Automatic precision screw and O-shaped rubber ring combination device

An automatic combination, rubber ring vibration technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., to achieve the effect of improving efficiency, reducing labor costs, and stable combination quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to facilitate the understanding of those skilled in the art, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments:

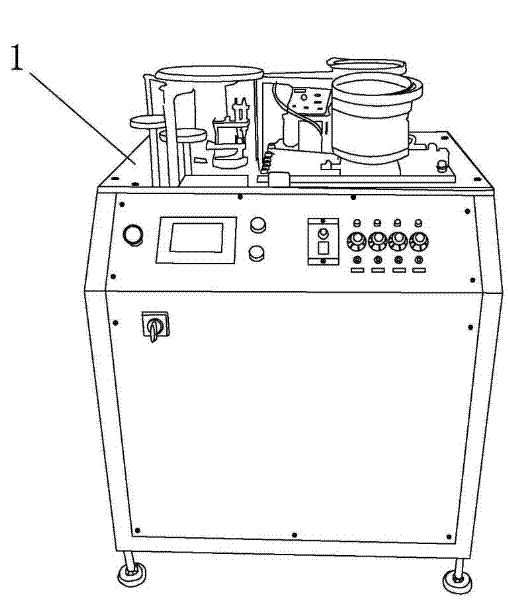

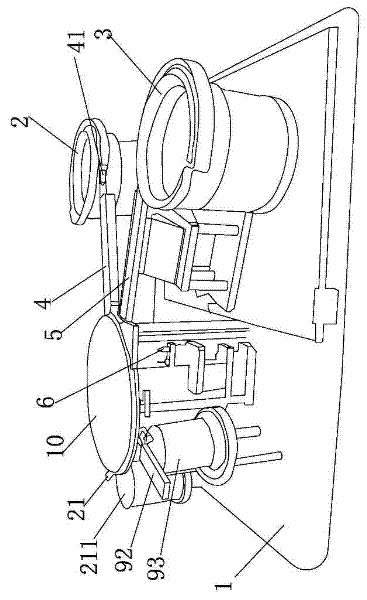

[0021] as attached figure 1 , 2 As shown, the precision screw and O-shaped rubber ring automatic assembly equipment disclosed in the embodiment of the present invention adopts PLC control to perform automatic operations. The equipment includes a working surface 1 and various mechanisms installed on the working surface 1. The working surface 1 is fixed on the chassis, and the chassis is used to install control circuits such as power supply and PLC. The chassis is provided with a touch screen control panel and operation buttons.

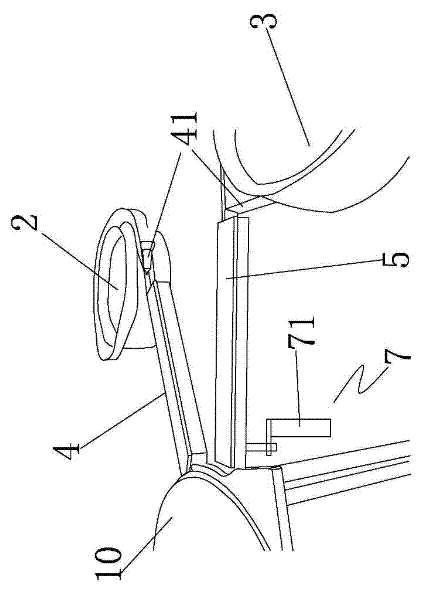

[0022] In this embodiment, an indexing turntable 10 driven by a motor is provided on the working surface 1 , and hanging grooves 11 for receiving screws are uniformly distributed around the indexing turntable 10 . The hanging groove 11 is set on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com