Hardware part casting working table

A technology for hardware parts and workbenches, which is applied in the field of metal parts casting workbenches, can solve the problems of inconvenient movement, heavy casting workbenches, and inability to fix rollers on the ground, etc., and achieves the effects of convenient operation, avoiding shaking, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

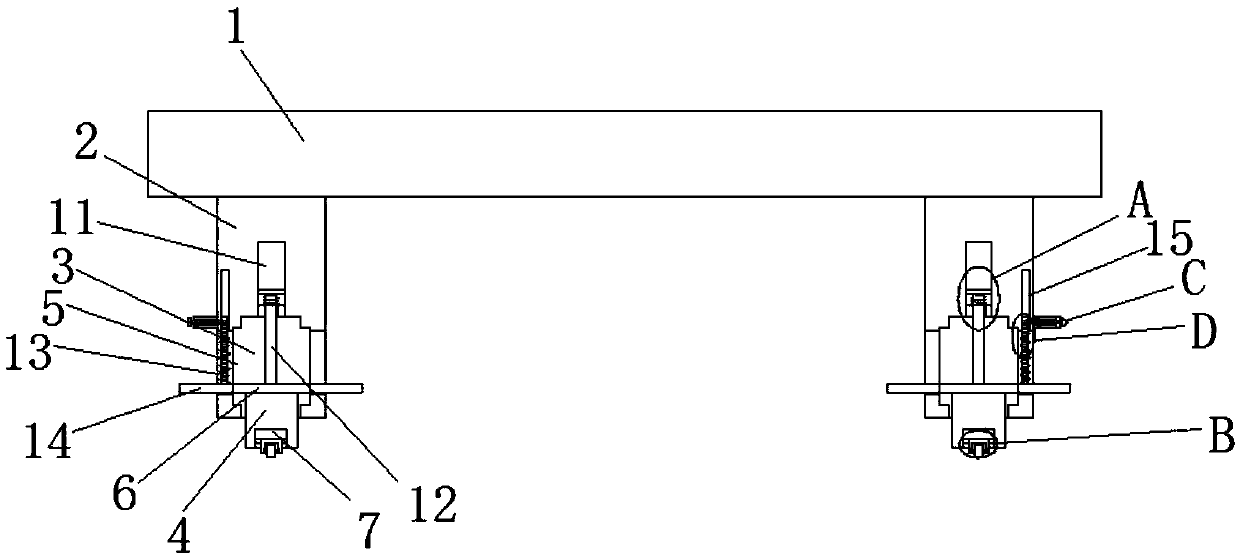

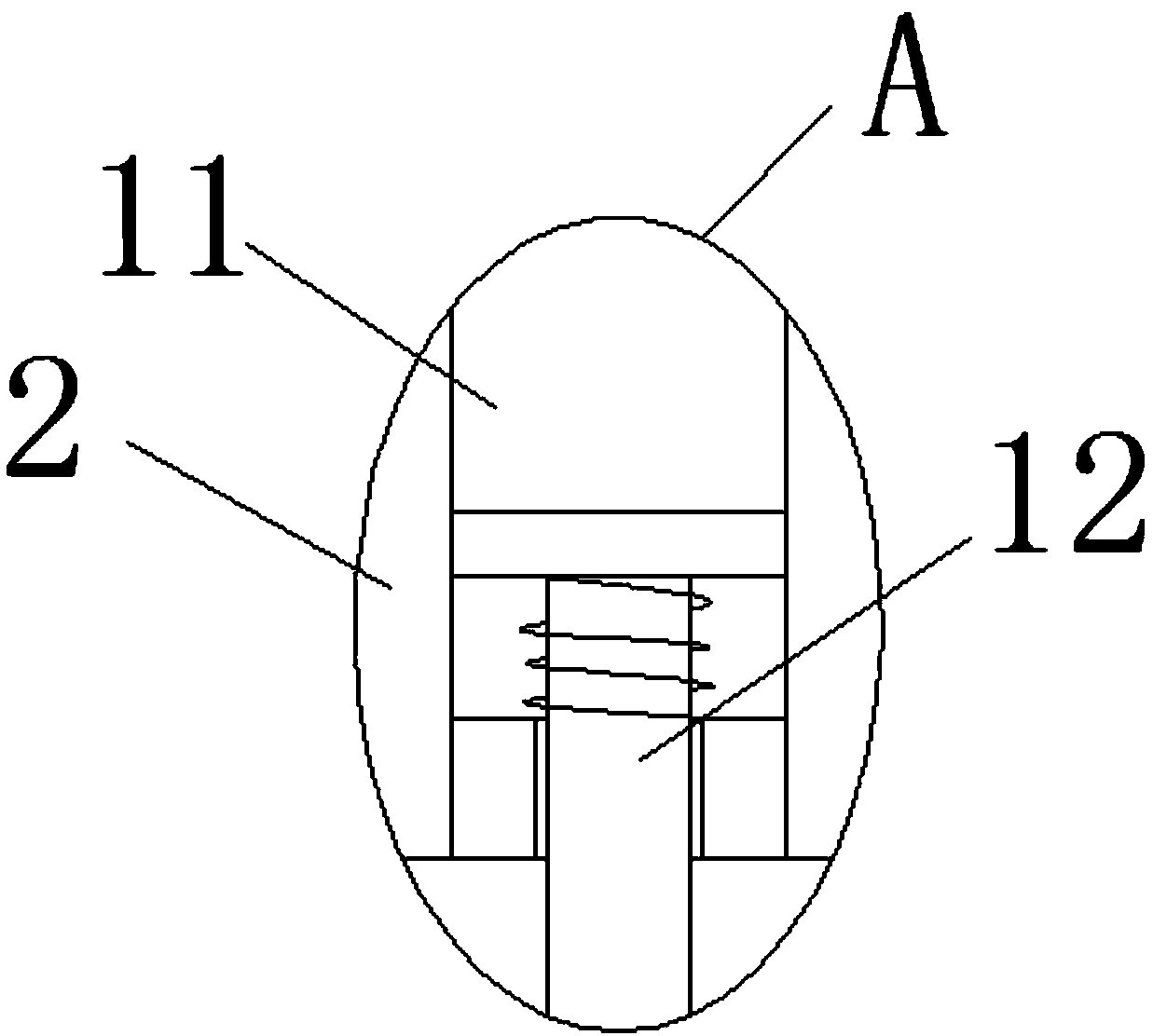

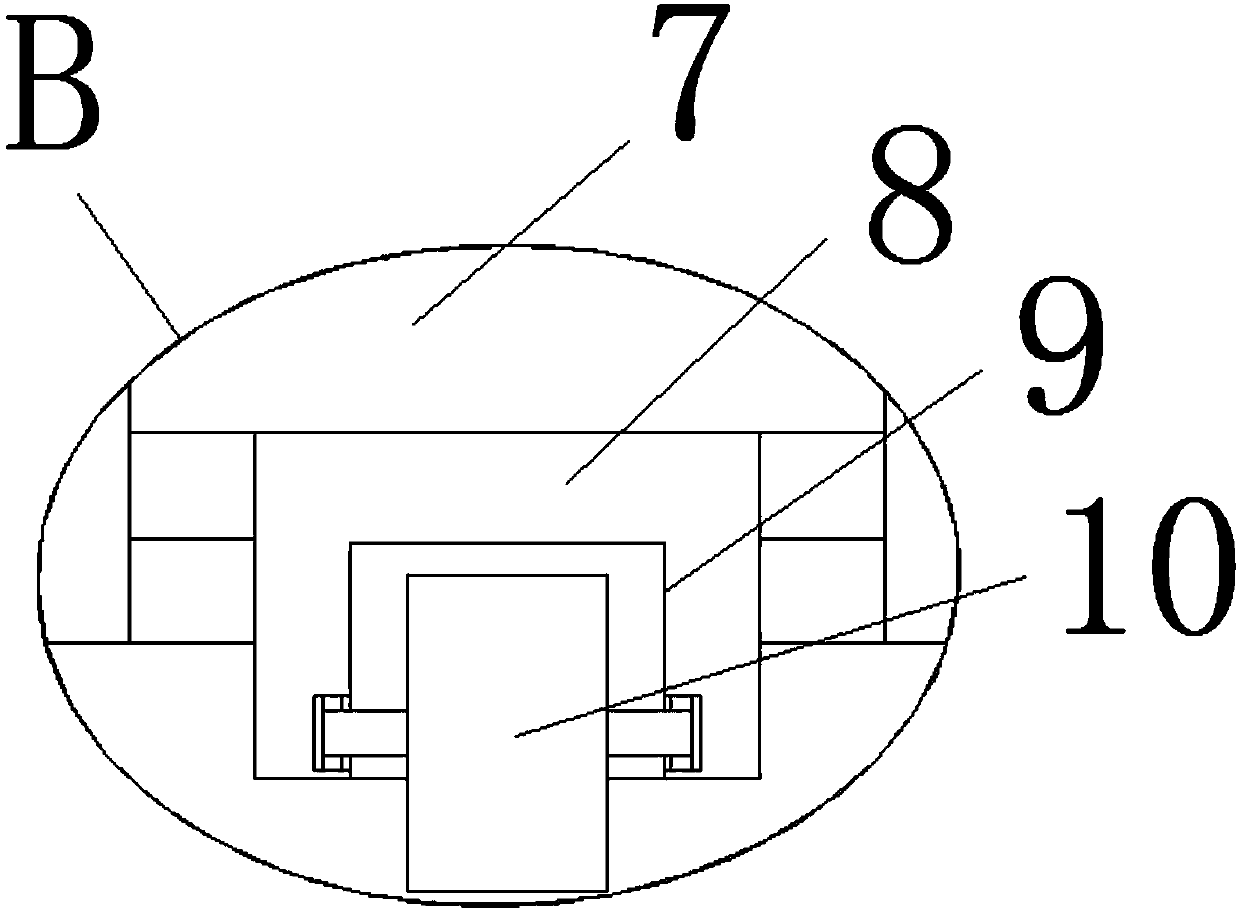

[0022] refer to Figure 1-5 , this embodiment proposes a casting workbench for hardware parts, including an operation platform 1, a plurality of support feet 2 are fixedly installed on the bottom of the operation platform 1, and a first installation groove 3 is opened on the bottom of the support feet 2, and the first installation groove A mounting block 4 is slidably installed inside the mounting block 3, and the bottom of the mounting block 4 extends to the outside of the first mounting groove 3. A telescopic assembly is arranged above the mounting block 4. The telescopic assembly includes symmetrical openings on the inner walls of the first mounting groove 3. The first limiting groove 5, the top of the mounting block 4 is fixedly installed with the first limiting block 6, and the two sides of the first limiting block 6 are respectively slidably installed in the corresponding first limiting groove 5, and the supporting feet 2 There are square through holes 13 symmetrically o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com