Woven health care textile fabric

A textile fabric and weaving technology, which is applied in the field of woven textile fabrics, can solve the problems of difficult production and processing, high cost, and reduced health care functions, and achieve the effects of excellent strength, simple production and processing process, and saving recycling space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

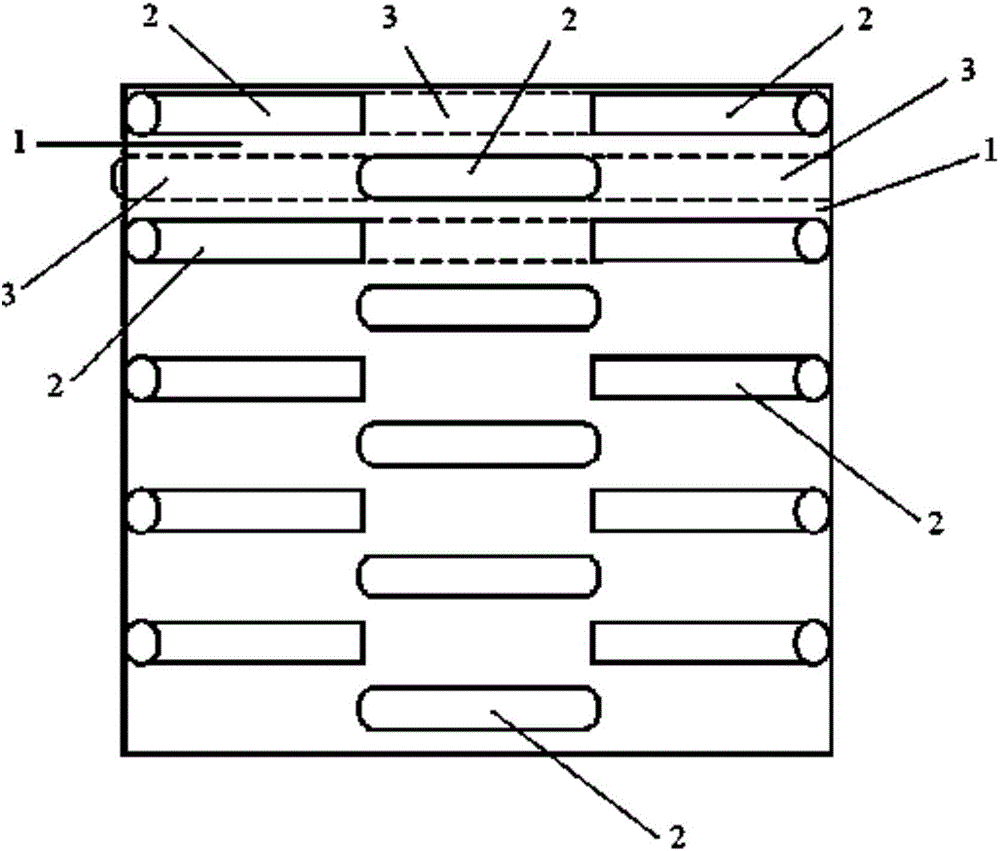

[0016] Embodiment 1: Weaving is carried out on the dobby loom, the arrangement mode of front pipe 2 and back pipe 3 is referring to figure 1 , the main part 1 of the fabric is a plain weave, the front tube 2 and the back tube 3 places, each using 32 weft yarns, and the main part 1 of the fabric uses 16 weft yarns.

