Material flowing platform for sand core assembly and sand core assembly material flowing method

A sand core and material technology, which is applied to the material flow turntable for sand core assembly and the field of sand core assembly material flow, can solve the problems of reducing the overall efficiency of assembly work, save material flow space, save energy, and reduce site requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

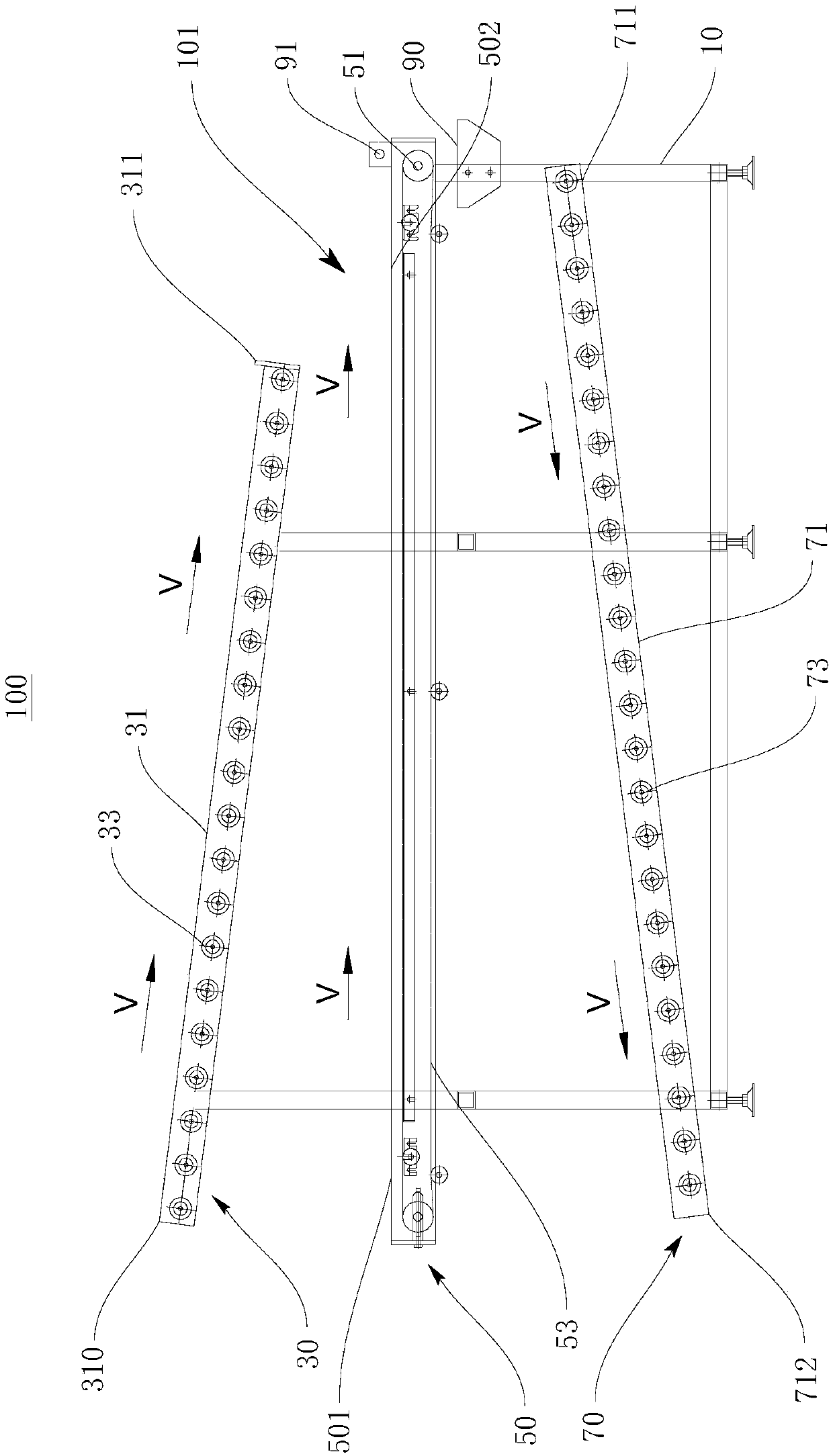

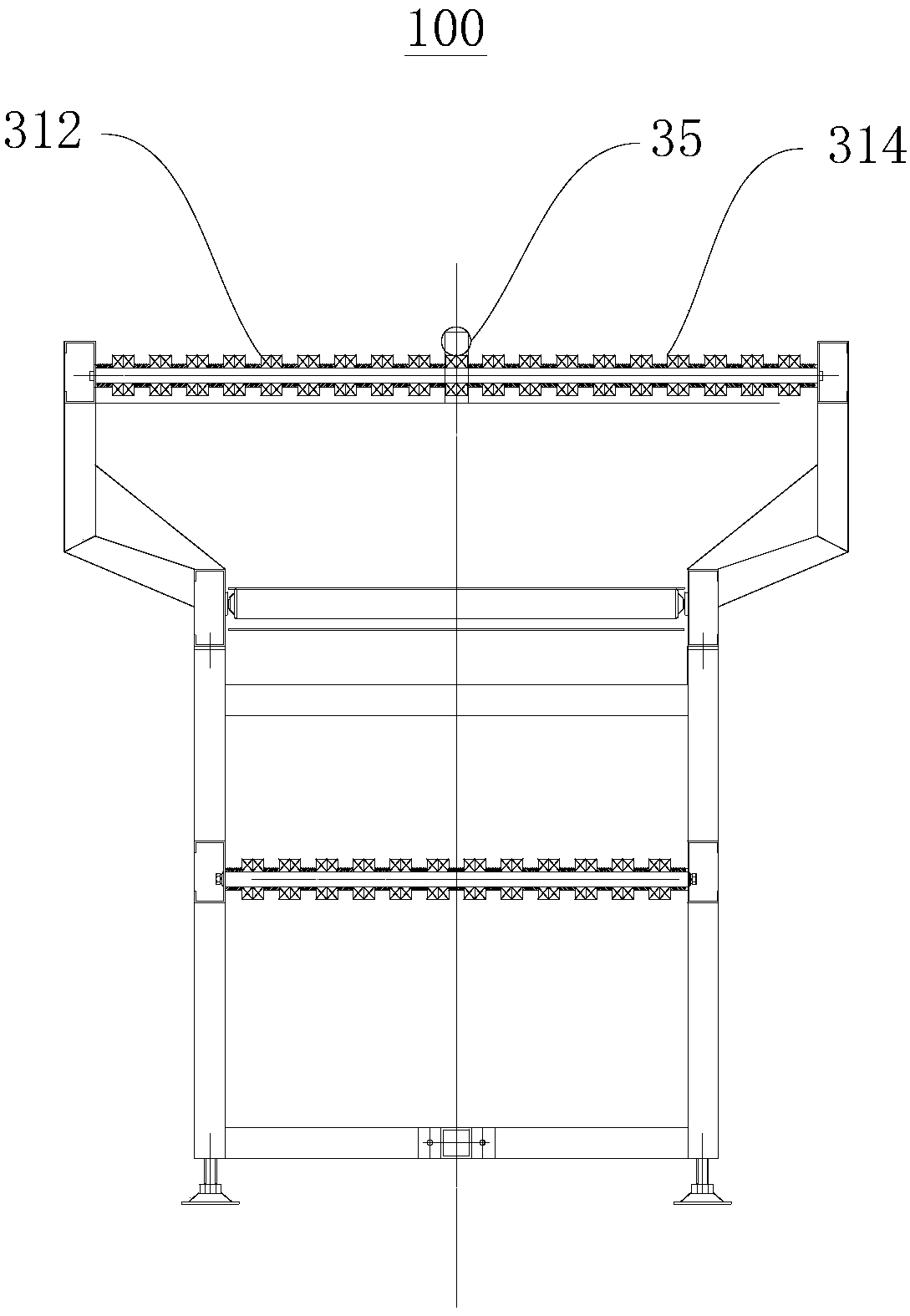

[0049] Please refer to Figure 1 to Figure 4 , this embodiment provides a material flow turntable 100 for sand core assembly, including:

[0050] Rack 10;

