Steam-water separation unit for steam-water separation reheater

A steam-water separation and reheater technology, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of decreasing steam-water separation efficiency, increasing pressure drop, affecting the overall efficiency of steam-water separation reheater, and the safety of steam turbine life. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

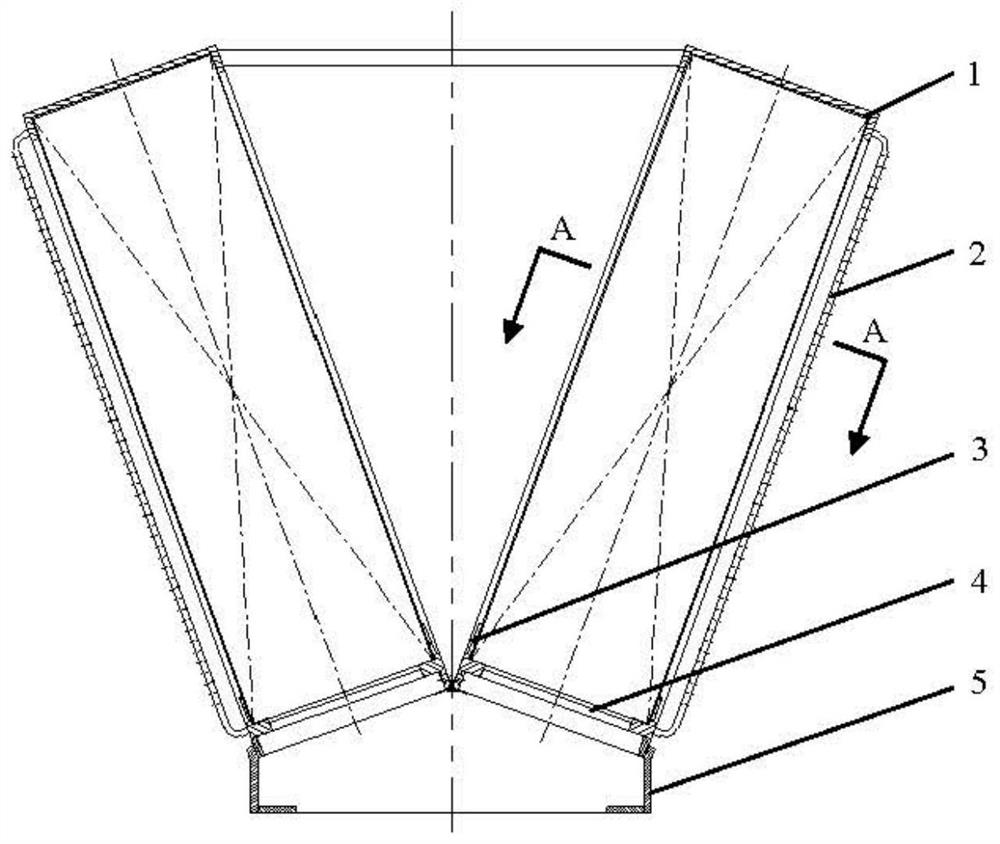

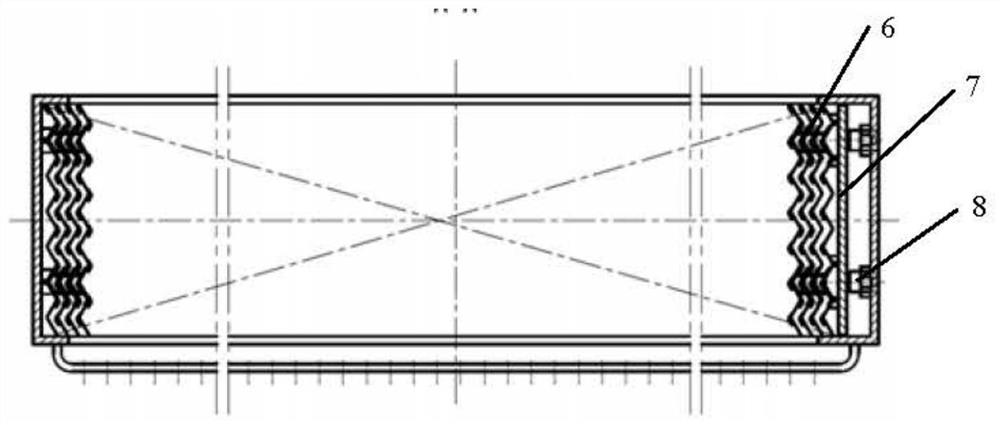

[0021]Such asFigure 1 to Figure 3 As shown, the steam-water separation unit for the steam-water separator reheater of the present invention includes two Y-shaped symmetrically arranged separation components, the separation component is composed of a frame component and a corrugated plate component, the corrugated plate component is arranged on the frame component Inside, the frame assembly includes a top support 1, an inlet vent plate 2, a bottom support 4, and a drainage groove 5, and the drainage groove 5 is arranged at the lower part of the bottom support 4.

[0022]In this embodiment, the inlet air-perforating plate 2 is provided with air holes with a diameter of 12.7 mm arranged in a regular triangle. The inlet homogenizing orifice plate 2 has the function of uniformly distributing the wet steam entering the separation unit, preventing local airflow from being too large and affecting the overall separation efficiency.

[0023]In this embodiment, the bottom support 4 mainly plays a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com