Four-station large rotary table

A four-station, turntable technology, applied in the direction of molding tables, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting molding line costs and reducing molding efficiency, so as to improve molding efficiency, save floor space, and compact equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

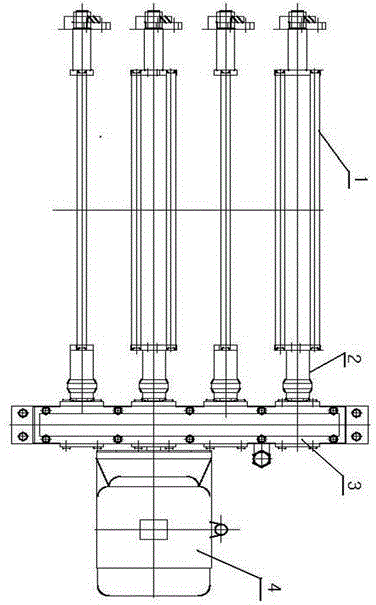

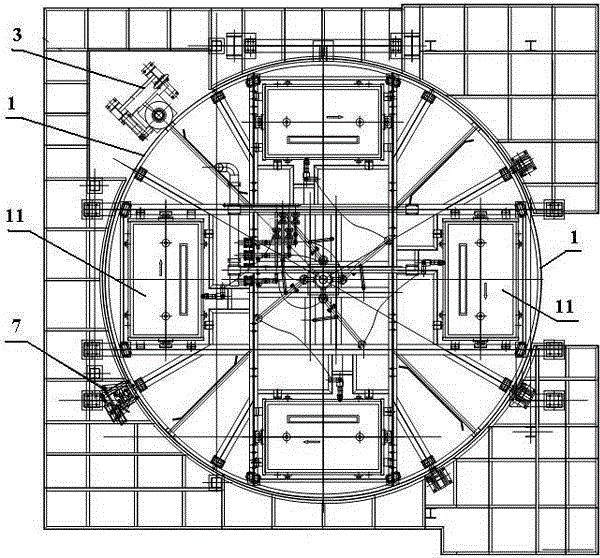

[0014] see figure 1 and figure 2 As shown, the present invention includes a support wall 8, a turntable 1, a support frame 10, and a walking wheel device 5. The support frame 10 is arranged on the support wall 8, and a support column 4 is provided below the support frame 10. A support plate 9 is arranged above the top, and the turntable 1 is connected with the support plate 9 through a center column 2, and the center column 2 is connected with the turntable 1 through a bearing mechanism, and the turntable 1 can rotate around the center column 2. A walking wheel device 5 is provided between the turntable 1 and the support plate 9, a vacuum system 6 is provided at the center of the upper surface of the turntable 1, the turntable 1 is circular, and a hydraulic motor drive system 3 and a positioning system are provided on the edge of the turntable 1. The locking device 7 and the traveling wheel device 5 can move on the support disc 9 driven by the rotation of the turntable 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com