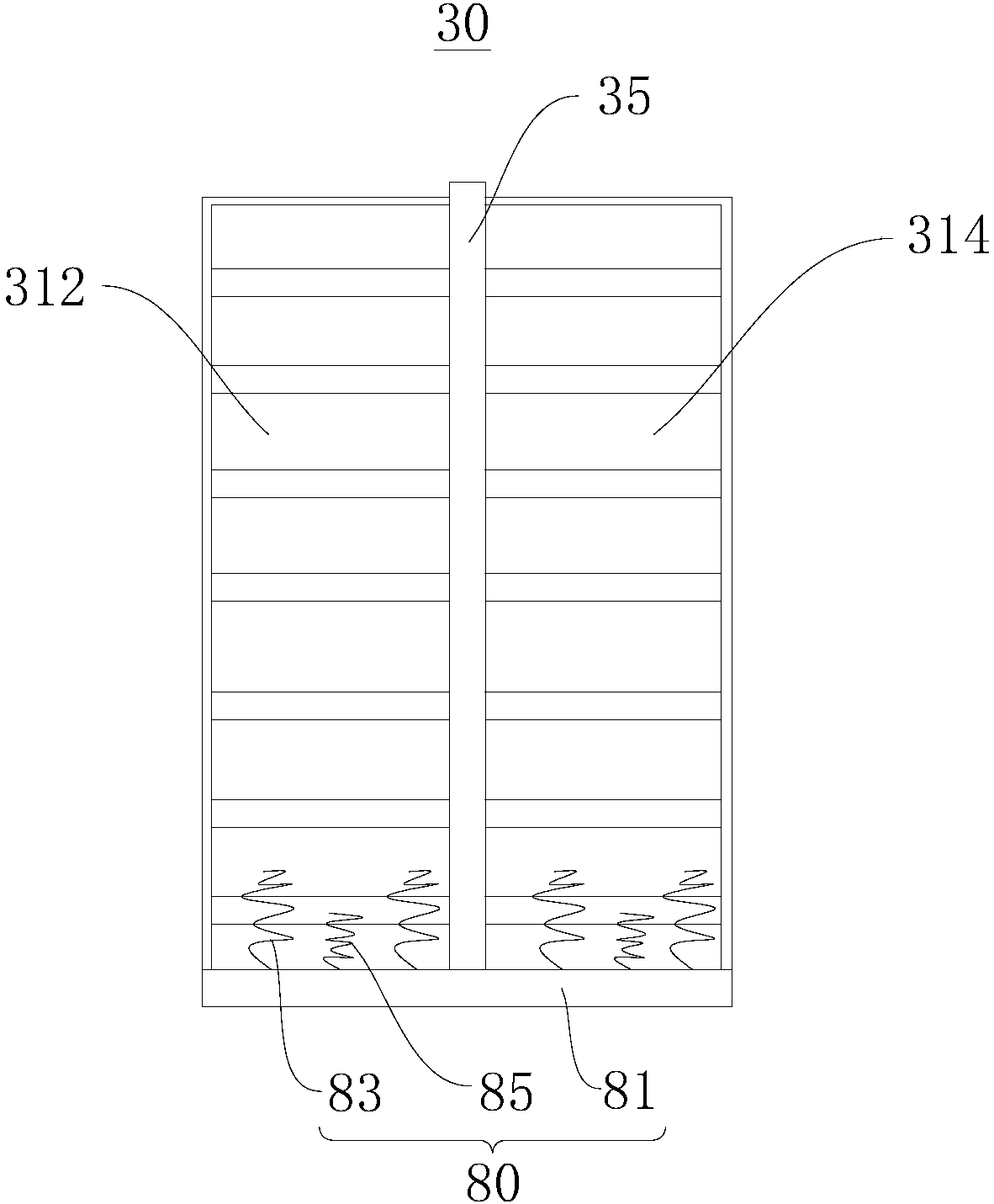

[0051] The first feeding part 30, the first feeding part 30 includes a first track 31 and a first roller 33, the first track 31 includes a first feed end 310 and a first discharge end 311 oppositely arranged, the first roll The number of sub 33 is multiple, and a plurality of first rollers 33 are rotatable and arranged side by side on the first track 31 along the length direction of the first track 31, and the first track 31 is obliquely arranged on the frame 10, so that the A tray 40 on the feeding part 30 can slide from the first feeding end 310 to the first discharging end 311 under the action of gravity;

[0052] The second feeding part 50, the second feeding part 50 is arranged below the first feeding part 30 at intervals, the second feeding part 50 includes a second feeding end 501 and a second discharging end 502 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com