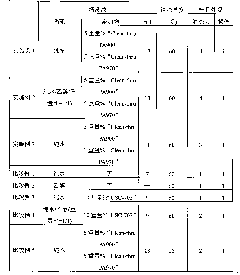

Patents

Literature

45results about "Mould tables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

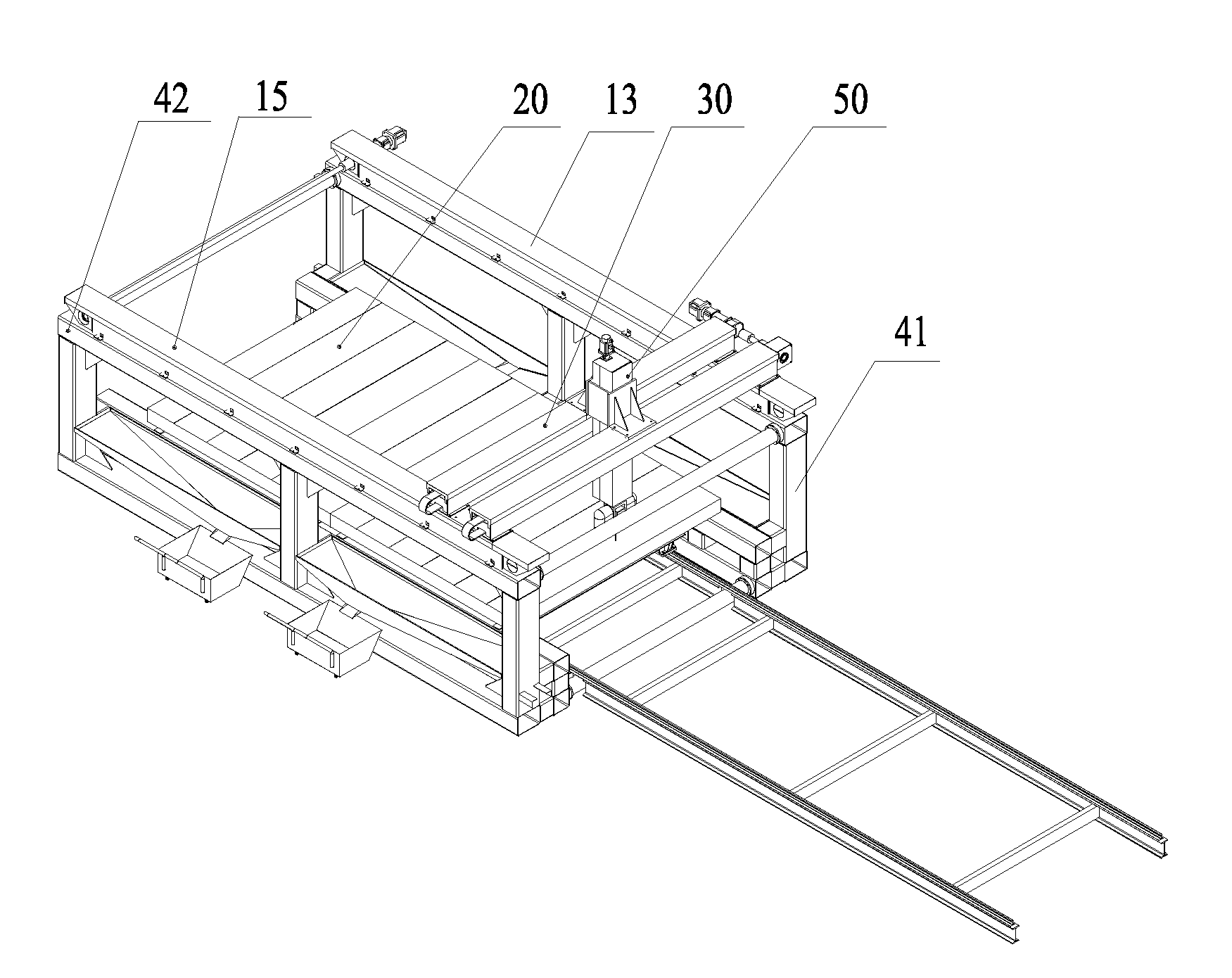

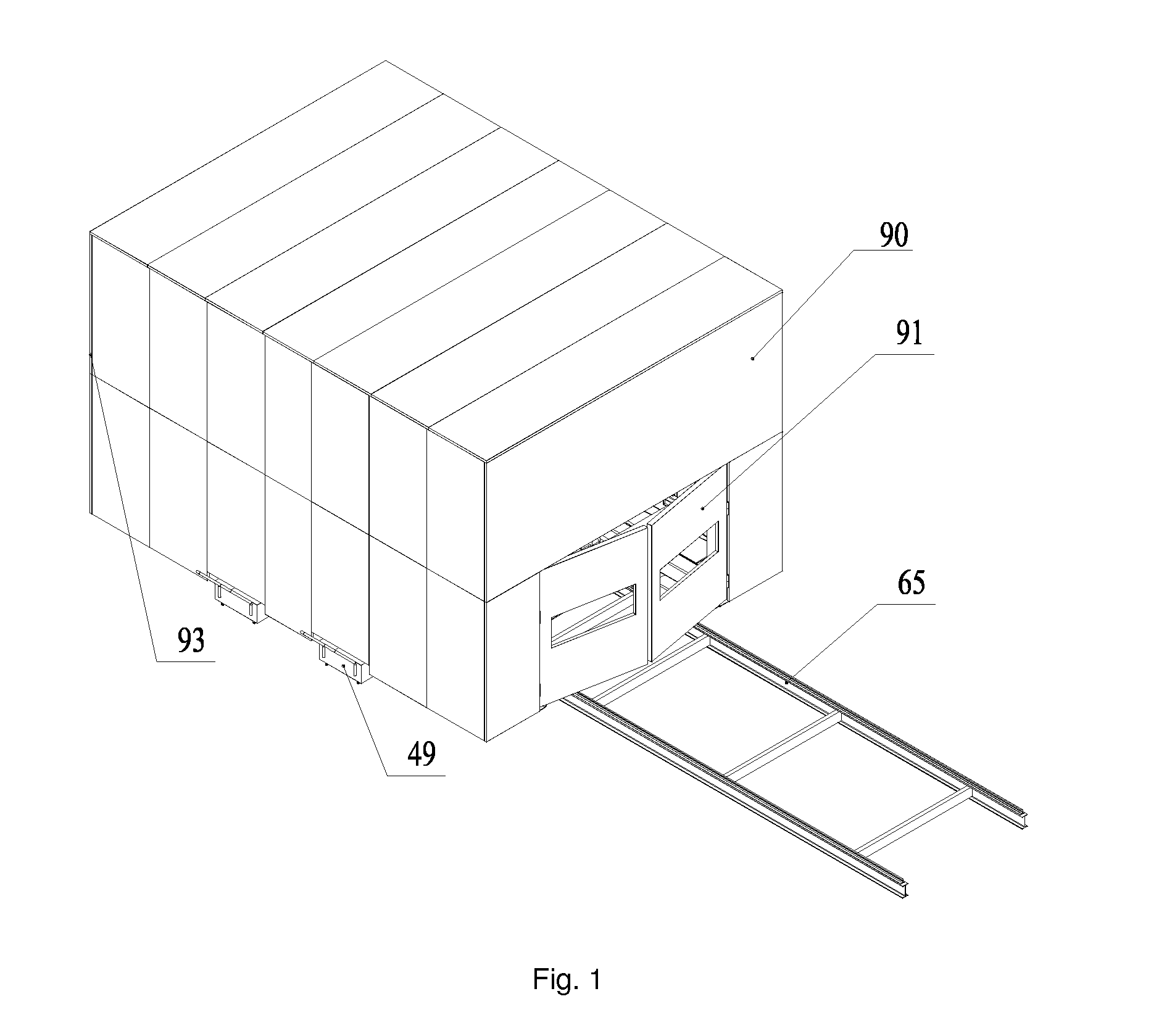

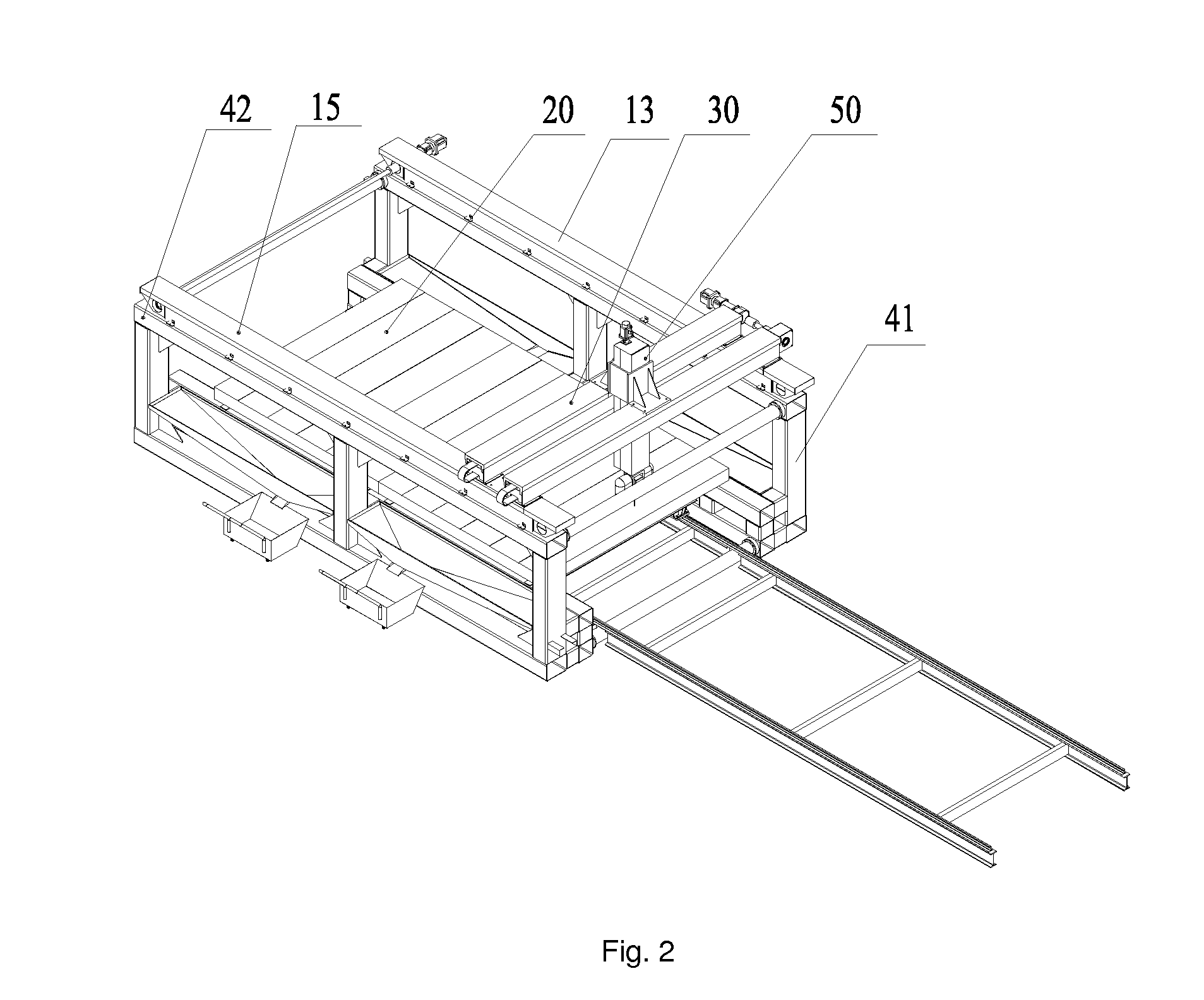

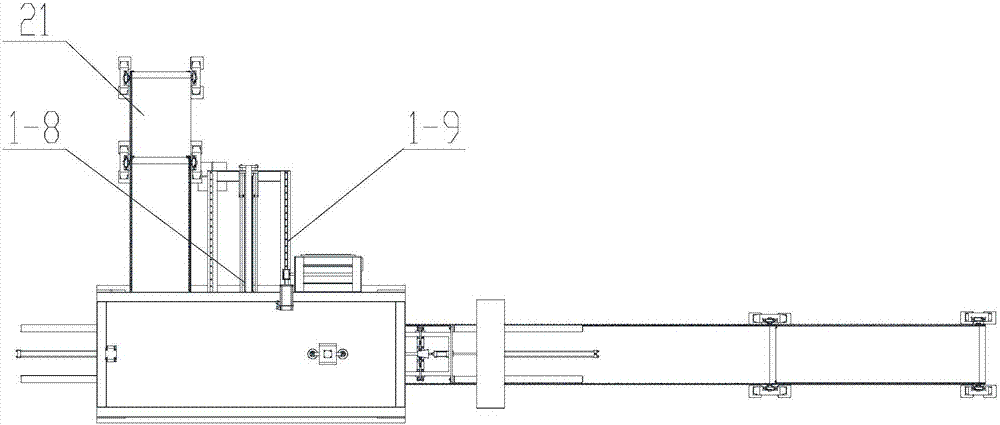

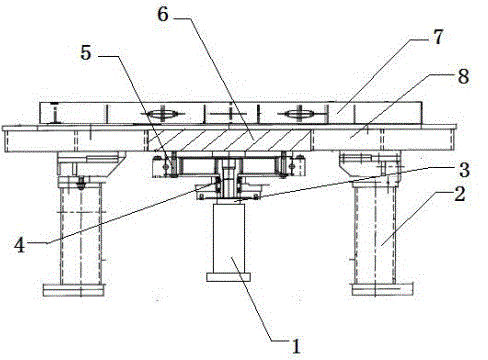

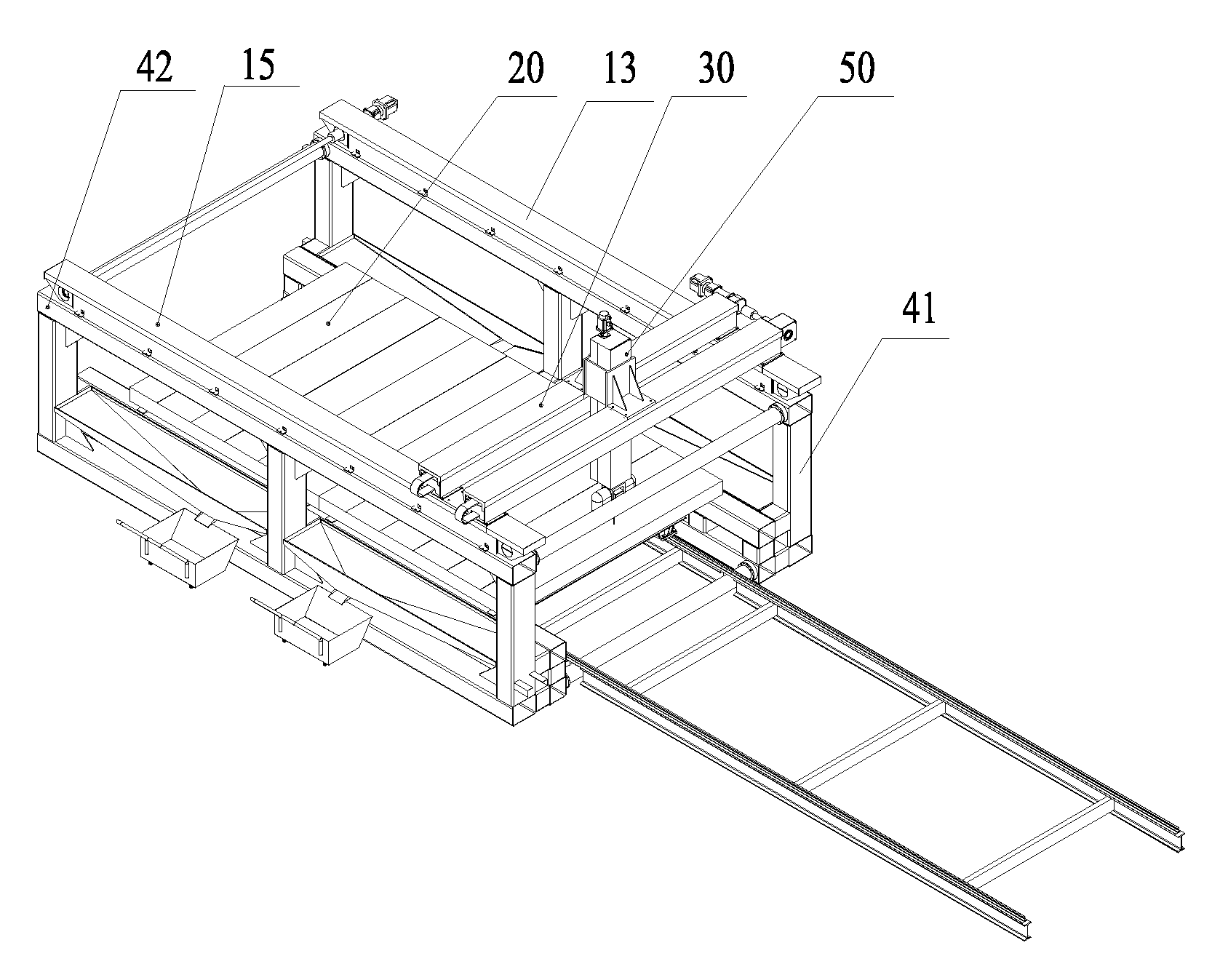

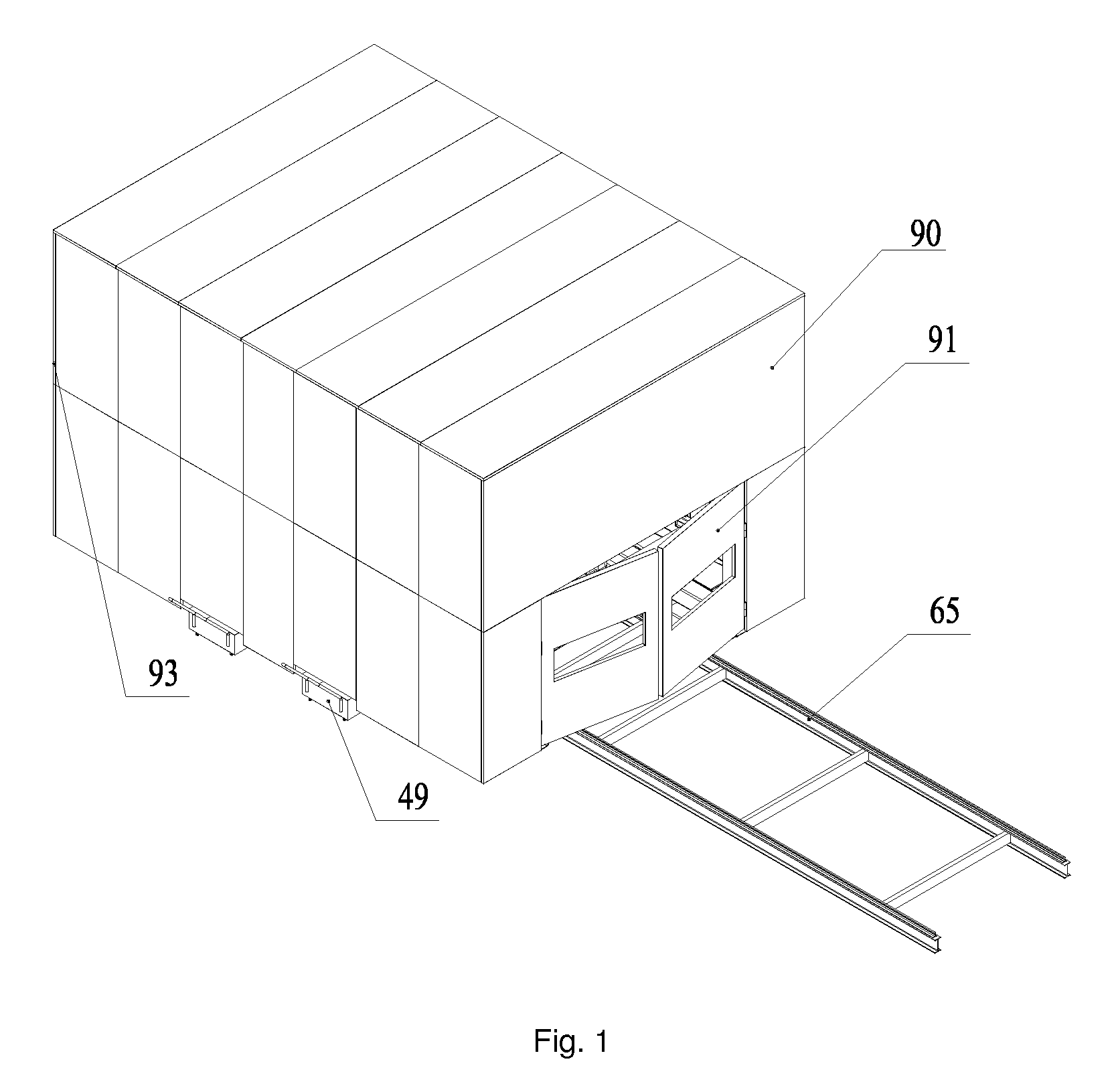

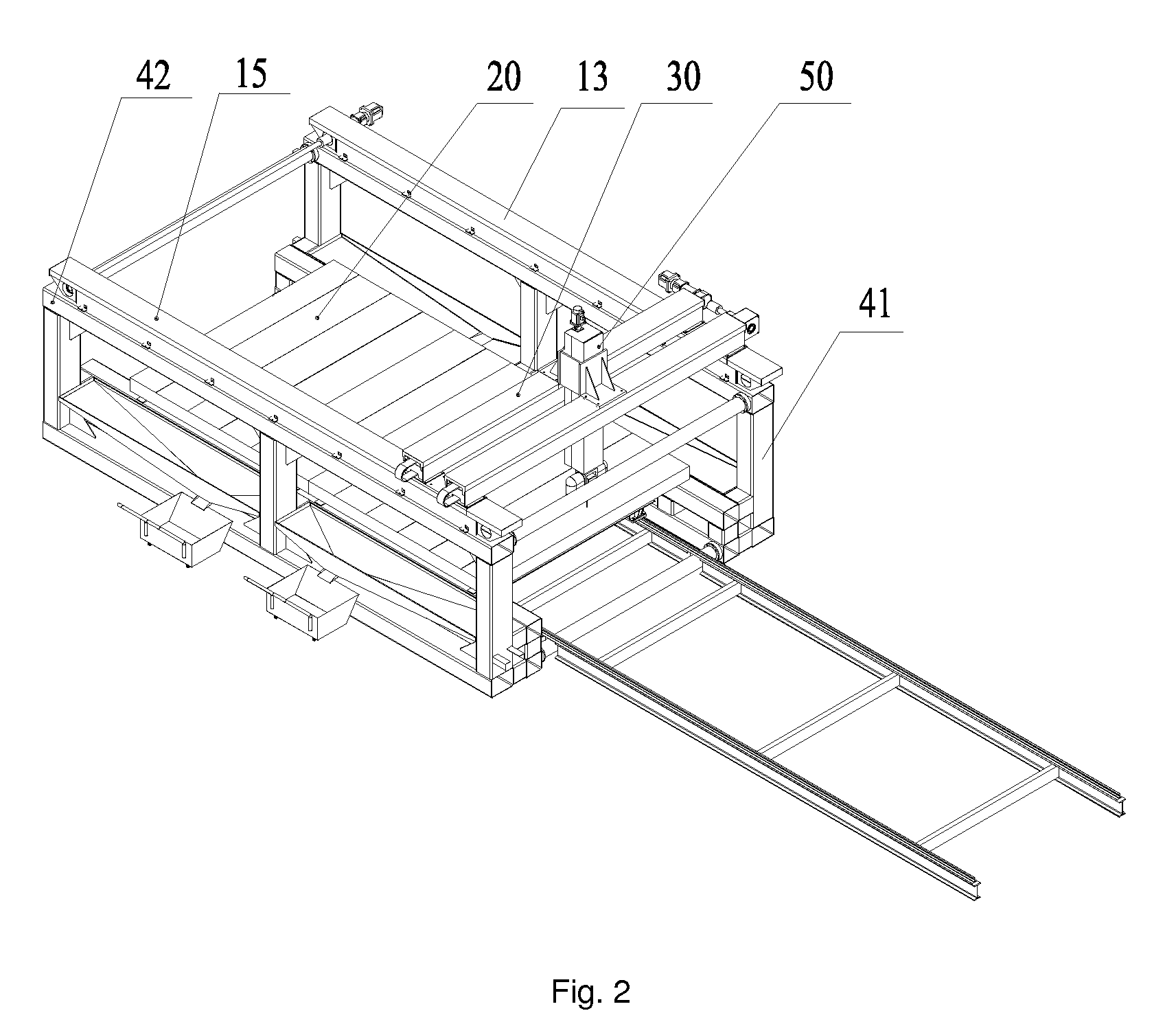

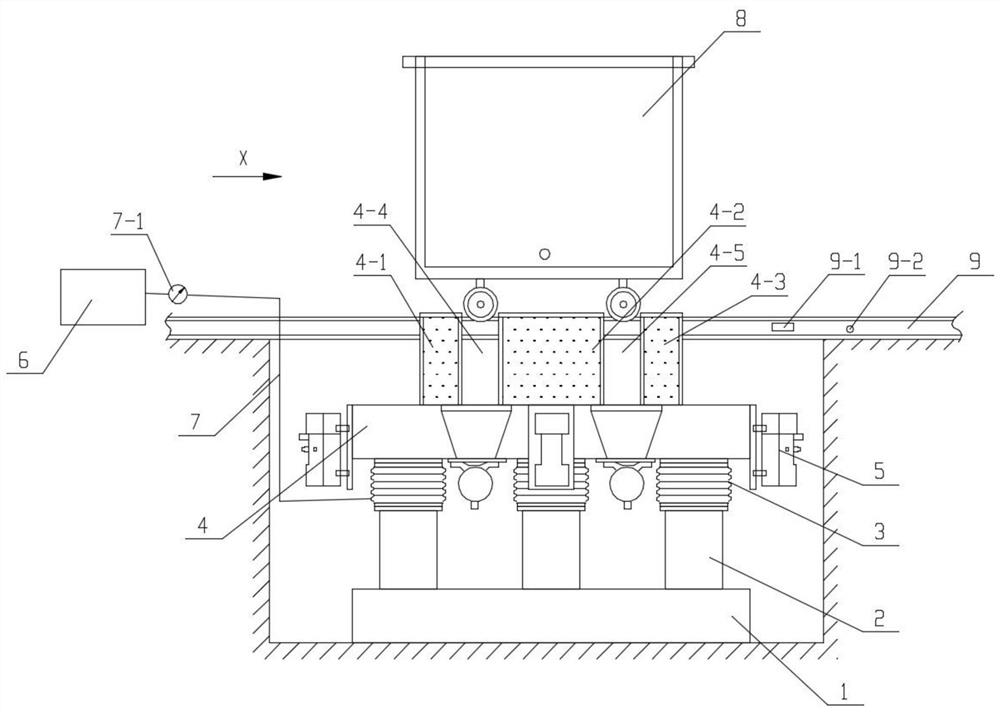

Model-free casting forming machine

The invention provides a model-free casting forming machine which comprises a multi-shaft moving system, a workbench and a moving platform system, wherein the multi-shaft moving system at least comprises an X-axis moving system, a Y-axis moving system and a Z-axis moving system; the workbench is located below the multi-axis moving system; the moving platform system is arranged below the workbench; the moving platform system comprises a moving bracket capable of moving to and fro along a direction parallel to the X-axis; a lifting device is arranged on the moving bracket; the lifting device isused for lifting and supporting the workbench, so that the workbench is linked with the moving bracket. According to the model-free casting forming machine provided by the invention, the workbench can be moved without a lifting tool; casting moulds with large-size and complicated cavities can be processed; and environmental pollution is small.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

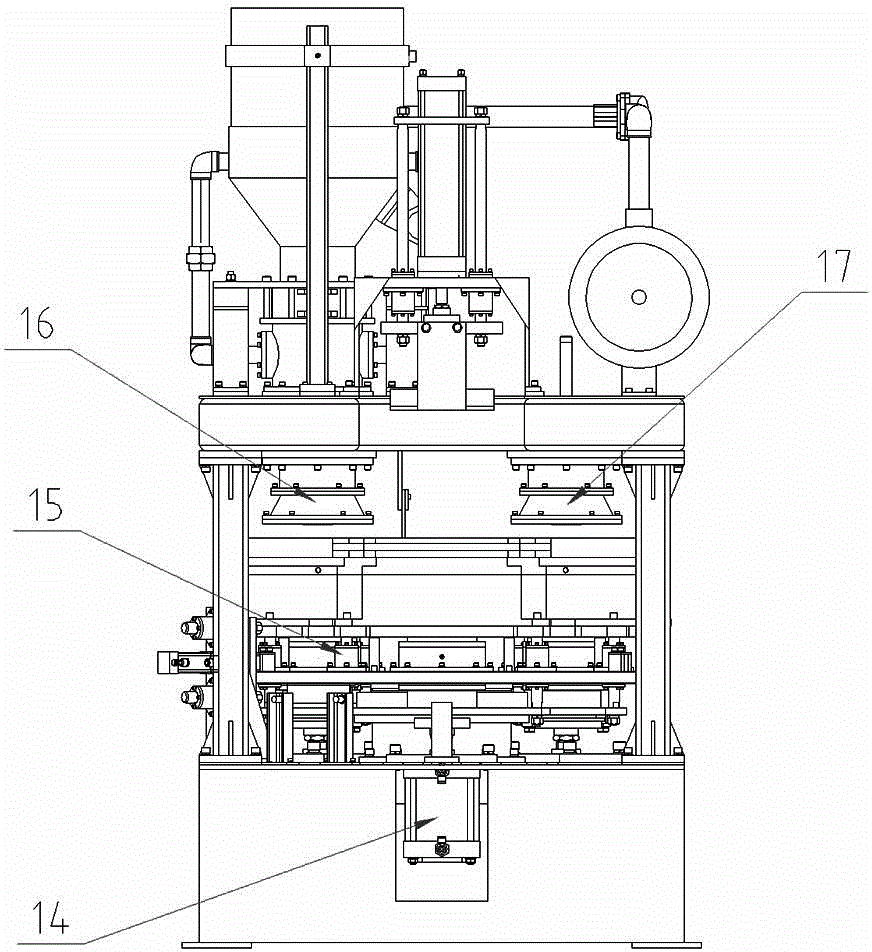

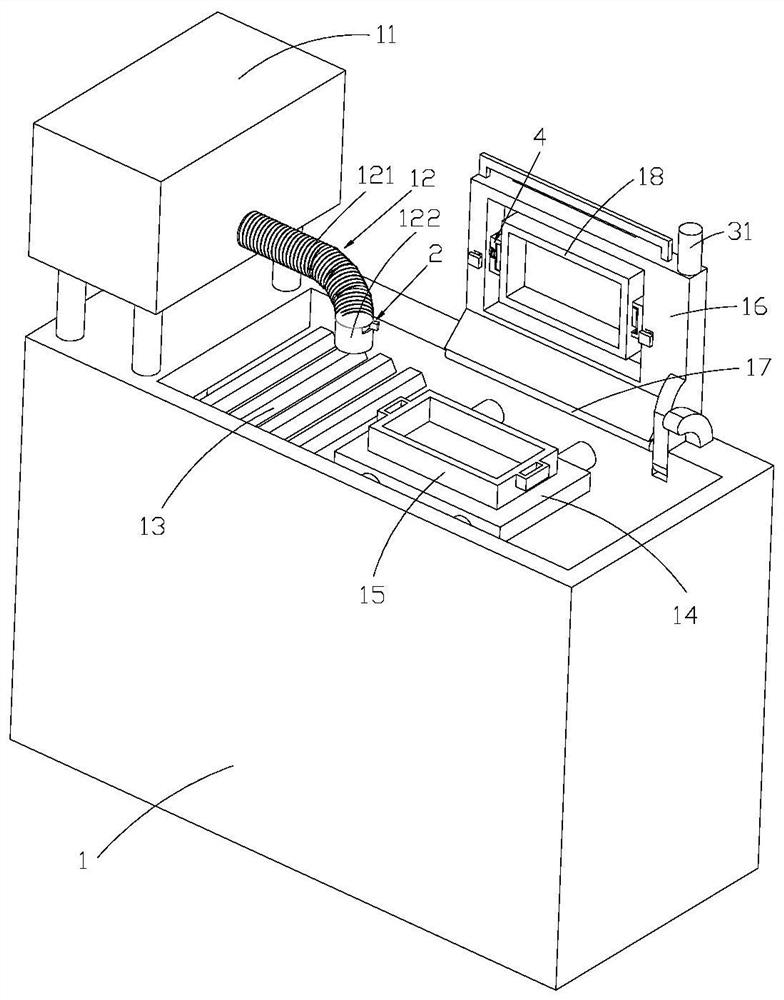

Servo control high-speed multi-station core making machine

InactiveCN104525875ASuitable for makingEasy to installFoundry mouldsMoulding machinesMotor driveAutomatic control

The invention relates to a servo control high-speed multi-station core making machine, which comprises a base, columns, a rotary worktable, a servo motor driving device, a mold lifting mechanism, a lower core ejecting mechanism, an auxiliary positioning mechanism, an upper beam frame, an upper mold opening mechanism, a sand blowing mechanism, a blowing mechanism and other auxiliary mechanisms, wherein three sets of core box molds can be simultaneously arranged on the rotary worktable, and a lower piece ejecting cylinder and a mold closing cylinder are arranged in the base; the columns are connected with the upper beam frame in a supporting way, and the upper mold opening mechanism, a sand storage hopper, an air pocket, a sand blowing head, a blowing head and the like are arranged on the upper beam frame. The servo control high-speed multi-station core making machine provided by the invention has the advantages of compact structure, easiness and convenience in operation of equipment, automatic control by adopting a PLC, convenience in daily maintenance, and high core making efficiency, and a core making circulation takes only about 16 seconds.

