Investment casted die mould auxiliary moving device

A compression mold and investment casting technology, which is applied in the field of mold auxiliary devices, can solve the problems of inability to adapt to mass production, low productivity, slow speed of push-pull molds and easy sabotage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

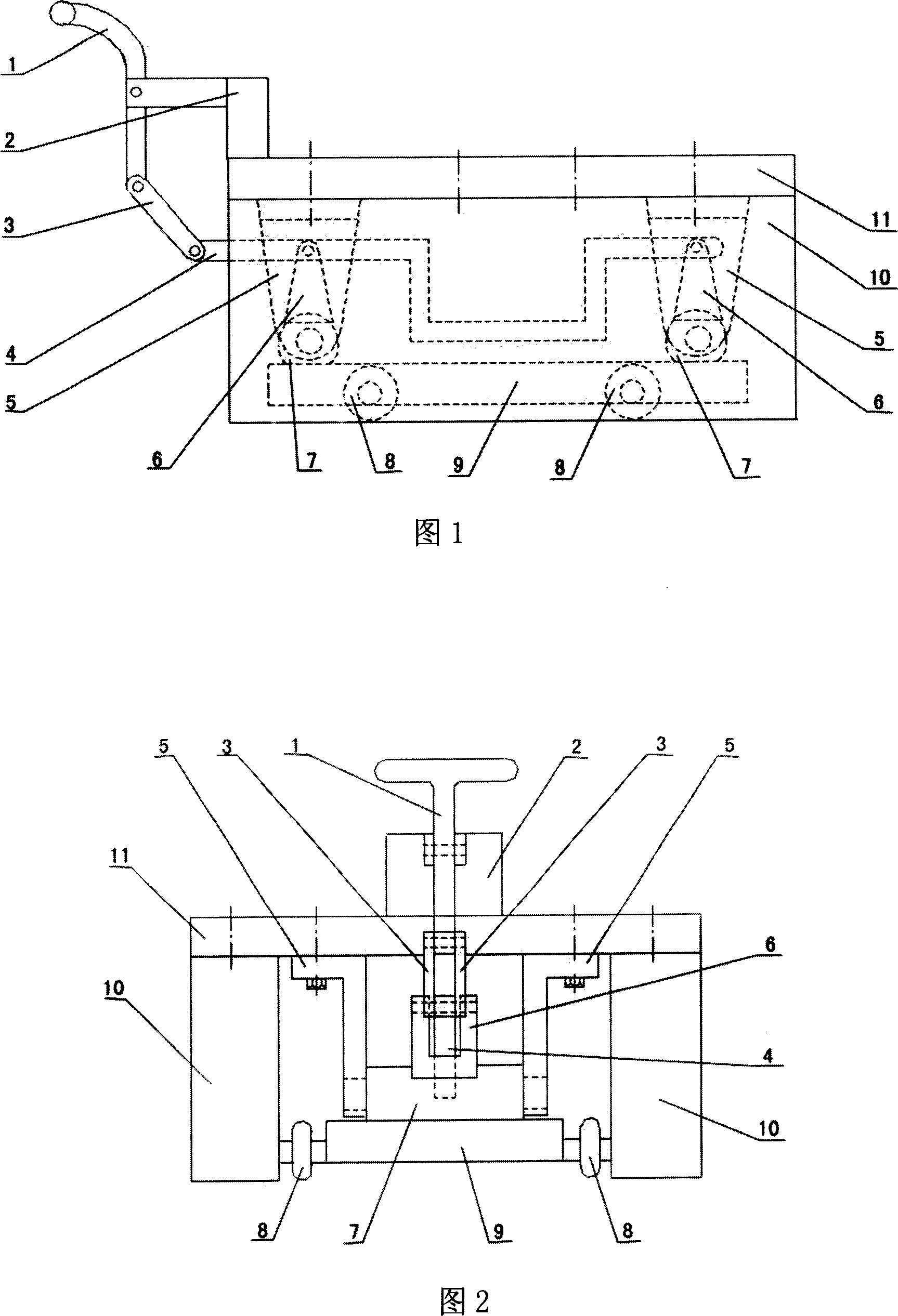

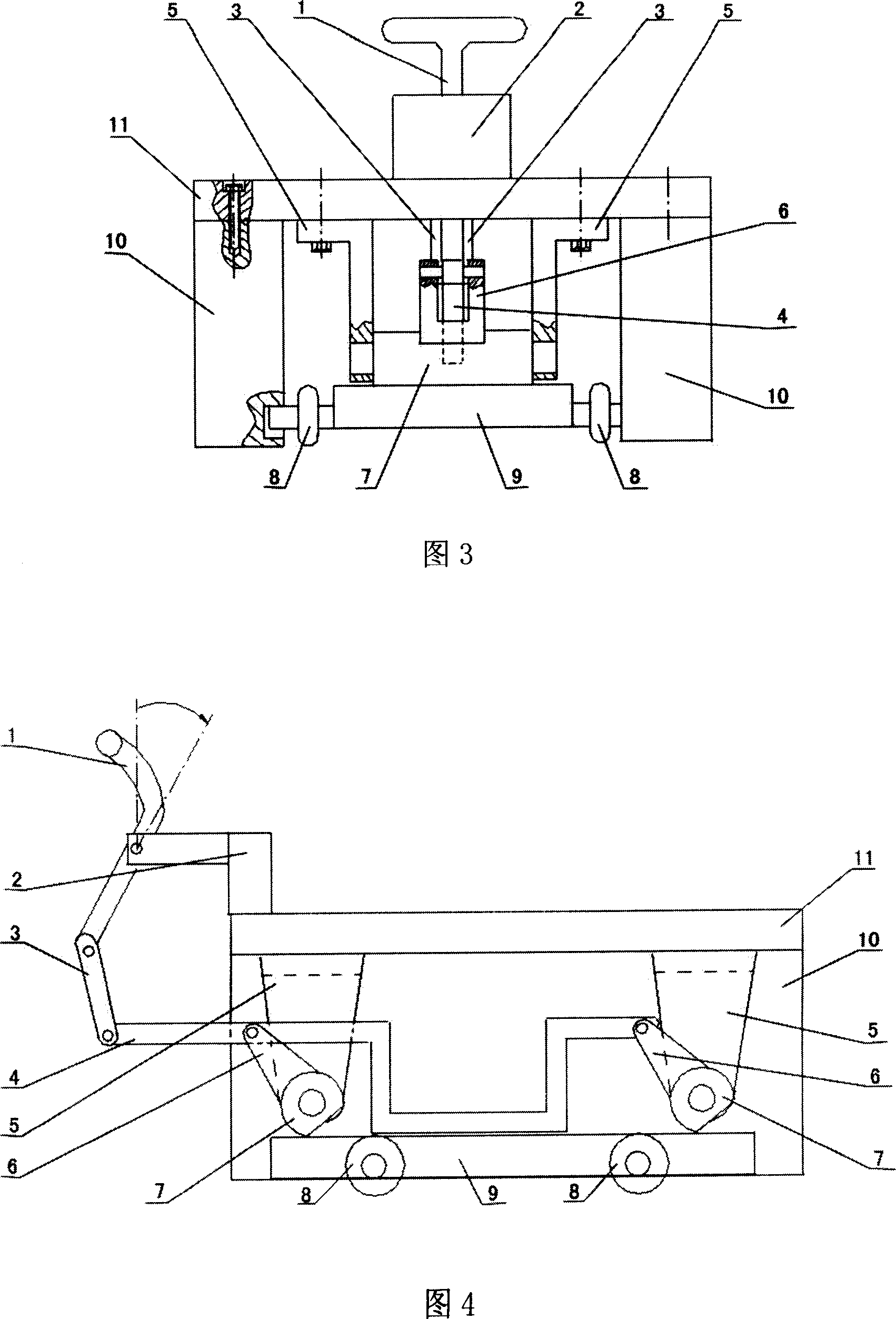

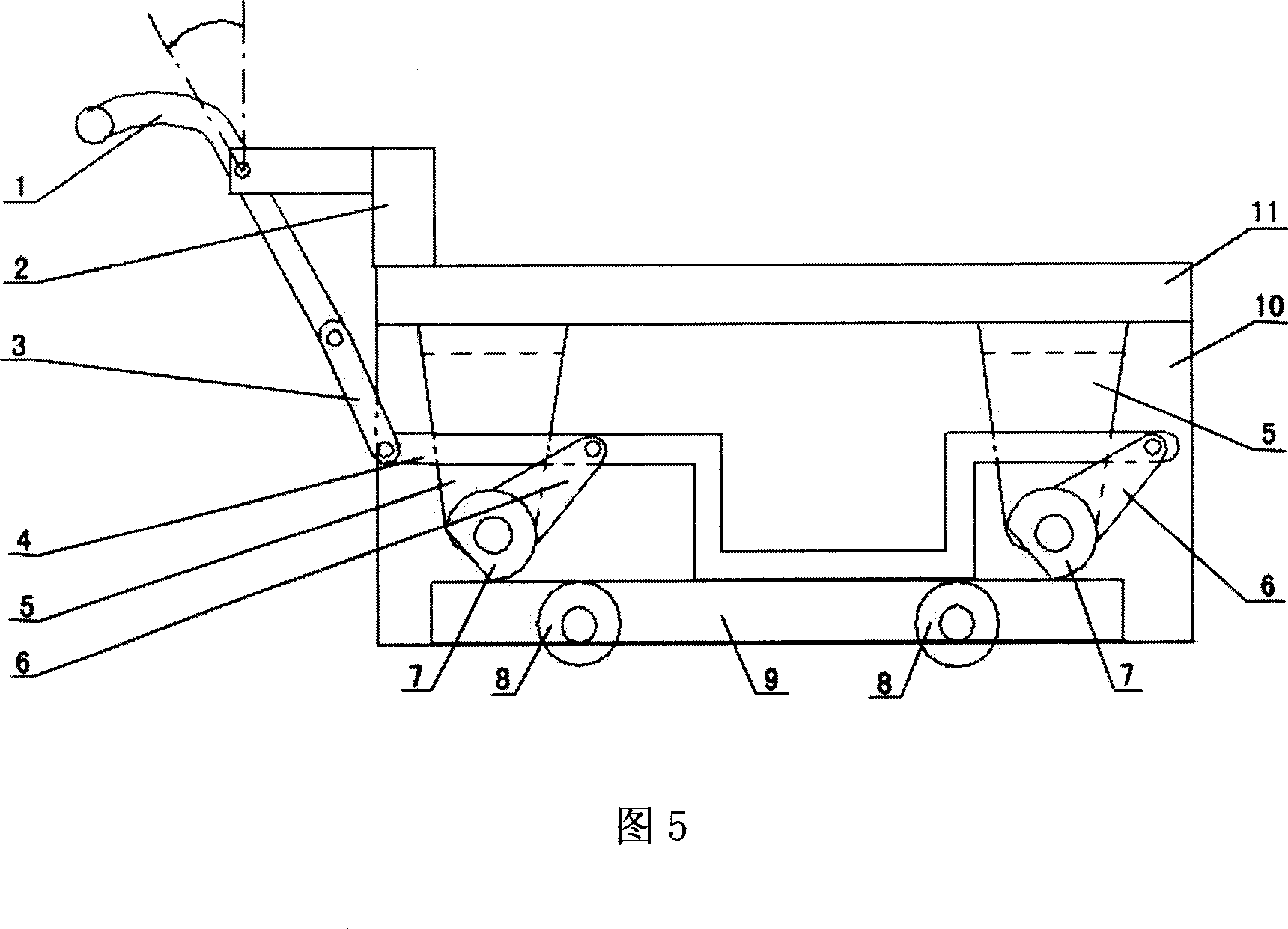

[0018] The auxiliary moving device for the pressure mold of investment casting shown in FIG. 1 is composed of a handle 1 , a flat plate 11 and a roller 8 . On the left side of the upper end surface of the flat plate 11, a supporting platform 2 is welded at the middle position along the width edge, and a round hole is correspondingly opened on the two arms of the supporting platform 2 near the ends. The lower end surface of the flat panel 11 is along the length Both sides of the direction are flush with the edge and are symmetrically installed with two bearing blocks 10 with bolts. Four grooves are correspondingly opened at a distance along the lengthwise direction near the bottom surface on the inner side. Four rollers 8 are symmetrically installed on the four axes of the bottom plate 9 and the four axes are respectively placed in the four grooves of the load-bearing block 10. And can move up and down, the position of groove and the cooperative relation with base plate 9 axles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com