Patents

Literature

76results about How to "Increase production quantity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel method for white fungus cultivation

InactiveCN101117621ASolve the contradiction between supply and demandExtended supply timeFungiTremellaPlanting seed

The present invention relates to a planting method of edible fungus, and provides a new method for white fungus planting. The method includes steps as follows: the raw material of a substrate is mixed, bagged and sterilized, the planting seed of white fungus is inoculated and planted, and the grew fungus is picked, the fungus age of the planting seed of the white fungus is 6 to 10 days; the planting steps are described as follows: after being inoculated, the planting seed is planted for 16 days when the planting temperature is 23 to 25 DEG C, adhesive plaster at the opening of an aperture is torn, the aperture is not expanded, after 5 to 6 days, the side of the opening of the aperture of a fungus bag, namely the side of the fungus bag is pulled a crack at the bag film by a blade. The application provides that the most ideal fungus age of the planting seed of white fungus is 6to 10 days, compared with the decided fungus age, the ideal fungus age is shortened 5 to 9 days, thereby quickening the fungus seed supplying time, increasing production amount of fungus seed, efficiently solving the supply and demand contradictory of fungus seed at the midseason for white fungus producing, and meeting the demands for big amount of production. In addition, the new technology that the fungus bag increases oxygen and produces white fungus provided by the application has the advantages of convenient operation, quickened white fungus producing, few pedicel heads of white fungus, and higher quality than the original products.