Owner:HEBEI HONOR MECHANICAL MOLD

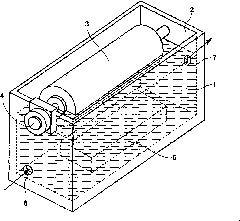

Cleaning method of roller type mold for manufacturing optical film

InactiveCN102189089AWon't hurtImprove qualityFoundry mouldsOptical articlesAlkaline waterCleaning methods

The present invention provides a cleaning method of a roller type mold for manufacturing an optical film. The cleaning method of the invention is characterized in that: the roller type mold which is provided with adhered mold pollutant is placed in alkaline water solution with pH value that is above 10. Furthermore an ultrasonic wave treatment is performed for the roller type mold under a temperature of 30-70 DEG C. The cleaning method does not damage the roller type mold and can well protect a polluted surface. Therefore, the cleaning method is preferably used for a state that the mold pollutant is photocurable resin.

Owner:SUMITOMO CHEM CO LTD

Hardware part casting working table

The invention discloses a hardware part casting working table comprising an operation platform. Multiple supporting legs are fixedly installed at the bottom of the operation platform. First installation grooves are formed in the bottoms of the supporting legs. Installation blocks are installed in the first installation grooves in a sliding manner. The bottoms of the installation blocks extend outof the first installation grooves. Telescopic assemblies are arranged above the installation blocks. Each telescopic assembly comprises first limiting grooves symmetrically formed in the inner walls of the two sides of the corresponding first installation groove. First limiting blocks are fixedly installed on the tops of the installation blocks. The two sides of each first limiting block are installed in the corresponding first limiting grooves in a sliding manner correspondingly. The hardware part casting working table is simple in structure and convenient to operate, rolling wheels can be very conveniently collected in the first installation grooves, the rolling wheels can be fixed in the first installation grooves after being collected, and the trouble caused by shaking of the operationplatform to casting of hardware parts is avoided.

Owner:柳州市钜嘉机械有限公司

Forming machine without pattern casting

The disclosure provides a forming machine without pattern casting, including: a multi-axis motion system which at least includes an X-axis motion system, a Y-axis motion system and a Z-axis motion system, and a workbench which is below the multi-axis motion system; and further includes: a moving platform system below the workbench, including a moving bracket which can reciprocate along the direction parallel to the X axis, a lifting device provided on the moving bracket, which is used for lifting and supporting the workbench to enable the linkage between the workbench and the moving bracket. The forming machine without pattern casting of the disclosure can move the workbench without a lifting tool, and machine a casting mold with a large size and a complex cavity, and causes little pollution to the environment.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Green sand box molding machine

ActiveCN107303598AImprove work efficiencyReduce loose sandMoulding machinesMould tablesMolding machineProcess engineering

The invention discloses a green sand box molding machine. The green sand box molding machine comprises a molding machine frame, wherein the box discharge end of a box opening conveying chain corresponds to the box feed side of the molding machine frame, a molding machine box feed manipulator is installed on the box feed side of the box molding machine, and a molding machine box discharge manipulator is installed on the box discharge side of the box molding machine; the box discharge side of the molding machine frame corresponds to the box feed end of a box closing conveying box; a molding machine workbench is installed in the molding machine frame, a sand shooting machine is installed outside the molding machine frame, and sand shooting openings correspond to the molding machine workbench. The working principle of the green sand box molding machine is to use compressed air to evenly shoot moulding sand into an upper sand box and a lower sand box at the same time and then apply external pressure for integral compaction. In this way, not only is working efficiency greatly improved, but also scattered sand and dust in the molding process are reduced. The molding mode can meet process requirements, cannot cause misalignment, and can guarantee sufficient core setting time.

Owner:HANGZHOU HUNING ELEVATOR PARTS CO LTD

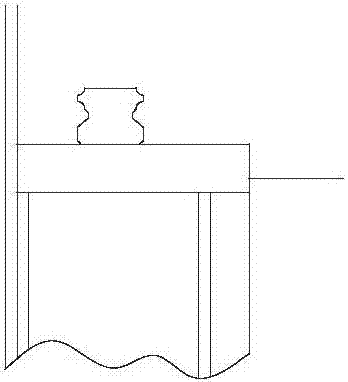

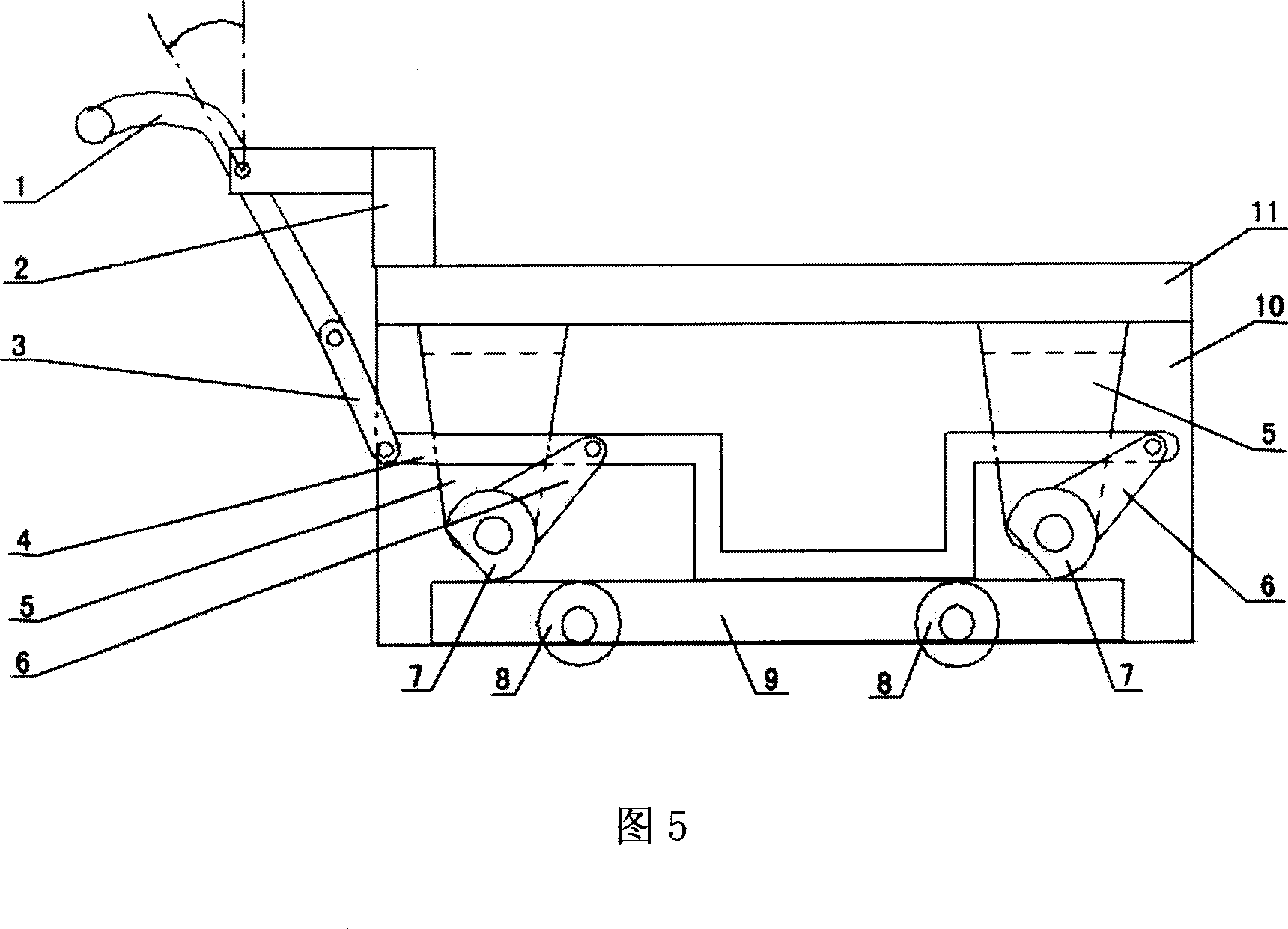

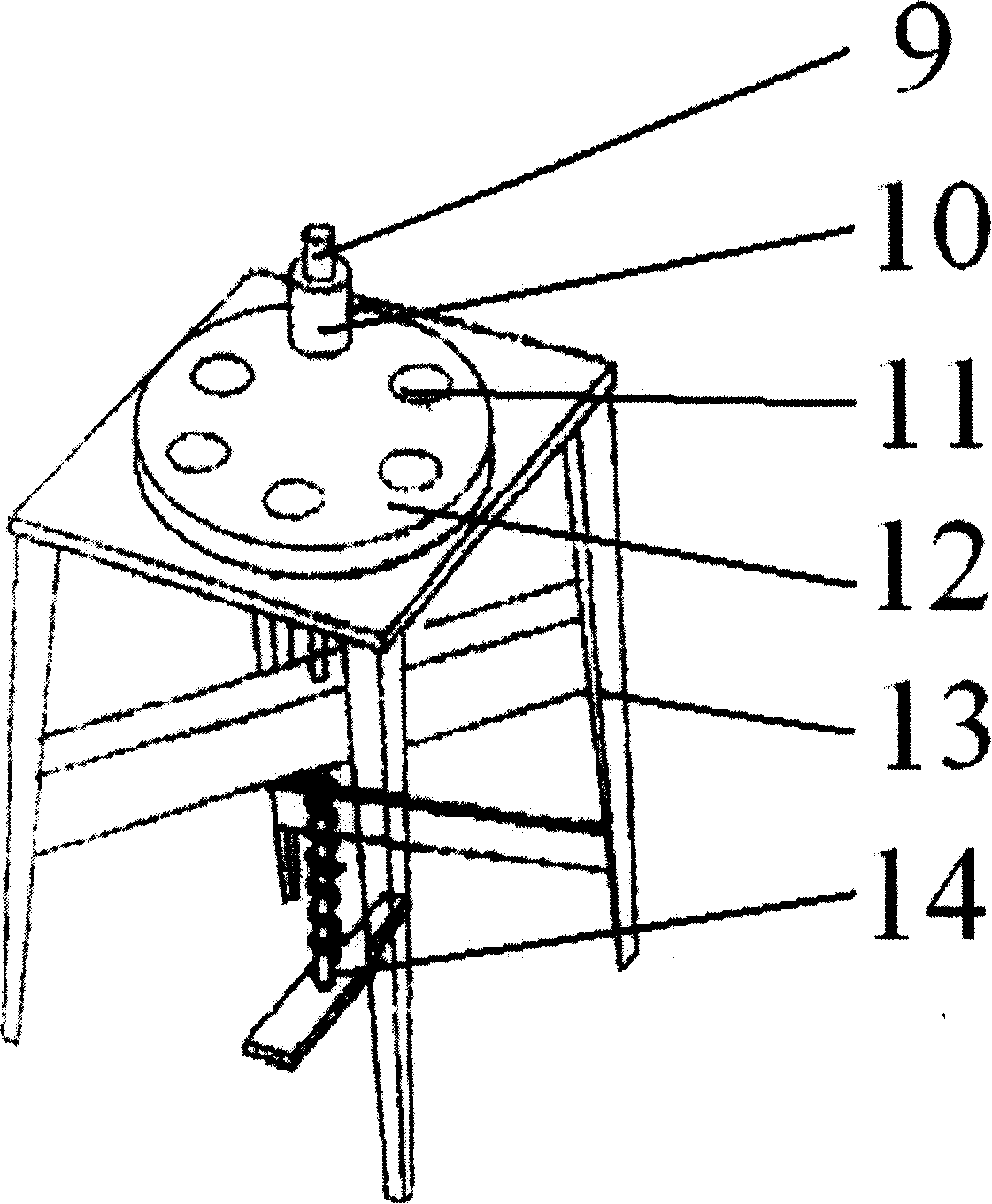

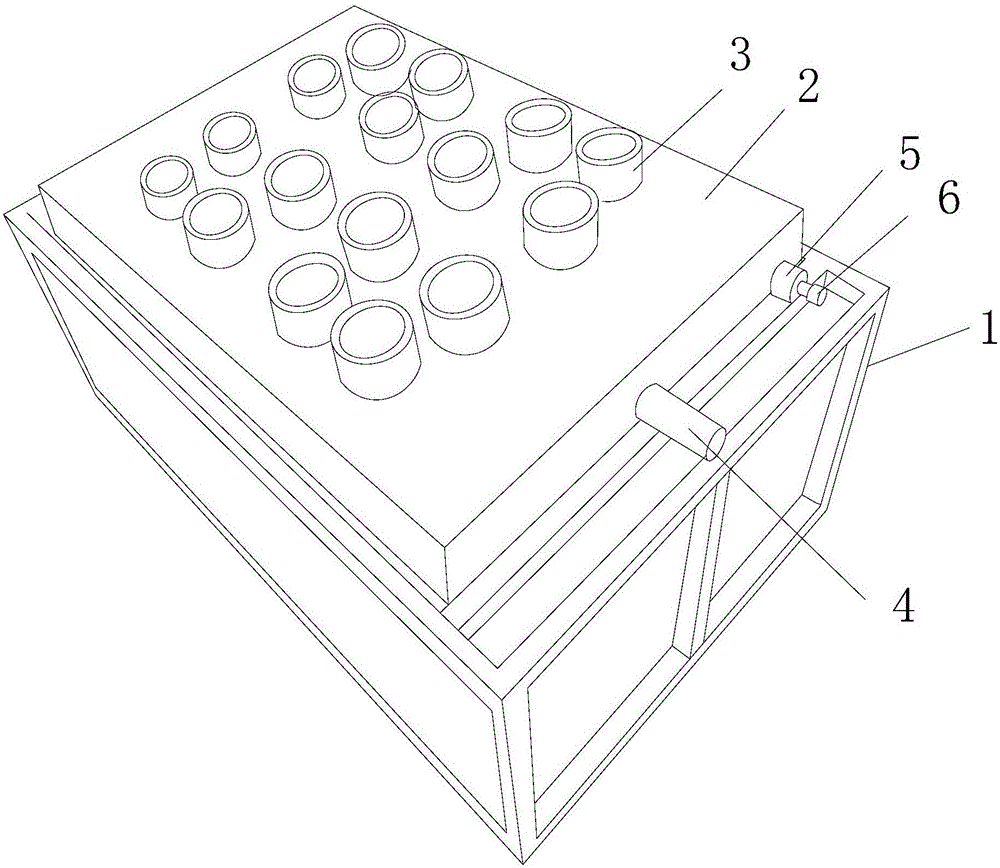

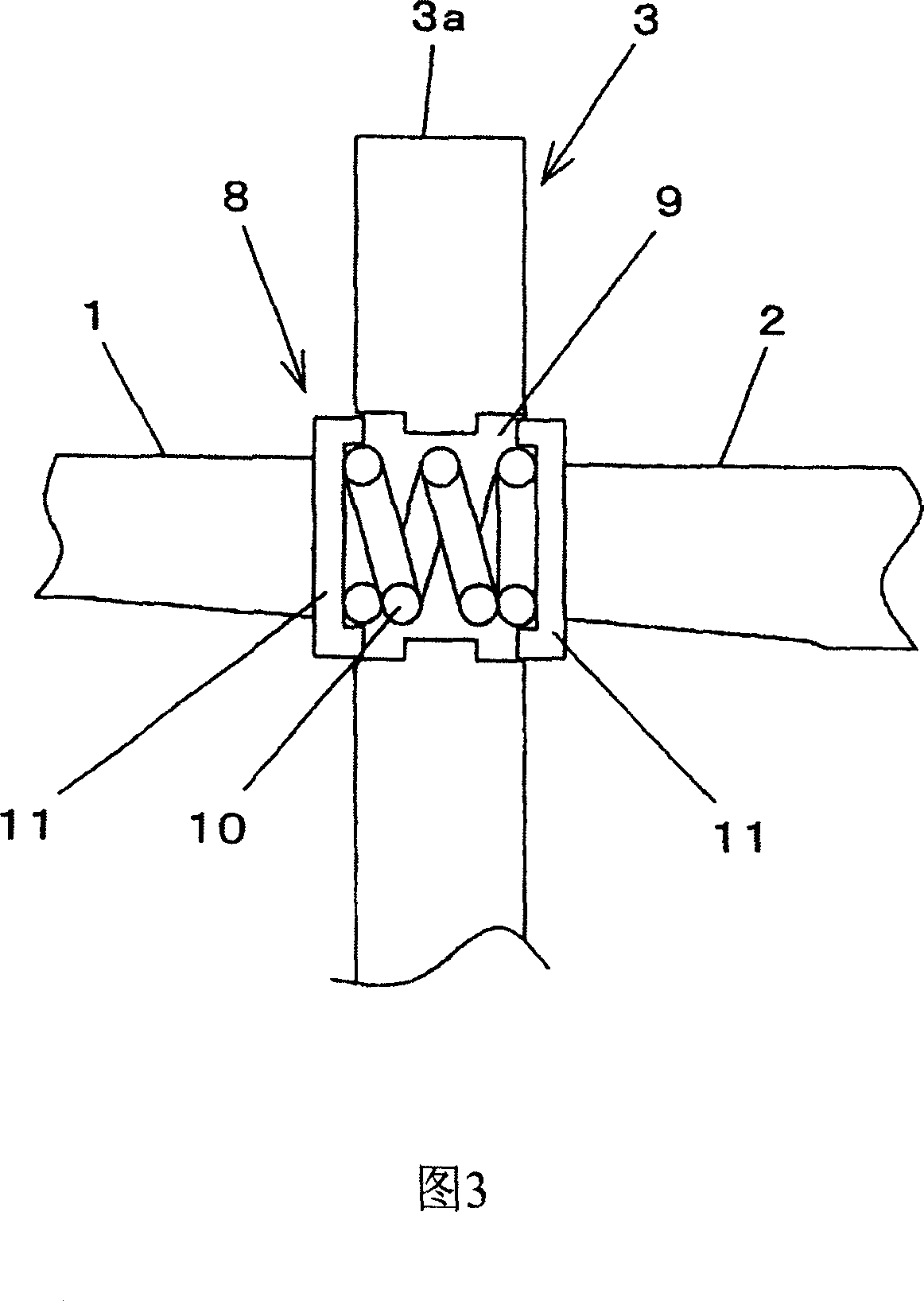

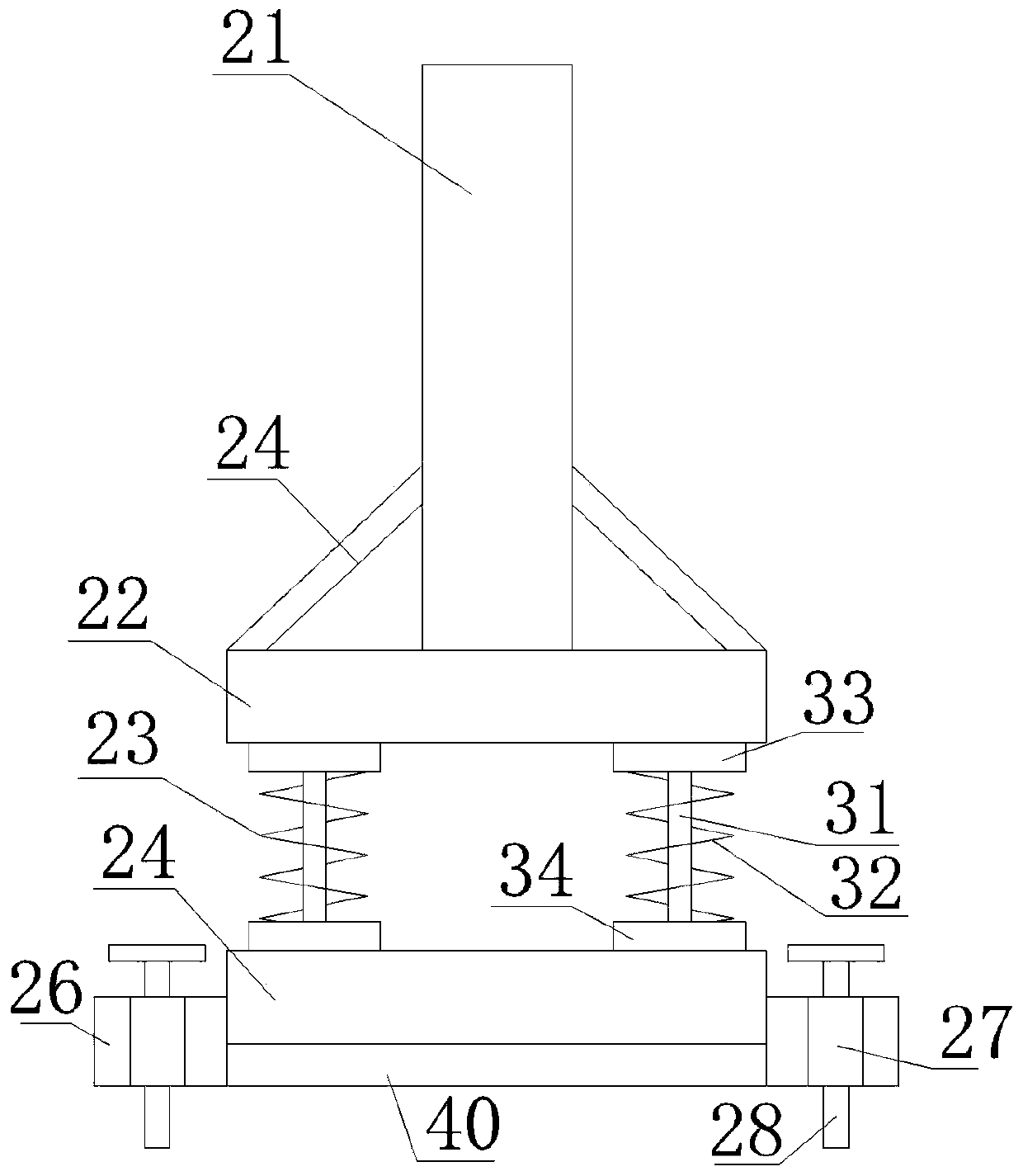

Investment casted die mould auxiliary moving device

InactiveCN100999010AContinuously workingSatisfy productivityMould tablesInvestment castingHinge joint

The present invention discloses a pattern die auxiliary movement equipment for investment casting process. Said pattern die auxiliary movement equipment is formed from handle, flat-plate and roller. On the flat-plate a supporting table is welded, under said flat-plate a bearing block and a cantilever are mounted, on the shaft of base plate a roller is mounted, and is placed in the groove interior of said bearing block, and can be upwards and downwards moved; on the camshaft a support abutment is wedded, and can be turned in the cantilever interior, the handle, supporting table, link joint, concave connecting rod and support abutment are successively hinge-jointed. Besides, said invention also provides its working principle and concrete operation method.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