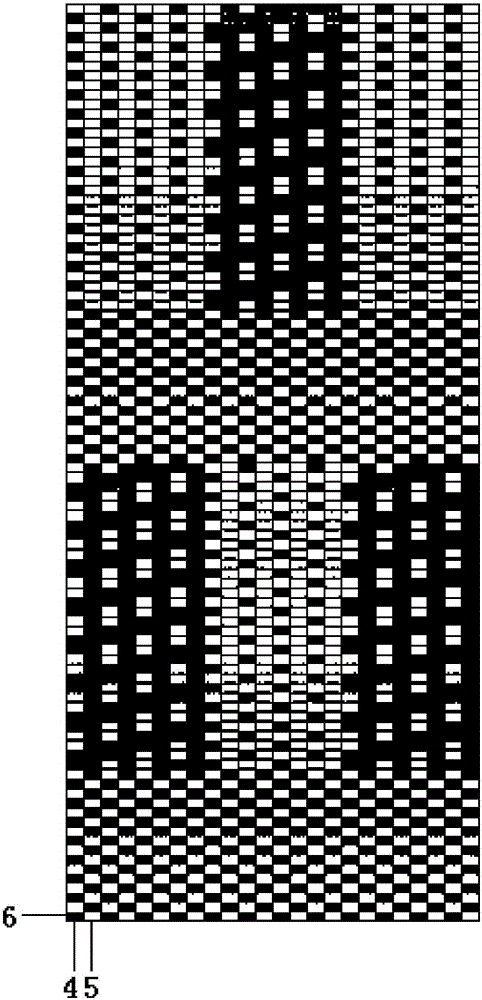

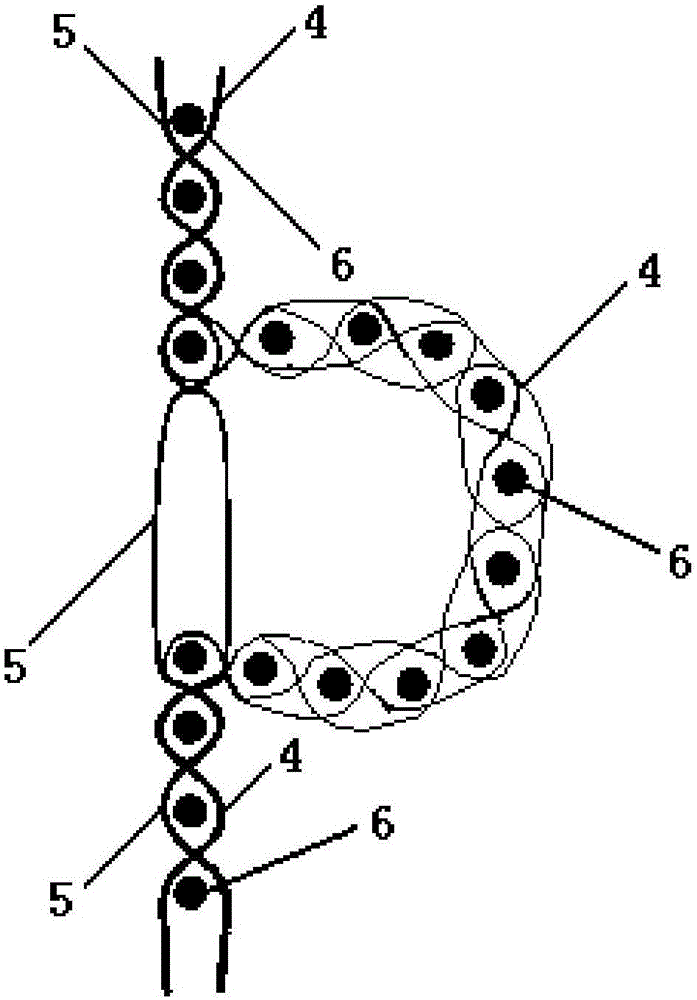

[0017] see figure 2 , the warp yarns are partitioned in the front tube structure and the back tube structure, and the arrangement ratio is A warp 4: B warp 5 = 1:1. different weaving beams, so that the respective let-off and tension can be controlled separately, so as to form tubes that meet the design requirements. When weaving the main body 1 of the textile fabric, the tension of the first warp 4 and the second warp 5 is consistent, and the weft yarn 6 is interwoven according to the plain weave. In the process of weaving the front tube 2 and the back tube 3, when weaving the first two weft yarns 6 , B warp 5 stops forward feeding and does not participate in in...

Embodiment 2

[0021] For weaving on a jacquard loom, the arrangement of front tube 2 and back tube 3 can be found in Figure 4 , the main part 1 of the fabric is a plain weave, and the front tube 2 and the back tube 3 places each use 24 weft yarns, and the main part 1 of the fabric uses 24 weft yarns.

[0022] The warp yarns are partitioned in the front tube structure and the reverse tube structure, and the arrangement ratio is A warp 4: B warp 5 = 1:1. When weaving on the machine, A warp 4 and B warp 5 need to be placed in two Different weaving beams, so that the respective let-off and tension can be controlled separately, so as to form tubes that meet the design requirements. When weaving the main body 1 of the textile fabric, the tension of the first warp 4 and the second warp 5 is consistent, and the weft yarn 6 is interwoven according to the plain weave. In the process of weaving the front tube 2 and the back tube 3, when weaving the first two weft yarns 6 , B warp 5 stops forward fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com