Owner:钟冬季

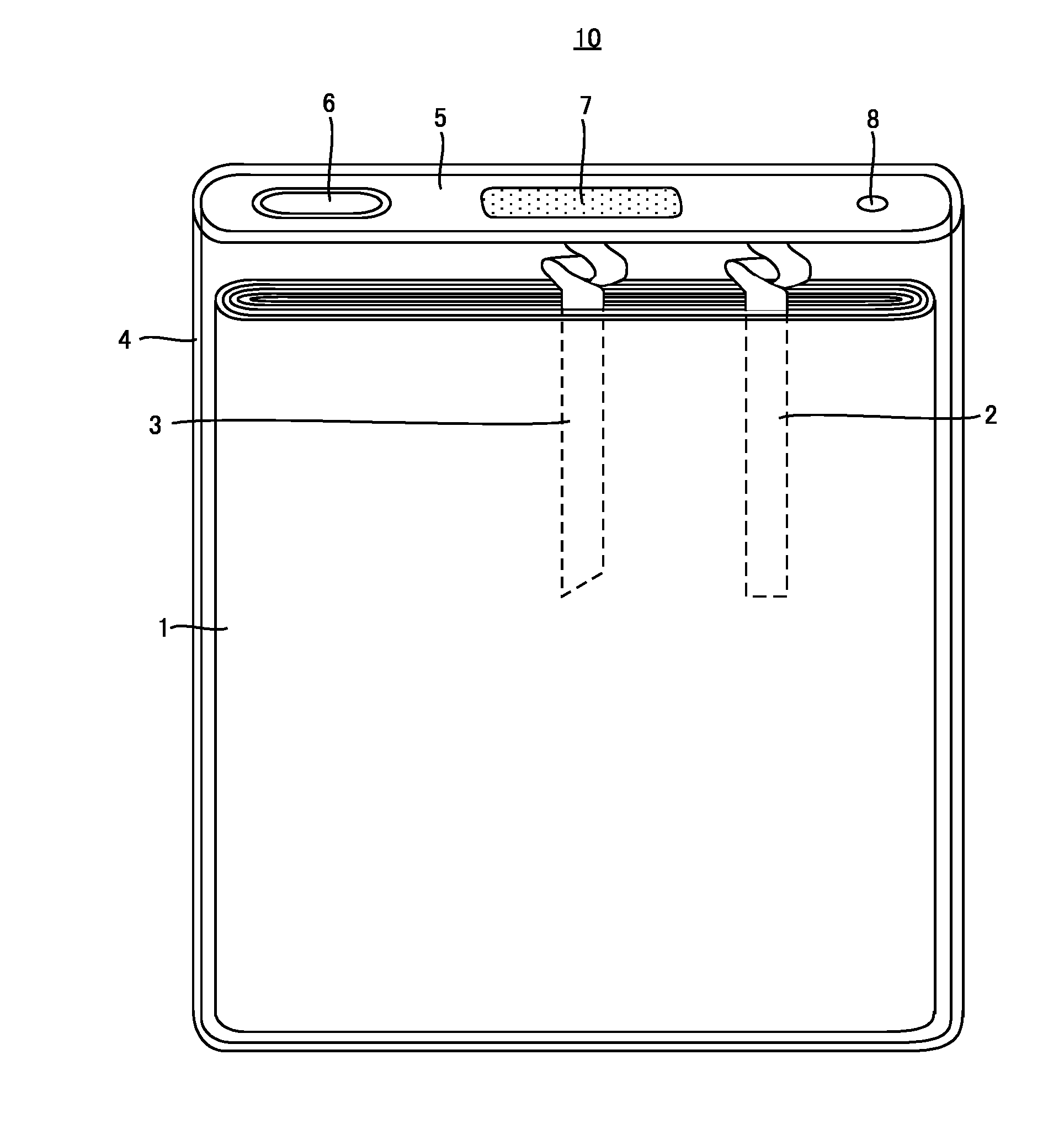

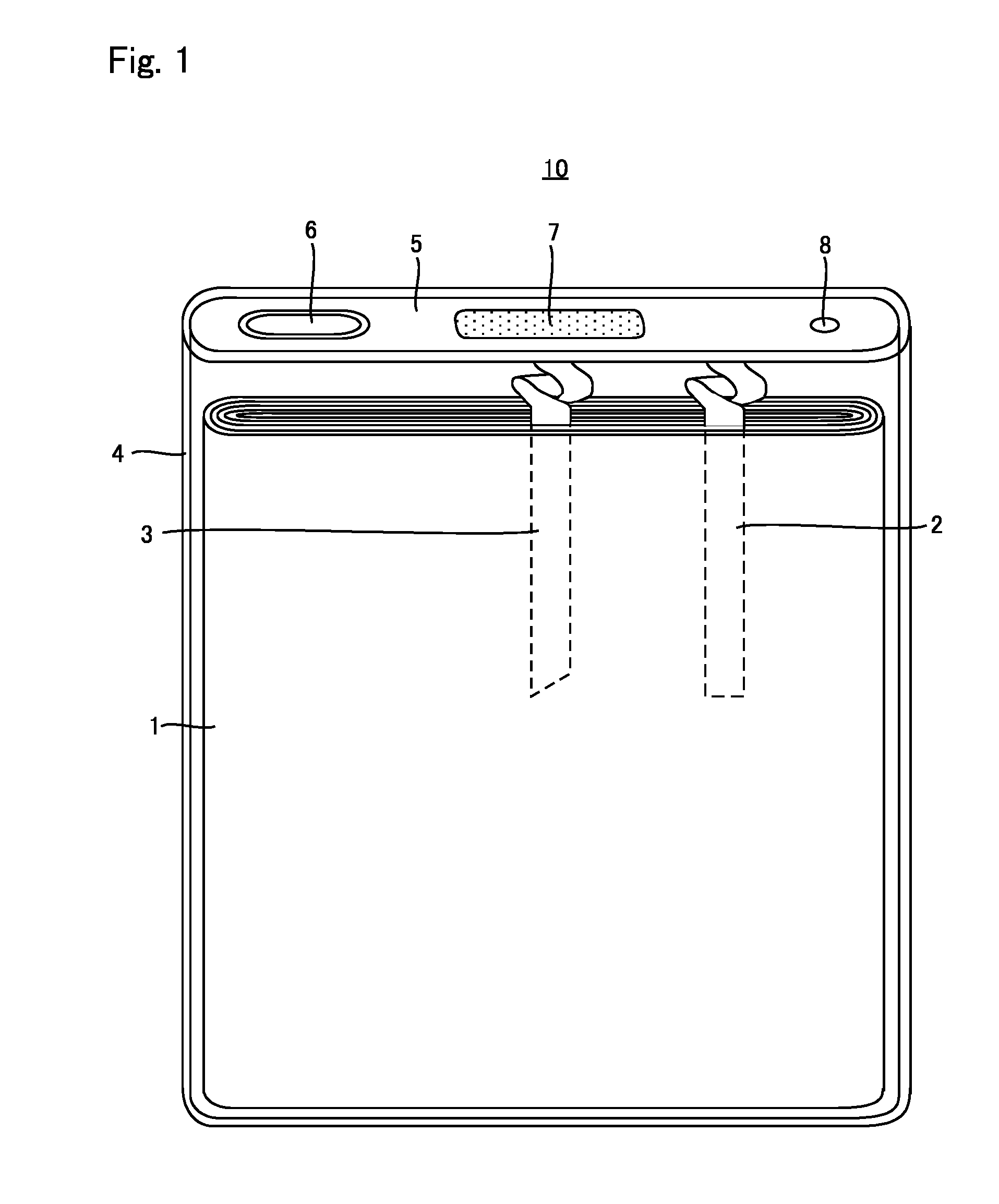

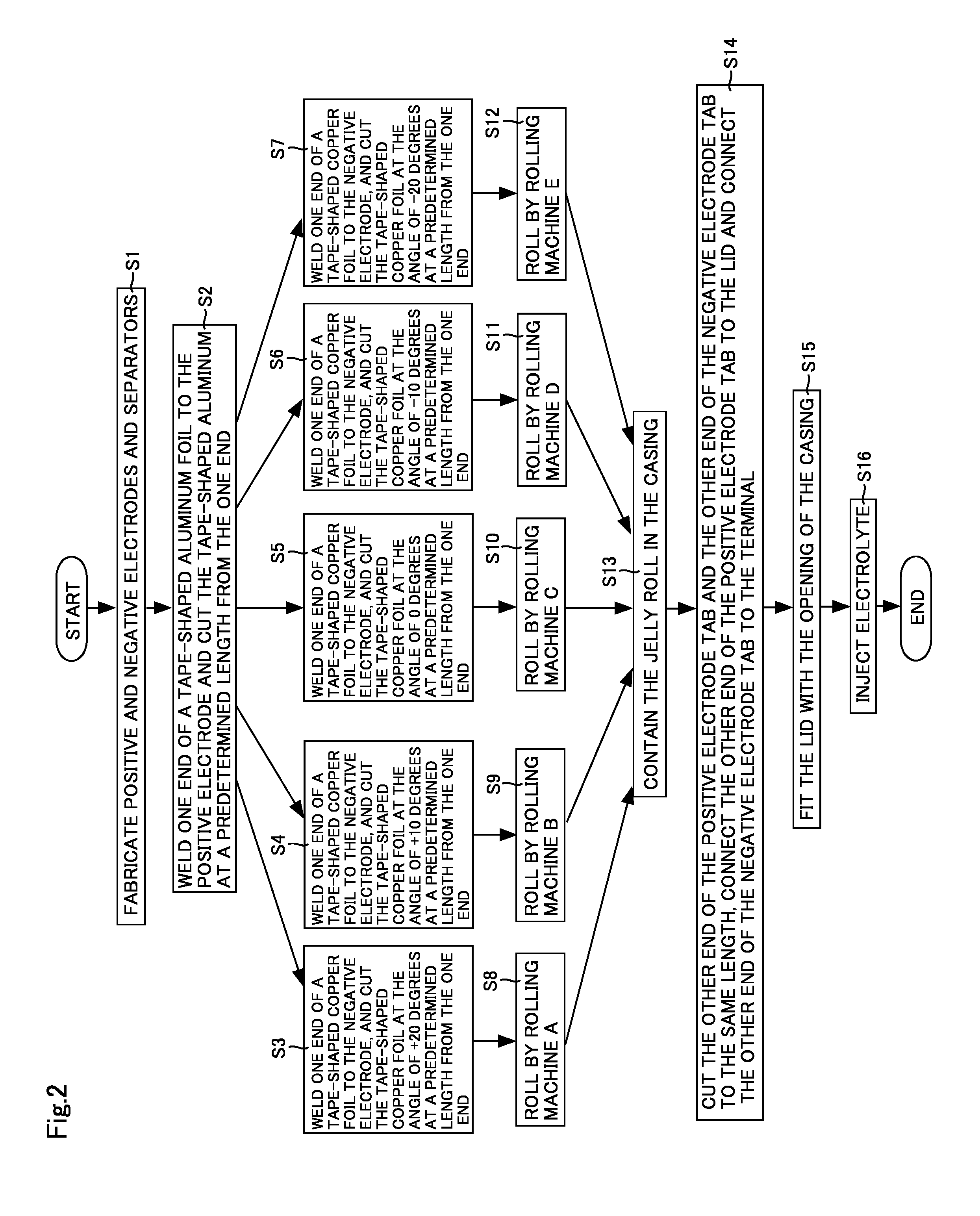

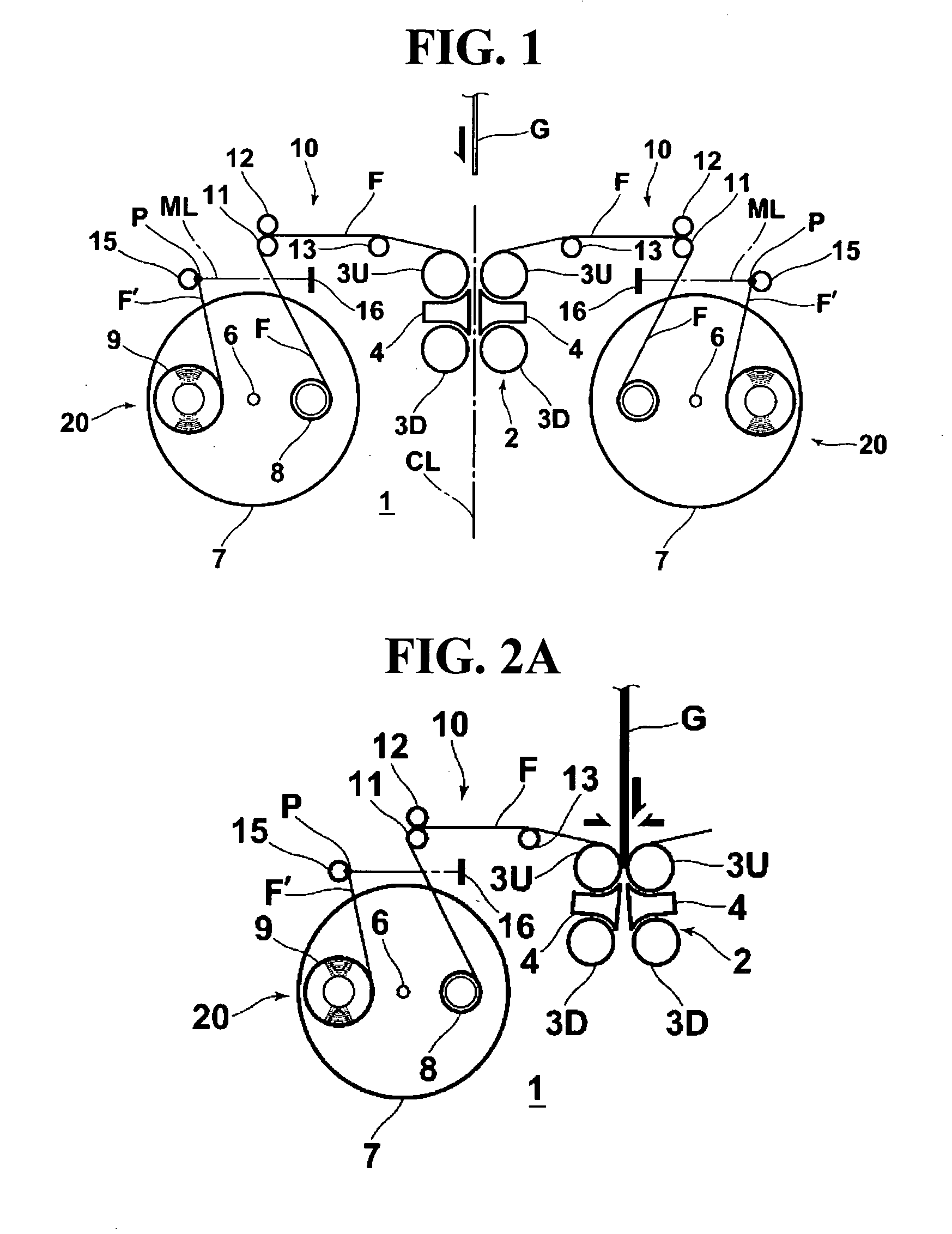

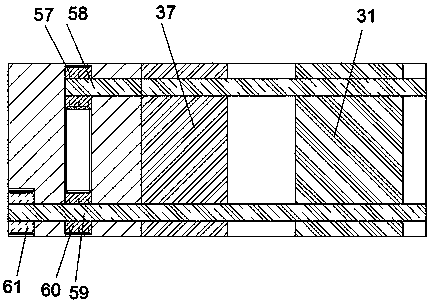

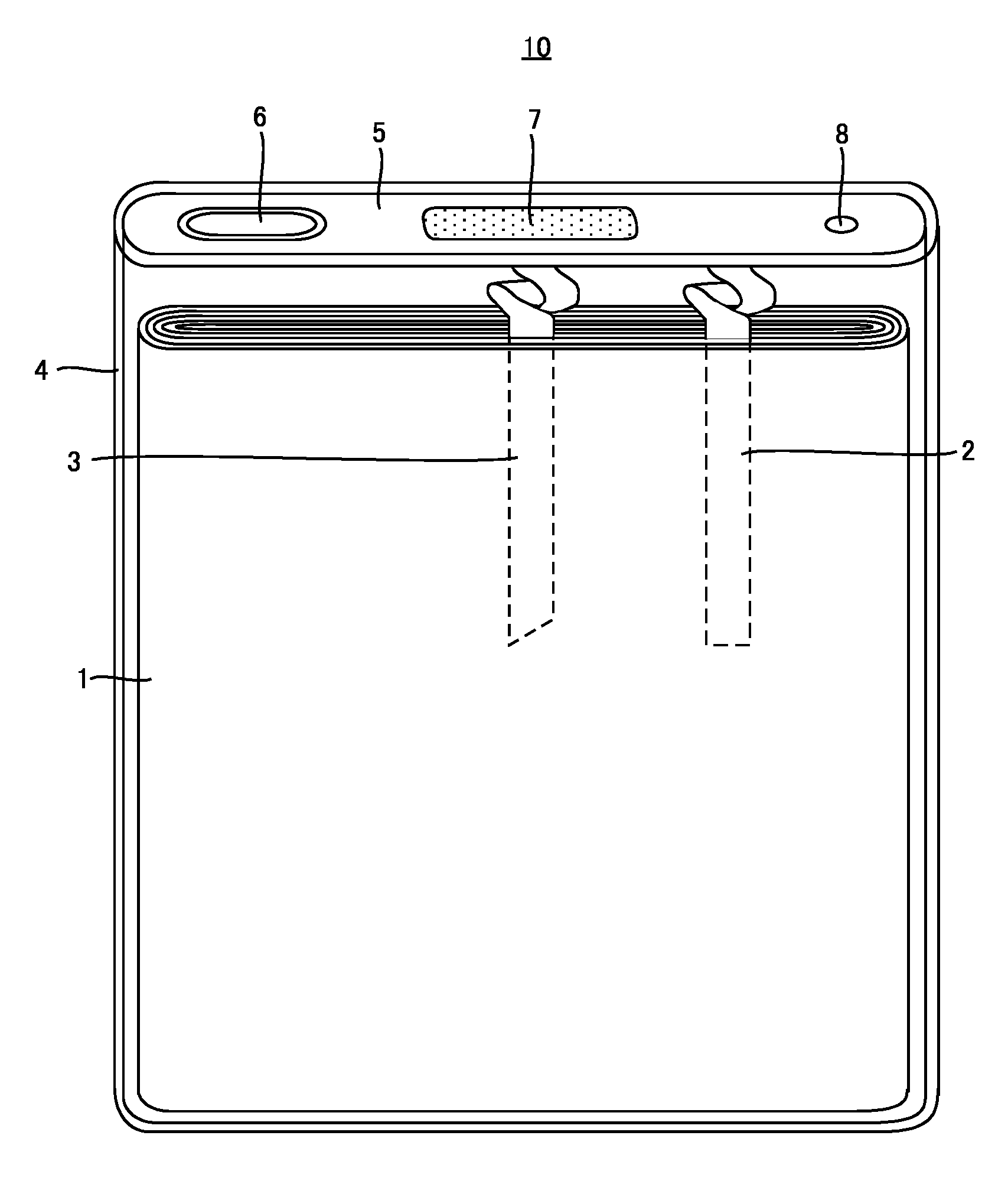

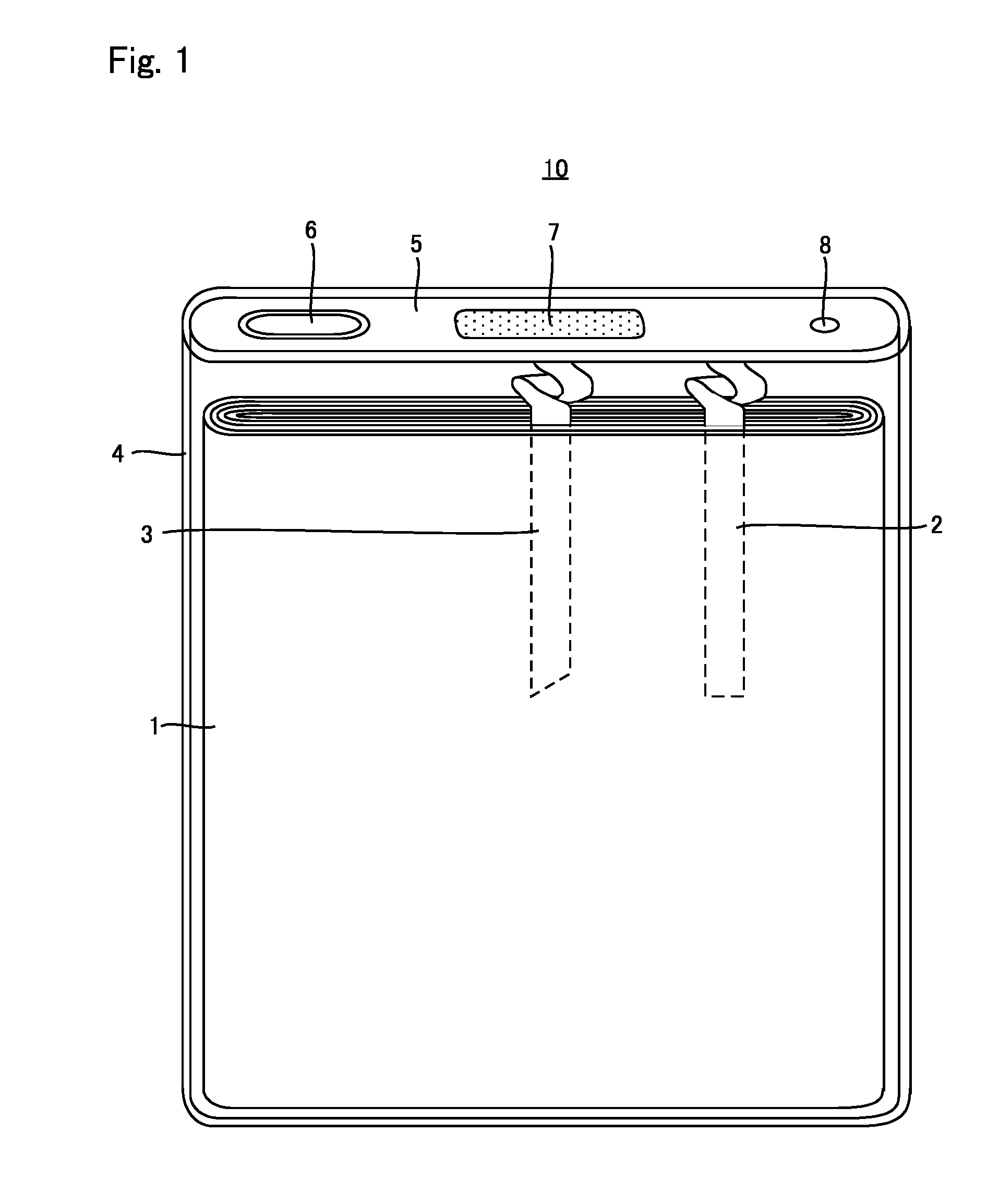

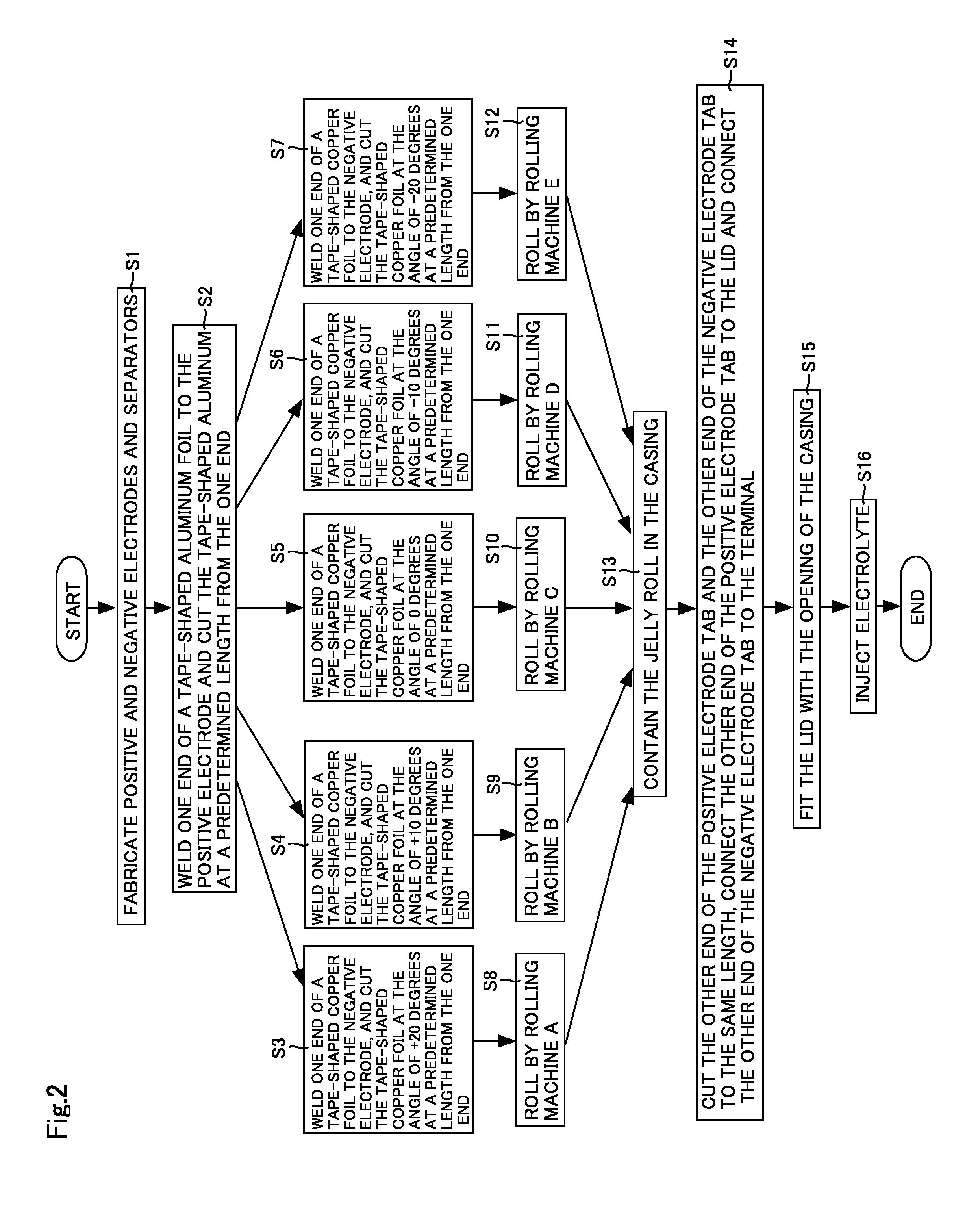

Lithium-ion secondary battery

ActiveUS20120121968A1Achieve traceabilityIncrease production quantityAssembling battery machinesFinal product manufactureLithiumElectrical battery

A lithium-ion secondary battery is provided where the production process line that fabricated it can be identified. The lithium-ion secondary battery includes a jelly roll, a positive electrode tab, a negative electrode tab, a positive electrode can, and a lid. The jelly roll is made by rolling the positive electrode and the negative electrode with an interposed separator, and is contained in the casing. The positive electrode tab has one end connected to the positive electrode of the jelly roll and the other end connected to the lid. The negative electrode tab has one end connected to the negative electrode of the jelly roll and the other end connected to a terminal provided on the lid. The other end of the negative electrode tab has a shape with a cut at a cut angle determined in accordance with the production process line that fabricated the lithium-ion secondary battery.