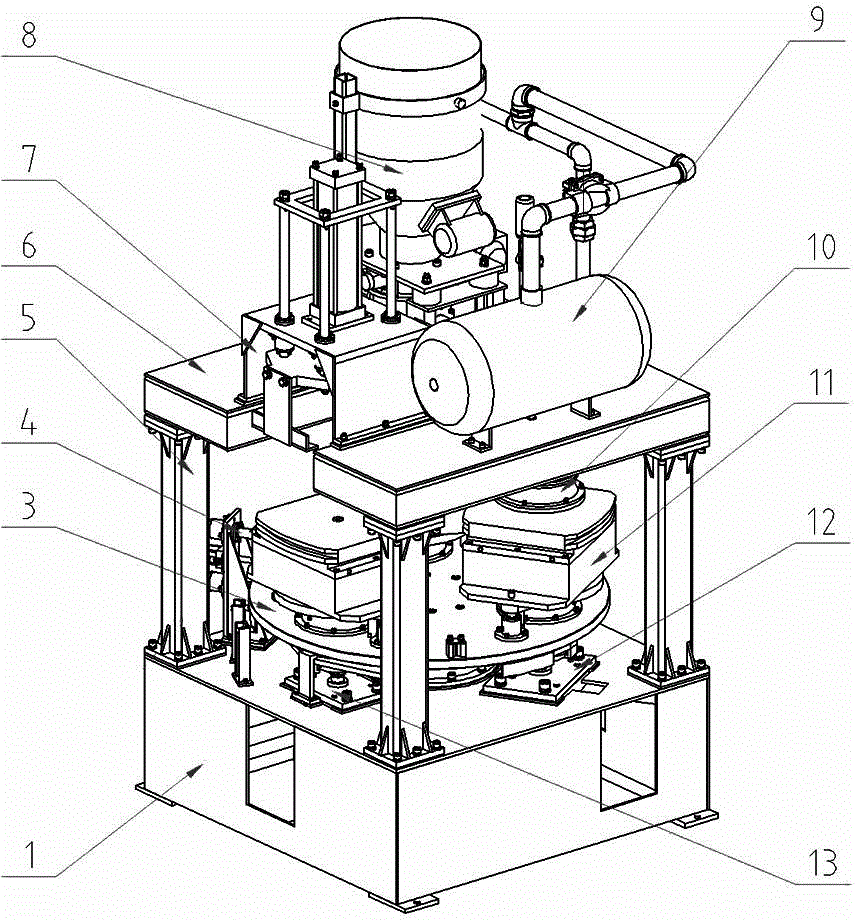

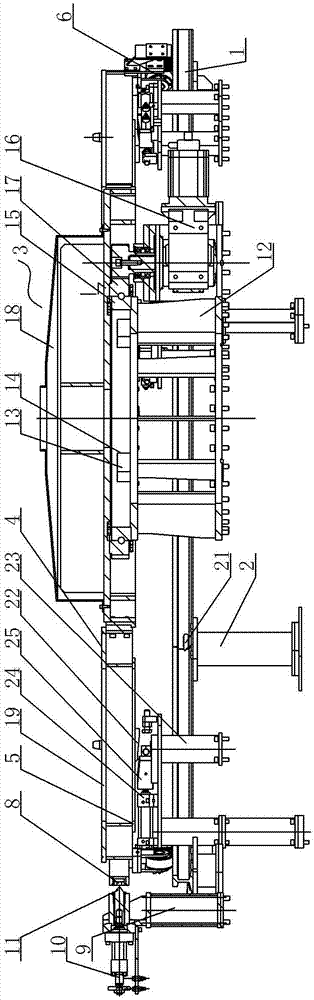

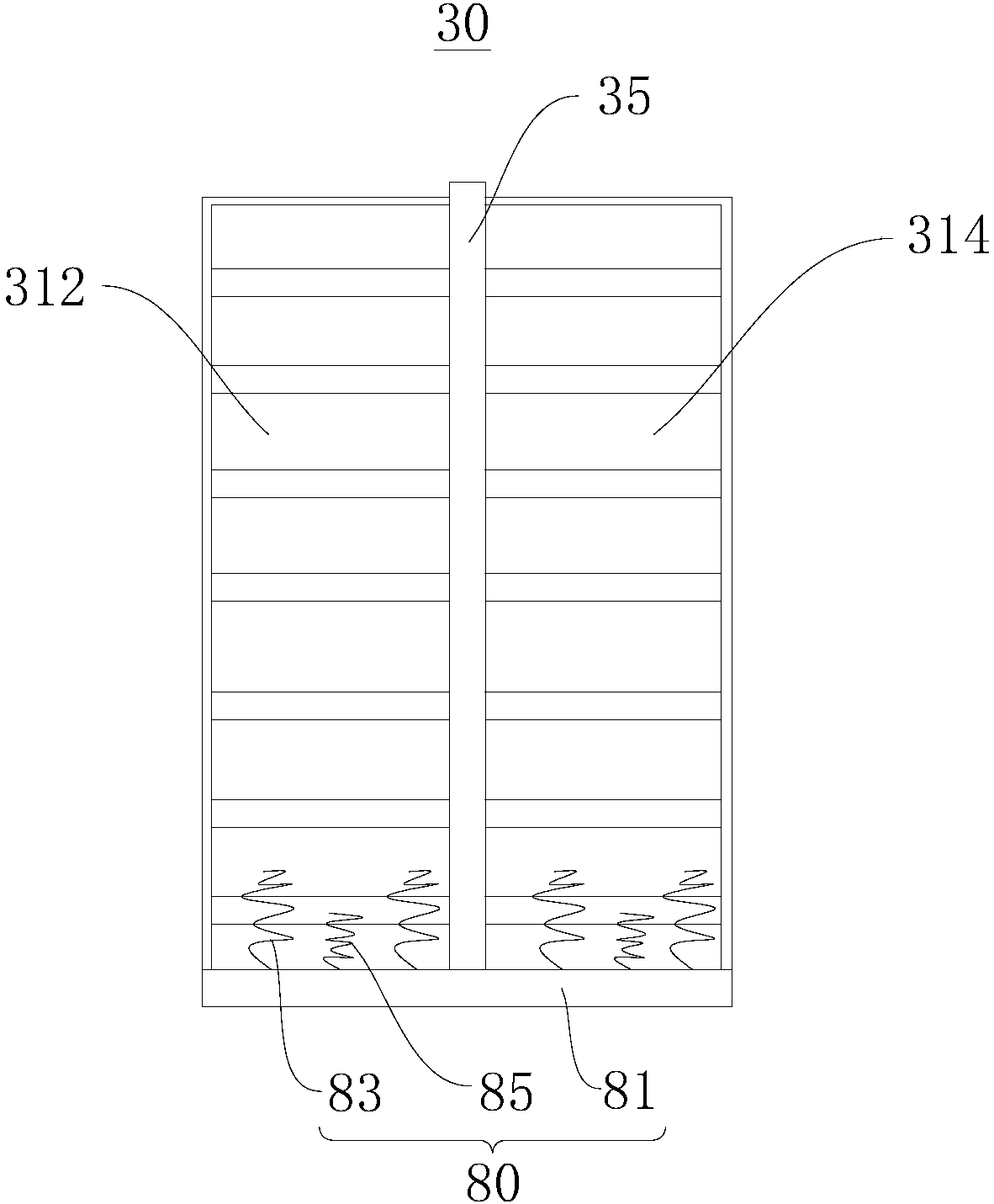

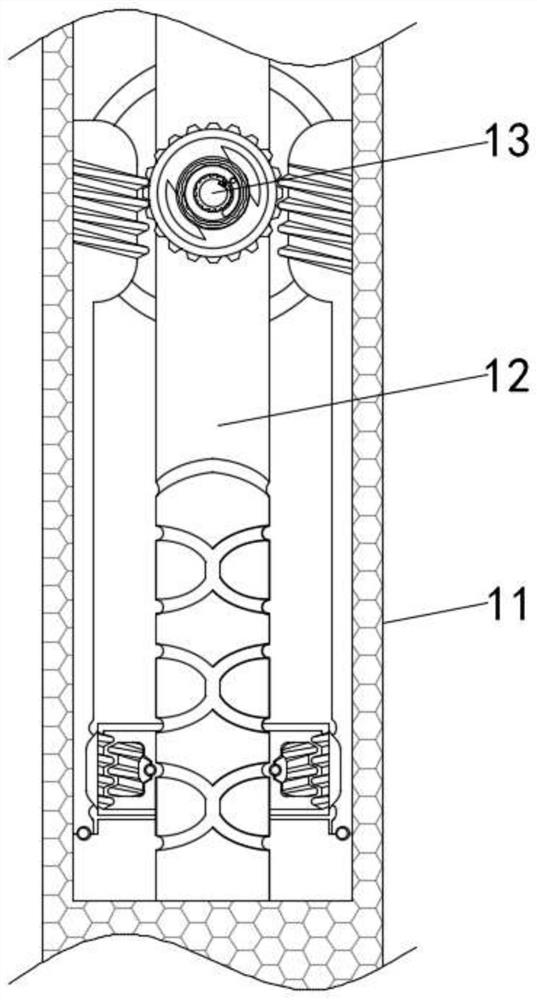

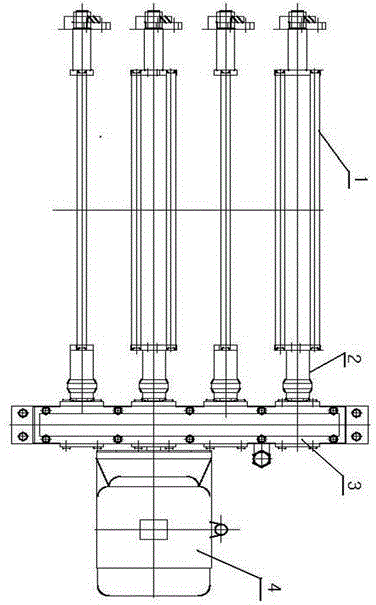

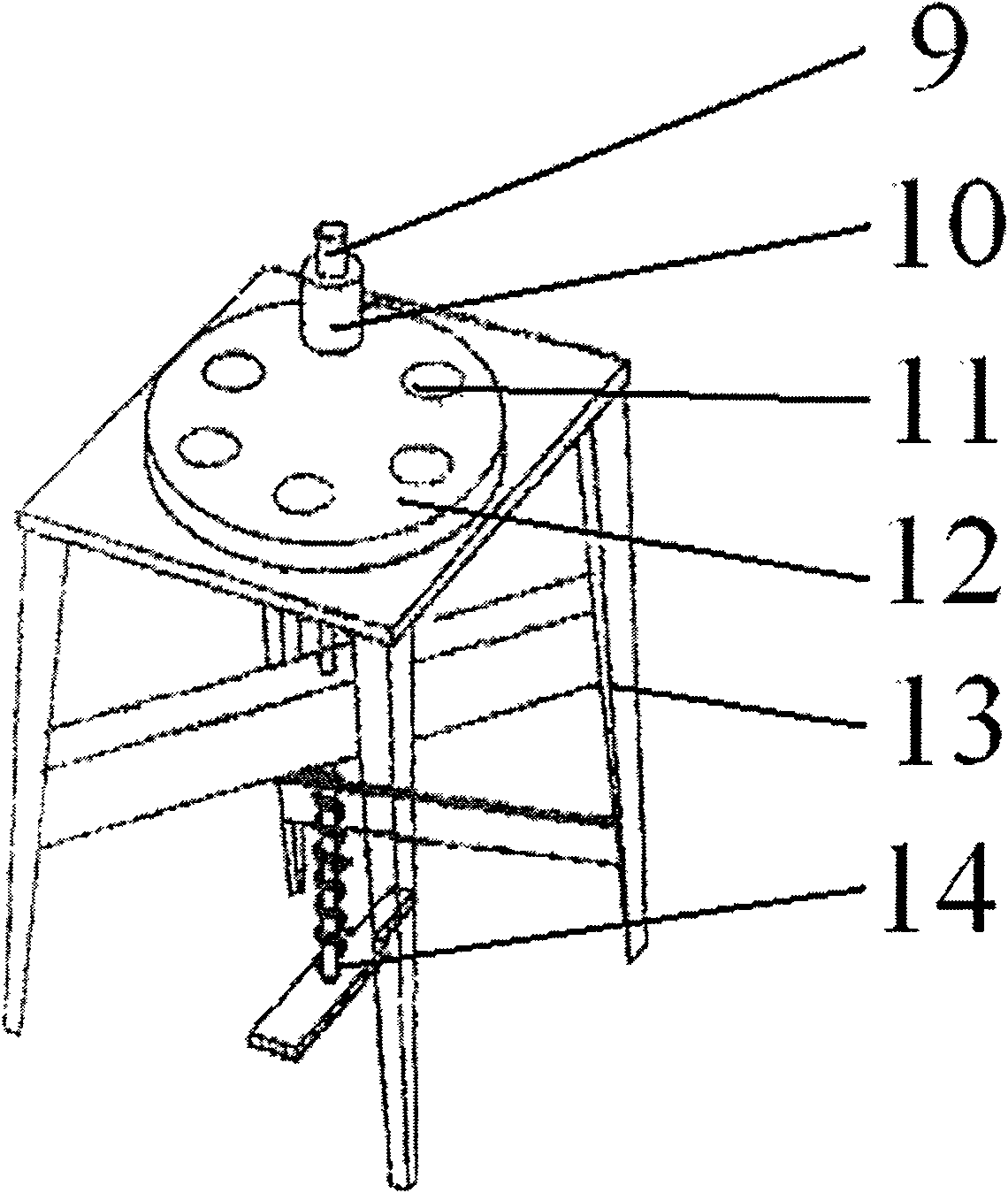

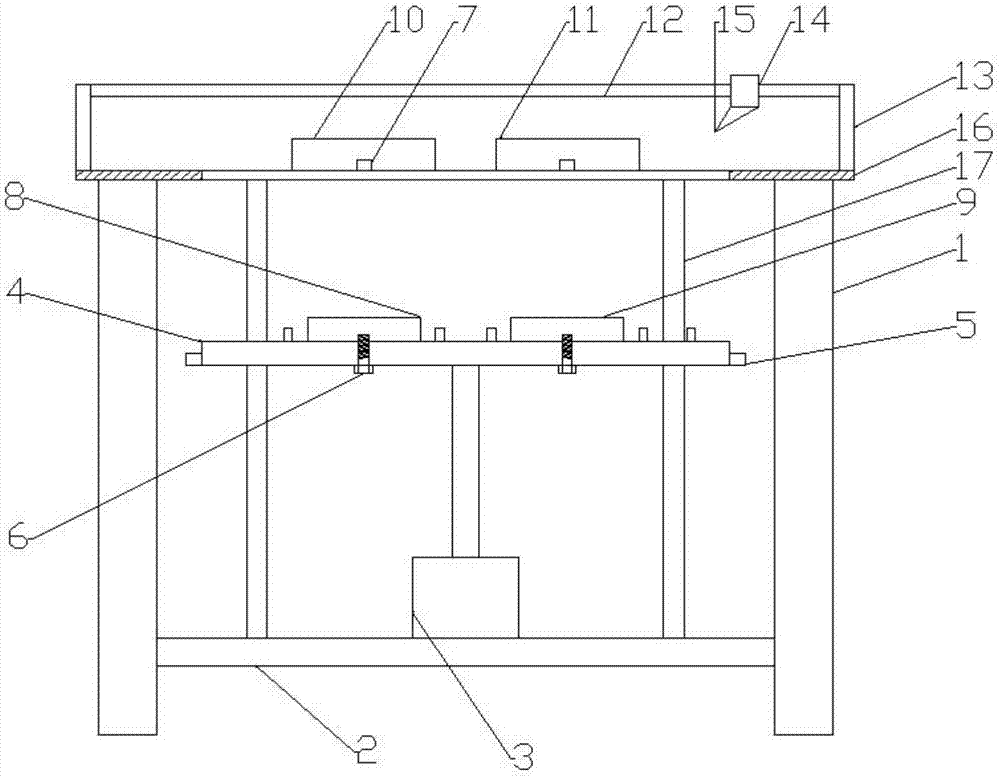

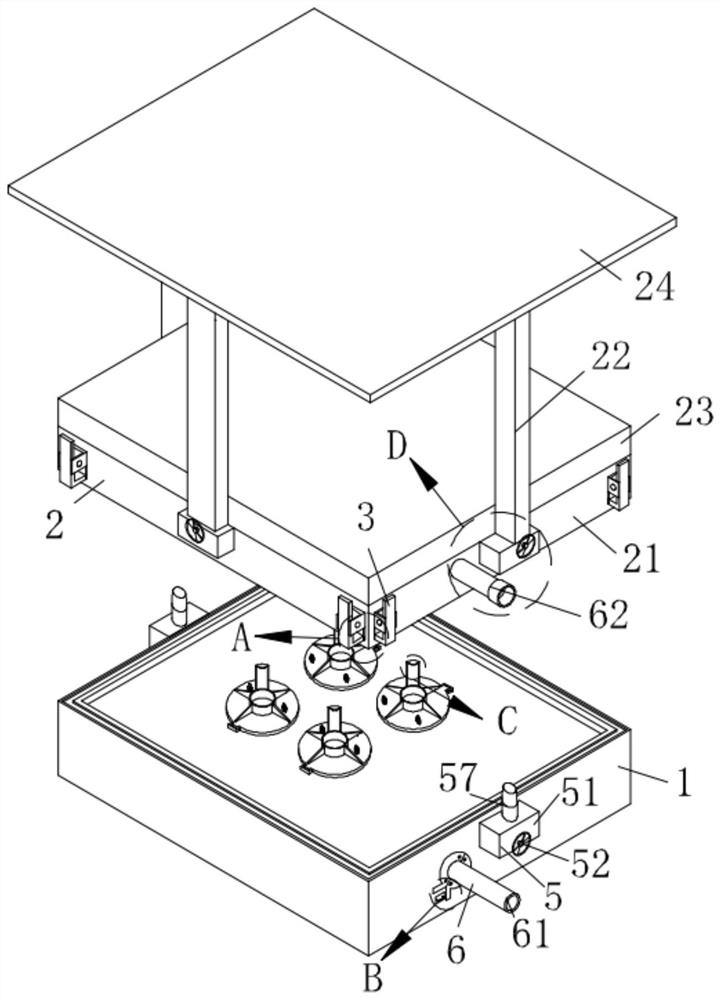

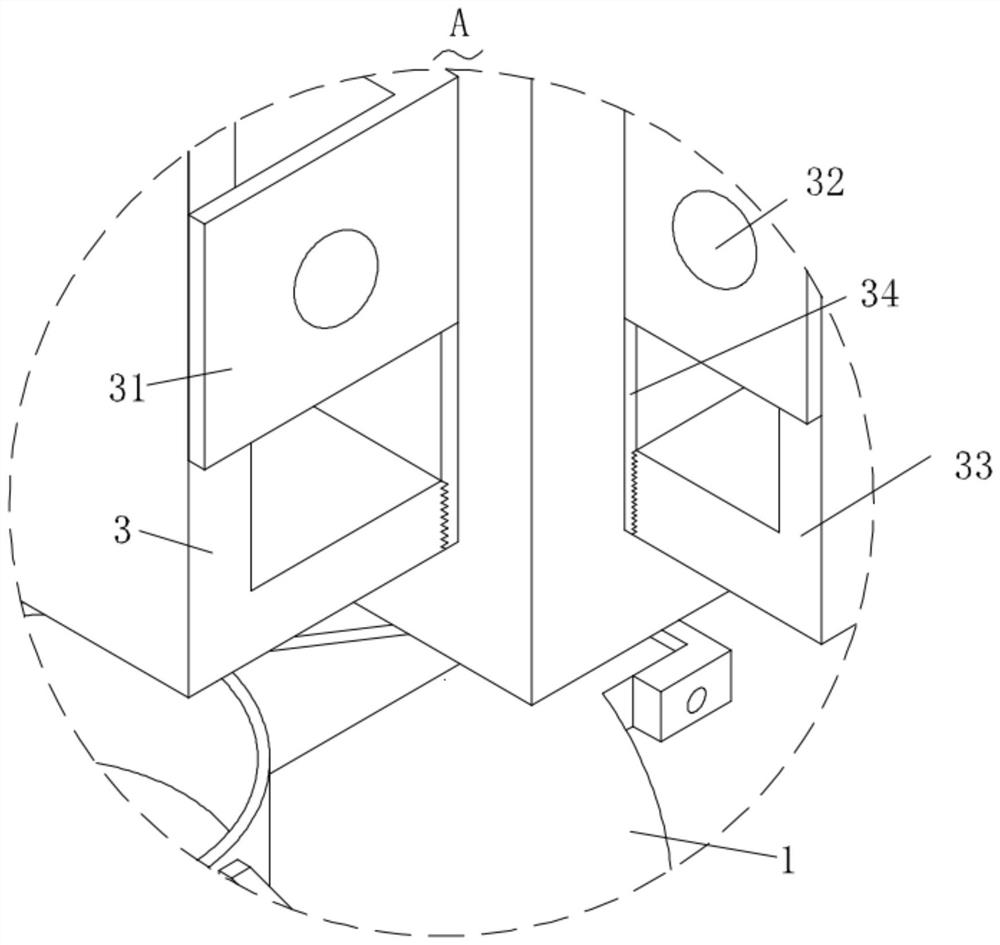

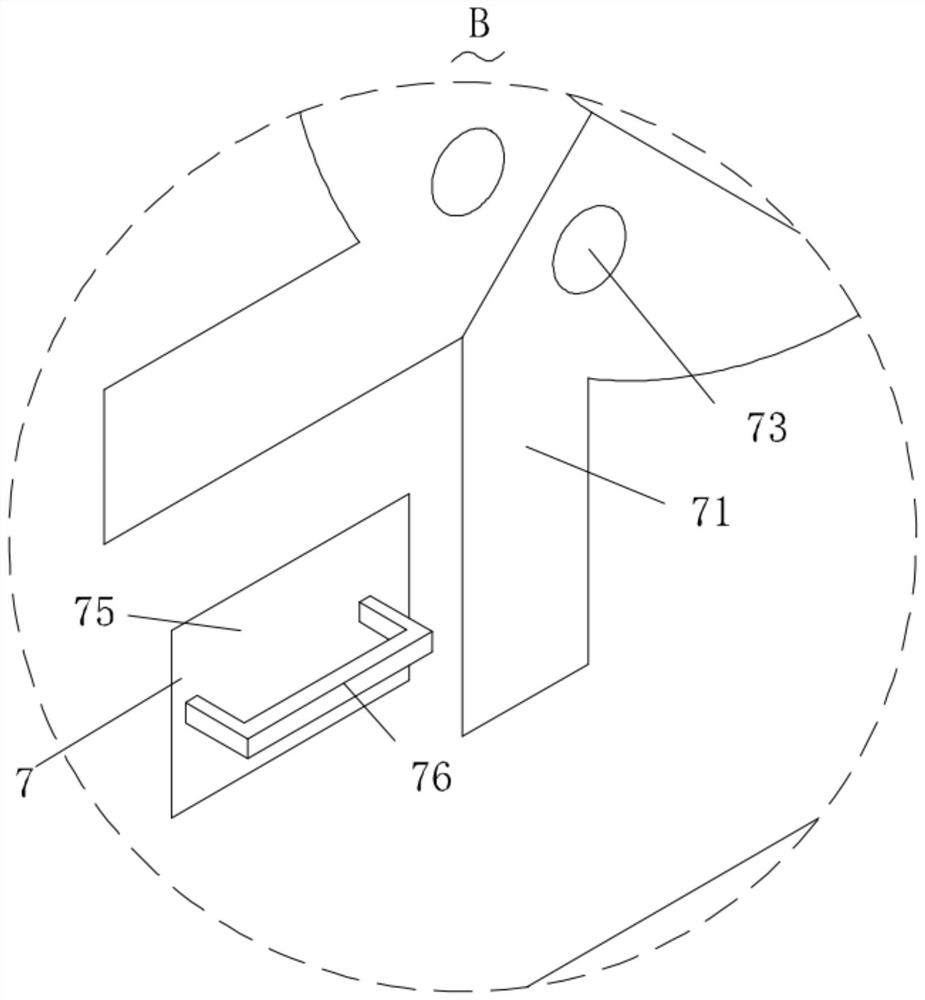

Sand mold manufacturing laser 3D printing platform with heating type sand boxes

ActiveCN105964952AMake sure to print layer by layerStable structureAdditive manufacturing apparatusMould tablesBond qualityEngineering

The invention belongs to the technical field of sand mold 3D printing equipment, and particularly relates to a sand mold manufacturing laser 3D printing platform with heating type sand boxes. The sand mold manufacturing laser 3D printing platform is characterized by comprising a base, stand columns arranged around the base, a suspension frame arranged on the tops of the stand columns, a lifting system arranged on the base, a displacement system arranged above the lifting system, a sand paving platform arranged on the displacement system, the heating type sand boxes surrounding the sand paving platform and located at the upper portion of a printing area, and collecting boxes arranged on side plates of the heating type sand boxes, and the tops of the heating type sand boxes are fixedly connected with the suspension frame through bolts. Rapidness and convenience are achieved through sand mold technology checking and technology correcting, and the sand mold manufacturing laser 3D printing platform is stable in structure and high in transmission efficiency. The printing platform can move up and down, each heating type sand box is formed by four heating plates in a defining manner, it is ensured that a sand mold printing layer is heated and solidified, accordingly, it is ensured that sand materials on the sand paving platform are constant in temperature, the temperature loss is low, and the sand material bonding quality and solidification rate are improved.

