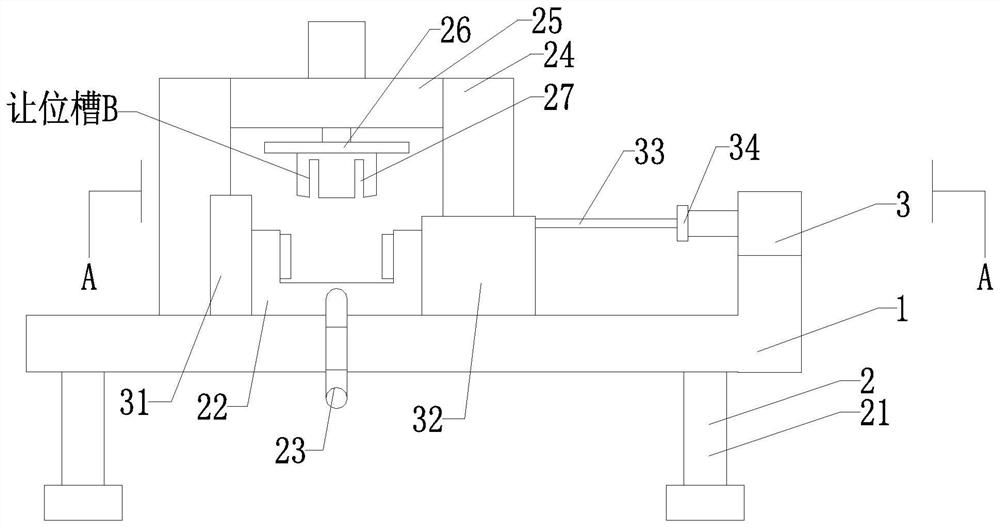

Manufacturing and machining process for automobile brake assembly

InactiveCN112917138AQuick disassemblyIncrease productivityAssembly machinesVehicle componentsBrakeMachining process

The invention relates to a manufacturing and machining process for an automobile brake assembly. The manufacturing and machining process mainly comprises the following steps of equipment inspection, outer frame clamping, part placement and combination molding. Automobile brake assembling equipment comprises a mounting frame, a clamping sleeve and a splicing sleeve, the clamping sleeve is mounted on the mounting frame, the splicing sleeve is arranged at the outer side of the clamping sleeve, and the splicing sleeve is fixedly mounted on the mounting frame. According to the a manufacturing and machining process, the following problems existing in the assembling process of an existing automobile brake can be solved, wherein a, in the assembling process of the existing automobile brake, in order to improve the assembling efficiency, assembling at multiple stations is commonly carried out at the same time, and then the automobile brake needs to be disassembled one by one during disassembly, so that the time is greatly wasted, and the production efficiency is slowed down; and b, in the assembling process of the existing automobile brake, the situation that combination cannot be achieved due to the fact that a brake caliper clamping pin shakes occurs, then manual righting is needed, and manpower is wasted.

Owner:冯伟

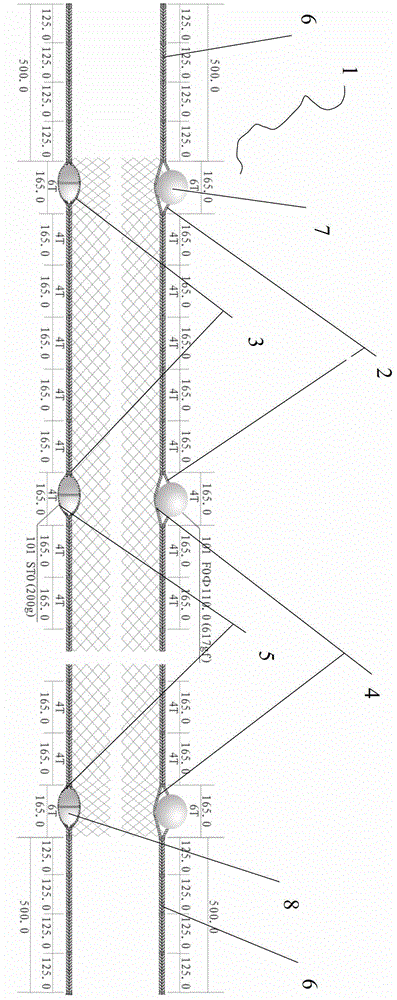

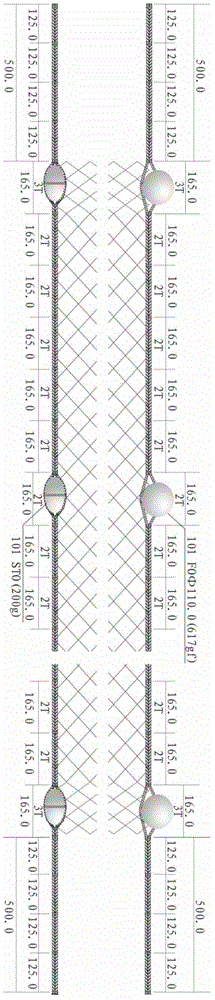

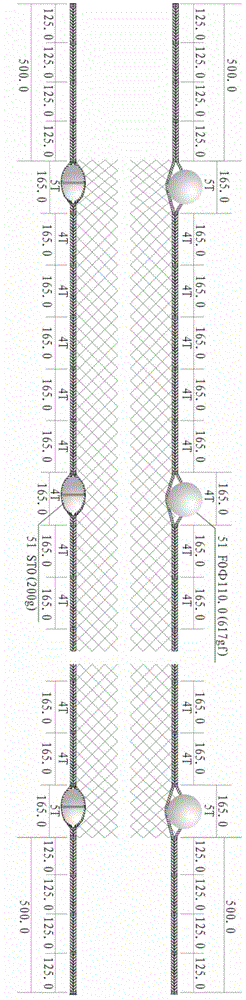

Novel bathing beach protection single net and bundling method thereof

The invention relates to a novel bathing beach protection single net and a bundling method thereof. Left and right edges of the single net can be combined into integral rows around seams; an upper edge of the single net is bundled and attached with a head line; a lower edge of the single net is bundled and attached with a foot line; the single net has three types of lengths of 99.00m, 49.50m and 24.75m, so that the single net is assembled into net rows according to the length-width requirements of a bathing beach; the single net has 12 types of straightening heights of 0.70m, 1.40m, 2.10m, 2.80m, 3.50m, 4.20m, 4.90m, 5.60m, 6.30m, 7.00m, 7.70m, and 8.40m so as to adapt to the requirement on the change of the water depth of the bathing beach; and each single net is divided into a plurality of sections. The novel bathing beach protection single net and the bundling method thereof have the beneficial effects that a plurality of adopted single nets can be connected and combined into an integral-row net tool, are convenient for connection, laying, management and maintenance of the net tool and can be used for simultaneously blocking nettlefishes and sharks.

Owner:河北省海洋与水产科学研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com