Owner:MAXELL HLDG LTD

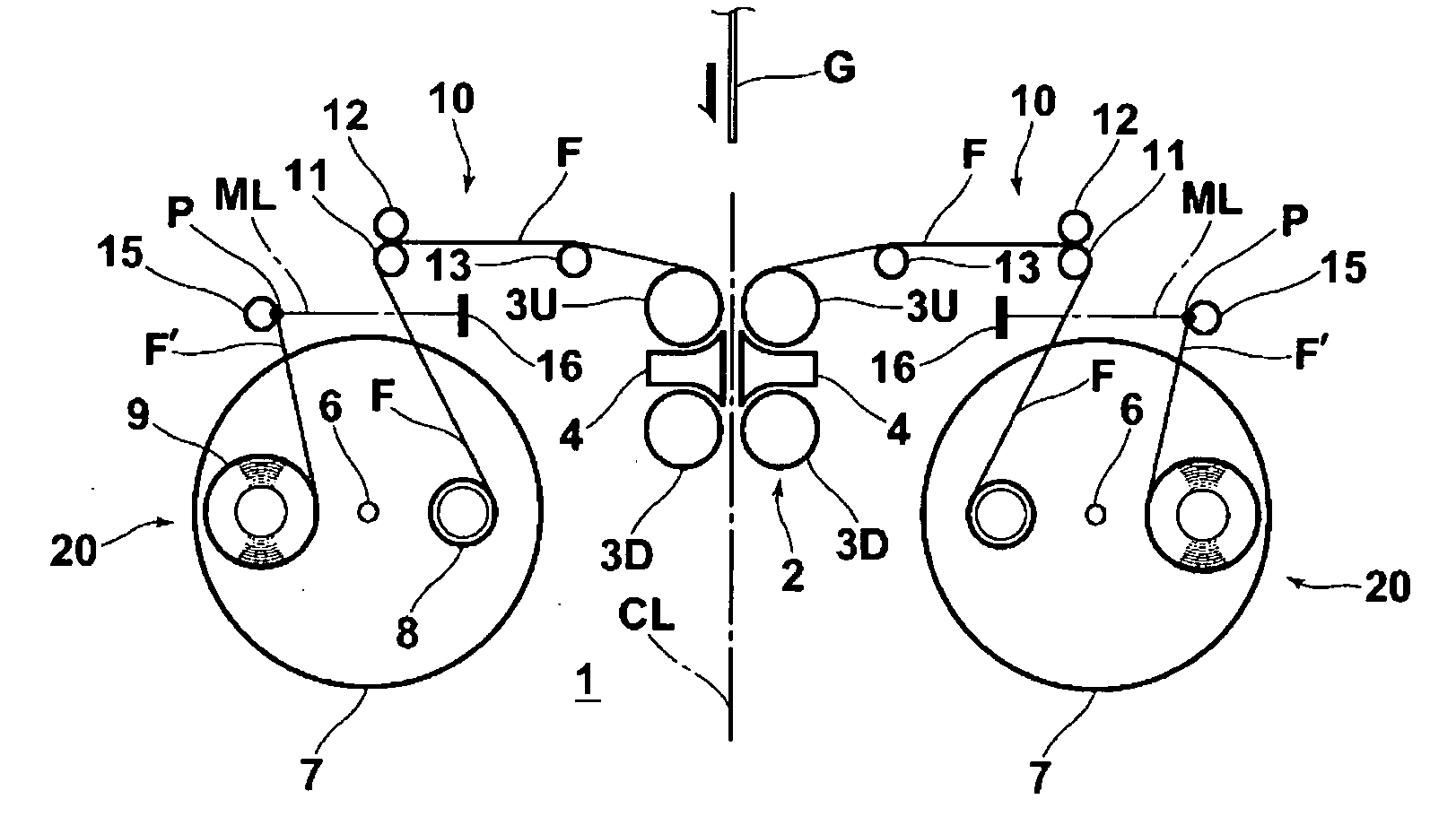

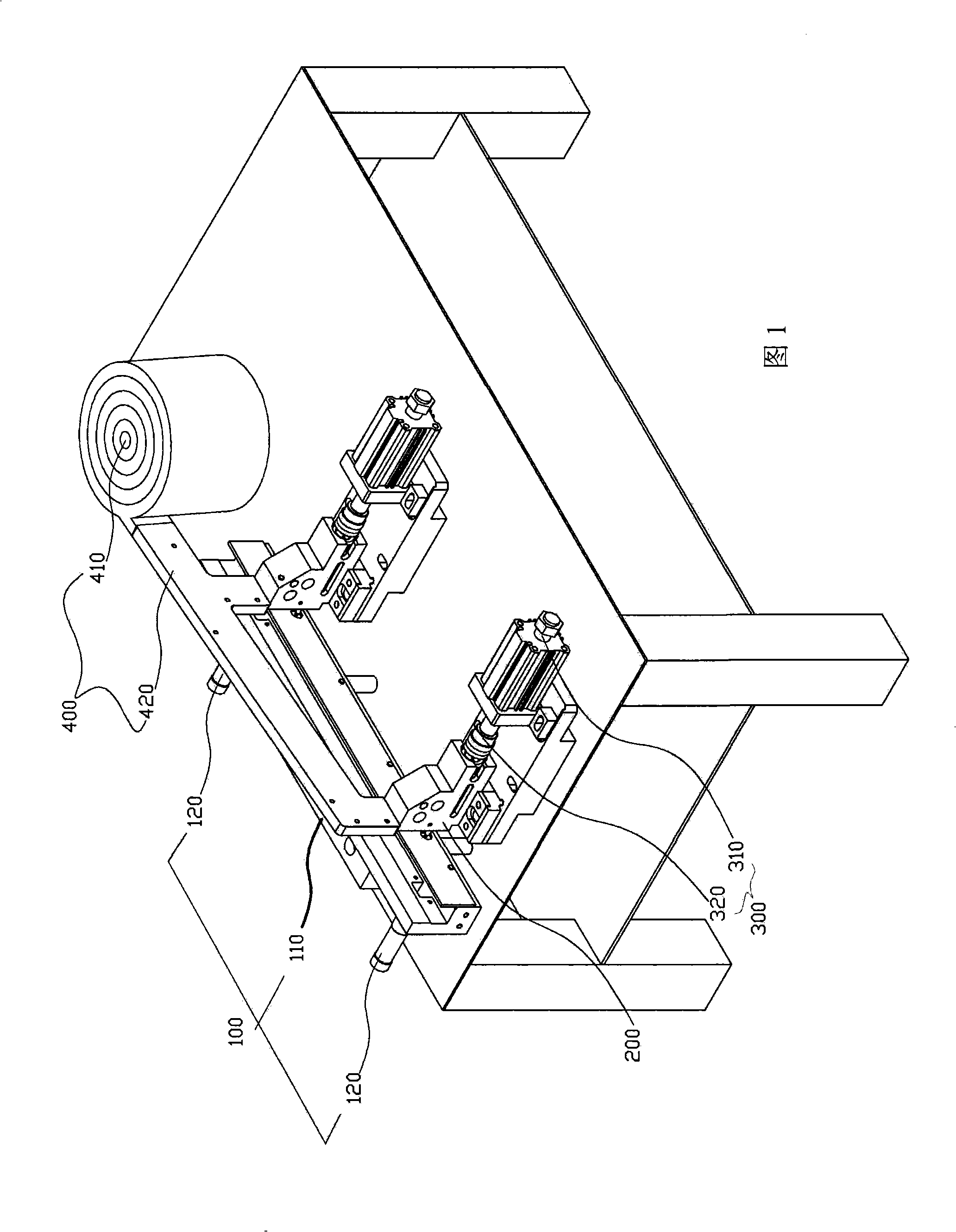

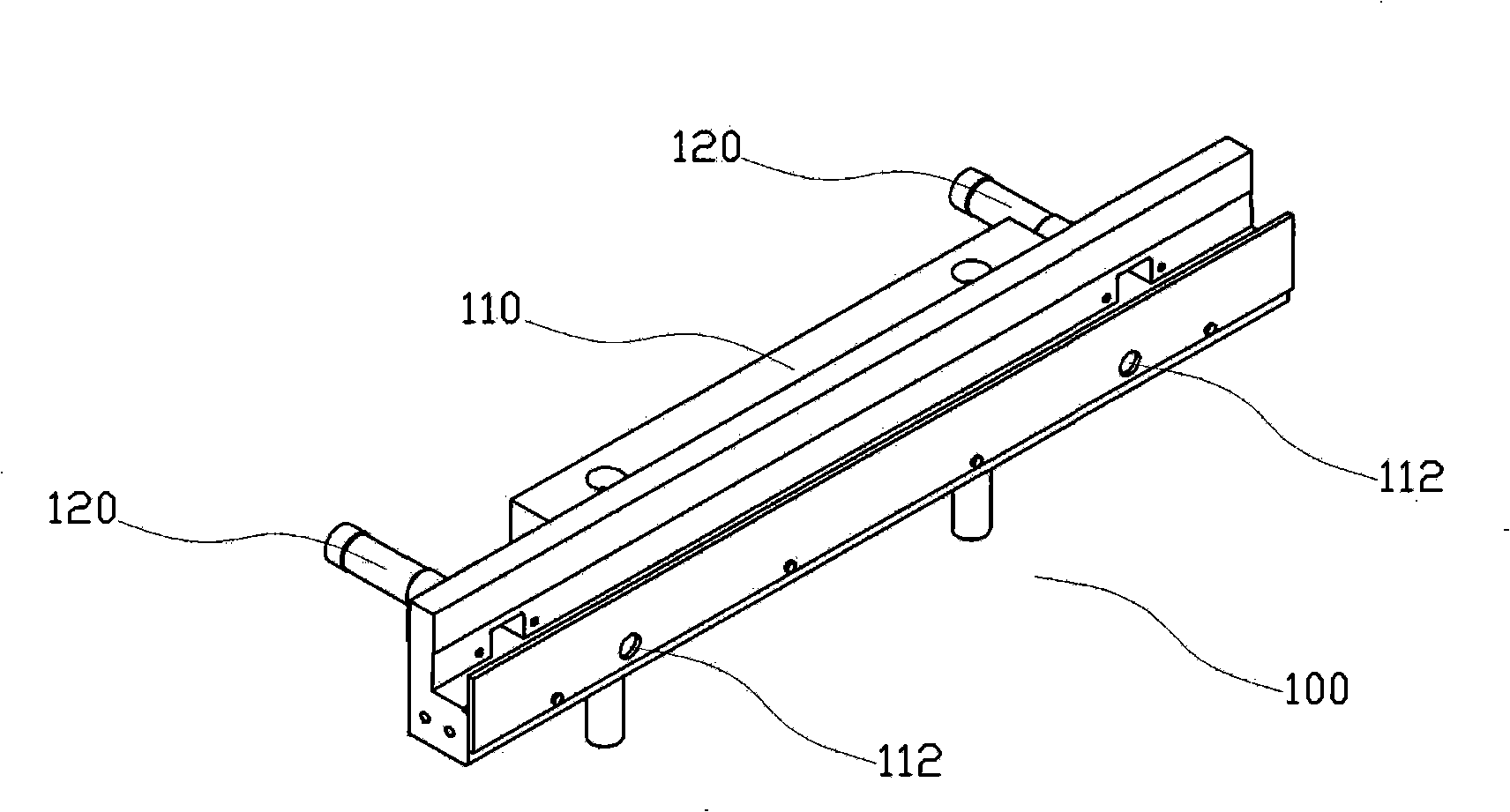

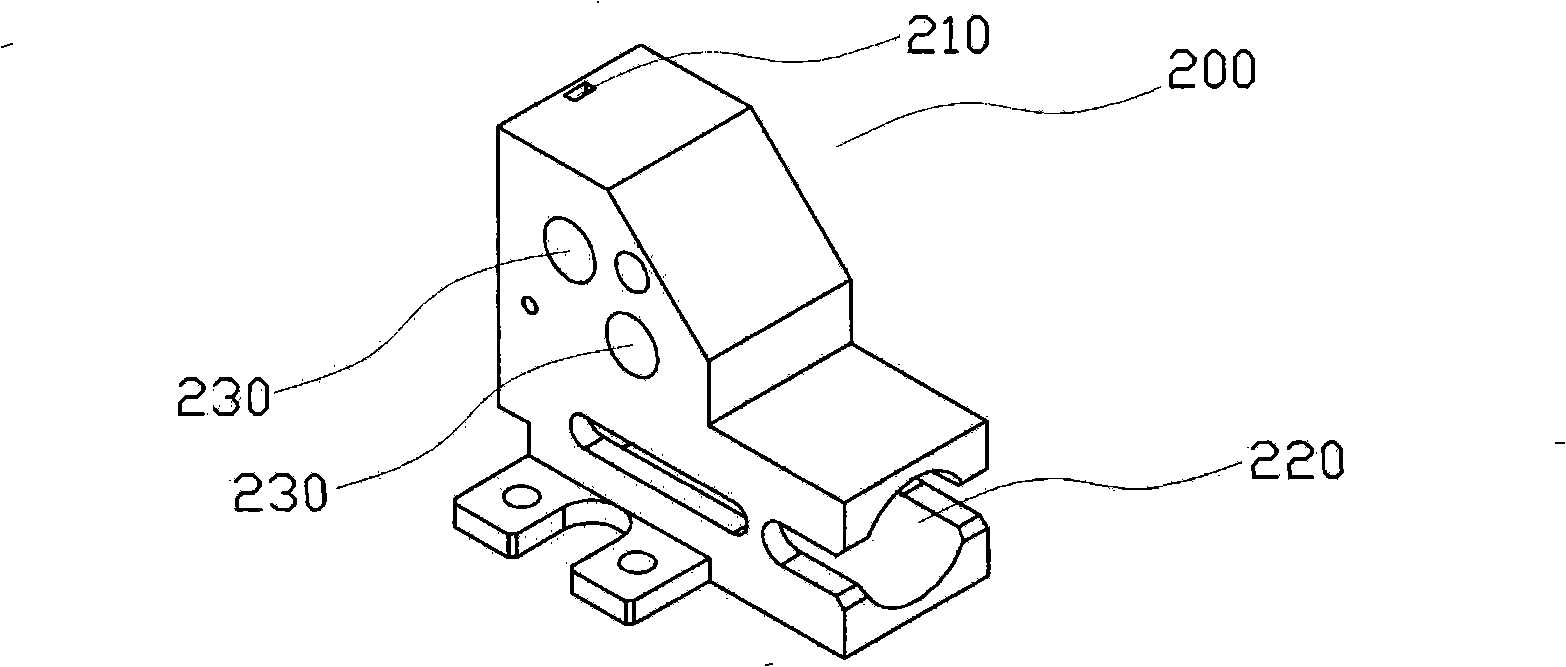

Film laminating apparatus

InactiveUS20090301659A1Increase production quantityReduce extra spaceLamination ancillary operationsLaminationEngineeringMechanical engineering

Owner:CORNING INC

Method for utilizing test tube potatoes for efficiently producing detoxication breeder's seeds

InactiveCN105766574AIncrease productionSolve the degradation problemAgriculture gas emission reductionCultivating equipmentsDiseaseGibberellin

The invention discloses a method for utilizing test tube potatoes for efficiently producing detoxication breeder's seeds.The method comprises the following steps of green net house preparation, test tube potato germination acceleration, matrix preparation, cultivation frame preparation, environmental disinfection, sowing, management after planting and breeder's seed harvesting and storing, wherein the test tube potatoes whose dormancy is not broken are soaked with a gibberellin solution for germination acceleration; a matrix is formed by mixing vermiculite and mushroom dreg, and potassium sulfate compound fertilizer is applied to the matrix; sowing is carried out according to the amount of 250 particles / m<2>, the planting distance is 5 cm, and the line distance is 8 cm; management after planting comprises temperature management, water management, matrix cultivation, fertilization management and disease and pest preventing management; after being harvested, the breeder's seeds are sorted and packaged into detoxification seed potato net bags and stored at the temperature ranging from 2 DEG C to 4 DEG C.The method has the advantages of being high in yield, high in economic benefit, storable and convenient to transport, secondary infection of pathogenic bacteria is eradicated, the potatoes can be planted mechanically, convenience is brought to cultivation and management, the survival rate is high, and the method has great significance in demonstration and popularization of production scales of detoxication breeder's seeds.