Owner:辽宁森远增材制造科技有限公司

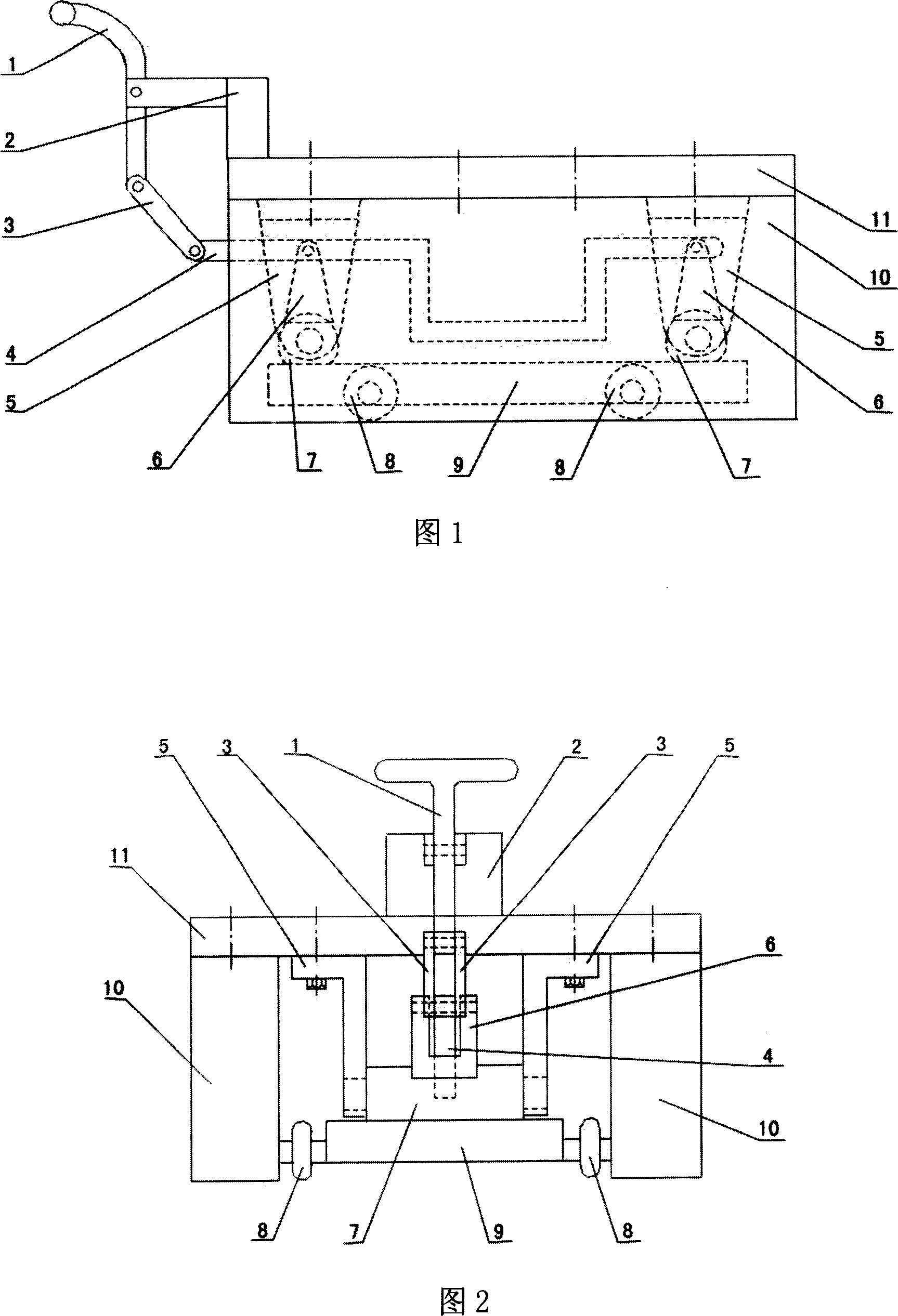

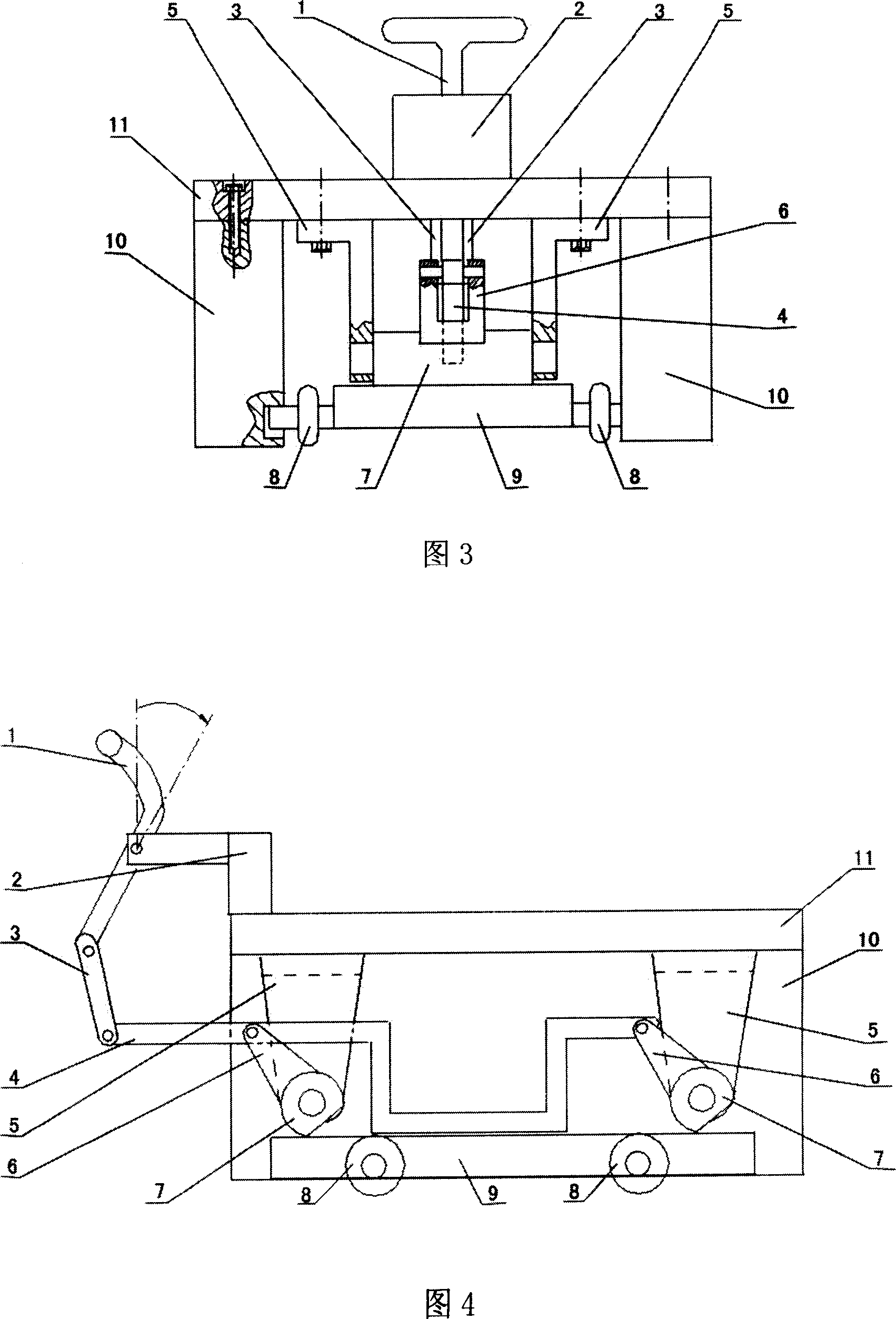

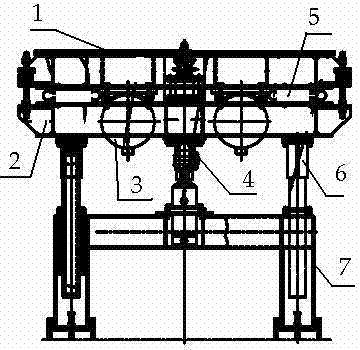

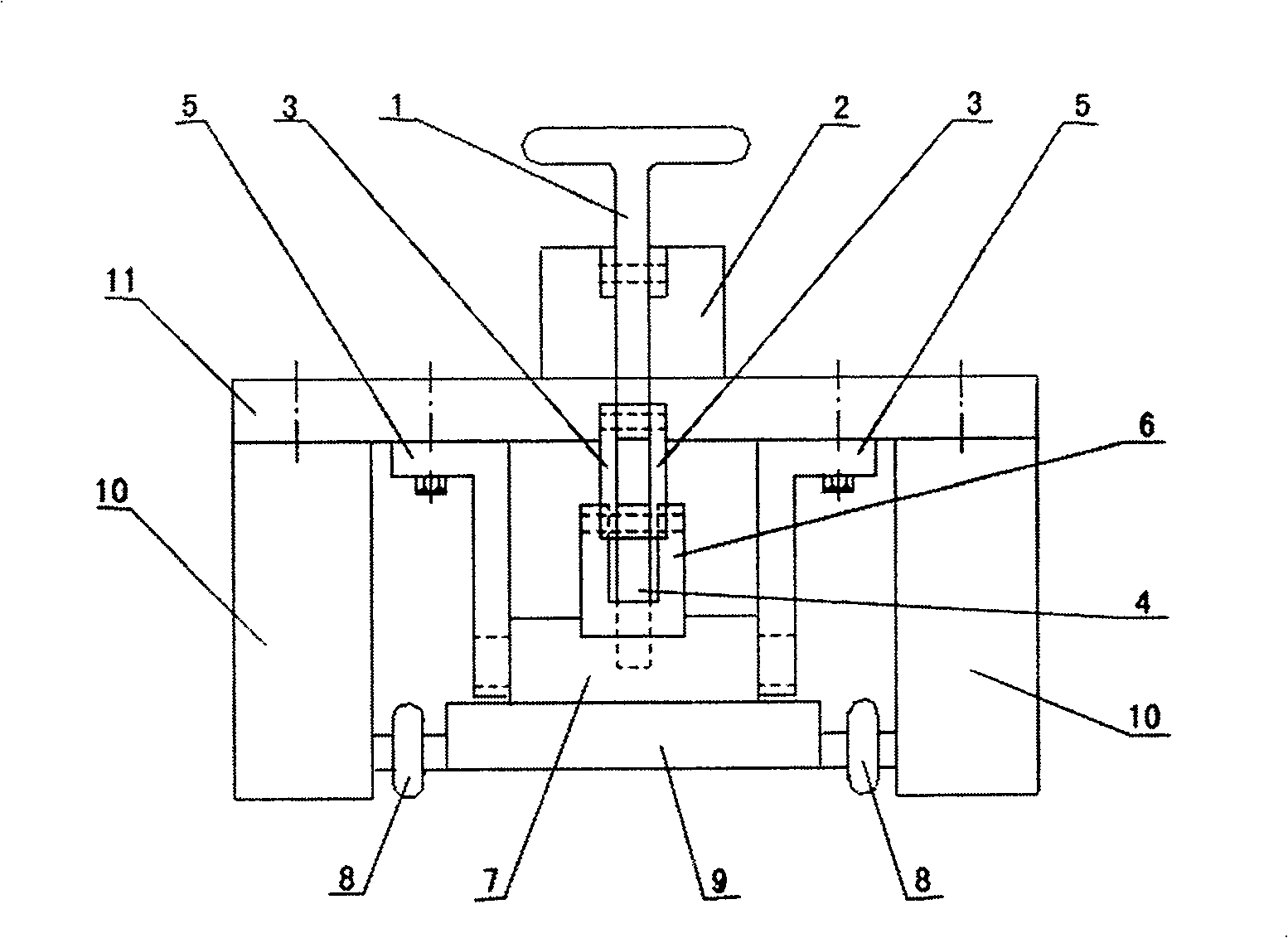

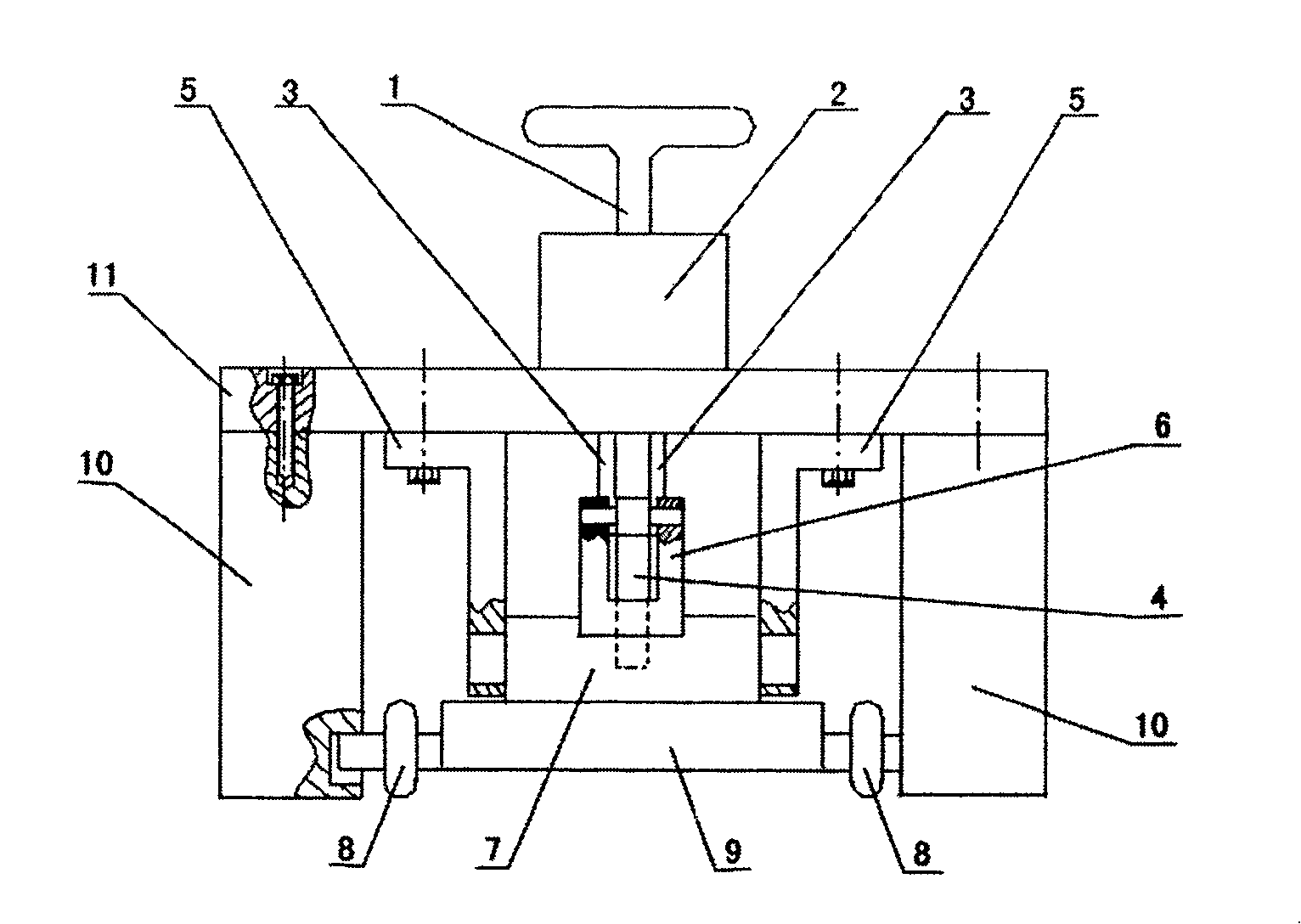

Automatic rotating mechanical worktable

InactiveCN105562629AImprove combination efficiencyGuaranteed rotation angleMould tablesHydraulic cylinderCoupling

An automatic rotating mechanical worktable is characterized by comprising a hydraulic cylinder, supporting stand columns, a hydraulic piston, a coupler, a fixing tool, a rotating disc, a worktable body and a fixing chuck, wherein the fixing chuck is fixed to the supporting stand columns, the worktable body is arranged on the fixing chuck and connected with the rotating disc arranged in the fixing chuck, the lower side of the rotating disc is connected with a driving device, the driving device comprises the hydraulic cylinder, the hydraulic piston and the coupler, the hydraulic piston of the hydraulic cylinder is connected with the coupler, the driving device is connected to the lower side of the rotating disc through the fixing tool, the rotating disc is in a round cake shape, a sliding wheel is arranged on the outer edge of the rotating disc, the fixing chuck is in a ring shape, and a sliding track matched with the sliding wheel of the rotating disc is arranged on the inner ring of the fixing chuck. The automatic rotating mechanical worktable has the advantages that the structure is simple, use is convenient, the combination efficiency of sand cores can be effectively improved, and the labor intensity of workers can be effectively relieved; besides, by adopting a tabletop rotating device, the rotating angle of the sand cores can be guaranteed, the sand cores can be prevented from being damaged, the rate of finished products can be increased, and requirements of modernized production can be met.

Owner:贾雪松

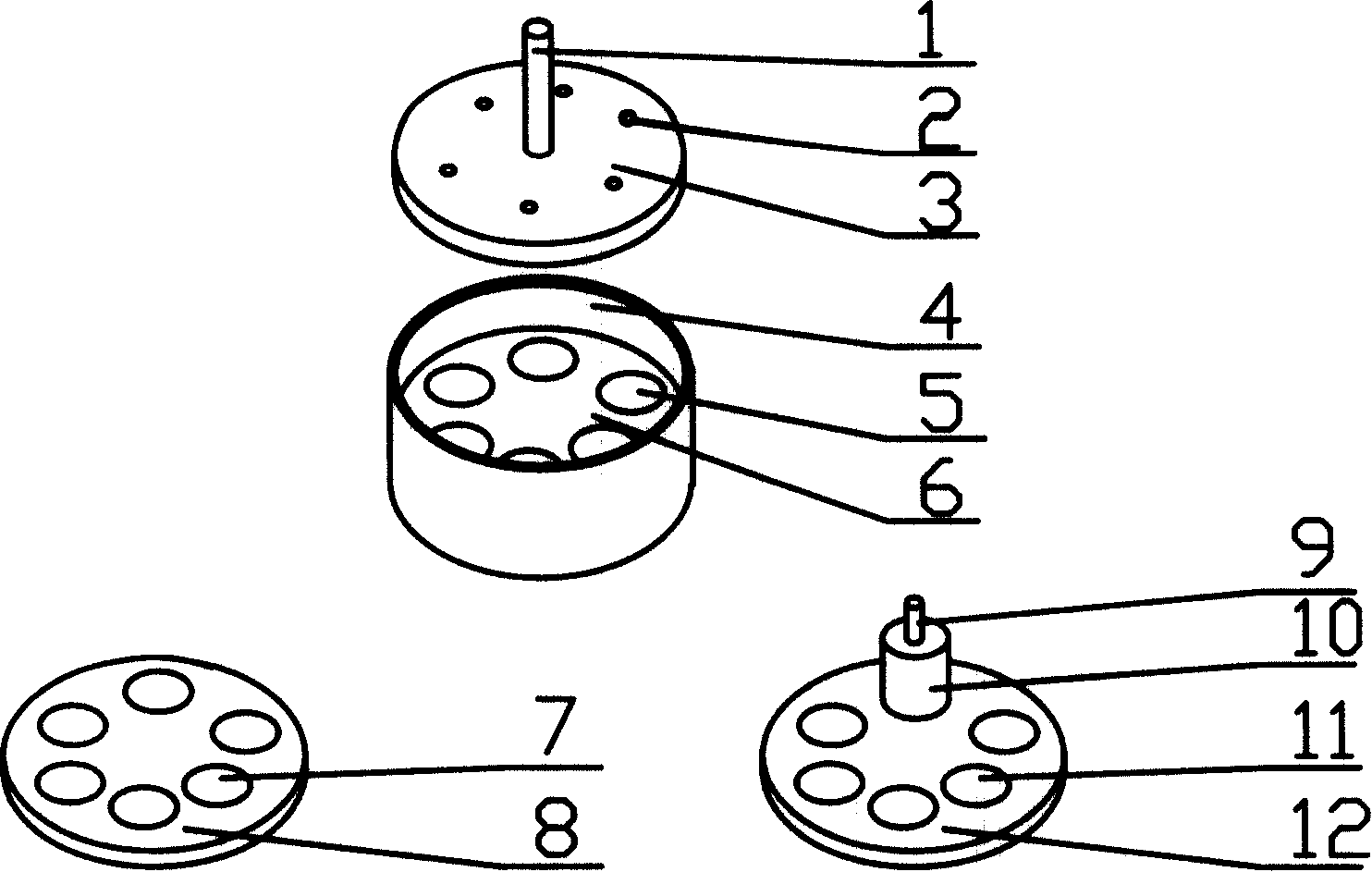

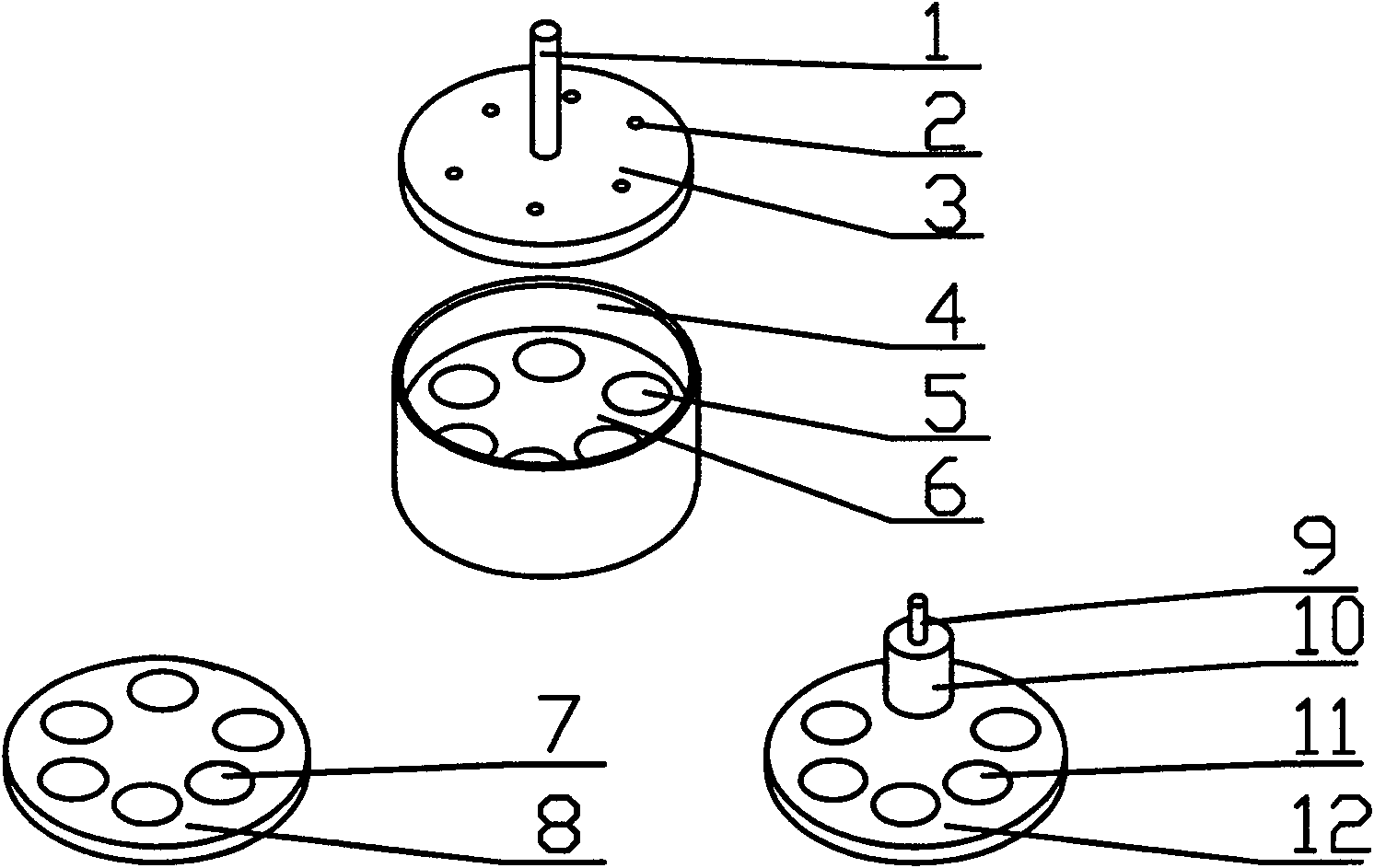

Sand coating mold module for casting and sand coating casting technique

InactiveCN101181734AQuality improvementSolve the problem of casting defectsFoundry mouldsFoundry coresLarge coreSmall hole

The invention discloses a forged sand hanging component, comprising a mold body, a mold bottom, a mold cover, a molding disc and a forging mold core. The mold body is a cylindrical iron mold with a depression platform arranged at one end, and the cylindrical iron mold is provided with a plurality of axially through holes. The mold cover is a round iron disc, and a round depression is arranged at the position corresponding to the mold holes of the mold body. The molding disc is also a mold cover shaped iron disc with small through holes at the positions corresponding to the depression section of the mold bottom. The forging mold core is a cylindrical steel core consisting of a large mold core and a small mold core, and the diameter of the large core is slightly smaller than that of round mold holes, and the center of the large mold core is provided with an axially through hole; the small mold core is movably arranged in the through hole of the large mold core, and the number of small mold cores are the same as that of round mold holes. The mold cover is a round iron disc with the same diameter as the depression platform of mold body, and is provided with round pores corresponding to the positions of the round mold holes of the mold body, and handle is arranged on the mold cover.

Owner:李祖长 +1

Forming machine without pattern casting

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD

Novel compaction platform

InactiveCN104259398ARealize sealing and sand vibrationEasy to operateMoulding machinesMould tablesHydraulic cylinderAir spring