Owner:李文超 +2

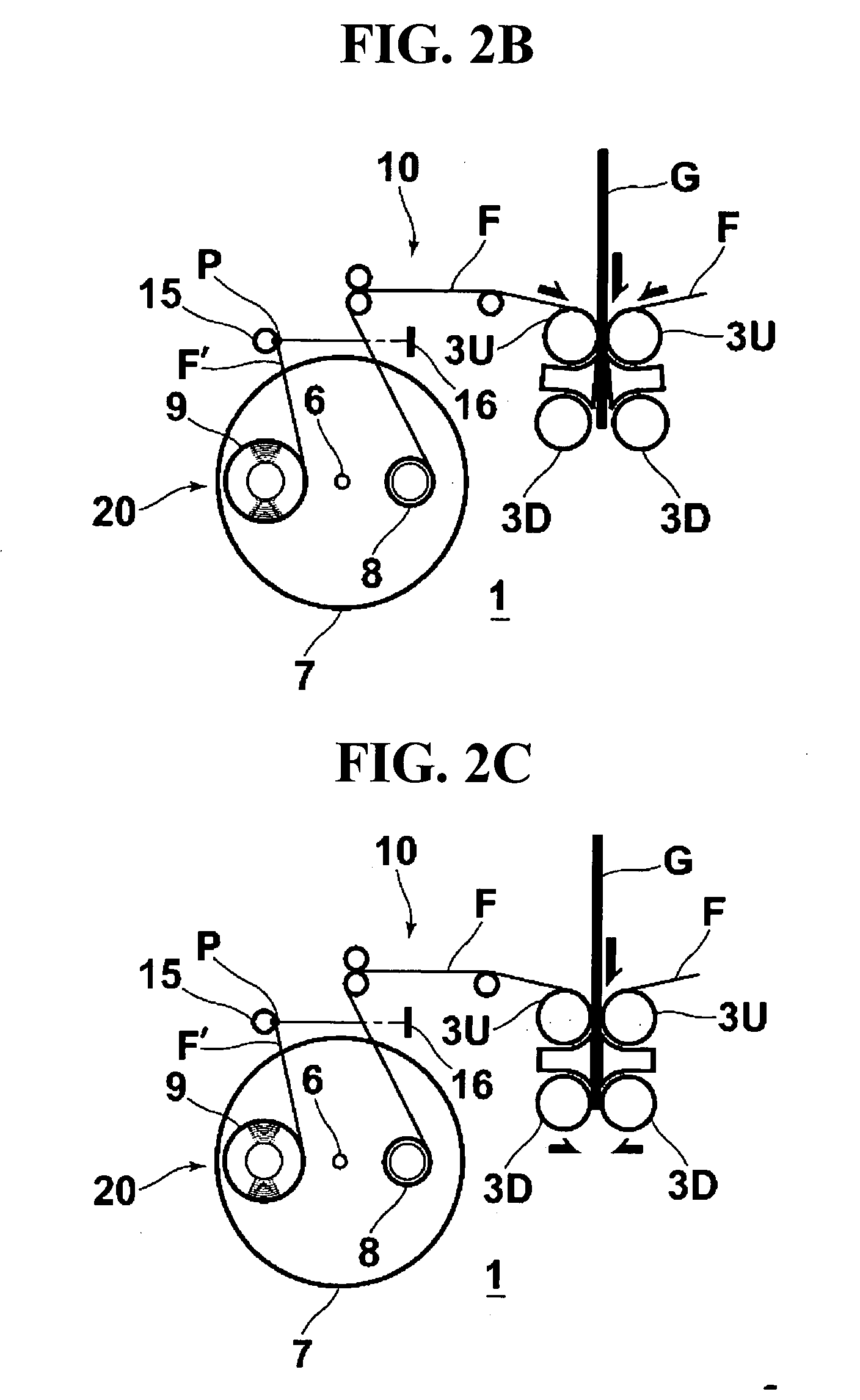

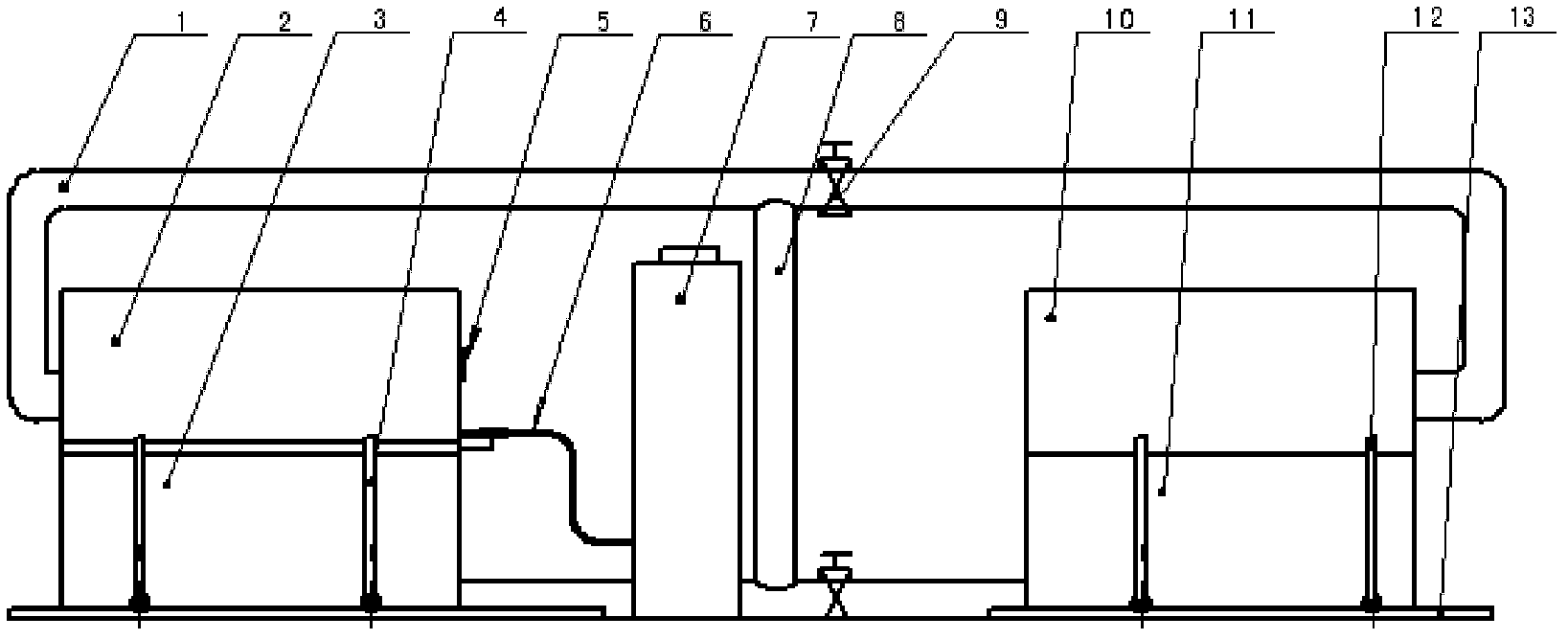

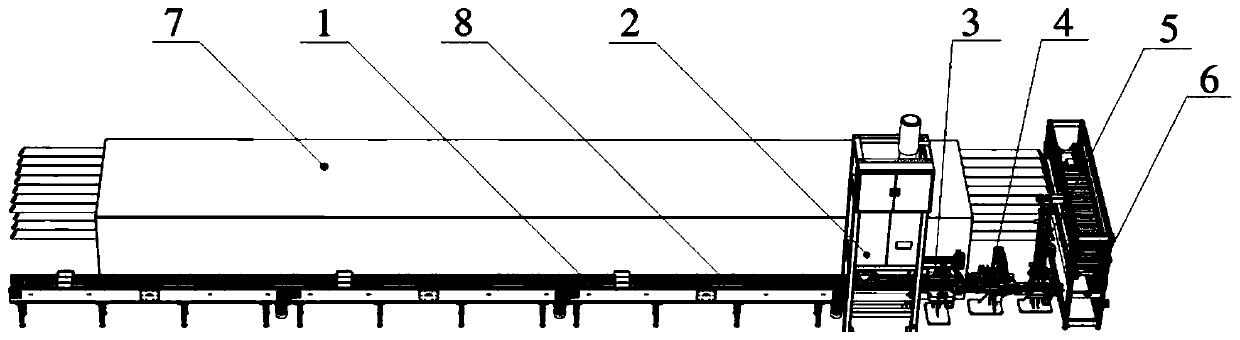

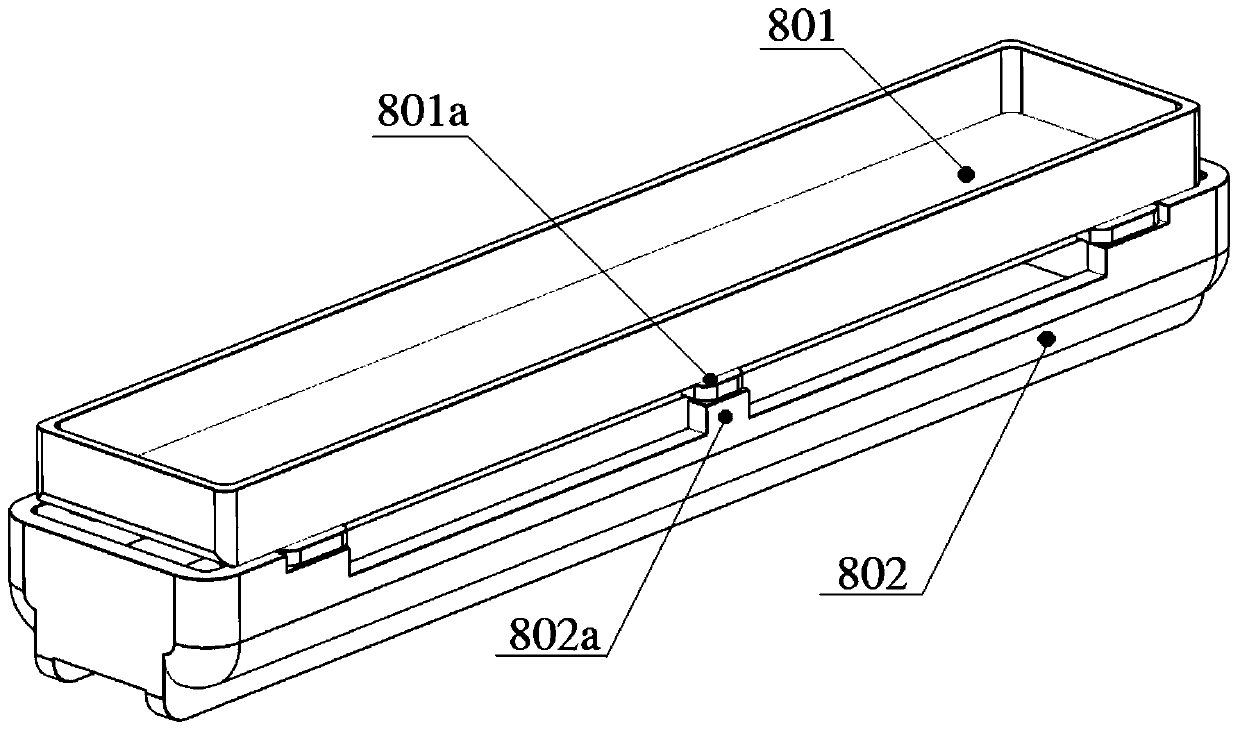

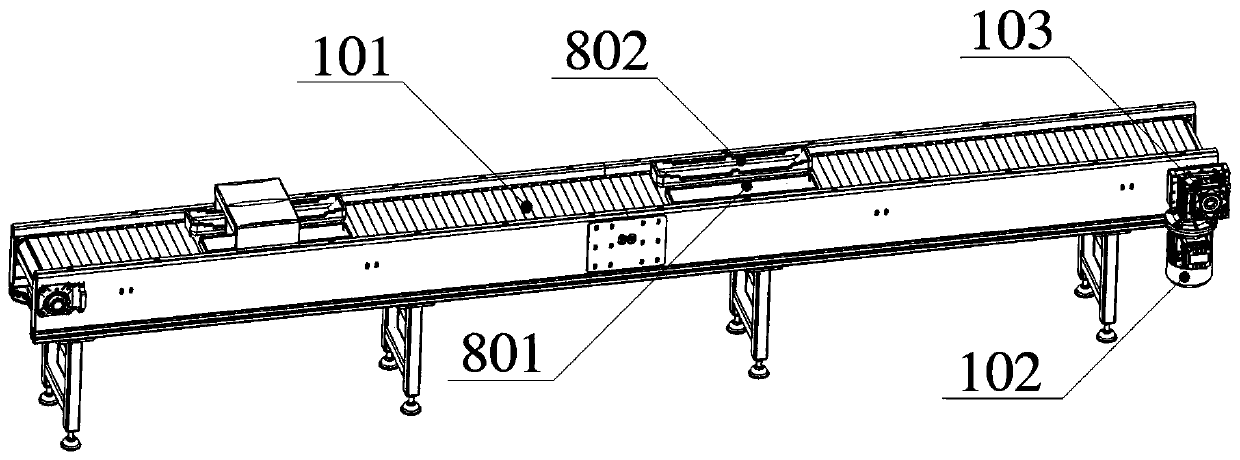

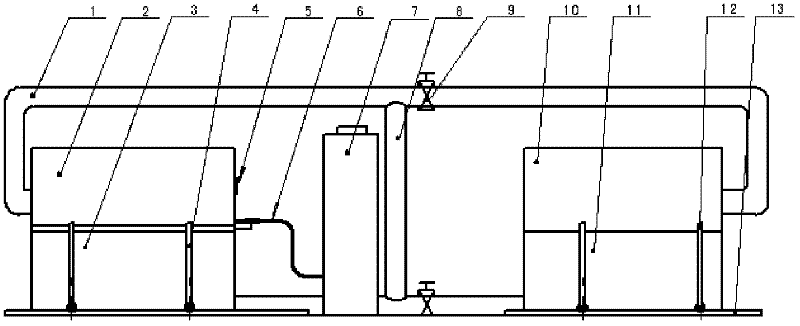

Automatic assembly line for spraying adhesives in tires and production method

InactiveCN105327823AReduce voidsReduce the number of peopleLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention discloses an automatic assembly line for spraying adhesives in tires. The automatic assembly line comprises two tire inner wall cleaning units, two heating units, three adhesive melting boxes, an adhesive collecting box, an adhesive spraying unit, a cooling unit and a packaging assembly line. The heating units, the adhesive spraying unit, the cooling unit and the packaging assembly line are sequentially arranged at the discharge ports of the tire inner wall cleaning units in the conveying direction of the automatic assembly line. The adhesive spraying feed port of the adhesive spraying unit is connected with the adhesive collecting box, the adhesive collecting box is provided with the adhesive melting boxes communicated with the adhesive collecting box, and mechanical arms are arranged between the tire inner wall cleaning units and the heating units and between the cooling unit and the packaging assembly line respectively. The automatic assembly line has the advantages that the mechanical arms are adopted for completing transferring so that mutual cooperation can be closer, the gap between the tires can be narrowed, the production quantity of the tires can be increased, one tire can be produced per minute, the cost can be effectively lowered, the number of employees can be greatly lowered, the safety can be high, and the auxiliary time can be shortened.

Owner:卢文哲

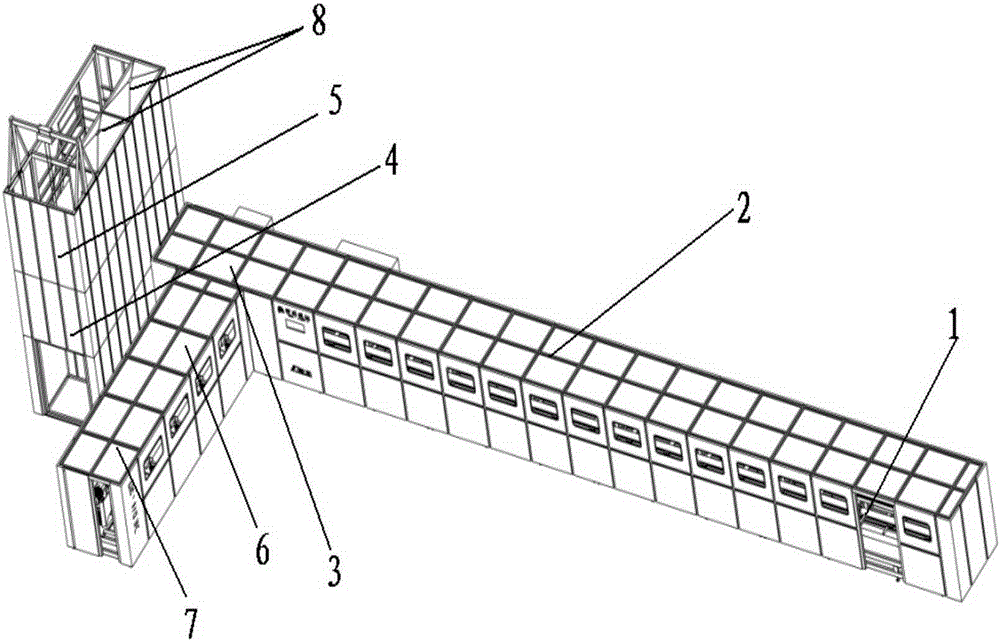

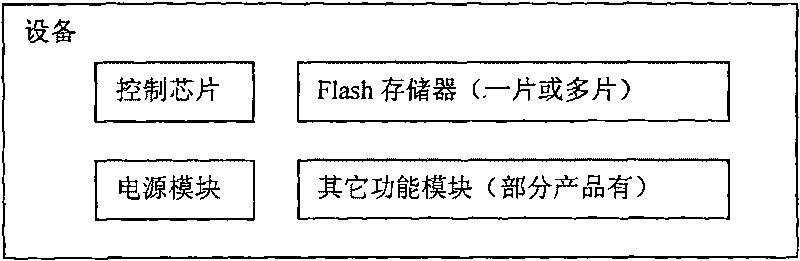

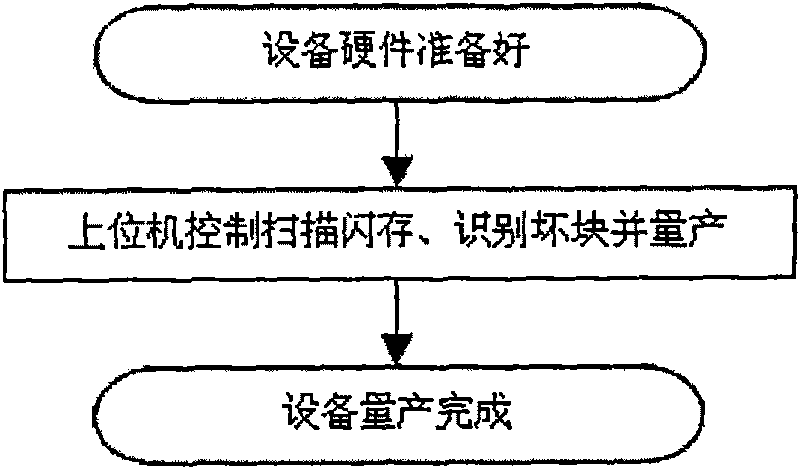

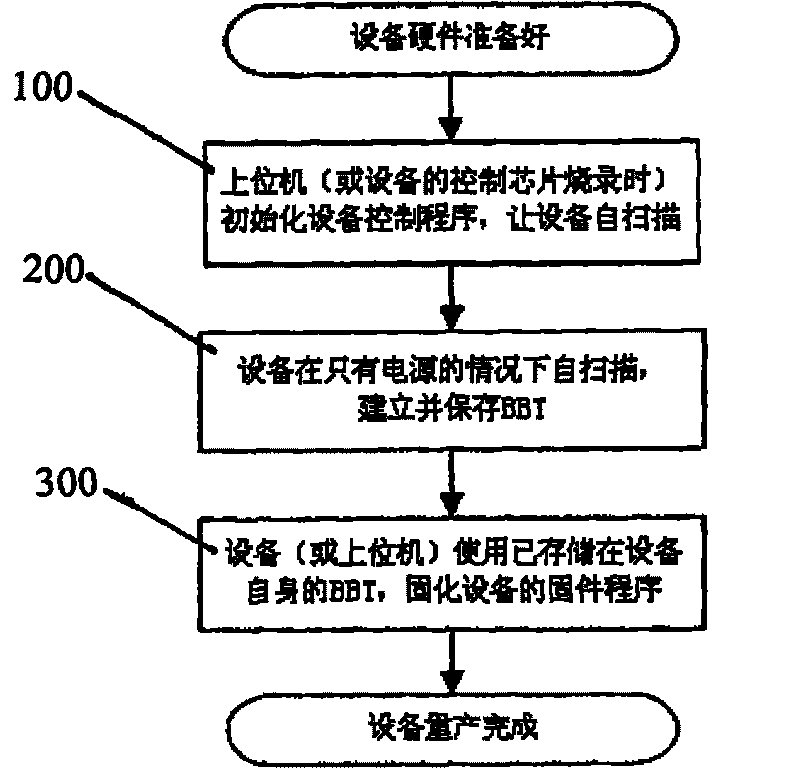

Equipment production flow using flash memory as storage medium

ActiveCN101710237AIncrease production quantityRealize mass productionStatic storageTotal factory controlProduction rateTime cost

The invention relates to an equipment production flow using a flash memory as a storage medium. The production flow comprises the following steps that: A, the equipment using the flash memory as the storage medium is used as a lower computer to be connected to a special production machine used as an upper computer, and the upper computer writes a control program in the lower machine; B, under a condition of being disconnected from the upper computer, the lower computer automatically scans and establishes and stores a bad block table BBT; and C, according to the BBT stored in the lower computer, the upper computer solidifies the proper firmware program to the lower computer. In the production flow, the bad blocks in the lower computer are scanned by the lower computer and the resources of the lower computer are not occupied, so that the condition that the upper computer is idled to wait is hardly happened. Just by being connected with a power supply, the lower computer can complete the scanning process; and if the productivity needs to be increased, the productivity increase can be achieved just by adding proper number of power supplies, so that the units of product of the lower computer in unit time are greatly increased, the production efficiency is greatly improved, and the time cost and the labor cost are lowered.

Owner:SHENZHEN NETCOM ELECTRONICS CO LTD

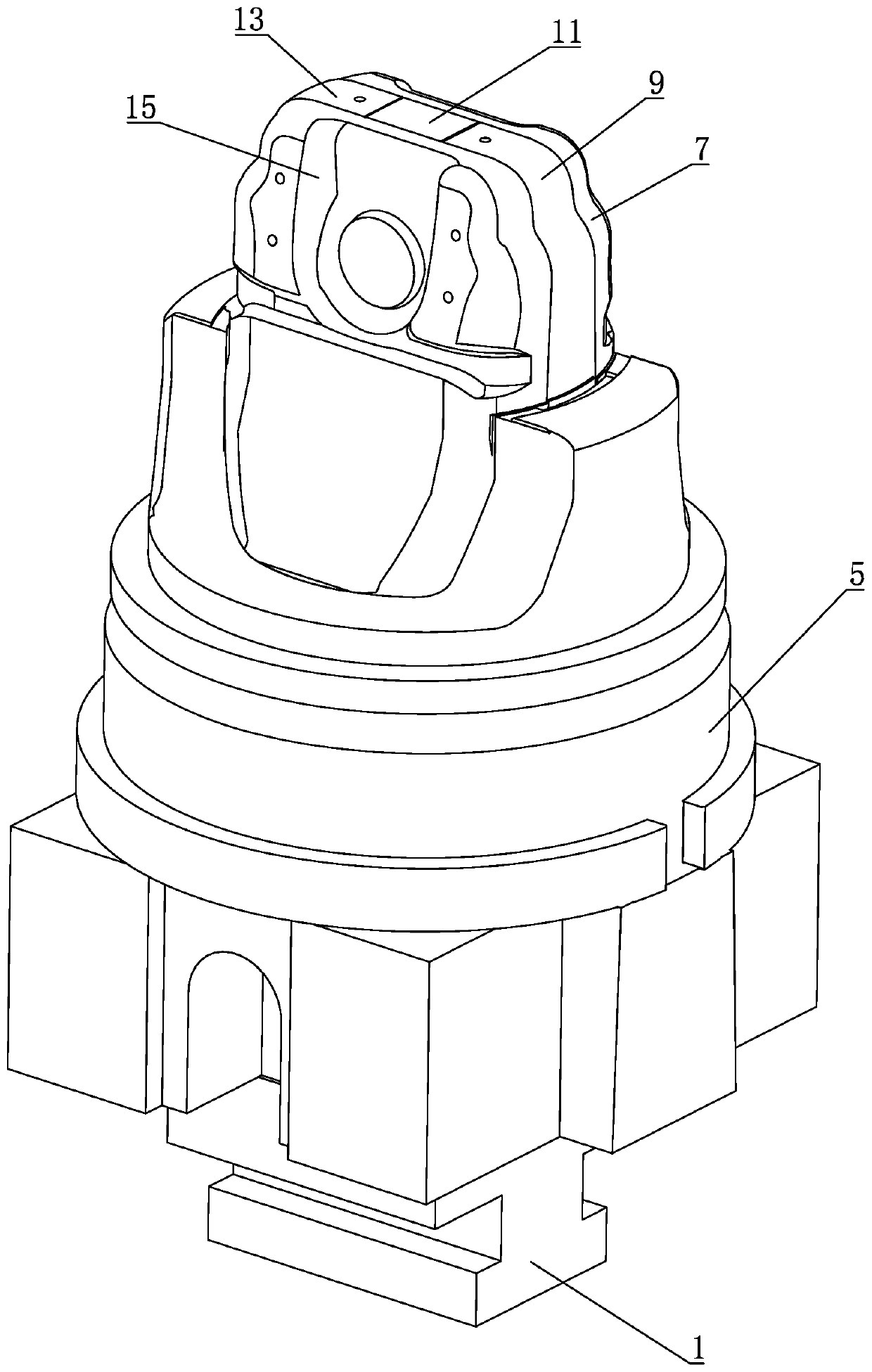

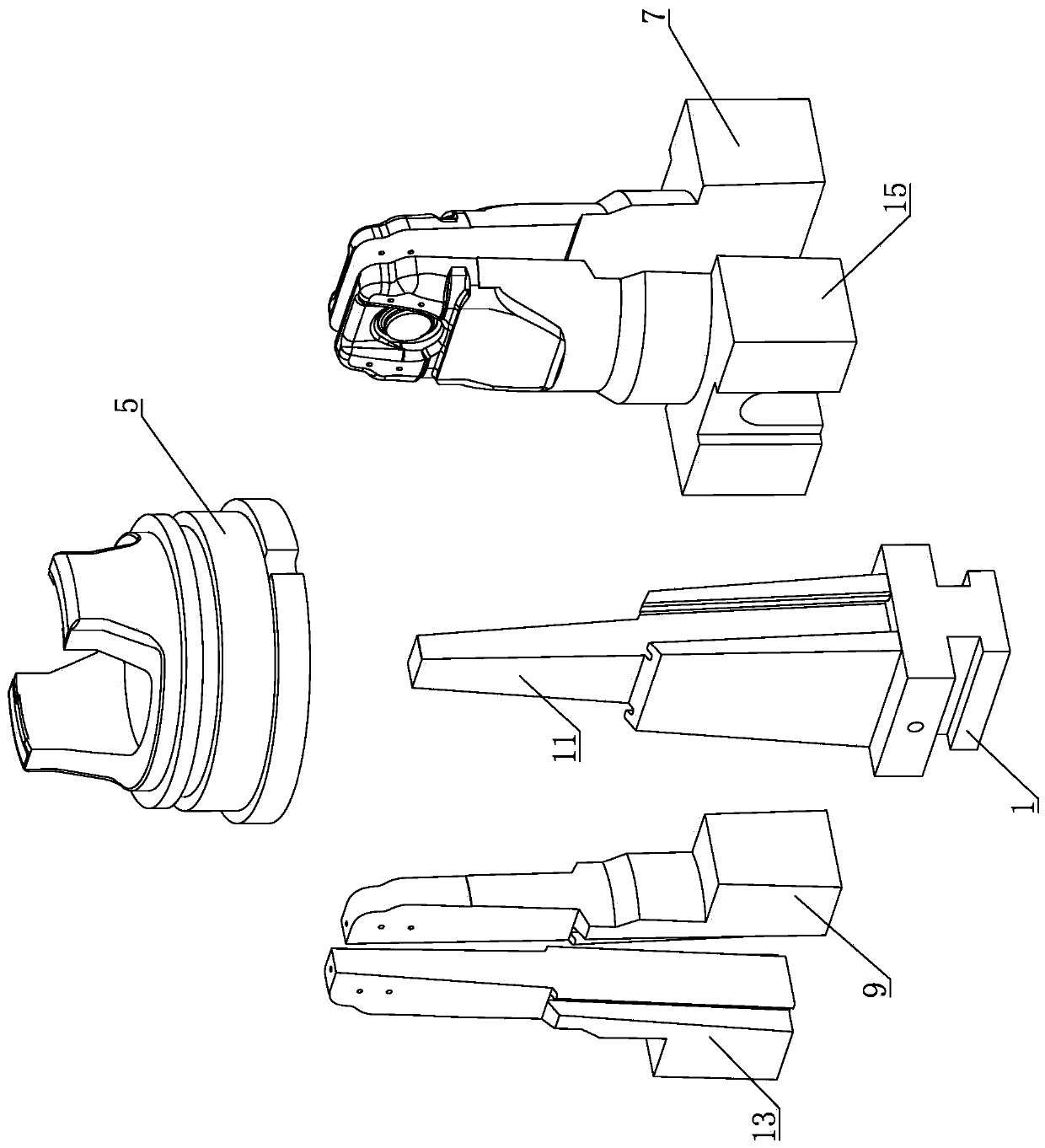

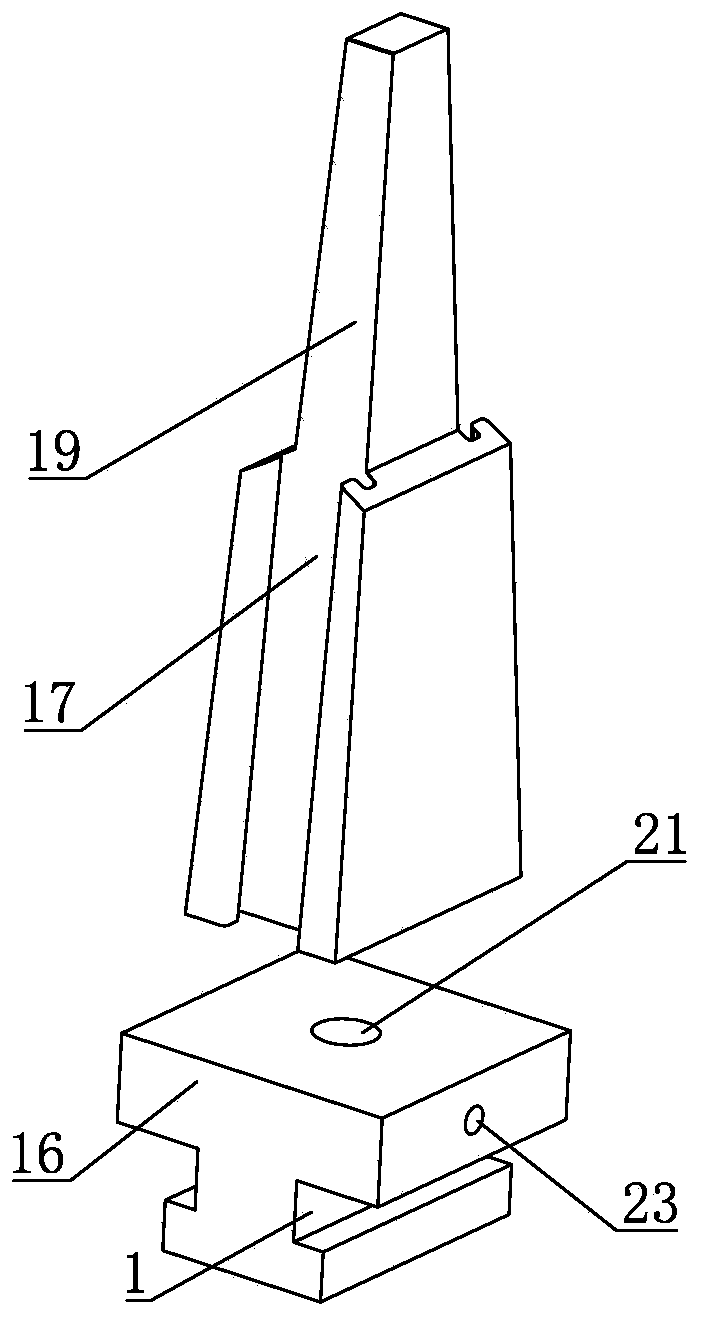

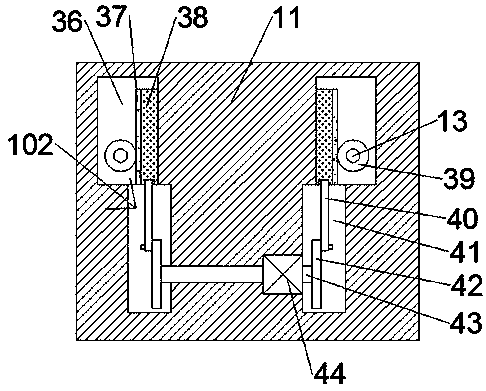

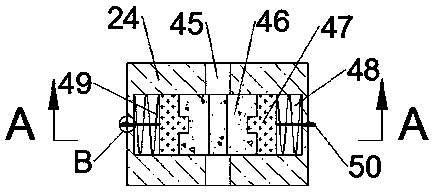

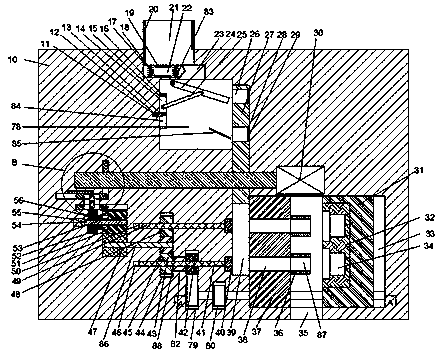

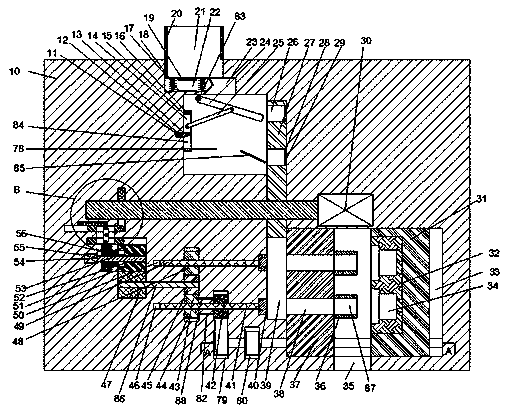

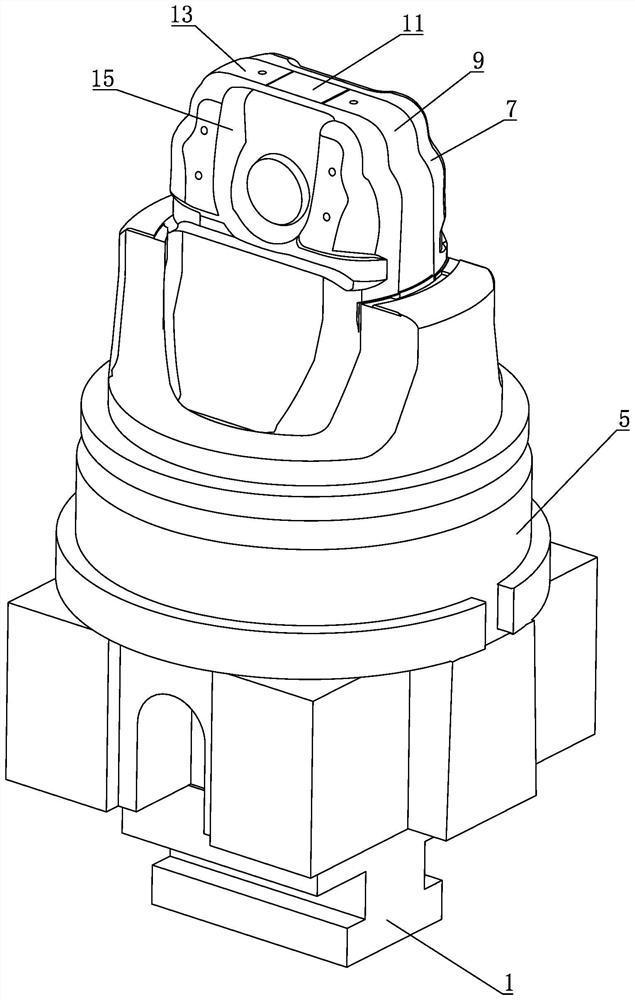

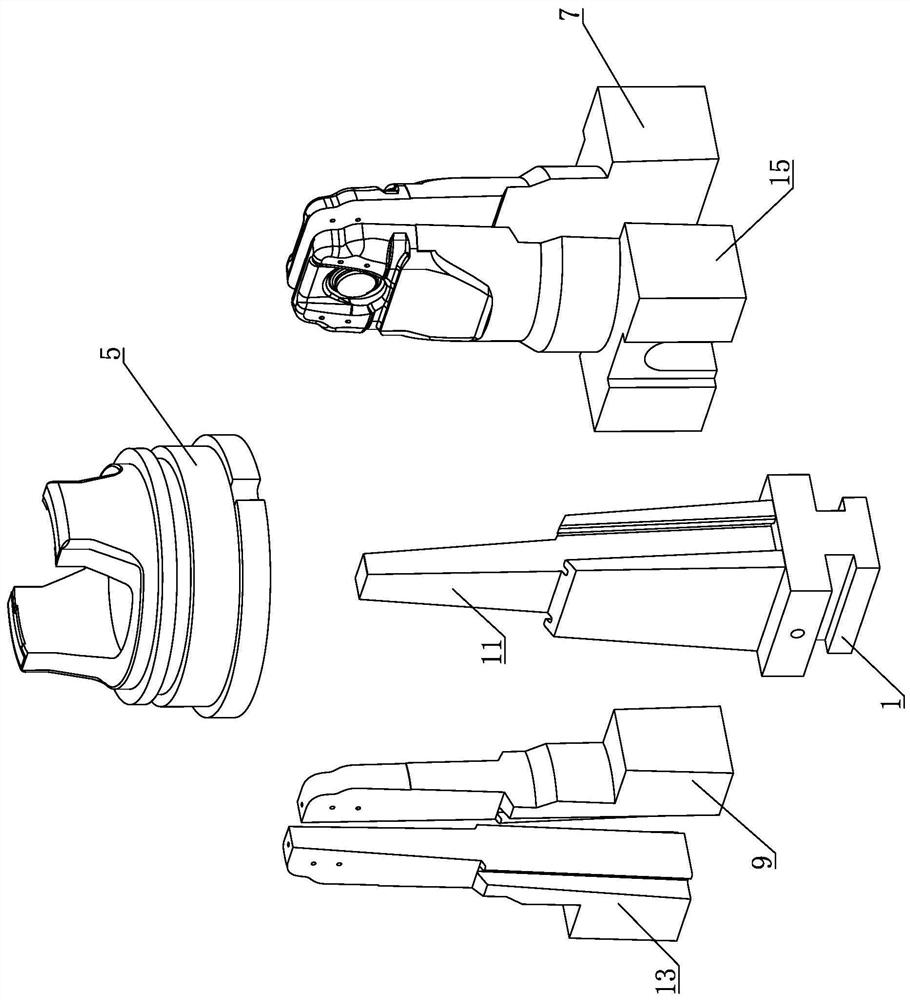

Mold assembly improved structure for greatly improving casting precision of light aluminum piston

ActiveCN111421114APrevent side swingEliminate distractionsFoundry mouldsFoundry coresEngineeringPiston

The invention relates to a mold assembly improved structure for greatly improving casting precision of a light aluminum piston. The mold assembly improved structure is applied to batch production of high-precision light aluminum pistons. The mold assembly improved structure comprises an outer mold, a pin hole mold, a sliding block mold and a core mold. The core mold comprises a piston core mold center piece. The piston core mold center piece is composed of a rectangular pyramid column and a supporting table connected with the rectangular pyramid column. The mold assembly improved structure ischaracterized in that a through groove is formed in a supporting rail along the center line, a straight rod is arranged at the bottom of the pin hole mold, the straight rod and the through groove areequal in width, and the straight rod extends into the through groove; and a T-shaped guide rail groove is formed in the upper portion of the pin hole mold, a T-shaped guide rail is arranged on the upper portion of the interior of a cavity of the outer mold, and the T-shaped guide rail is sleeved with the T-shaped guide rail groove. The pin hole mold is provided with a pin column hole lower pressing block. The rectangular pyramid column and the supporting table are connected in a fastened mode through a bolt with a tangential plane. An end face hole in the tail end of the bolt communicates witha side hole of the bolt, and a rectangular pyramid column deep hole is formed in the lower end face of the rectangular pyramid column. The mold assembly improved structure has the advantages that various abnormal abrasion of the pin hole mold is avoided, the bumping resistance is greatly improved, and the precision of the thickness of a radial casting involved in the sliding block mold in production is improved.

Owner:HUAMIN NANPING AUTOMOBILE FITTINGS GROUP

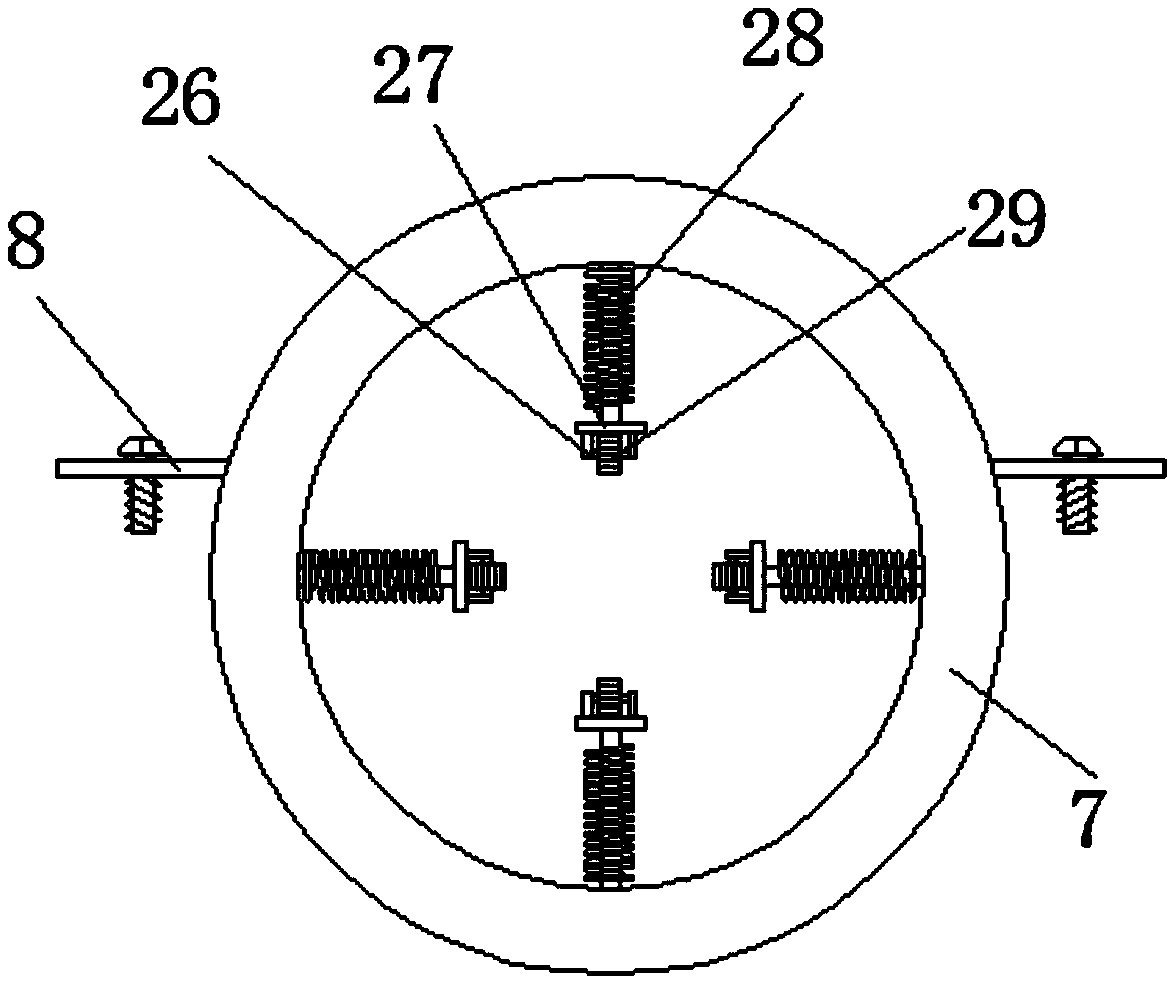

Automatic insert equipment of nut

InactiveCN101332674APrevent failure and damageIncrease production quantityMetal working apparatusPistonWorking hours

The invention relates to an automatic insertion equipment of nut, comprising a clamper, a preheater, a compression joint device and a supplier. The clamper has a fixed circular cylinder working horizontally, and a nut hole formed on the surface opposite to that arranged with the fixed circular cylinder. The preheater is arranged in the front opposite to the nut hole of the clamper, having heater, a nut groove is vertically formed on the upper surface of one side of the preheater and an insertion hole is horizontally formed to intersect with the nut groove. The compression joint device is arranged on the rear part of the preheater, comprising the fore-and-aft movable compression joint circular cylinder and the inserter combined with the piston end of the compression joint circular cylinder. The supplier is arranged on the upper part of the nut groove, comprising an external member and a feeder. Because the fixed circular cylinder works horizontally, the support can be easily replaced so as to improve the production efficiency; and multiple nuts can be simultaneously heated so as to greatly reduce work hours.