Owner:杨配媛

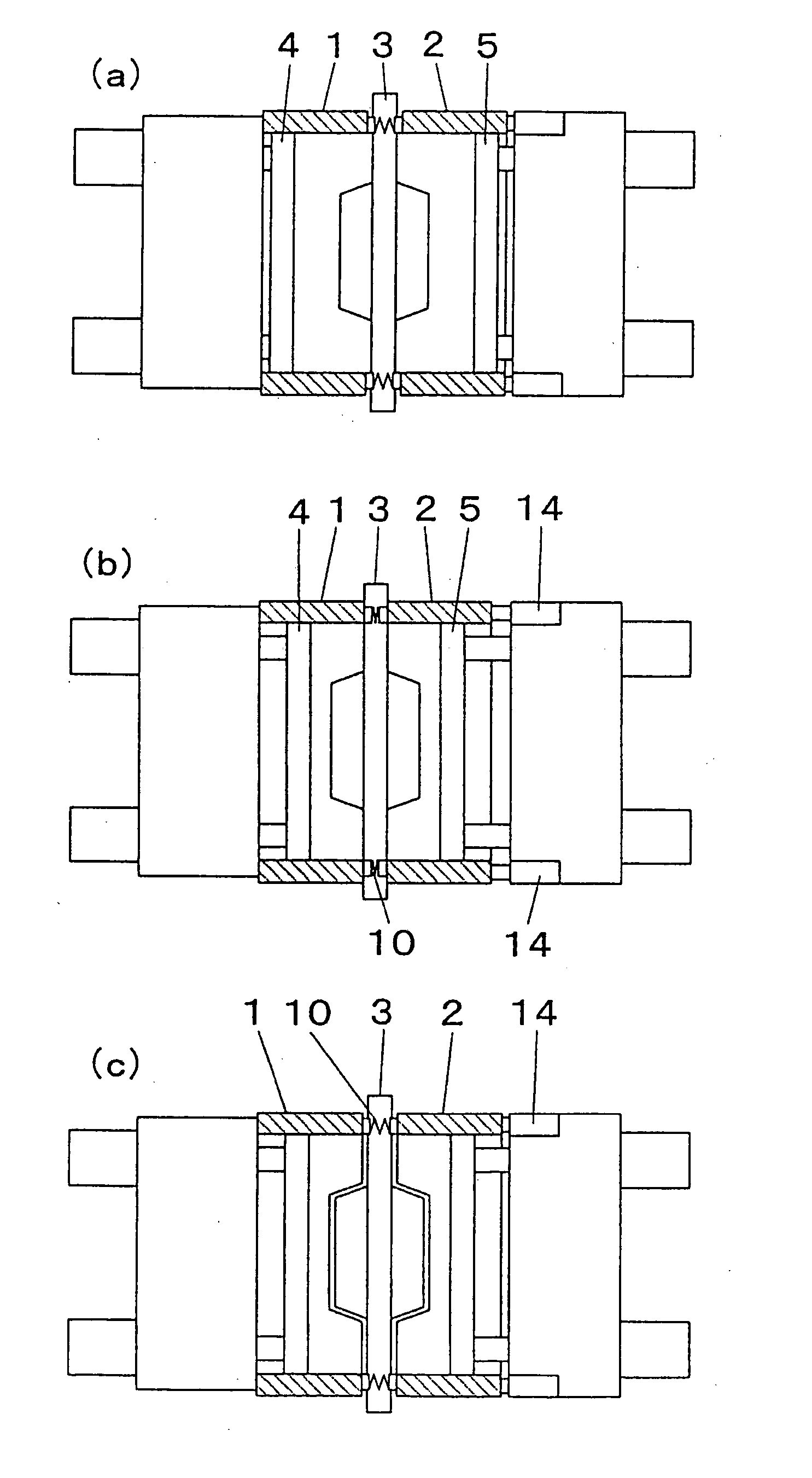

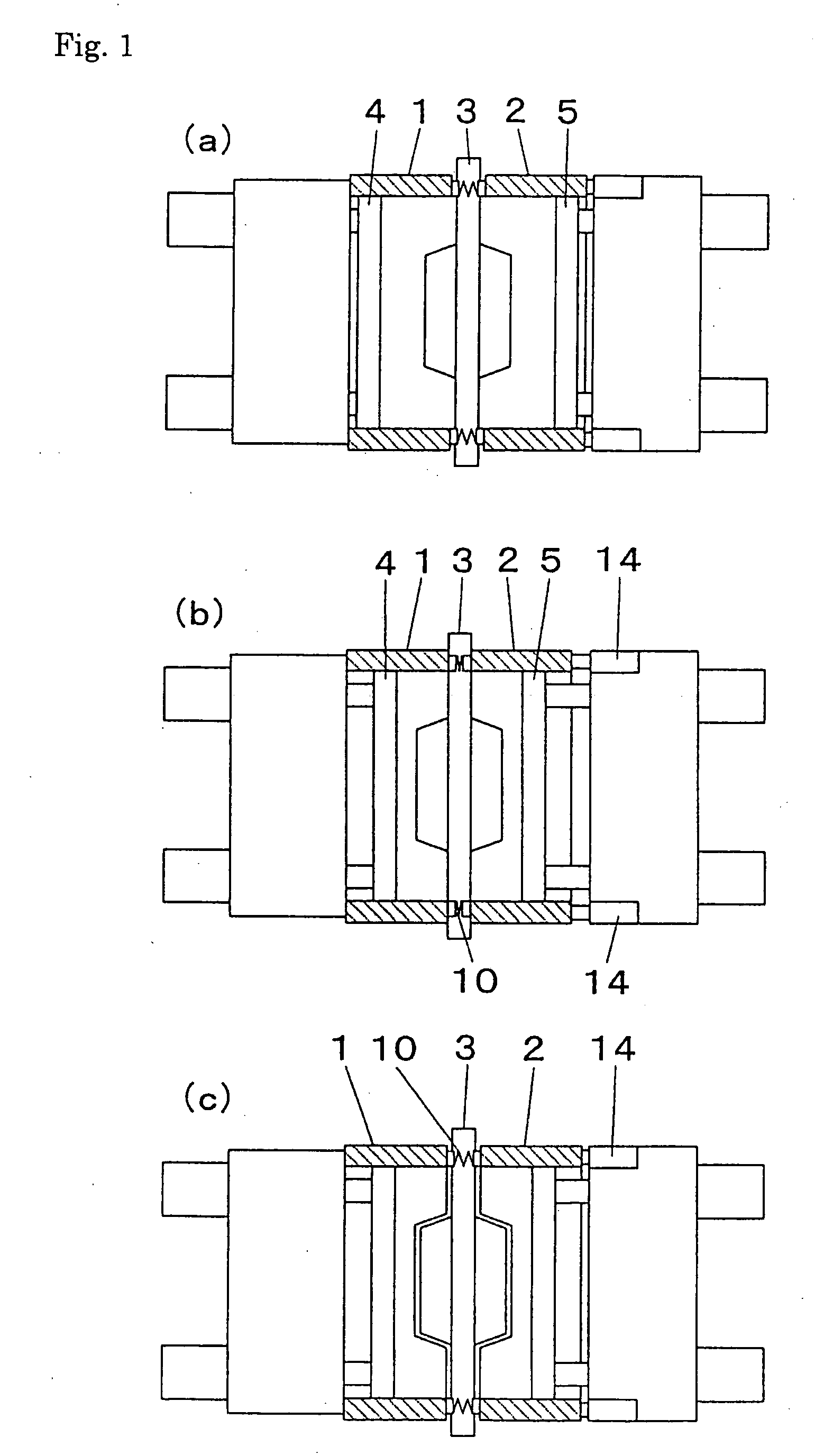

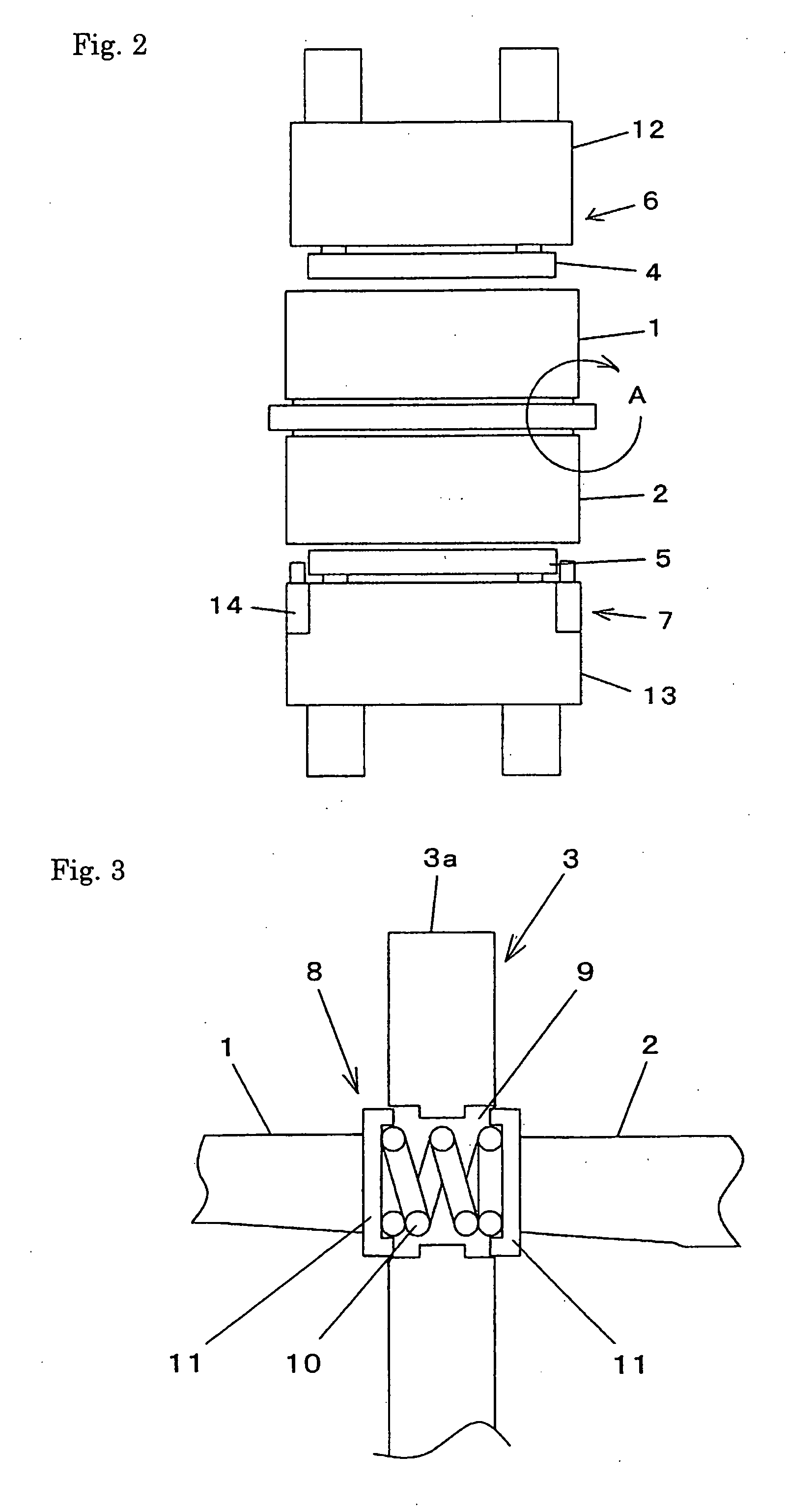

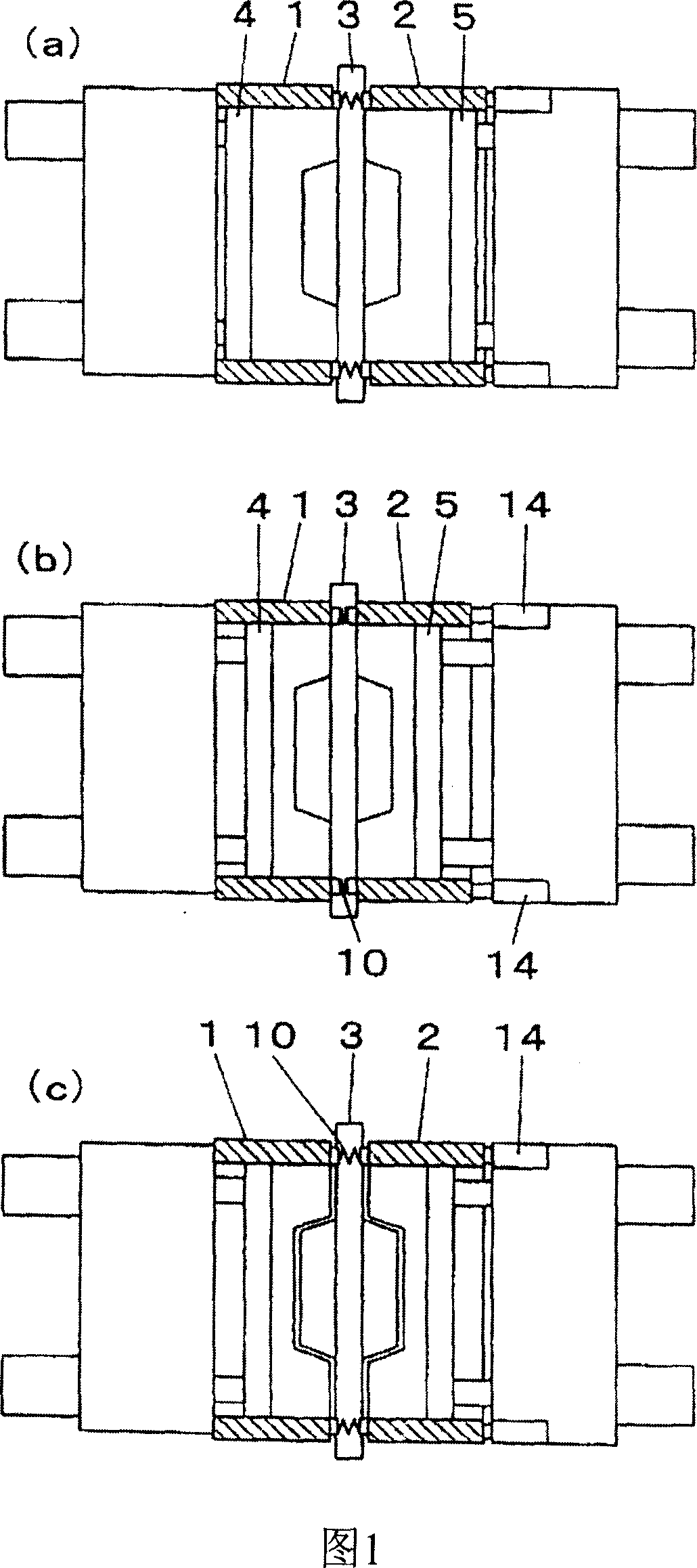

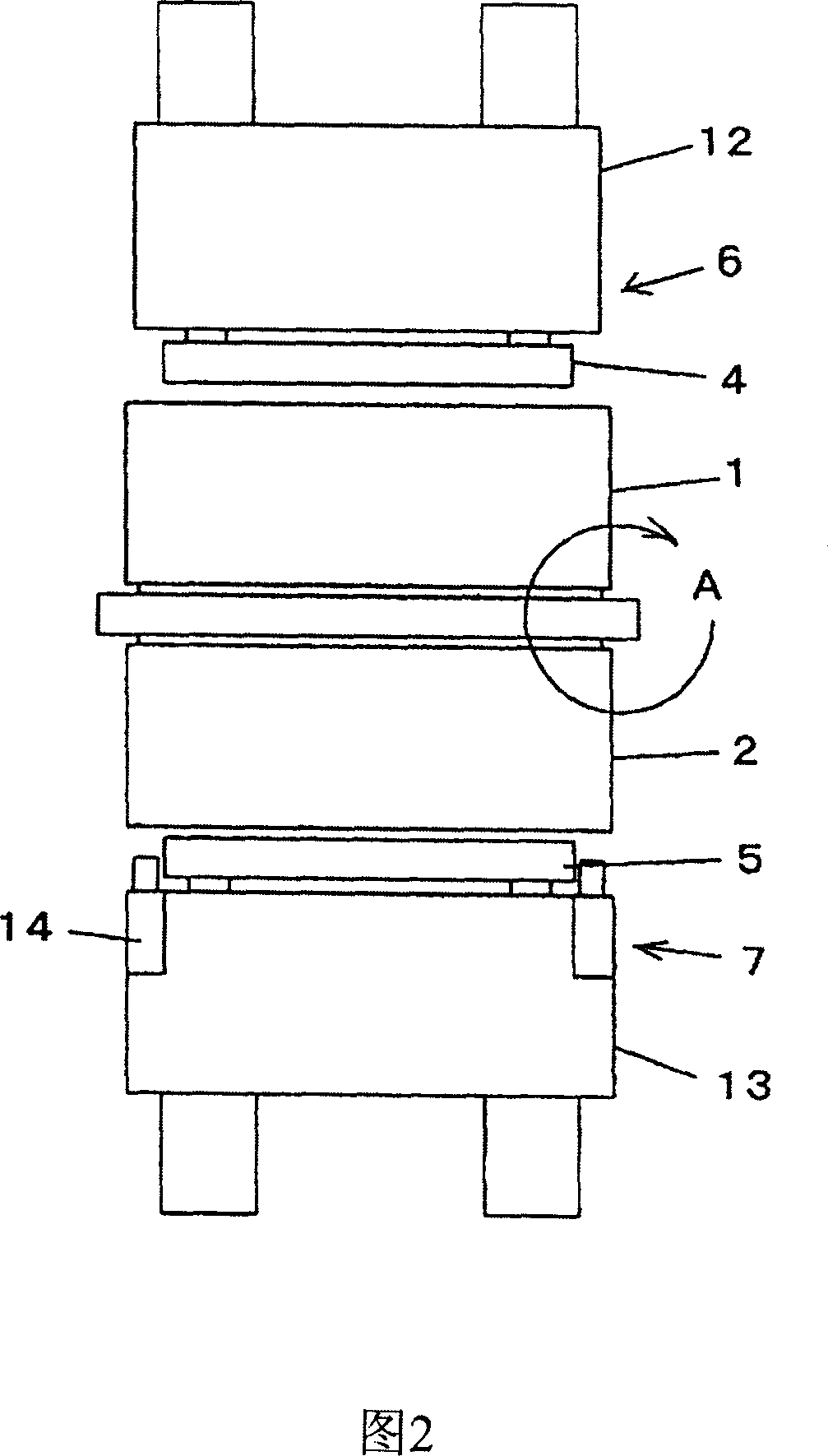

Method for Squeezing Foundry Sand, a Match Plate, and an Upper and a Lower Flask

In a conventional apparatus for molding molds, foundry sand is filled in an upper and a lower molding space defined by a match plate, an upper and a lower flask, and an upper and a lower squeeze plate, and then the foundry sand is squeezed by causing the upper and the lower squeeze plate to further approach each other. However, the hardness and strength near the inner surface that corresponds to the match plate, of an upper and a lower mold made by the conventional apparatus, are not high enough. To solve this problem, in this invention the following method is applied: a method for squeezing foundry sand filled in an upper and a lower molding space, comprising: a step to squeeze the foundry sand by causing the upper and the lower squeeze plate to further approach each other, and a step to squeeze it by causing the pattern portions of the match plate to move to each of the upper and the lower squeeze plate.

Owner:SINTOKOGIO LTD

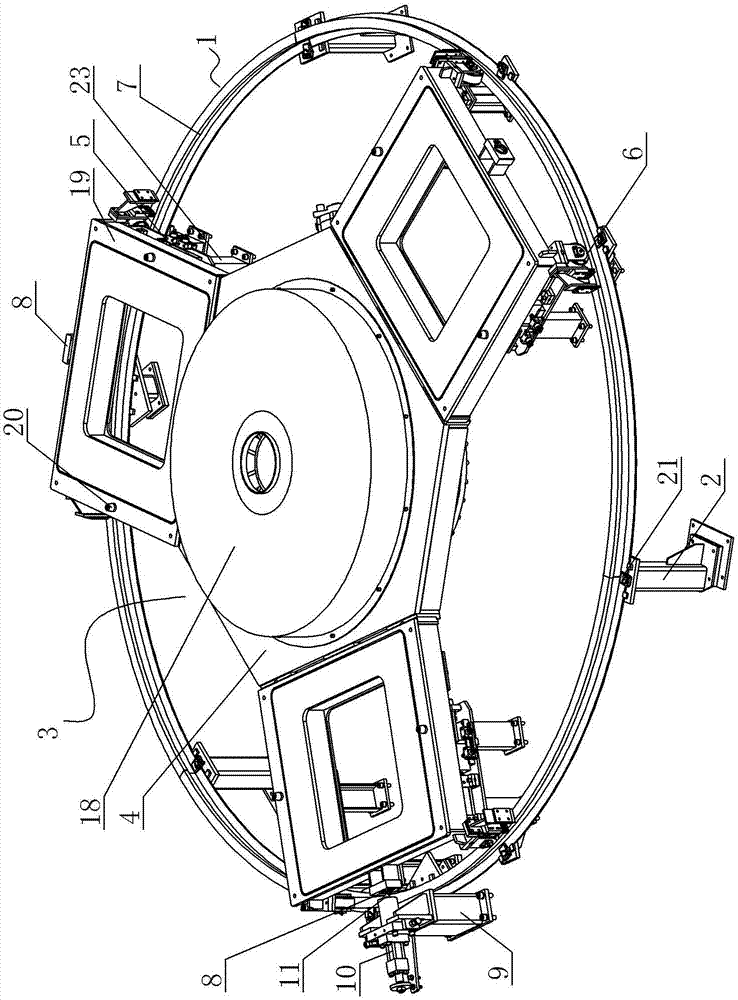

Driving working platform of sand shooting machine

PendingCN107297467AImprove production efficiencyReduce labor costsMoulding machinesMould tablesClassical mechanicsStructural engineering

The invention provides a driving working platform of a sand shooting machine. The driving working platform comprises an annular track which is sealed, wherein a plurality of bearing frames are supported on the lower end surface of the annular track; a revolving platform is arranged at the center of the annular track; three bearing platforms protruding towards one side are uniformly distributed on the output outer annular surface of the revolving platform; two travelling wheels are arranged on the lower end surface of the outer part of each bearing platform; the bottom parts of the travelling wheels are arranged in a concave track on the upper end surface of the annular track in a supporting way; a centering and locking hole is formed in the outer side of each bearing platform; a revolving location seat is arranged in a position, corresponding to one working position, on the outer side of the annular track; the revolving location seat is provided with a radial location oil cylinder; a location cone is fixedly arranged on the output end of the radial location oil cylinder. According to the driving working platform provided by the invention, molds are respectively arranged on the annular track in the supporting way, so that mold structures can sequentially pass through a sand shooting working position, an air blowing working position and a drawing working position along a working driving direction, the preparation efficiency is greatly increased, and labor cost is reduced.

Owner:SUZHOU SUZHU FOUNDRY MACHINERY MFG

Wet sand mold production turnover apparatus

InactiveCN106041003AReduce consumptionSimple structureMould tablesManufacturing technologyMoving frame

The present invention relates to the technical field of vehicle part manufacturing, particularly to a wet sand mold production turnover apparatus, which comprises a moving frame and a flipping work table, wherein the upper portion of the flipping work table is provided with a plurality of positioning sleeves, both ends of the flipping work table are connected to the moving frame through rotation shafts, the moving frame is provided with a shaft sleeve, the shaft sleeve is matched to a pin shaft, the side surface of the flipping work table is provided with pin holes, and the position of the pin hole and the position of the shaft sleeve are corresponding. According to the present invention, the plurality of the positioning sleeves are arranged on the flipping work table, the positioning sleeve can perform positioning fixing on the wet sand mold to be finished, the manual finishing is performed after the fixing, and the positioning of the flipping work table and the moving frame is performed through the pin shaft, such that the finishing efficiency is substantially improved, and the product quality is improved.

Owner:天津津晨汽车缸盖有限公司

Evanescent mode sand box three-dimensional compaction table

PendingCN113210574AAchieve clampingAchieve fixationMoulding machinesMould controlling devicesControl systemElectric machine

The invention relates to an evanescent mode sand box three-dimensional compaction table, belongs to the technical field of mechanical compaction, and solves the technical problems that a traditional sand box to be compacted is not firmly clamped during compaction, and the compaction effect is poor. According to the solution, the evanescent mode sand box three-dimensional compaction table comprises a base, a plurality of supporting columns, a plurality of air springs, a vibrating table, a plurality of vibrating motors, an air source and at least two clamping devices, wherein each clamping device comprises an air cylinder, an air cylinder fixing seat, a clamping block and a control system, and the air cylinders and the vibrating motors are electrically connected with the control systems respectively; and a first supporting table, a second supporting table and a third supporting table which are consistent in height are sequentially arranged in the middle of the top face of the vibrating table in the length direction, and a three-dimensional compaction table body is arranged below a sand box running track. The three-dimensional compaction table is simple in structure, stable and firm, the running noise is greatly lowered, the vibration source energy of the compaction table is fully utilized through the improvement in the clamping degree, optimal filling is achieved, and the compaction effect is better.

Owner:晋城市金工铸业有限公司

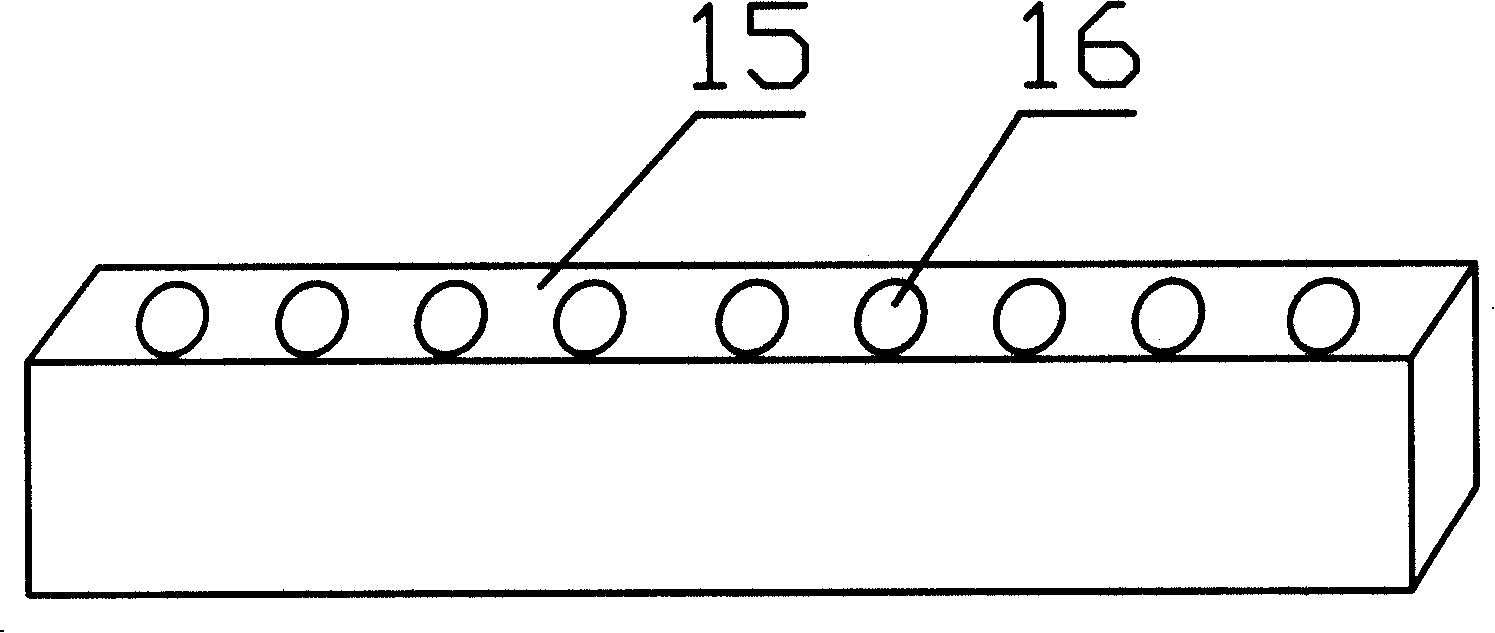

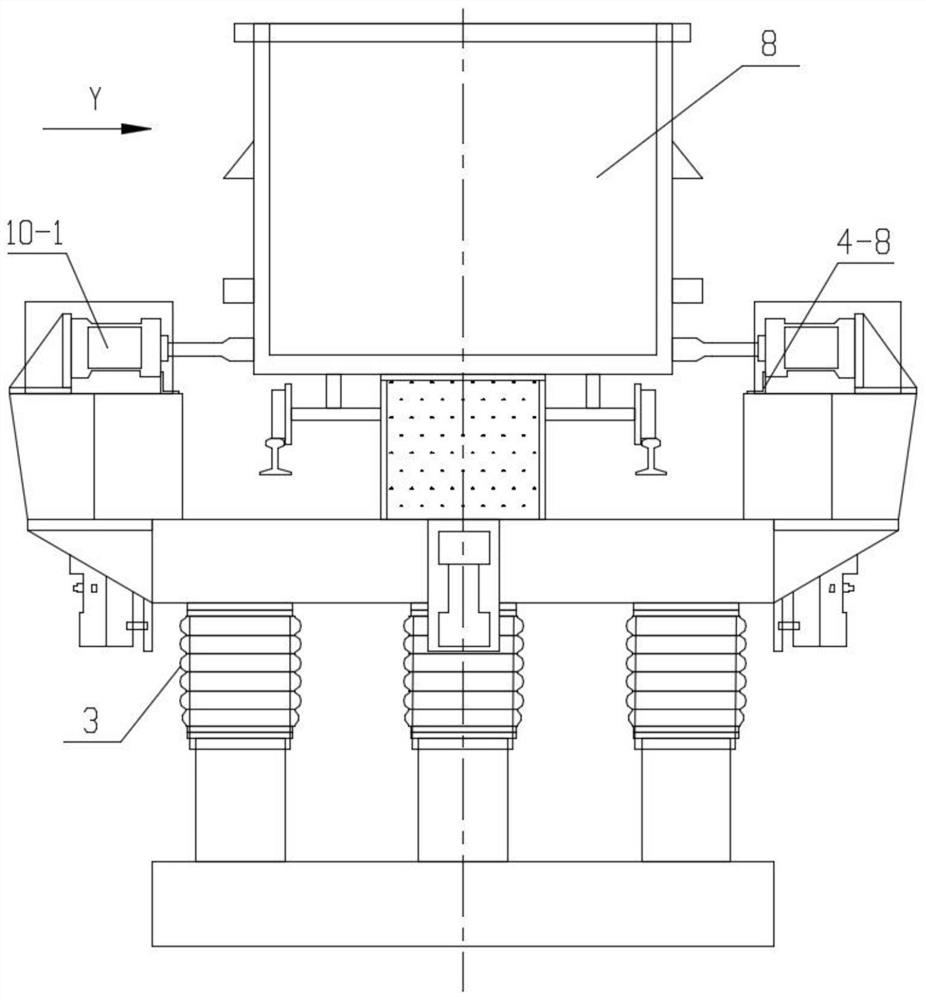

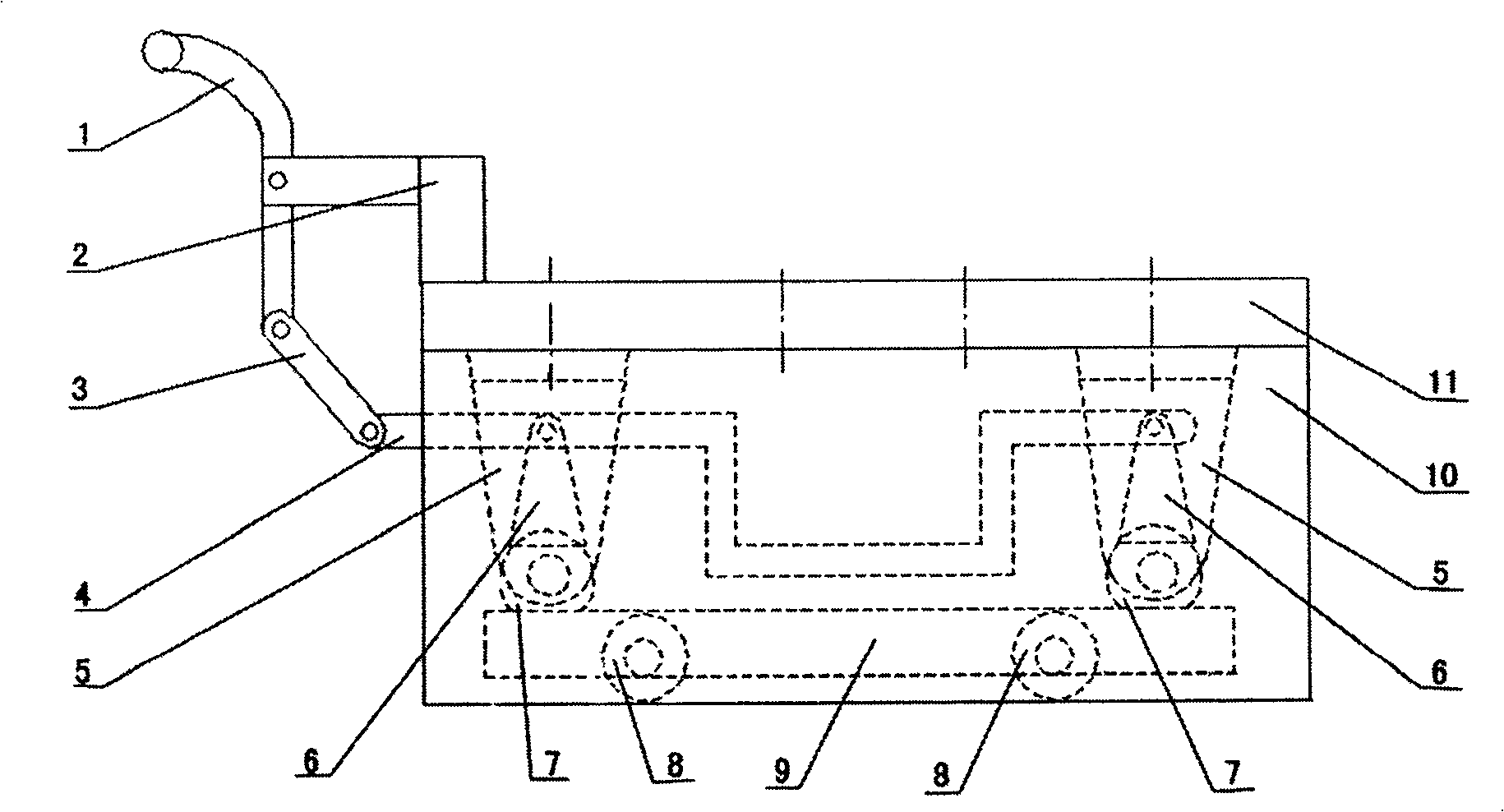

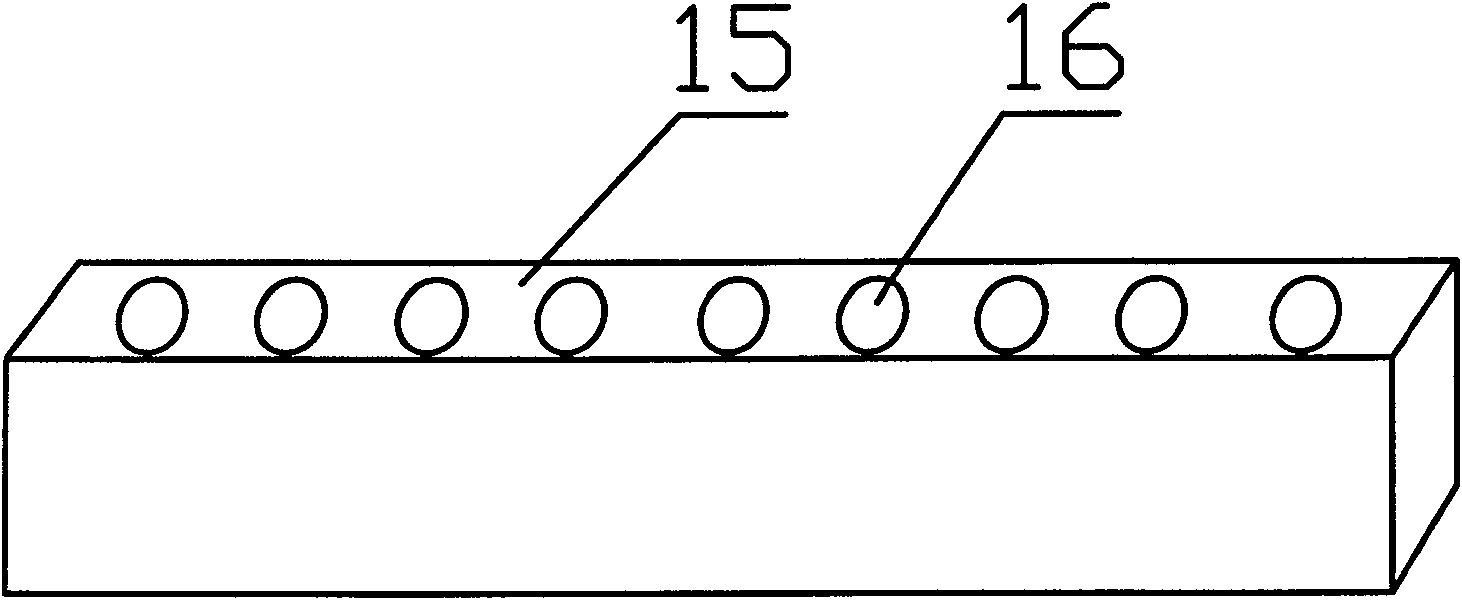

Material flowing platform for sand core assembly and sand core assembly material flowing method

ActiveCN108044044ASave circulation spaceOptimize facility planningFoundry mouldsFoundry coresPalletManufacturing engineering

The invention provides a material flowing platform for a sand core assembly and a sand core assembly material flowing method, and relates to the technical field of sand core assembly. The material flowing platform for the sand core assembly includes a frame, a first feeding part, a second feeding part and a pallet recovery part. The first feeding part includes a first rail and first rollers, the first rail is obliquely arranged on the frame, and a plurality of first rollers are arranged on the first rail. The second feeding part includes an electric roller and a conveyer belt, the electric roller is rotatably arranged on the frame, and located on the lower portion of the first feeding part, and the conveyer belt is used to convey sand core. The pallet recovery part includes a third rail and second rollers, a plurality of second rollers are arranged on the third rail side by side, and the third rail is obliquely arranged on the frame. The material flowing platform for the sand core assembly is used by the sand core assembly material flowing method, the material flowing is more reasonable, the simultaneous assembly of two work positions is achieved, and the production efficiency is greatly improved.