Owner:金度完

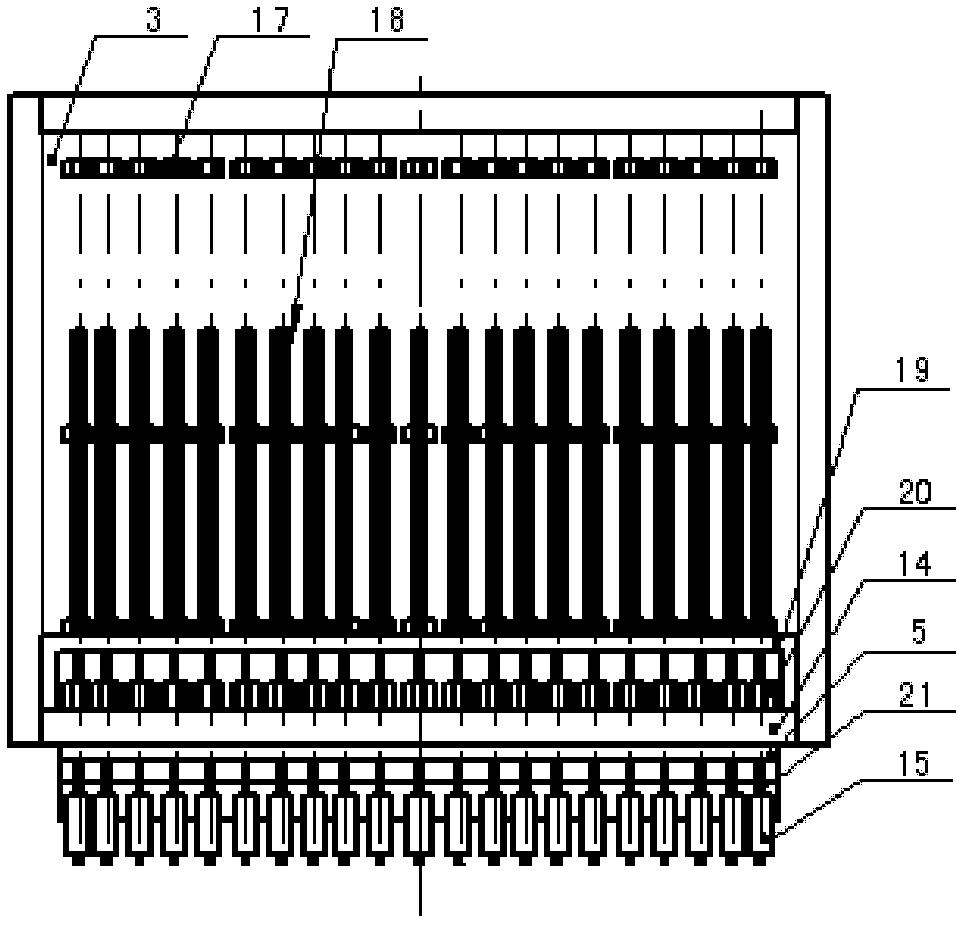

Vertical air extraction preparation process of vacuum glass

ActiveCN102320726AQuality improvementRealize continuous productionGlass reforming apparatusGlass productionEngineeringLow vacuum

The invention relates to a vertical air extraction preparation process of vacuum glass. The process comprises the following steps of: (1) combining pieces: putting a support and glass powder with low melting point or adhesive between upper and lower flat glass cut pieces, and arranging an air extraction glass tube on the side or the lateral surface of a corner; (2) sealing the edges by heating ina high-temperature heating box; (3) vertically placing the edge sealed glass into a cassette fixedly arranged on a bottom plate in an air extraction box in sequence; and (4) vacuumizing: opening a vacuum pump to vacuumize the cavity in the vacuum glass, performing hot melting sealing on the air extraction tube by adopting an electric fusing electrode after the set vacuum degree is achieved, cooling the glass to room temperature and then discharging the glass out of a furnace, and thus obtaining the vacuum glass. Multiple groups of positioning assemblies are uniformly distributed and fixedly arranged in the vacuumizing furnace at intervals in the vacuum glass manufacturing system, the vacuum glass can be installed in a vertical mode or a superposition mode, and the distance between the vacuum glass pieces is shortened and can reach 0.5 to 10 centimeters by calculation, so that the production number of the vacuum glass is greatly improved, the production efficiency is improved by at least two times, and the problem of low vacuum glass yield is effectively solved.