Owner:CRRC CHANGZHOU AUTO PARTS CO LTD +1

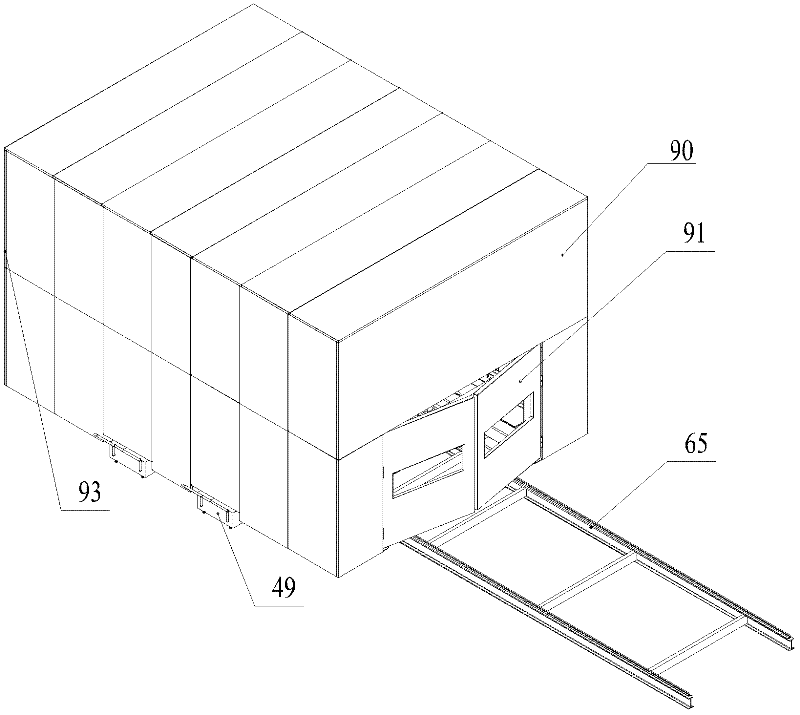

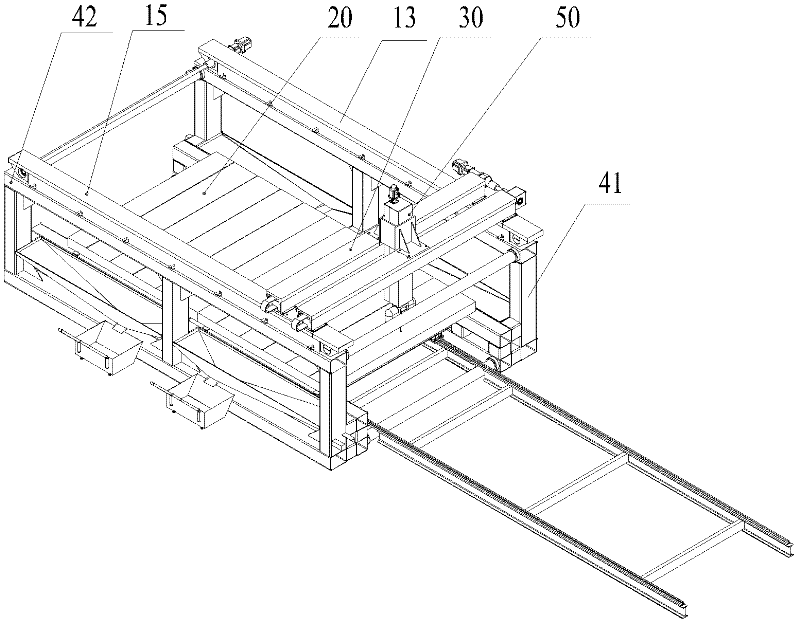

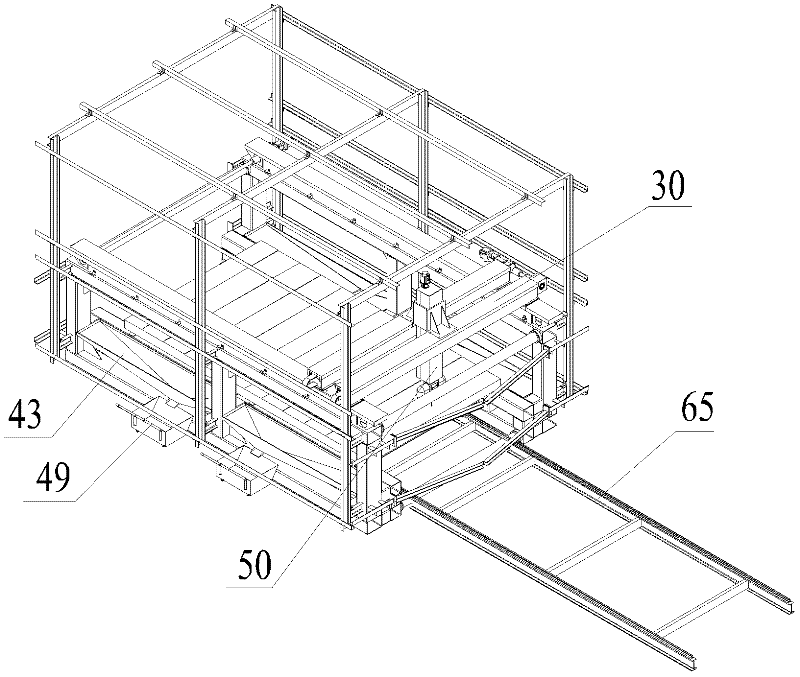

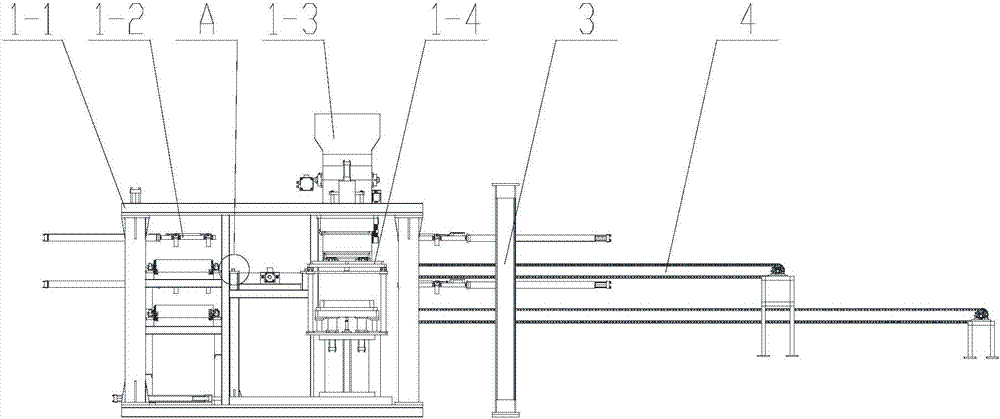

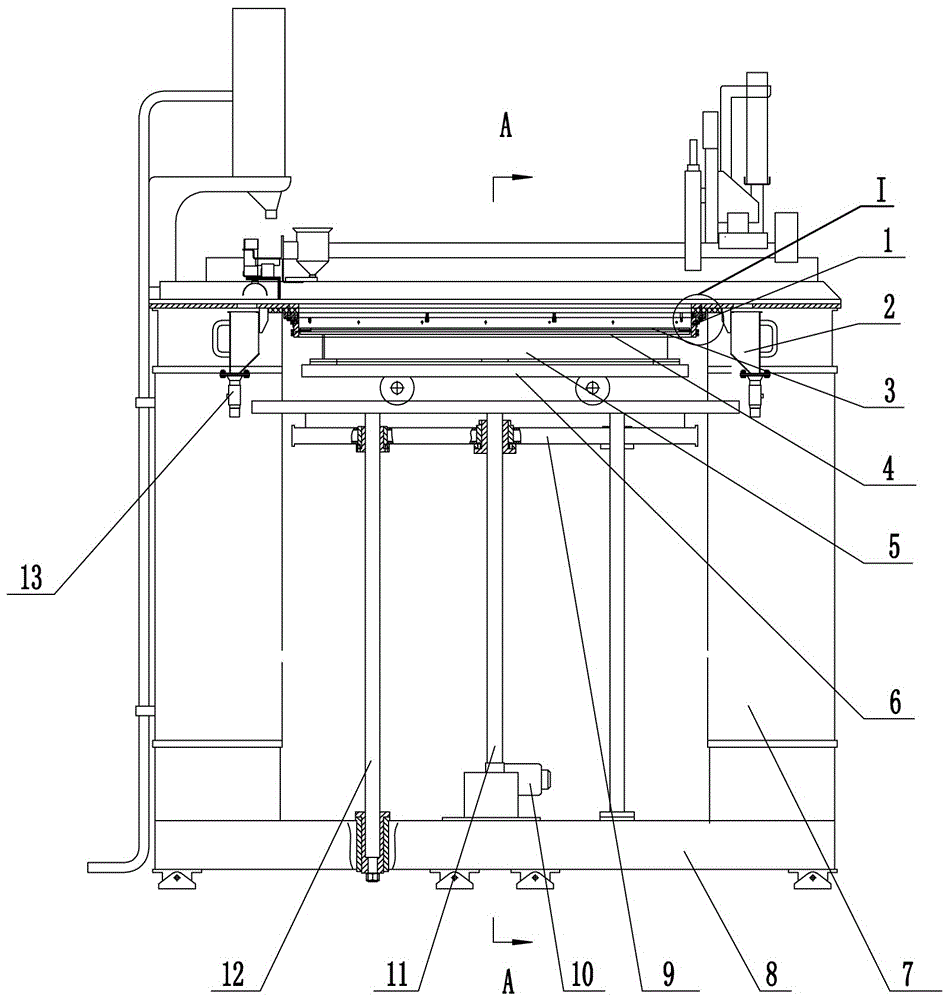

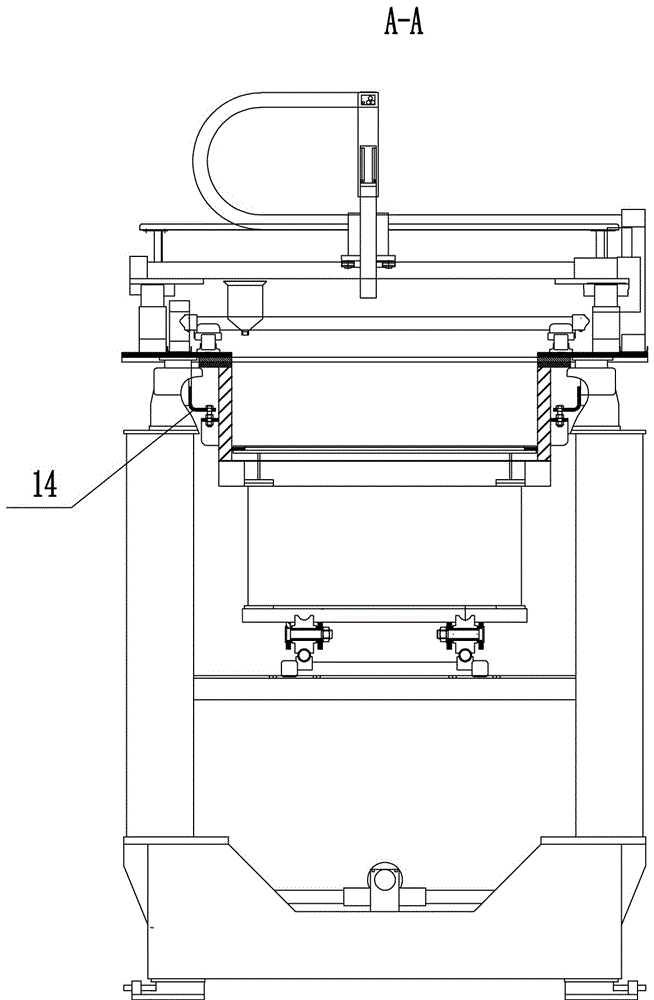

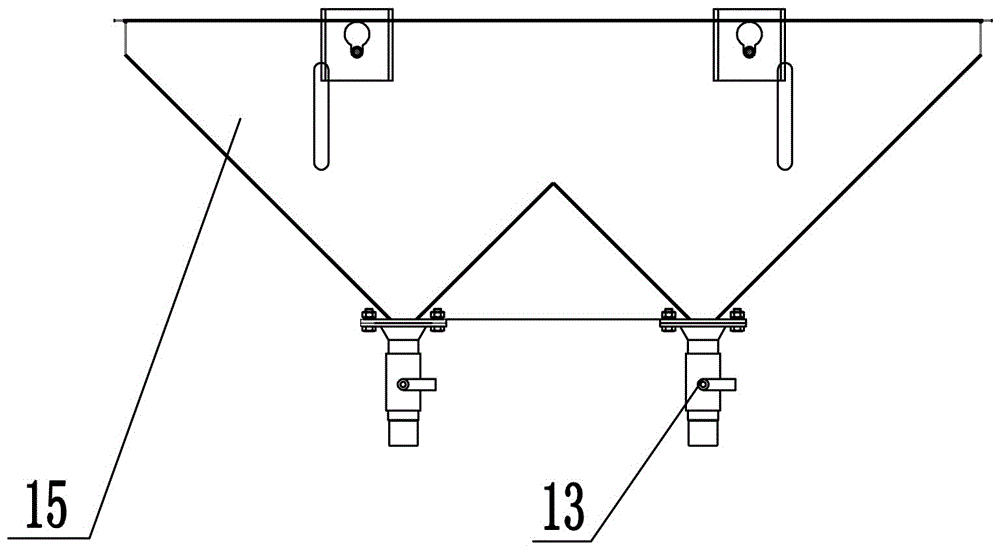

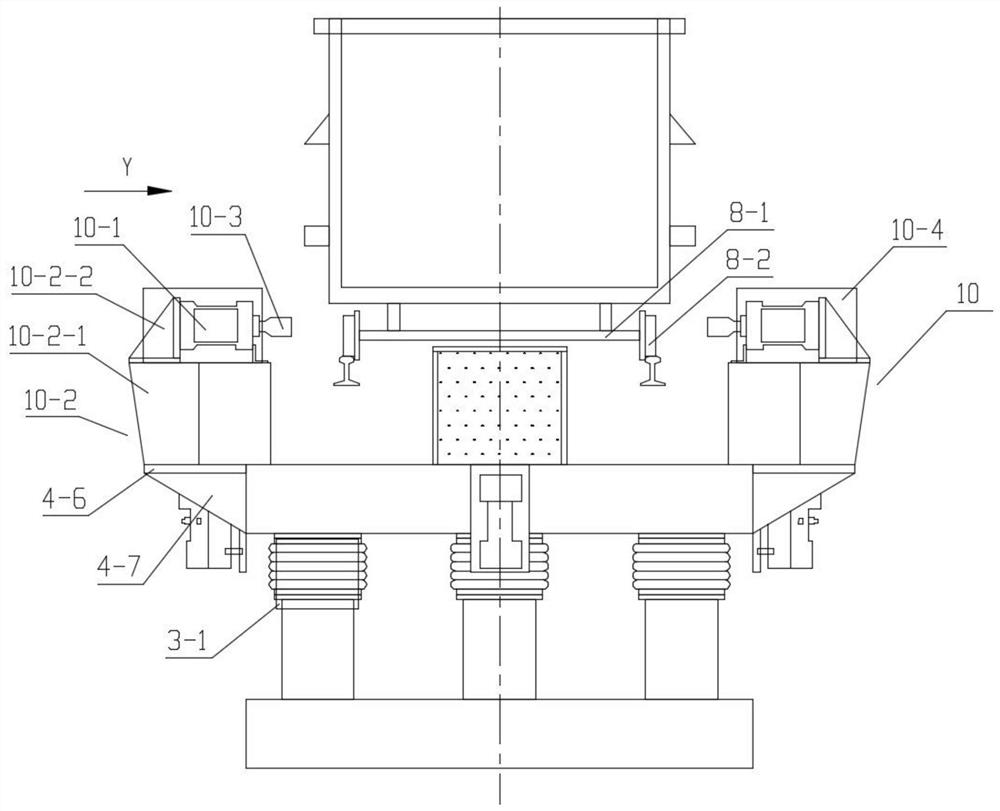

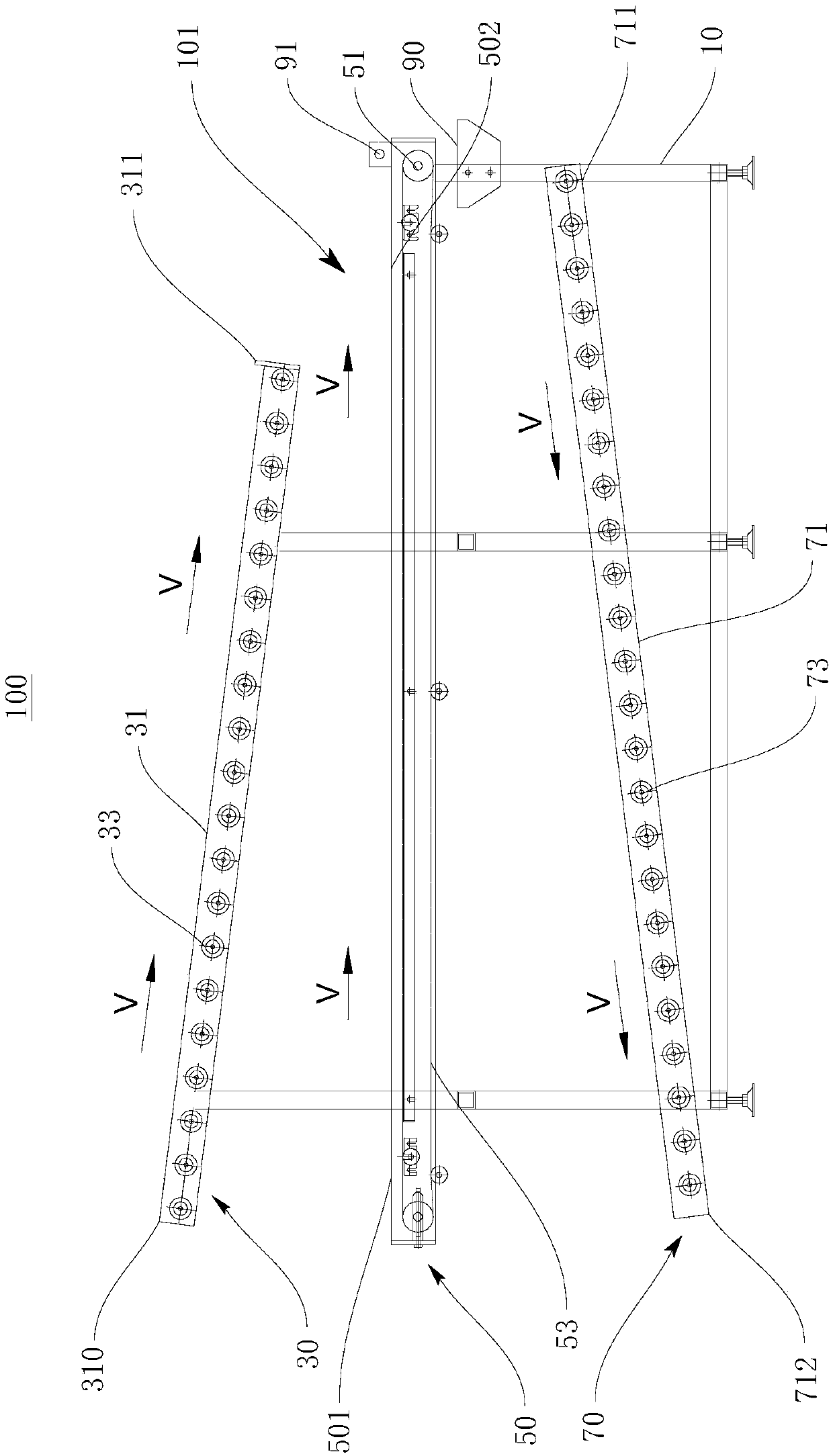

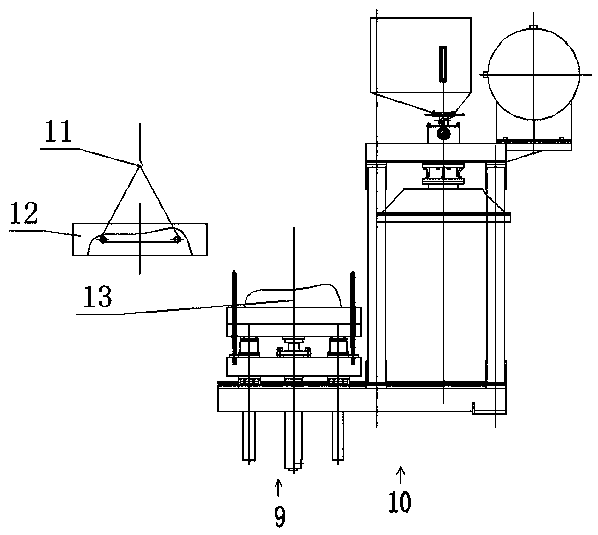

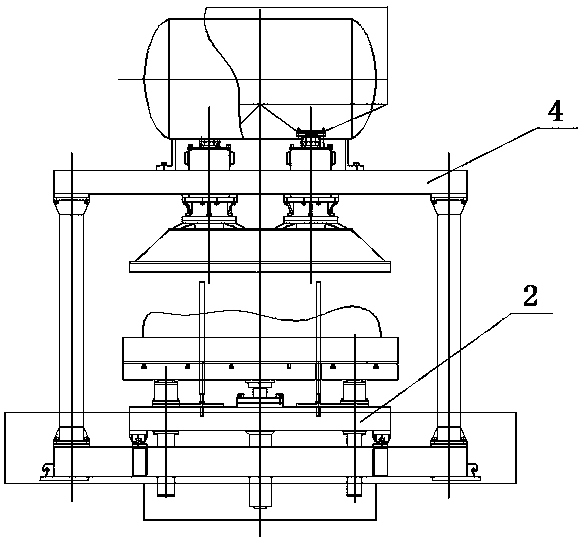

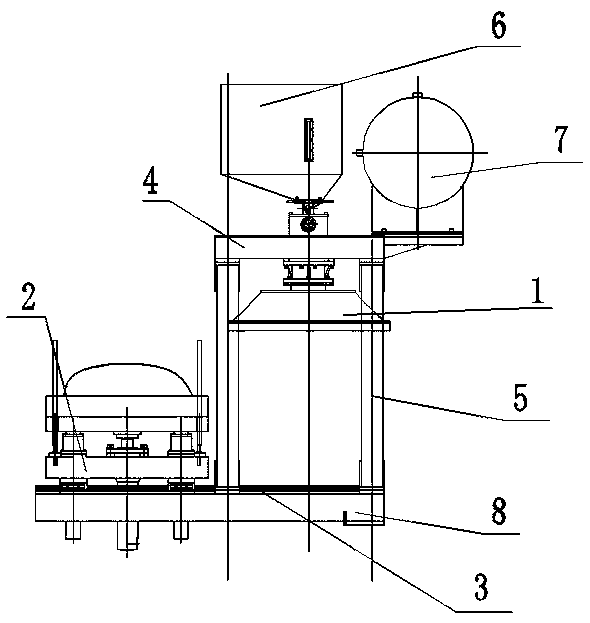

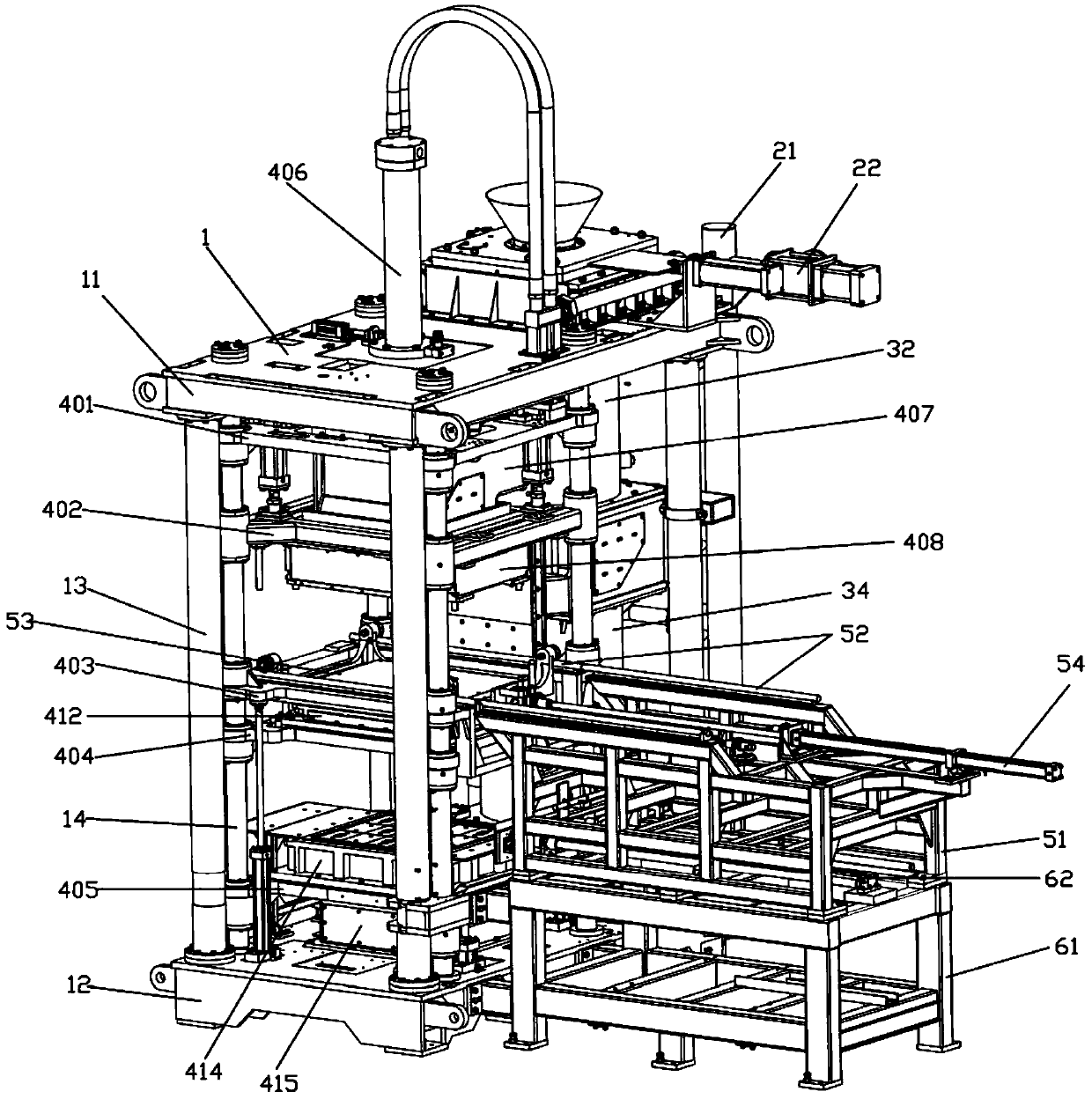

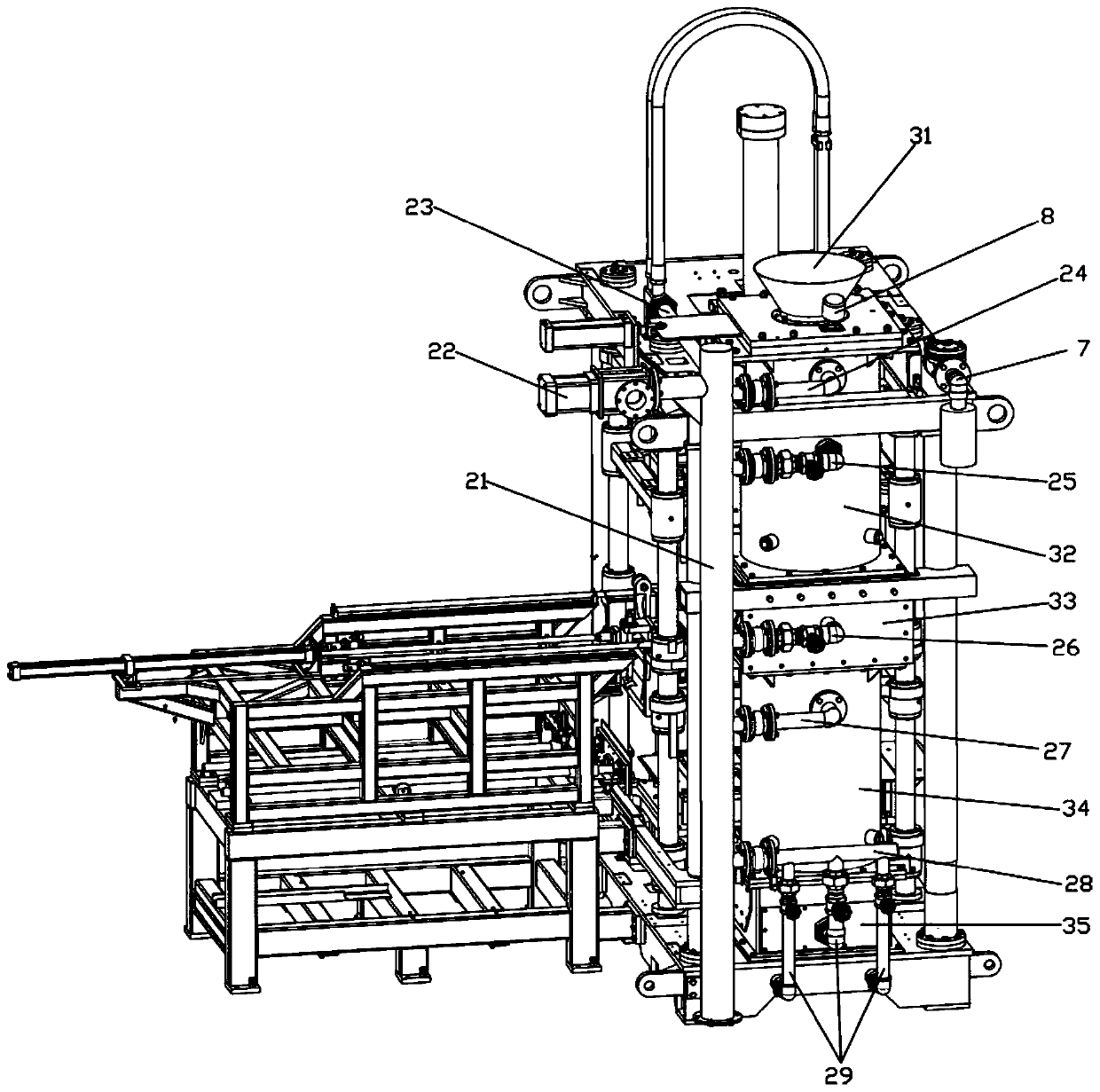

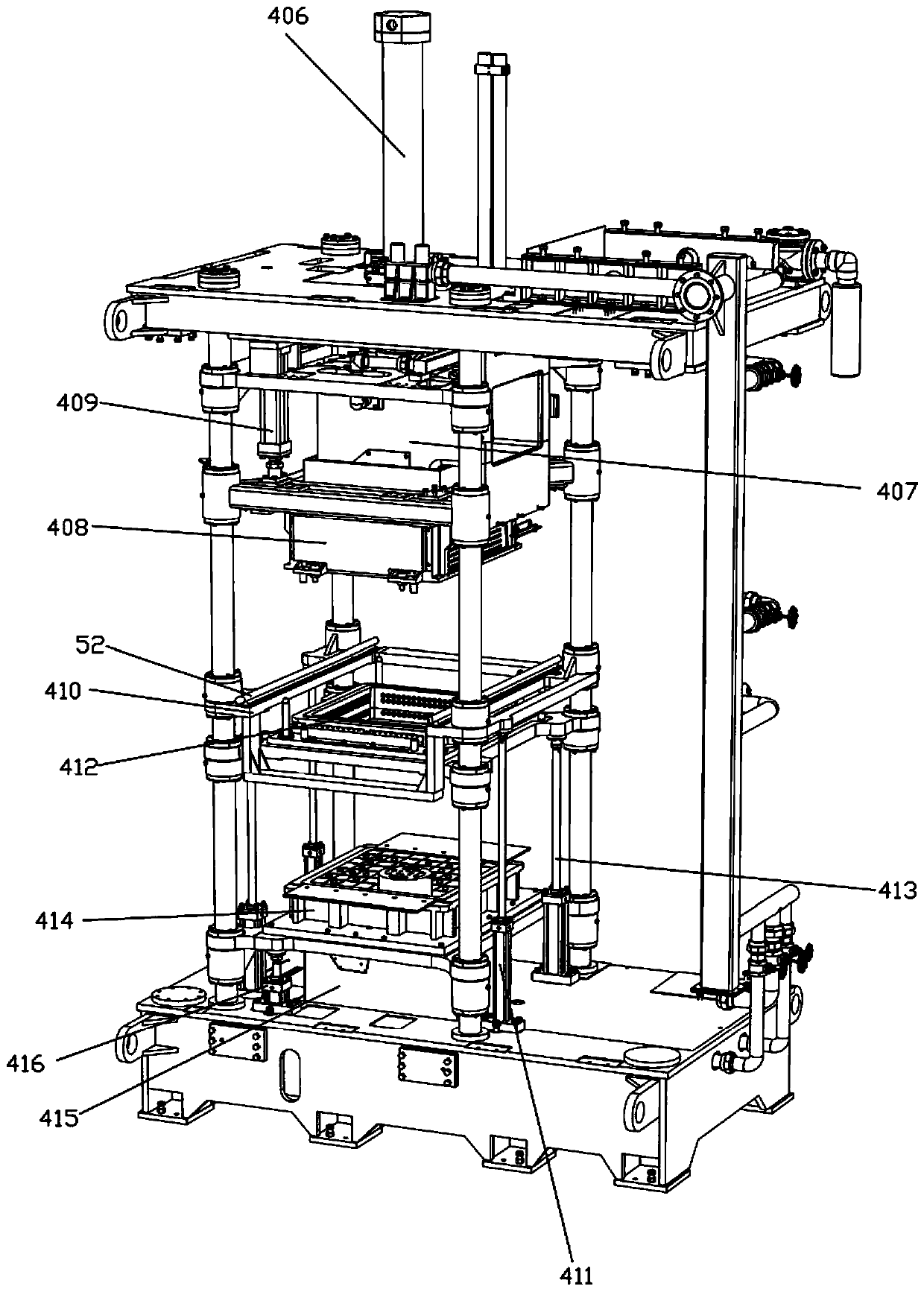

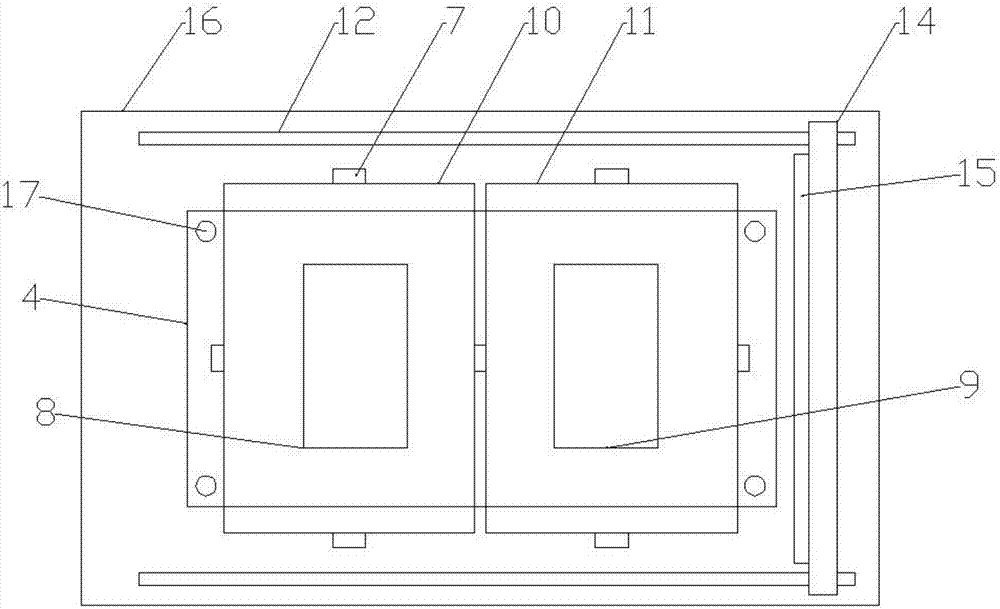

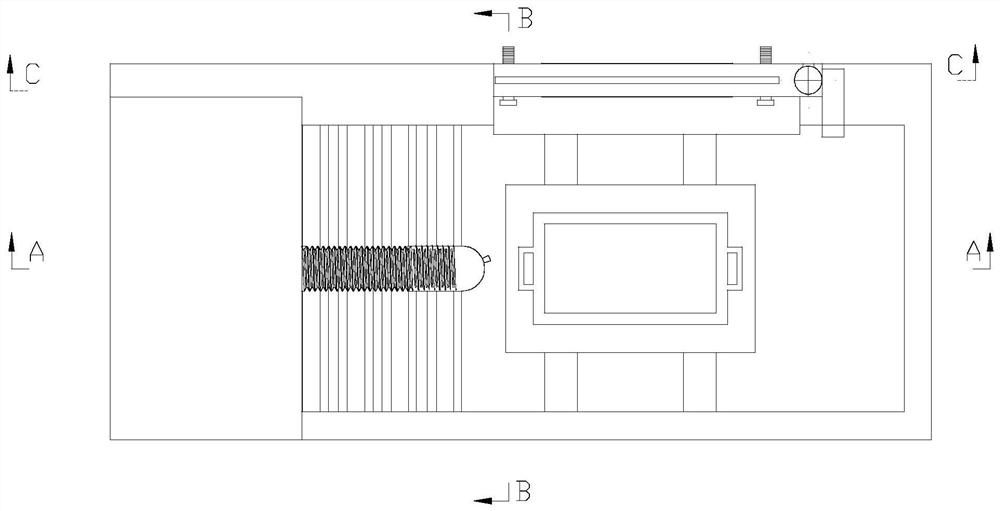

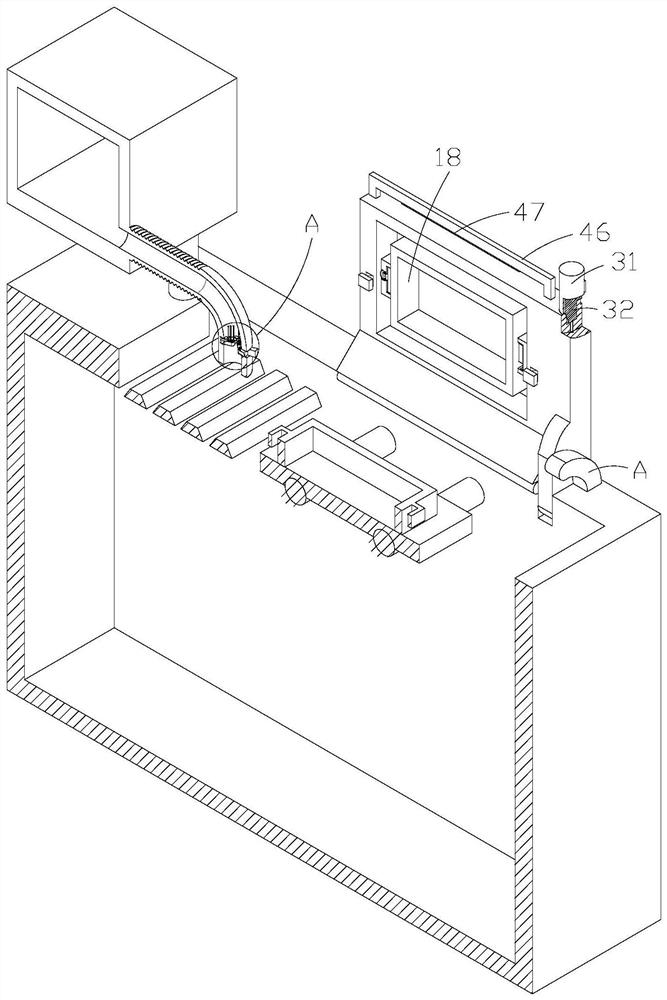

Super-large iron type sand coating molding machine device and molding method thereof

PendingCN109822059ASimple Precision AdjustmentEasy to hoist into molding stationMoulding machinesMould tablesMolding machineUltimate tensile strength

The invention relates to a super-large iron type sand coating molding machine device and a molding method thereof, and belongs to machinery. The super-large iron type sand coating molding machine device comprises a sand shooting and coating mechanism, a mold closing and lifting molding trolley, a trolley moving linear track, an upper beam, an upright column and a base; the sand shooting and covering mechanism is fixed to the upper beam; the upper beam is connected with the base through the upright column; the trolley moving linear track is fixedly mounted on the base; and the trolley moving linear track is used for back-and-forth movement of the mold closing and lifting molding trolley. The invention also provides a molding method of a molding machine. The super-large iron type sand coating molding machine device is simple and reasonable in structural design and is safe and reliable, mold closing, mold lifting, sand shooting and sand coating processes operate stably, the labor intensity in operation is low, a hanging and molding station of an iron mold is convenient, a mold is convenient to clean, and the use requirements are met.

Owner:浙江省机电设计研究院有限公司

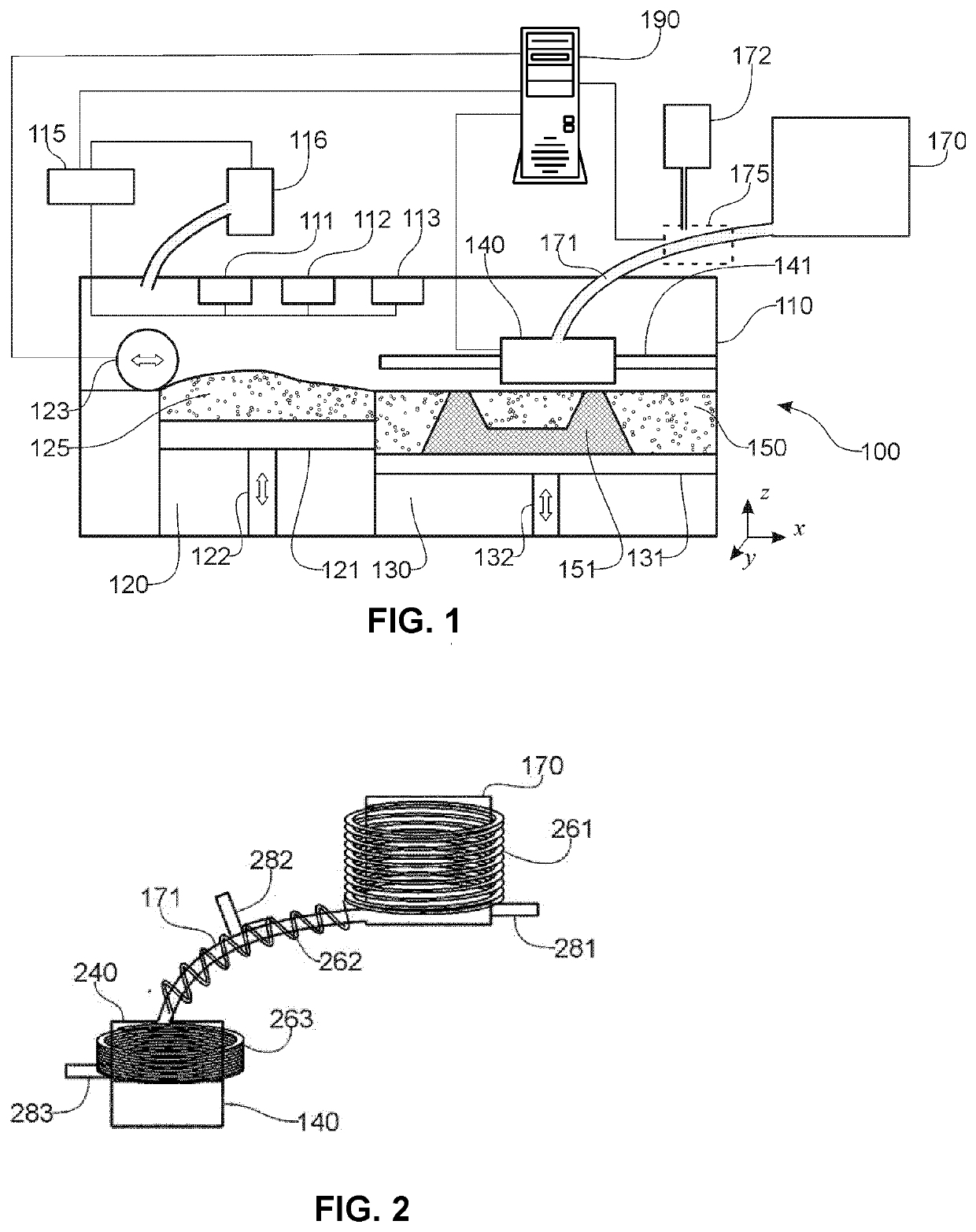

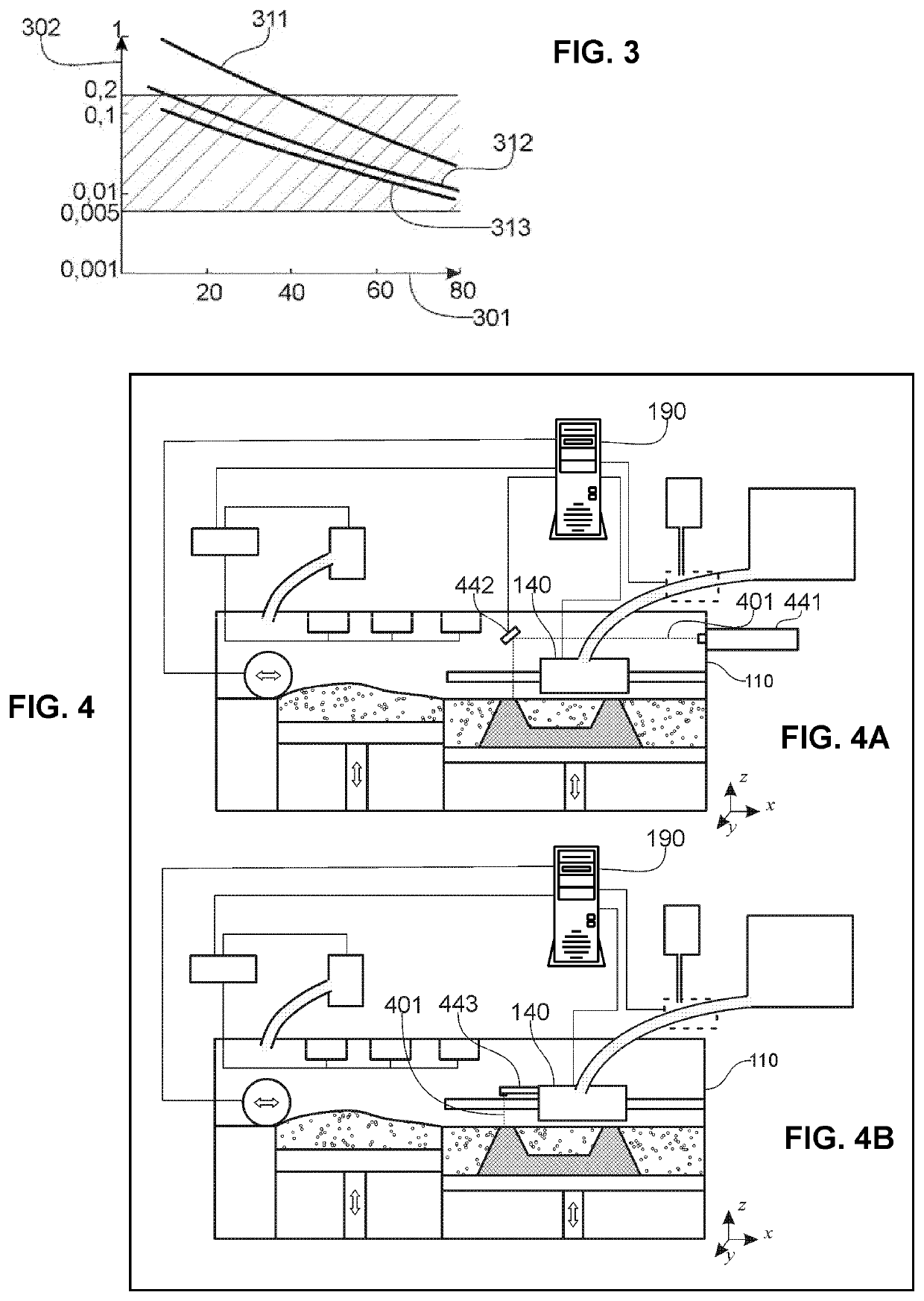

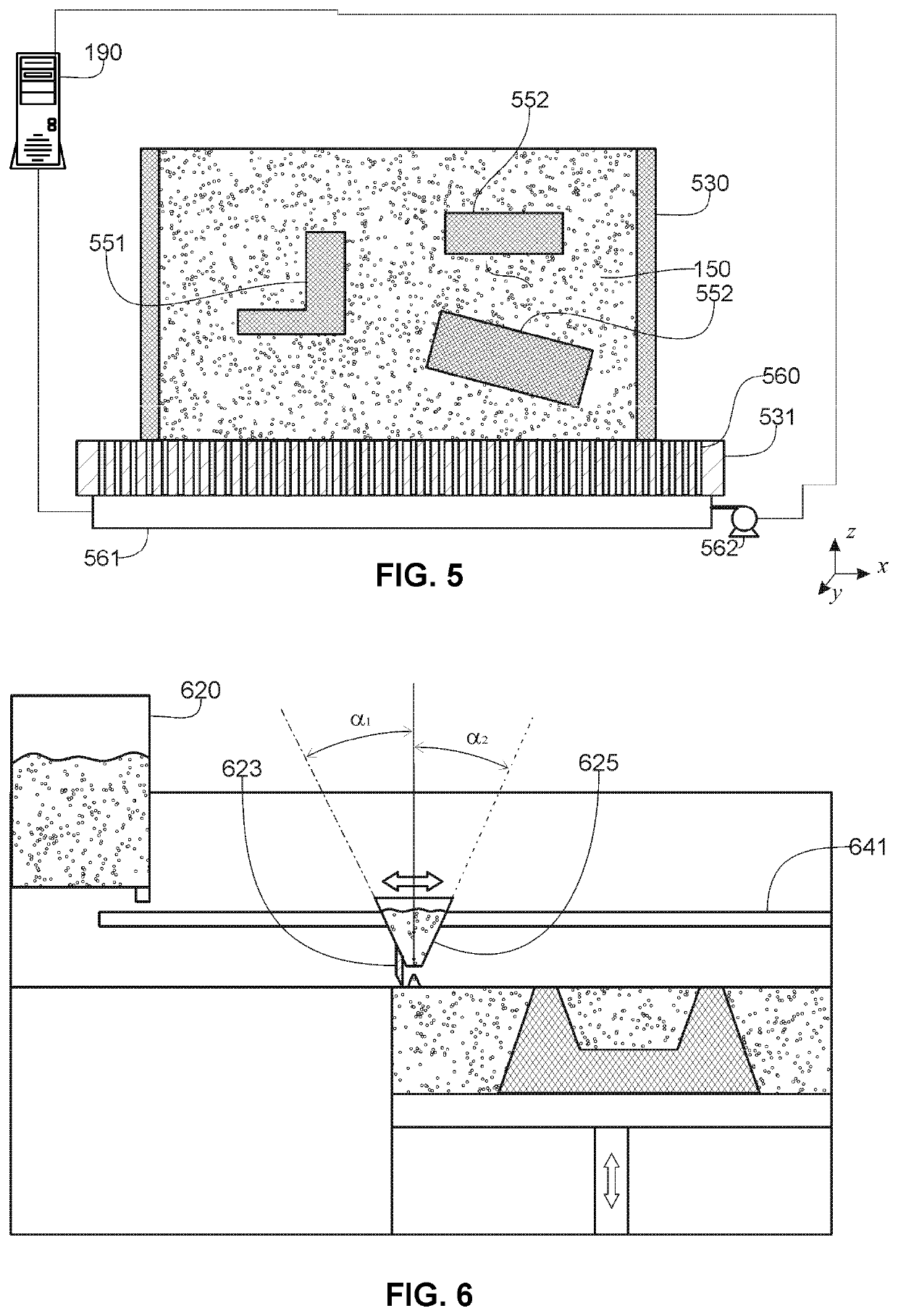

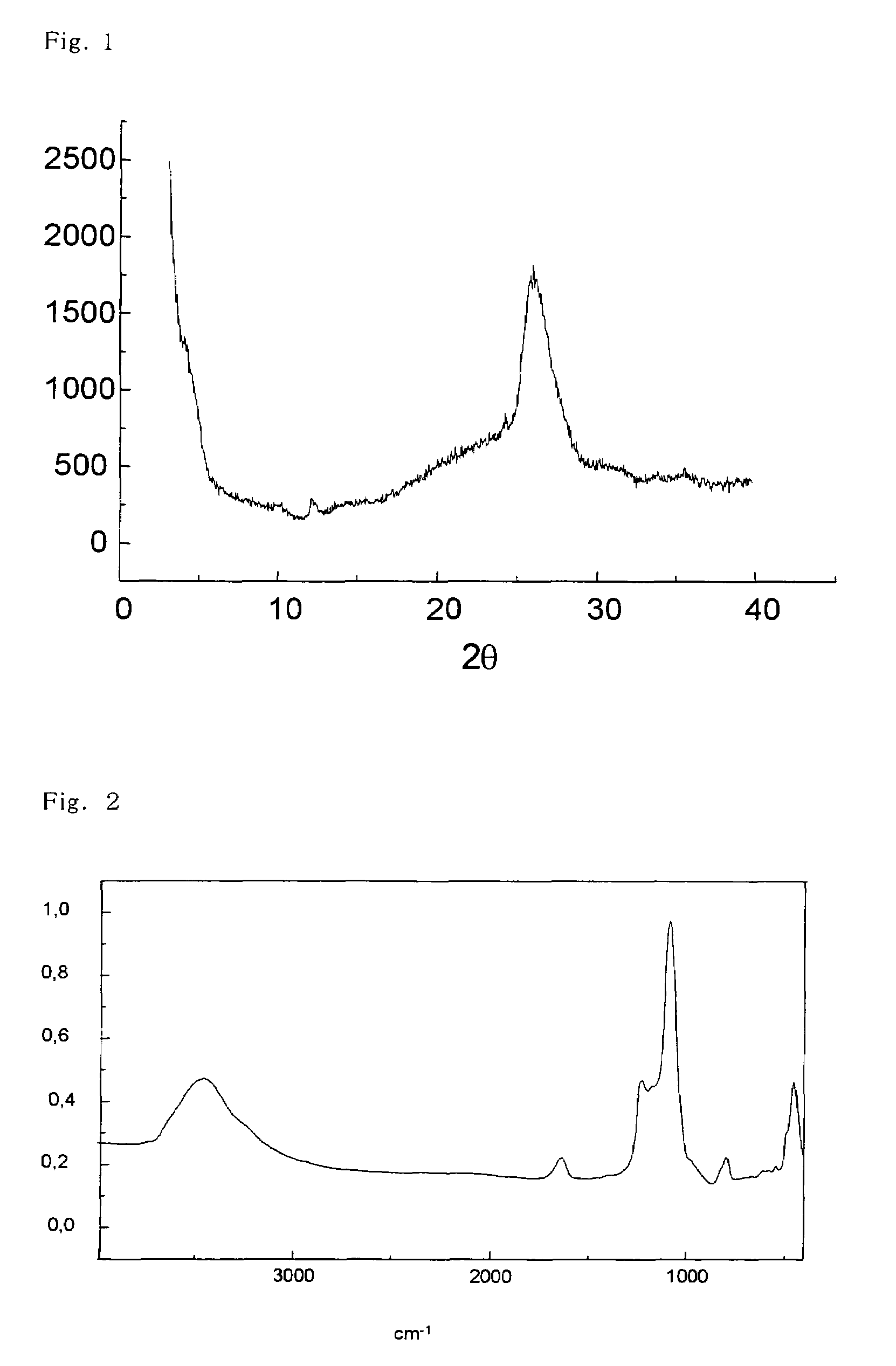

Method and device for additive manufacturing by agglomeration of a granular material

PendingUS20220347739A1Good selective impregnationLow viscosityAdditive manufacturing apparatusFoundry mouldsSpray nozzleAdditive layer manufacturing

A method for manufacturing a structure from a granular material, called sand, in particular a mold. A layer of sand is deposited. The layer of sand is selectively agglomerated by spraying, using a spray nozzle, an inorganic binder having an M2SiO3 type (meta)silicate dissolved in a solvent. Prior to the spraying, the inorganic binder is heated to a temperature to confer on it a viscosity less than 0.2 Pa·s. A device for implementing the method is provided.