Owner:沃卡姆(山东)真空玻璃科技有限公司

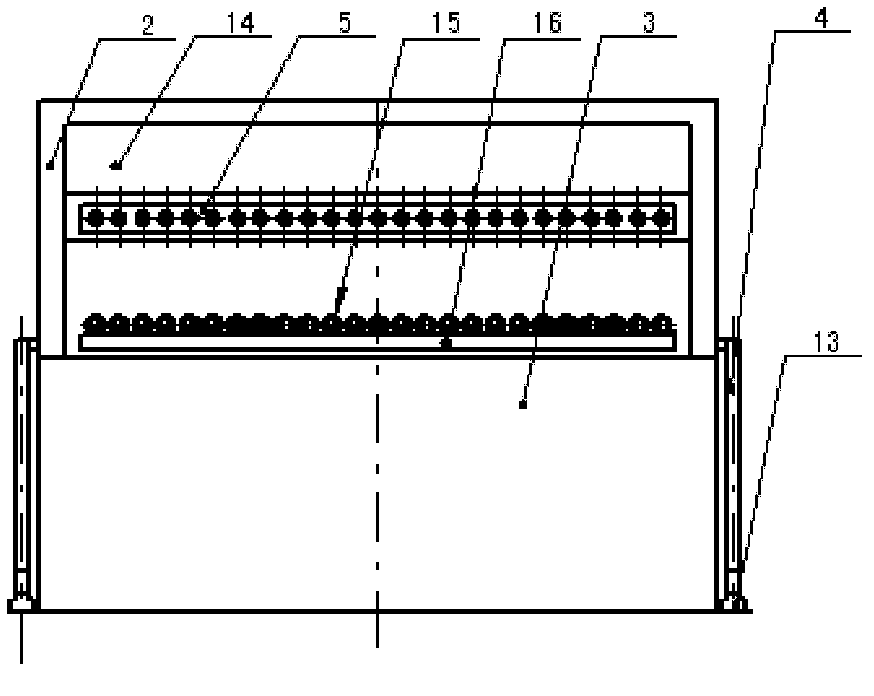

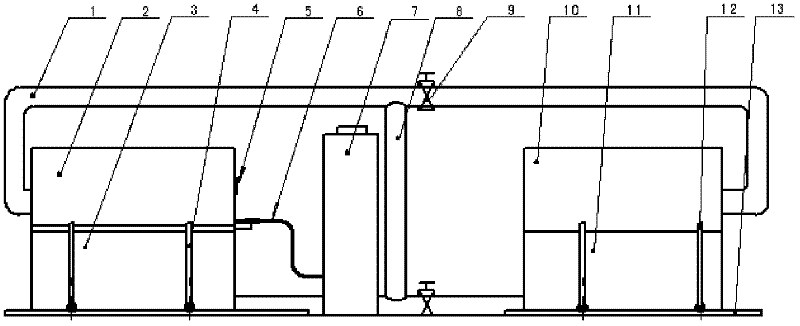

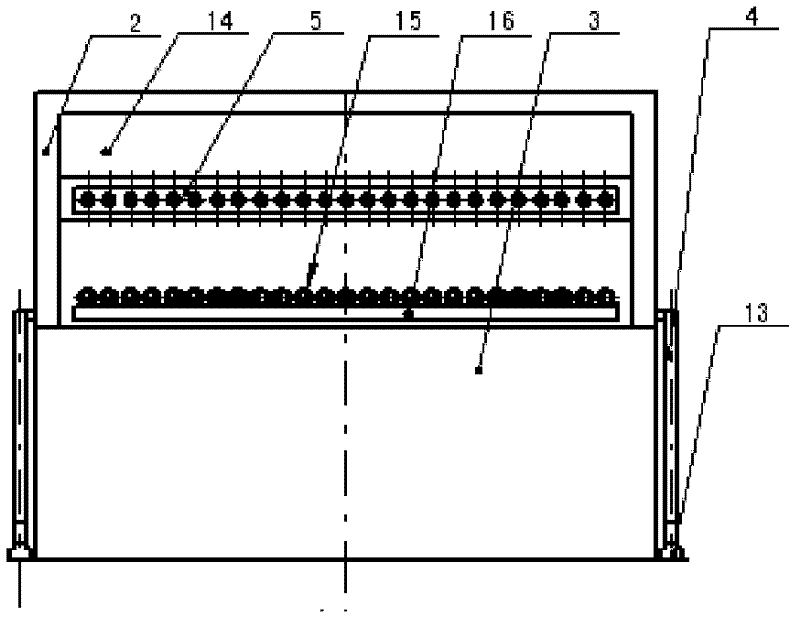

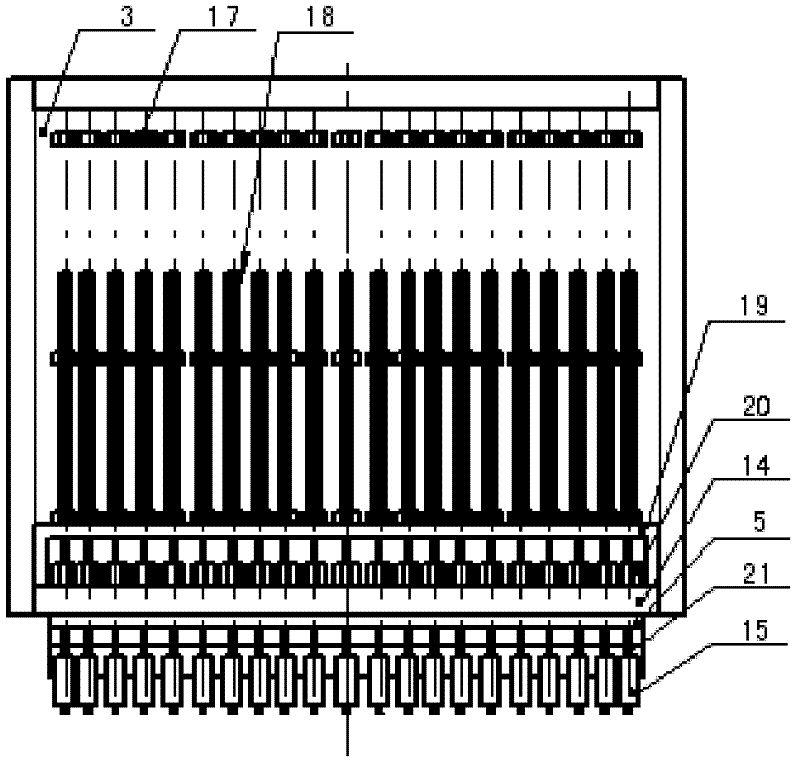

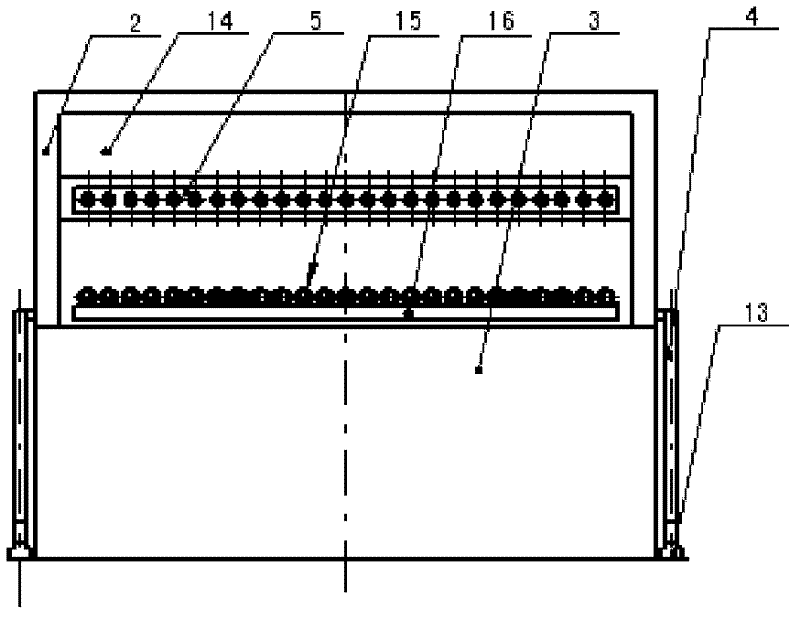

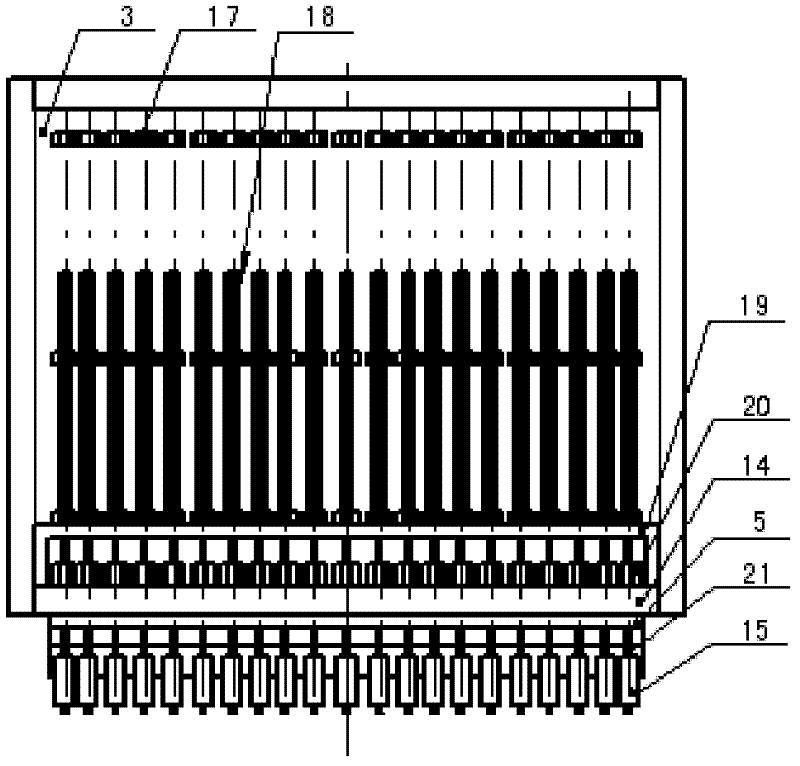

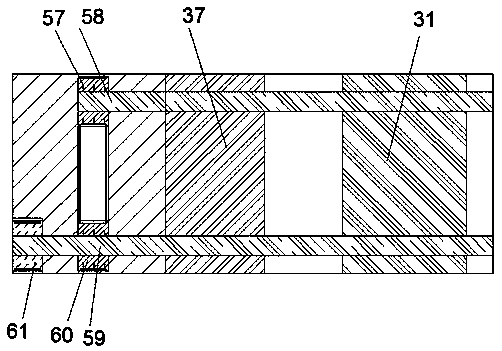

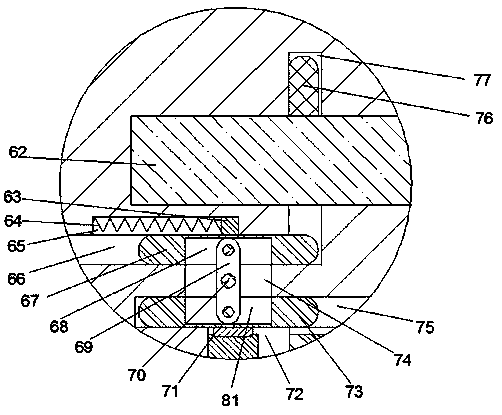

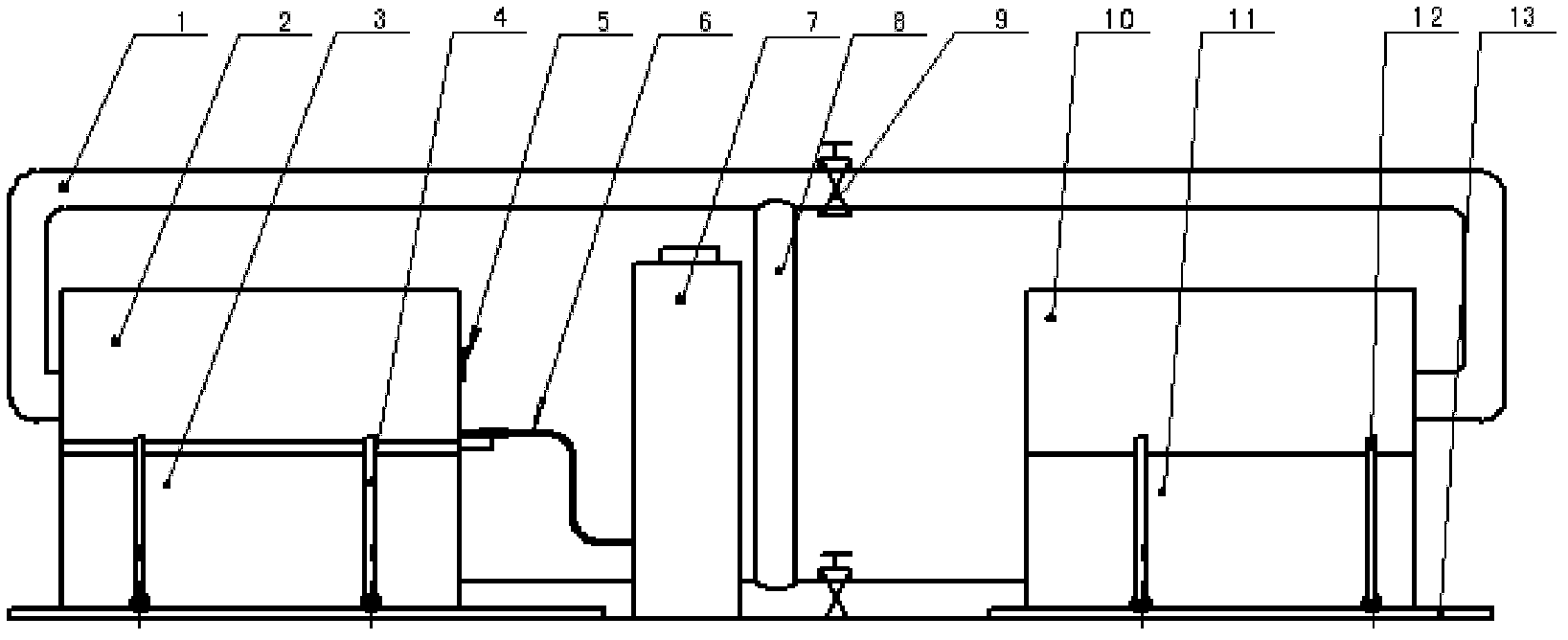

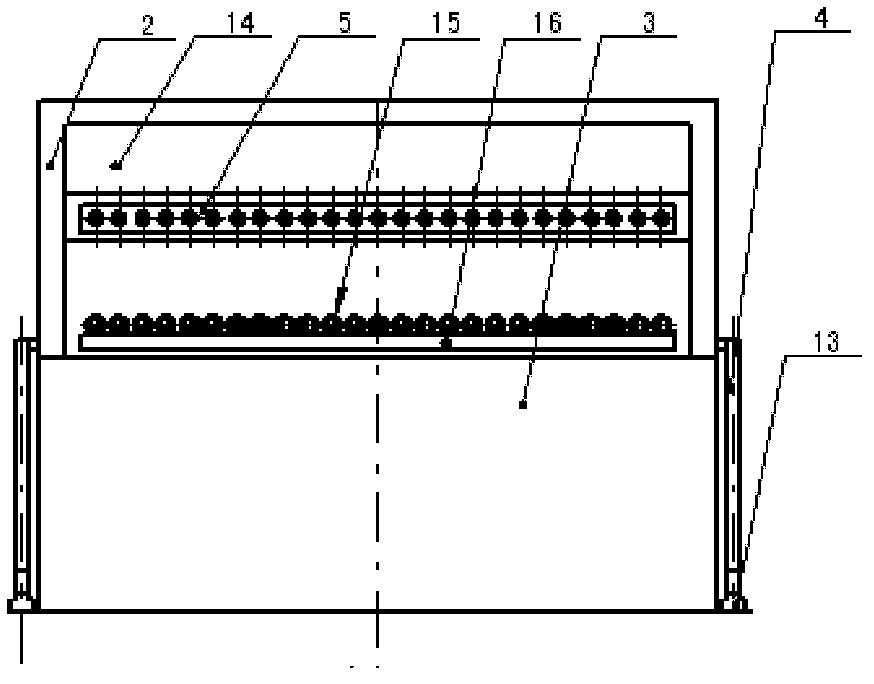

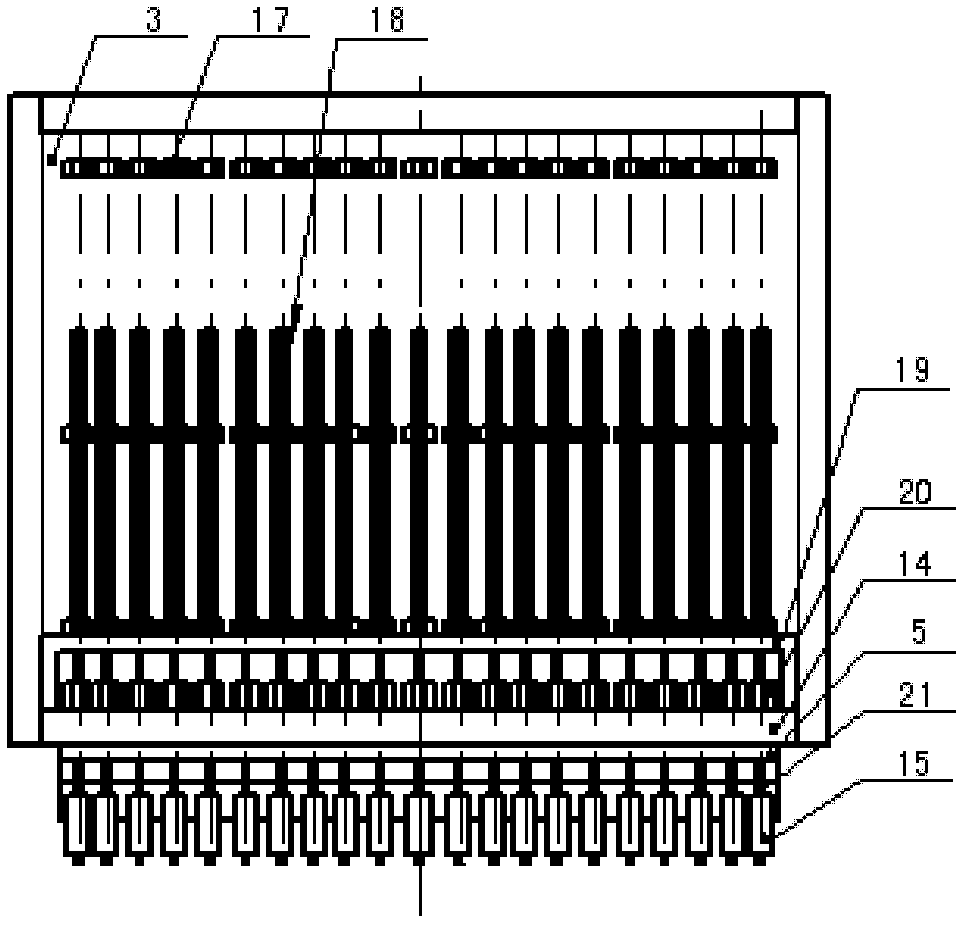

Intelligent pneumatic automatic sealing machine for edible fungus material sticks

ActiveCN105075658ASealing rod process safetyIncrease production quantityHorticultureIntelligent control systemEngineering

The invention provides an intelligent pneumatic automatic sealing machine for edible fungus material sticks and belongs to the field of edible fungi. The intelligent pneumatic automatic sealing machine is especially suitable for suitable for automatic sealing, stick insertion and conveying-out of edible fungus material sticks. The automatic sealing machine is characterized in that an intelligent control system, a sealing system, an inoculation stick insertion system and a material stick conveying system. The systems are controlled by the intelligent system, and the sealing system and the inoculation stick insertion system are perpendicular to the material stick conveying system in the horizontal direction. The material stick conveying system moves linearly in the horizontal direction. The intelligent pneumatic automatic sealing machine has the advantages that sealing, inoculation stick insertion and stick conveying are completed intelligently, pneumatically and automatically; tight sealing, correct inoculation stick insertion and stable transmission are guaranteed for material stick quality; timing and positioning are guaranteed in material stick output and the number is increased while the material stick quality is improved. The intelligent pneumatic automatic sealing machine can be used independently and is also an indispensible mating machine for factorization of edible fungi.

Owner:大连富森智能科技有限公司

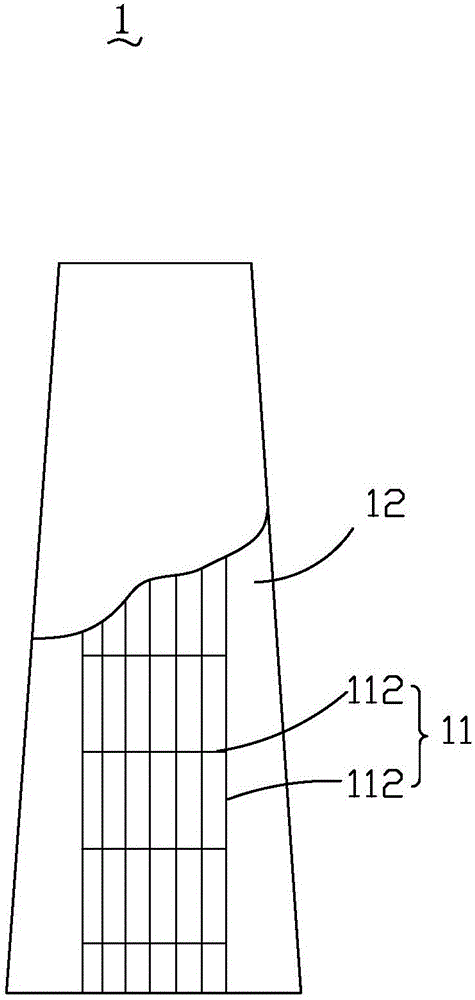

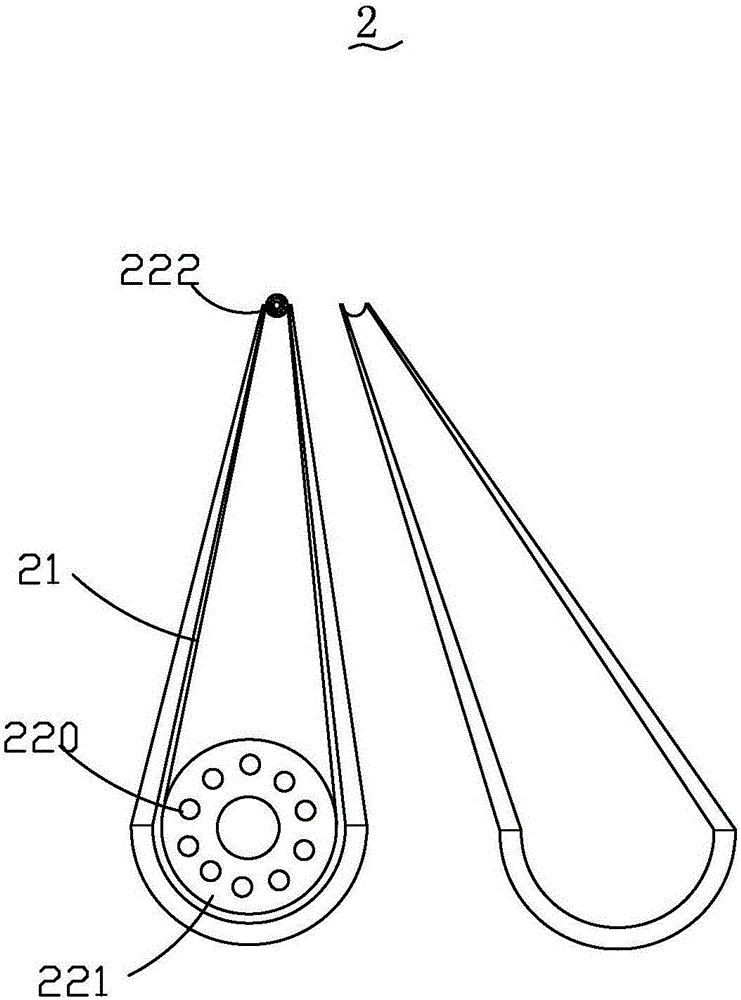

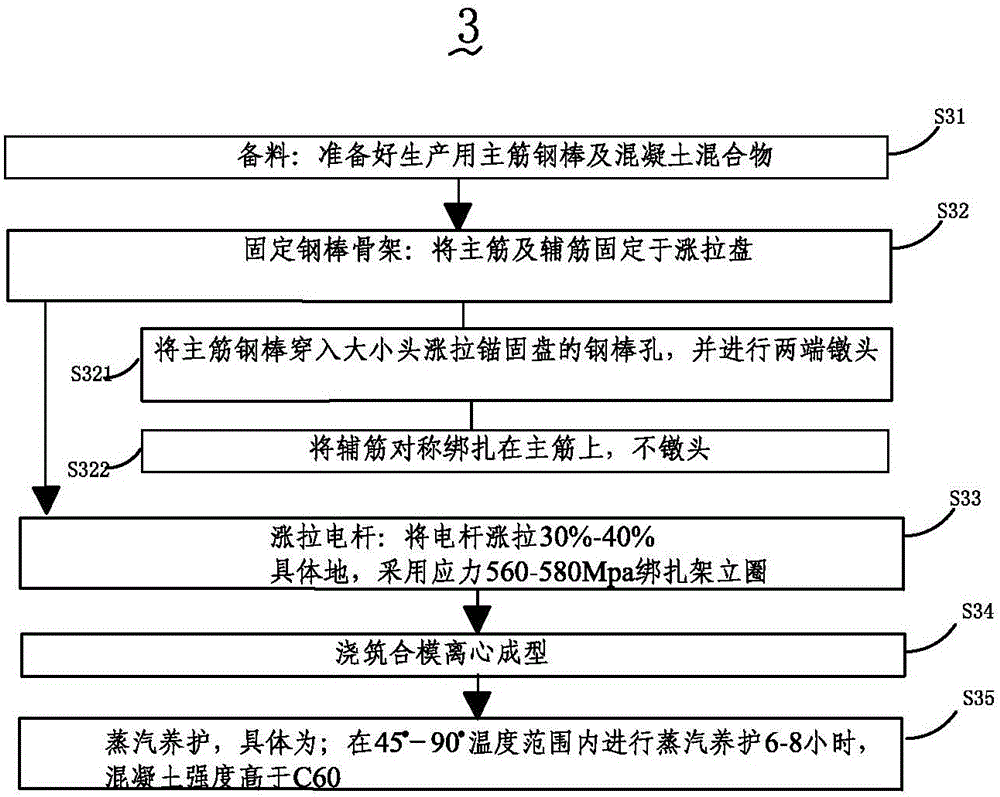

Small-bending-moment steel bar concrete pole as well as production device and manufacturing process thereof

InactiveCN105715093ASolve the ring crack problemExtensiveMouldsShaping reinforcementsPre stressRebar

The invention provides a small-bending-moment steel bar concrete pole as well as a production device and a manufacturing process thereof. The small-bending-moment steel bar concrete pole comprises a steel bar framework and a concrete layer; the concrete layer wraps the steel bar framework; the steel bar framework comprises multiple main ribs and multiple auxiliary ribs; the main ribs and the auxiliary ribs are steel bars for prestressed concrete; the multiple main ribs are axially and annularly arranged in the small-bending-moment steel bar concrete pole; the auxiliary ribs are symmetrically bound to the main ribs. The small-bending-moment steel bar concrete pole provided by the invention is widely applied to all 10kV integral electric pole types on state grid lines; the steel bars for prestressed concrete are adopted for replacing steel bar HRB concrete to upgrade electric poles, so that the ring shake problem of the electric poles is fundamentally solved, the labor productivity is improved, and the yield is free from limitation of a reinforcing mesh, and the product production quantity is improved to the greatest extent.