Owner:ECOLE CENTE DE NANTES

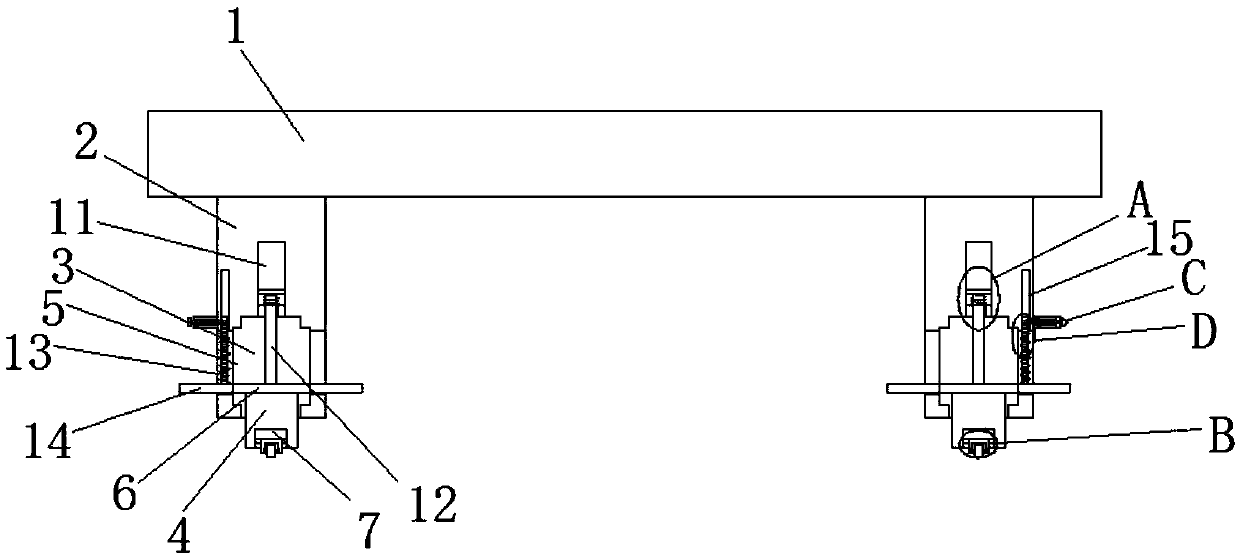

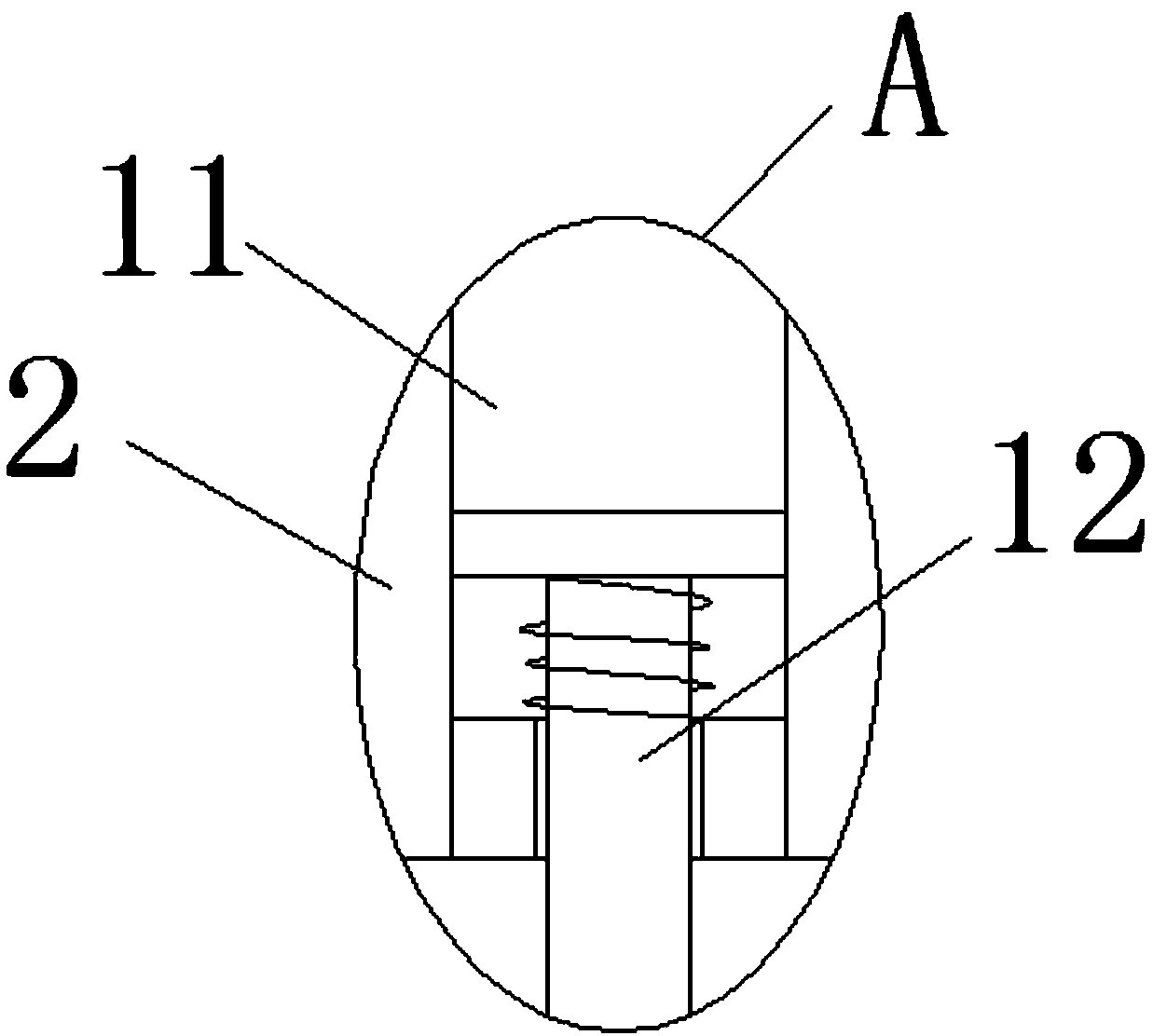

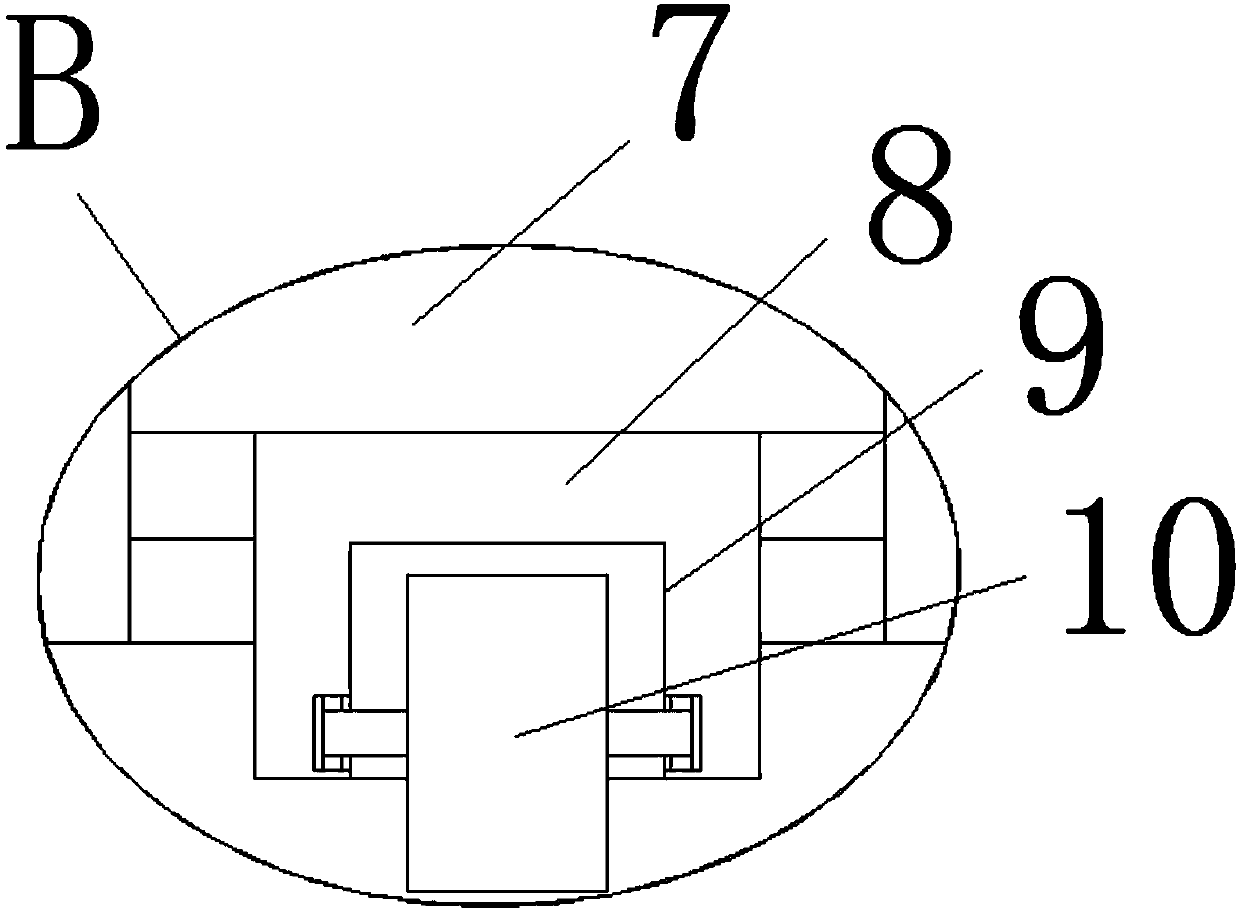

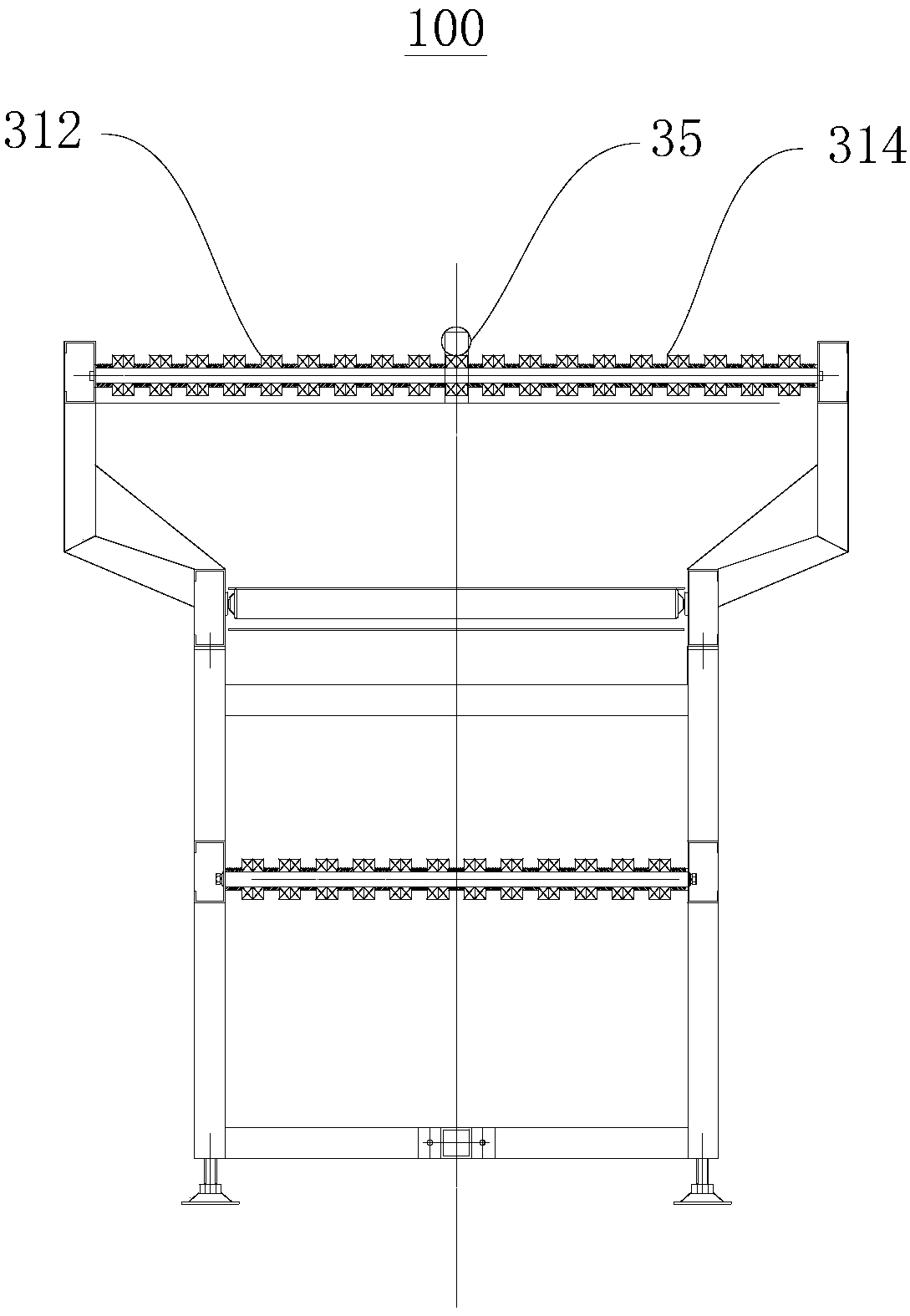

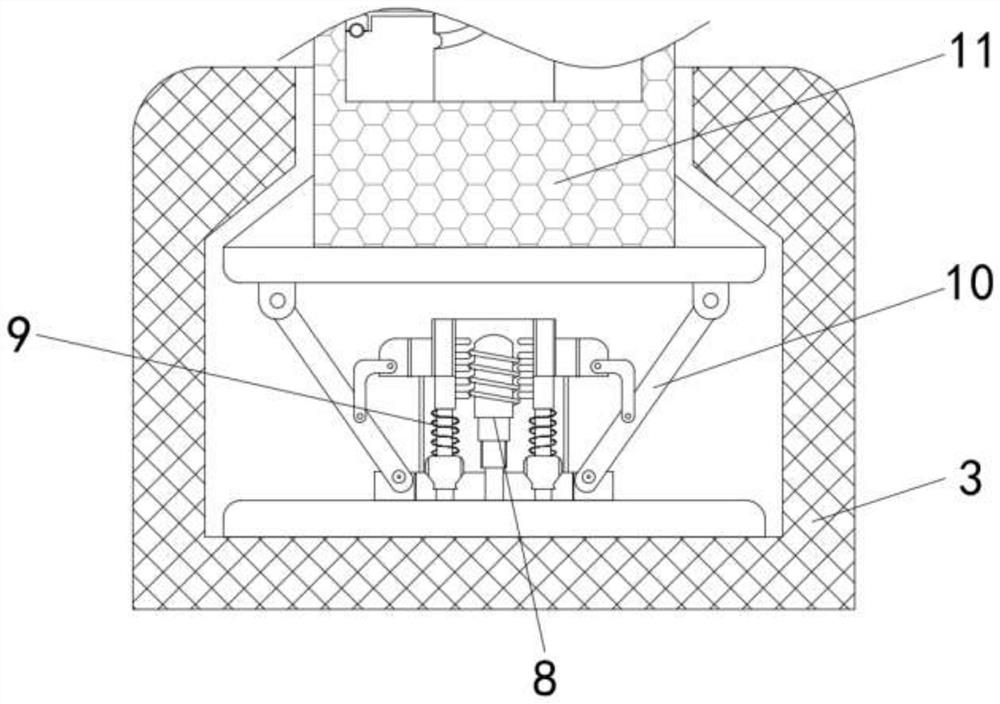

Auxiliary mechanism for automatically adjusting gap between vibration tables for clay sand horizontal molding machine

PendingCN112517858AImprove the vibration effectQuick resetMoulding machinesMould tablesMolding machineClassical mechanics

The invention provides an auxiliary mechanism for automatically adjusting a gap between vibration tables for a clay sand horizontal molding machine. The auxiliary mechanism comprises a base, wherein amounting base and fixing parts are fixedly mounted on the upper side of the base, a vibration mechanism and vibration supports are mounted on the upper side of the mounting base, the mounting vibration table is mounted on the upper side of the vibration mechanism, and an equipment shell is fixedly mounted on the upper side of the mounting vibration table. According to the auxiliary mechanism forautomatically adjusting the gap between the vibration tables for the clay sand horizontal molding machine, the mounting vibration table makes contact with connecting pieces so as to drive movable blocks to move downwards; mounting blocks make contact with movable mechanisms in an attached mode, so that movable connecting rods are used for pushing ejector rods to drive ejector pieces to push adjusting mechanisms to move upwards, and the adjusting mechanisms make contact with the mounting vibration table, so that the mounting vibration table is effectively and quickly reset, the vibration tableson the mounting vibration table are prevented from being separated from pistons, the vibration effect of the equipment is further improved, and the production efficiency is improved.

Owner:厦门幻栢机械有限公司

Method of squeezing foundry sand, match plate, and upper and lower flasks

A method of squeezing a foundry sand capable of solving a problem in upper and lower molds manufactured by a mold manufacturing apparatus, in which the foundry sand is squeezed by moving upper and lower squeeze plates close to each other after the foundry sand is filled in upper and lower molding spaces formed by the upper and lower flasks, match plates, and upper and lower squeeze means, wherein the hardness and strength thereof near the inner surfaces of the upper and lower flasks are not sufficient. The method is characterized in that the upper and lower squeeze plates are moved close to each other to squeeze the foundry sand in upper and lower molding chambers, and the pattern parts of the match plates are advanced to the upper and lower squeeze plate sides to further squeeze the foundry sand in the upper and lower molding chambers.

Owner:SINTOKOGIO LTD

Full-automatic sand mold casting molding machine

PendingCN110252961AIncrease compactionImprove the compaction effectMoulding machinesMould tablesMolding machineMaterials science

The invention relates to the technical field of sand mold casting and discloses a full-automatic sand mold casting molding machine. A rack, a gas inflow pipeline arranged on one side of the rack, a sand entering mechanism, a forming and compacting mechanism, a mold conveying mechanism and a sand mold push-out mechanism are included, wherein the sand entering mechanism and the forming and compacting mechanism are arranged on the rack, and the mold conveying mechanism and the sand mold push-out mechanism are arranged on one side of the rack; and the rack comprises a top plate, a base and four guide columns connecting the top plate with four stand columns of the base. A first oil cylinder is arranged on an upper gas storing bin, and drives an upper sand box to move downwards; a fifth oil cylinder drives a lower sand box to move upwards, so that the upper sand box and the lower sand box are closed, and the forming and compacting work is performed, the compacting degree is improved, and the compacting effect is better. The four stand columns are additionally arranged, and play a main supporting role; the guide columns can be independently used for installing the forming and the compacting mechanism, and meanwhile play an auxiliary supporting role; and the stand columns and the guide columns jointly play the roles, so that the whole device is firmer and more stable.

Owner:盐城市东云自动化科技有限公司

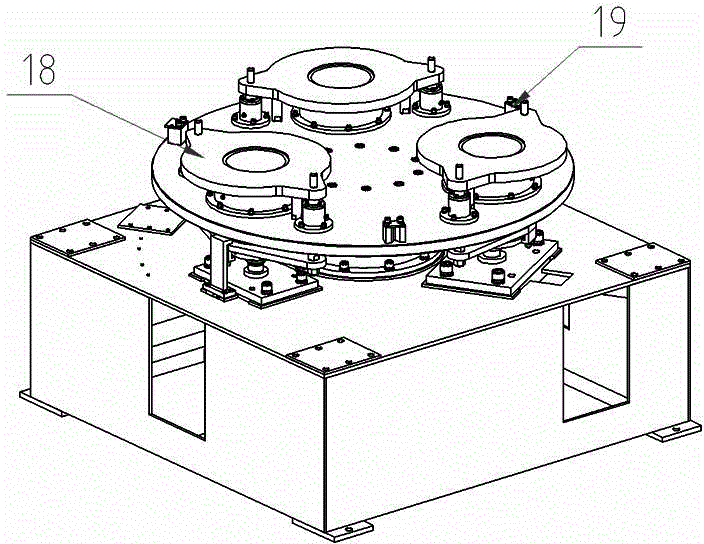

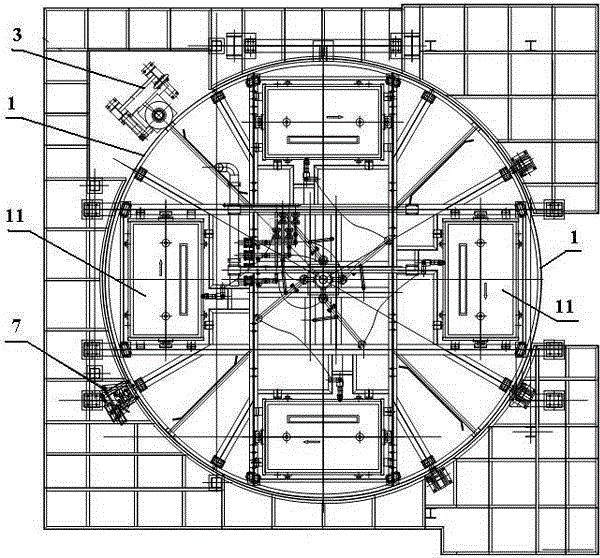

Four-station large rotary table

InactiveCN104439117AImprove modeling efficiencySmall footprintFoundry mouldsMoulding machinesHydraulic motorEngineering

The invention relates to a four-station large rotary table which comprises a supporting wall, a rotary table, a support frame and a traveling wheel device, wherein the support frame is arranged on the supporting wall; supporting columns are arranged below the support frame; a supporting disc is arranged above the support frame; the rotary table is connected with the supporting disc by virtue of a central upright post; the traveling wheel device is arranged between the rotary table and the supporting disc; a vacuum system is arranged at the central position of the upper surface of the rotary table; the rotary table is circular; and a hydraulic motor driving system and a positioning and locking device are arranged on the edge of the rotary table. According to the four-station large rotary table disclosed by the invention, a novel modeling mode is adopted so that the modeling efficiency is improved, the equipment is compact, and the area occupied by the equipment is reduced.

Owner:QINGDAO HOSEN HEAVY IND

Investment casted die mould auxiliary moving device

The present invention discloses a pattern die auxiliary movement equipment for investment casting process. Said pattern die auxiliary movement equipment is formed from handle, flat-plate and roller. On the flat-plate a supporting table is welded, under said flat-plate a bearing block and a cantilever are mounted, on the shaft of base plate a roller is mounted, and is placed in the groove interior of said bearing block, and can be upwards and downwards moved; on the camshaft a support abutment is wedded, and can be turned in the cantilever interior, the handle, supporting table, link joint, concave connecting rod and support abutment are successively hinge-jointed. Besides, said invention also provides its working principle and concrete operation method.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

Sand coating mold module for casting and sand coating casting technique

InactiveCN100560247CQuality improvementSolve the problem of casting defectsFoundry mouldsFoundry coresEngineeringSmall hole

Owner:李祖长 +1

Modeling platform for automobile casting

The invention discloses a modeling platform for an automobile casting. The modeling platform comprises supporting legs, wherein a supporting plate is arranged on the supporting legs; a linear drivingdevice is arranged on the supporting plate; a platform I is arranged at the upper end of the linear driving device; four guide columns are further arranged on the supporting plate; the guide columns are connected with the platform I in a sliding manner; limiting blocks are arranged at two ends of the platform I; an upper model and a lower model are arranged on the platform I; the upper model and the lower model are both fixed on the platform I through fixing bolts; a platform II is arranged at the upper end of the supporting legs; an upper sand box and a lower sand box are arranged on the platform II; supporting rods are arranged at two ends of the platform II; sliding rails are arranged on the supporting rods; a sliding seat for sliding connection is arranged on the sliding rails; a scraper blade is arranged at the bottom of the sliding seat; and locating plates are arranged on both the platform II and the platform I. The modeling platform is simple in structure, low in cost and applicable to modeling of different castings; the occupied area is reduced; the modeling efficiency is improved; and the modeling platform has extremely high economical benefits.

Owner:芜湖市云峰铸造有限责任公司

Cast casting machining process

ActiveCN112317687AIncrease production quantityReduce vibrationFoundry mouldsMoulding machinesMachining processManufacturing engineering

The invention discloses a cast casting machining process. The process includes the steps of (1) smelting; (2) mold preparation: preparing a casting sample, putting the casting sample into a molding sand mold, and machining through a mold machining table to obtain a sand mold; (3) pouring; and (4) cooling. The mold machining table comprises a box body, a molding sand cavity formed in the box body,a conveying pipe arranged on the molding sand cavity, an adjusting component arranged on the conveying pipe, a supporting plate slidably arranged on the box body, a first molding sand mold arranged onthe supporting plate, a machining plate rotatably arranged on the box body, a second molding sand mold arranged on the machining plate, and a grabbing component symmetrically arranged on the machining plate. According to the cast casting machining process, when the sand molds are machined, through the mold machining equipment, the use amount of molding sand can be reduced, the mold production number is increased, vibration generated when the molds are turned over is reduced, and the stability and the integrity of sand mold forming are guaranteed.

Owner:梅州市福德金属制品有限公司

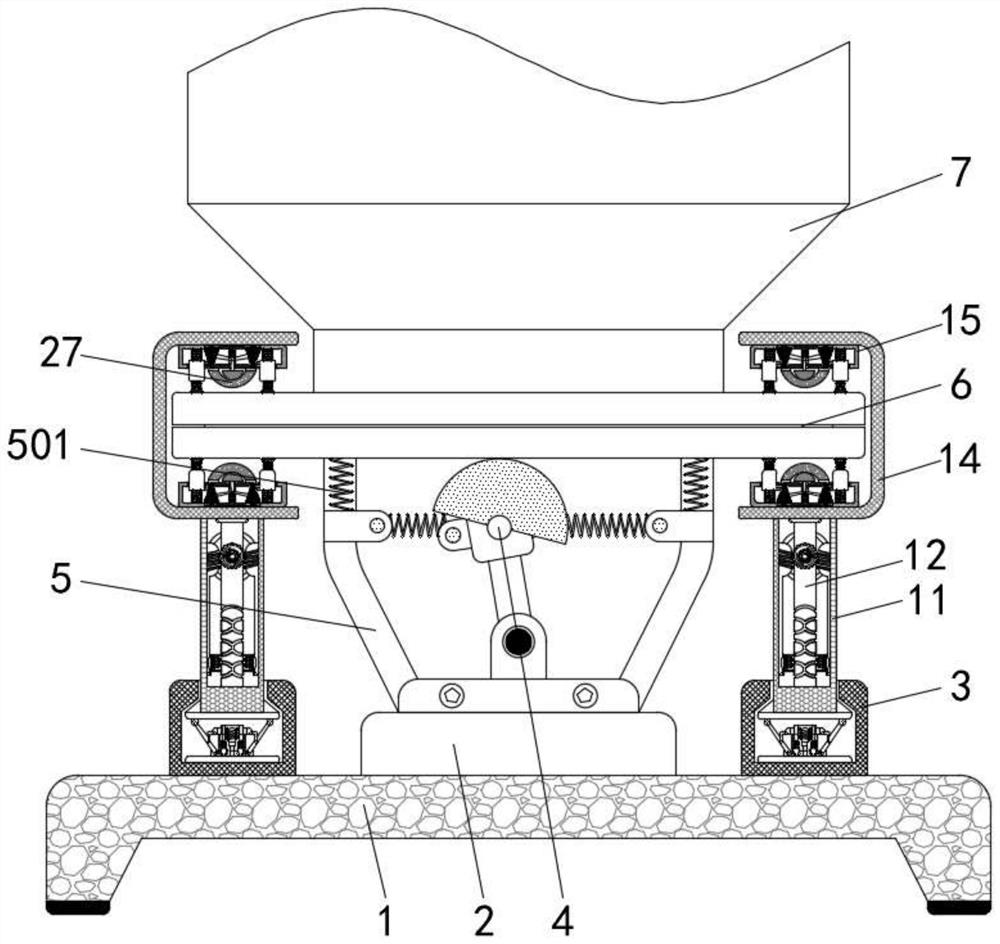

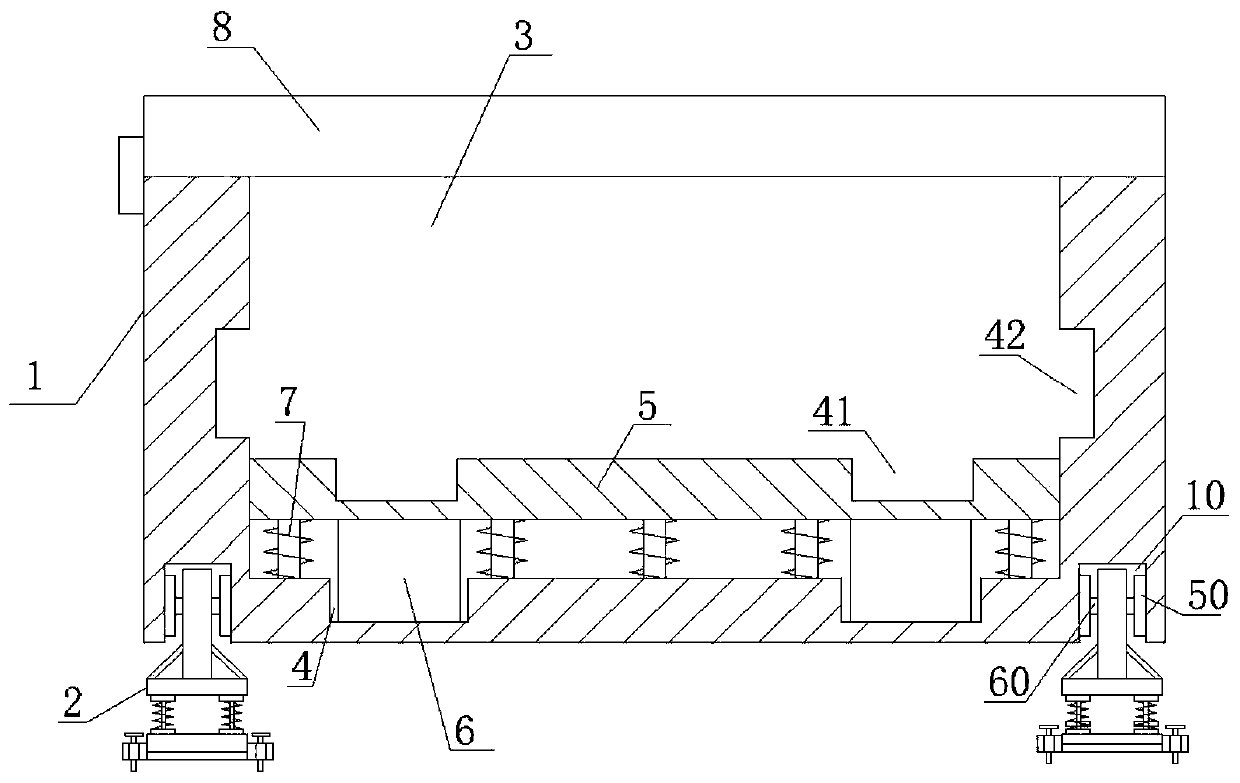

Shock-resistant type sand mould bearing device

InactiveCN111438337AReduce collisionReduce vibration and shakingVibration suppression adjustmentsMould tablesEngineeringShock absorber

The invention discloses a shock-resistant type sand mould bearing device. The bearing device comprises a bearing device body and shock absorption devices; a placing tank is formed in the bottom of theinner surface of the bearing device; a limiting groove is formed in the surface of the placing tank and is symmetrical relative to the central line of the surface; a load bearing plate is further arranged in the bearing device body; limiting blocks are arranged below the load bearing plate and correspond to the limiting groove; the load bearing plate is fixedly connected with the bottom of the inner surface of the bearing device body via buffer springs; a fixing groove is formed in each of two sides of the lower end surface of the bearing device body; the shock absorption devices are arrangedin the fixing grooves; each shock absorption device comprises a connecting pole, an upper fixed plate, a shock absorber and a lower fixed plate; the upper fixed plate is arranged above the lower fixed plate; the shock absorber is arranged between the upper fixed plate and the lower fixed plate; and the connecting pole is fixedly installed on the upper end face of the upper fixed plate and is connected with the fixing groove. Via the arrangement of the shock absorption devices on the bearing device body and buffer assemblies arranged therein, collision- or shock-caused swaying of a sand mouldin the process of model manufacturing is effectively lessen.

Owner:WUHU JINMAO FLUID TECH CO LTD

Method for manufacturing cycloalkanol and/or cycloalkanone

InactiveUS7358401B2Good coefficientFavorable degree of conversionPreparation by oxidation reactionsOrganic compound preparationAlkaneHeteropoly acid

The object of the present invention is to provide a method for manufacturing cycloalkanol and / or cycloalkanone with favorable selectivity coefficient by oxidizing cycloalkane with favorable degree of conversion.In the present invention, cycloalkane is oxidized with oxygen in the presence of a catalyst such that cobalt is supported on layer silicate cycloalkane. Said oxidation is performed in the coexistence of a heteropoly acid compound and the heteropoly acid compound preferably contains cobalt as a central element and / or a skeletal element.

Owner:SUMITOMO CHEM CO LTD

Film sealing and attaching device in V-method casting

ActiveCN113770305AIntegrity guaranteedImprove sealingFoundry mouldsFoundry coresStructural engineeringMechanical engineering

The invention relates to the technical field of V-method casting equipment, in particular to a film sealing and attaching device in V-method casting, the film sealing and attaching device comprises a casting table body, a mounting structure is arranged at the top end of the casting table body, two groups of clamping structures are arranged at each of the four corners of the mounting structure, and a group of sealing structures are arranged at each of the four sides of the mounting structure. The two sides of the casting table body are each provided with a limiting structure, a demolding structure is arranged on one side of the casting table body, a cooling structure is arranged outside the demolding structure, and a protection structure is arranged at the top end of the casting table body. The mounting structure, the clamping structures and the sealing structures are matched for use, a film is pasted to the surface of the casting table body, and the sealing performance of the film is improved; the mounting structure can be conveniently limited through the limiting structures, and the film pasting effect is improved; the cooling structure and the demolding structure are matched for use, the casting table body is demolded, and the demolding effect is improved; and the film can be conveniently supported through the protection structure, and the film integrity is effectively protected.

Owner:XINTAI XINSHENG CASTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com