Owner:WENGNIUTEQI SHUANGYUAN ELECTRIC CEMENT PROD CO LTD

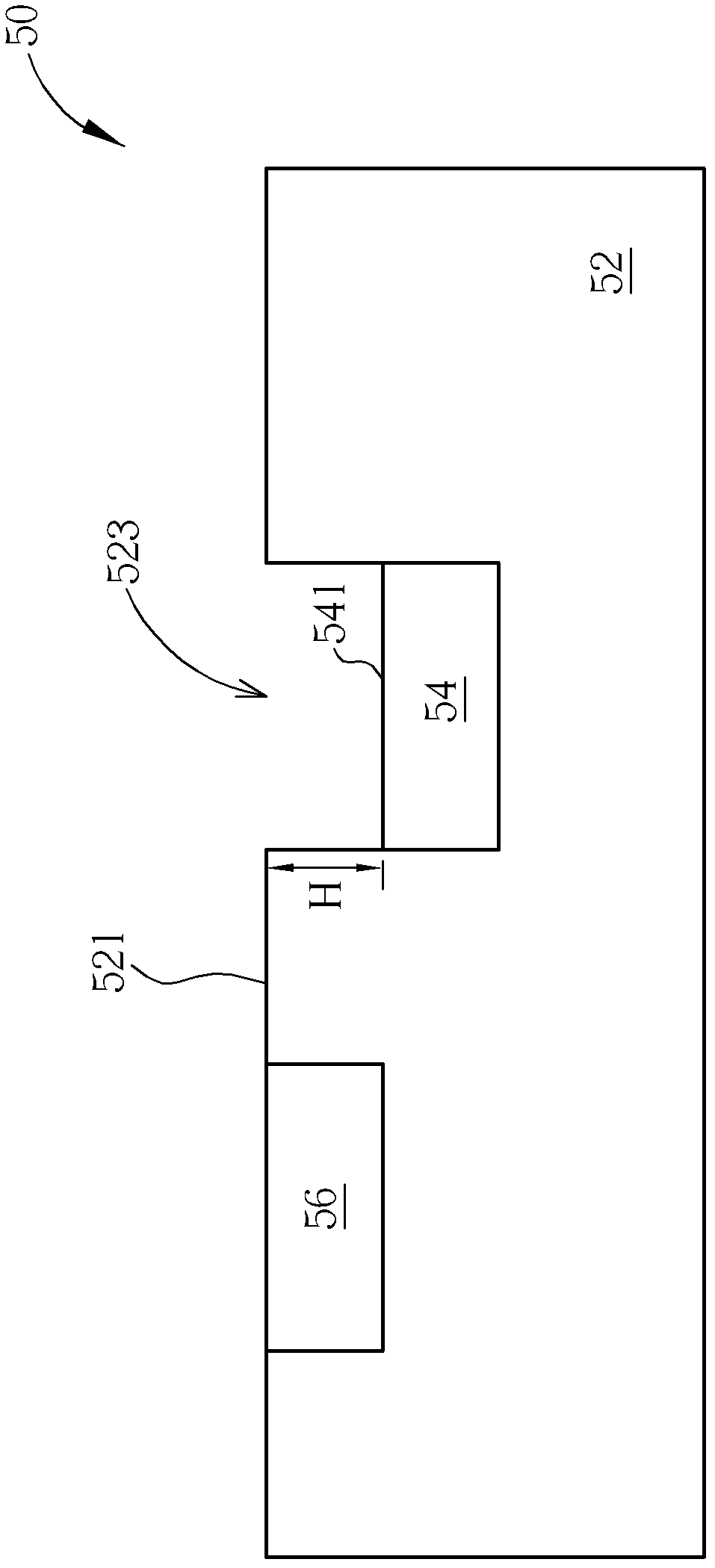

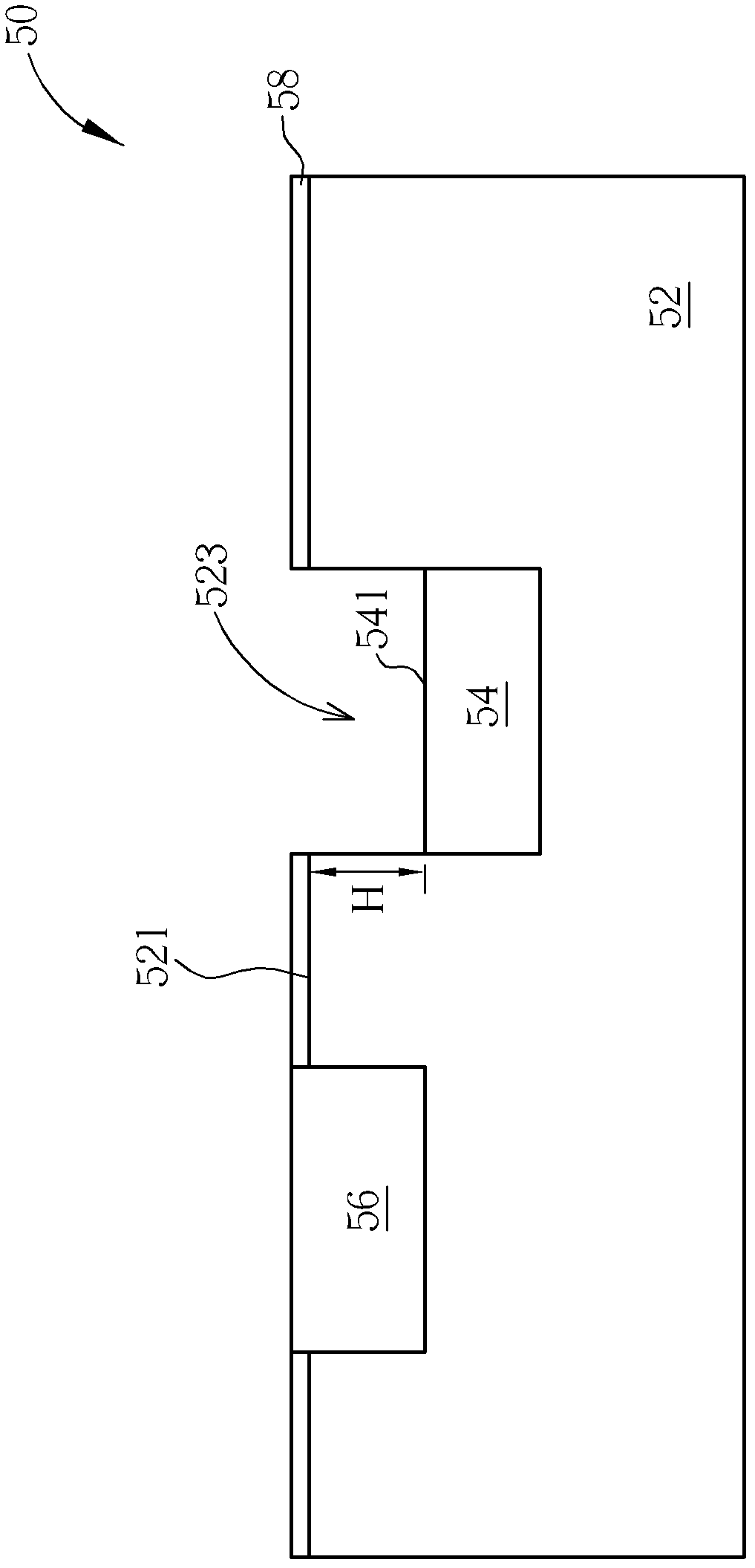

Circuit board capable of preventing contact of a gold finger and solder

InactiveCN103167732AAvoid the bad phenomenon of tin stickingReduce manufacturing defect ratePrinted circuit aspectsPrinted circuit manufactureFinger structureHeight difference

A circuit board includes a substrate whereon a sunken portion is formed. The circuit board further includes a gold finger structure disposed inside the sunken portion. A height difference is formed between a top surface of the gold finger structure and a surface of the substrate substantially.

Owner:WISTRON CORP

Manufacturing process of vacuum glass

ActiveCN102295404AQuality improvementRealize continuous productionGlass reforming apparatusGlass productionEngineeringMoisture

The invention relates to a manufacturing process of vacuum glass, which comprises the following steps: (1) sheet binding, that is, cutting an upper and a lower piece of flat glass into sheets, placing a supporting substance between the two pieces of glass, placing a low-melting glass powder or a binder between the upper and the lower piece of flat glass, welding and mounting an air exhaust glass tube at the side edge or the side surface of the angle part, wherein the air exhaust glass tube is a sealed glass tube; (2) heating for edge sealing in a high-temperature heating box; (3) orderly placing the glass with a sealed edge into a clamping frame which is fixedly mounted on a bottom plate in an air exhaust box of a low-temperature heating furnace; (4) vacuum pumping, that is, starting a vacuum pump, performing vacuum pumping of a cavity in the vacuum glass to reach a set vacuum degree, performing hot-melt sealing of the air exhaust tube by an electrically-fusing electrode, cooling to room temperature, taking the product out of the furnace to obtain the vacuum glass. In the manufacturing process of vacuum glass, the air exhaust tube mounted in the high-temperature heating box is a blind-hole tube, and thus during the cooling process after the edge sealing of the vacuum glass, outdoor air is prevented from entering the vacuum glass cavity; the air in the cavity is maintained to be dry; the specific gravity of the air in the cavity is decreased; the vacuum degree in the cavity is increased; during the vacuum pumping of the cavity, the air exhausting efficiency is increased; procedures for removing moisture in the cavity is reduced; and the quality of the vacuum glass is guaranteed.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

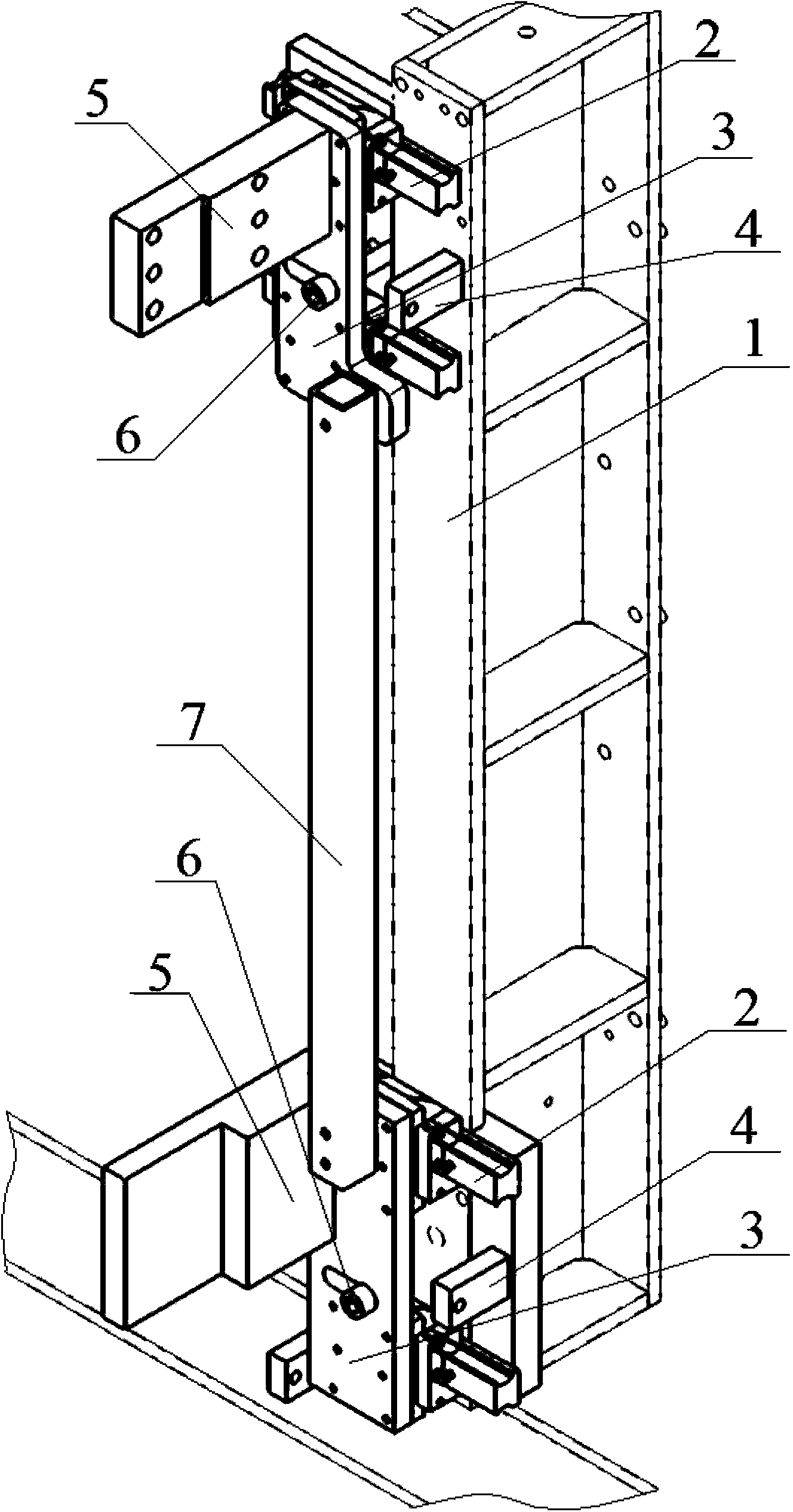

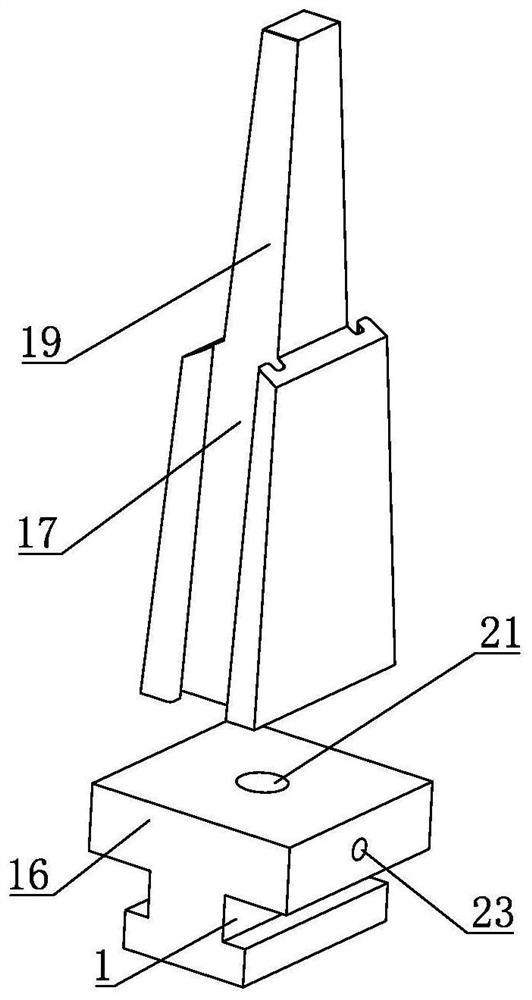

Assembling tooling simultaneously applicable to die-cutting machine and gilding press

ActiveCN104339300ATooling structure is simpleEasy to operateMetal-working hand toolsWall plateEngineering

The invention relates to an assembling tooling simultaneously applicable to a die-cutting machine and a gilding press. The assembling tooling comprises a support, four linear guide ways, two sliding blocks, two fixing blocks and a connecting rod, two linear guide ways are fixed at the upper end of the support, the other two linear guide ways are fixed at the lower end of the support, the two sliding blocks are in sliding joint with the linear guide ways located at upper and lower ends of the support respectively, the two fixing blocks are vertically fixed on the sliding blocks respectively, the connecting rod is fixedly arranged between the two sliding blocks in a connecting mode so as to limit synchronous movement of the two sliding blocks, the fixing blocks are used for fixing machine wall plates of a to-be-assembled machine, and the positions of the sliding blocks on the linear guide ways are adjusted so as to be adapted to the machine widths of the die-cutting machine and the gilding press. Compared with assembling toolings in the prior art, the assembling tooling simultaneously applicable to the die-cutting machine and the gilding press has the advantages that simple and convenient switching between two machine types can be performed so that the tooling can conveniently assemble the two types of machines, and the assembling efficiency is generally increased by the aid of reduced switching time of the tooling.

Owner:BOBST SHANGHAI

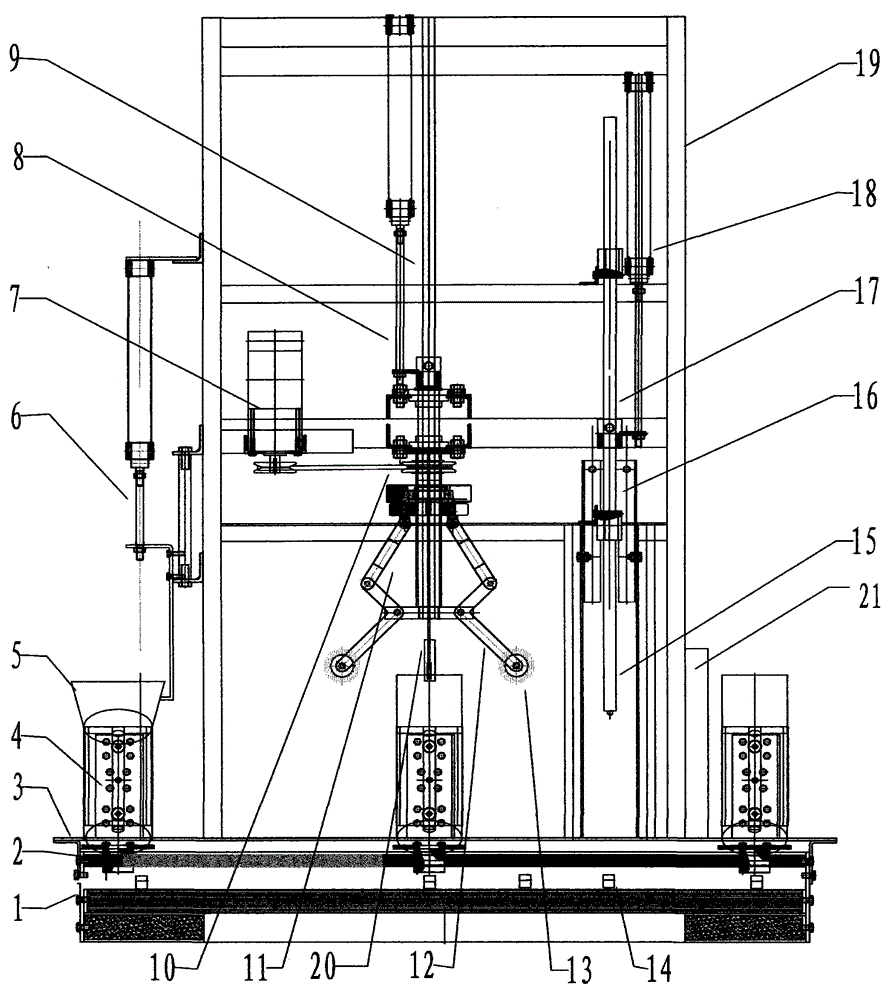

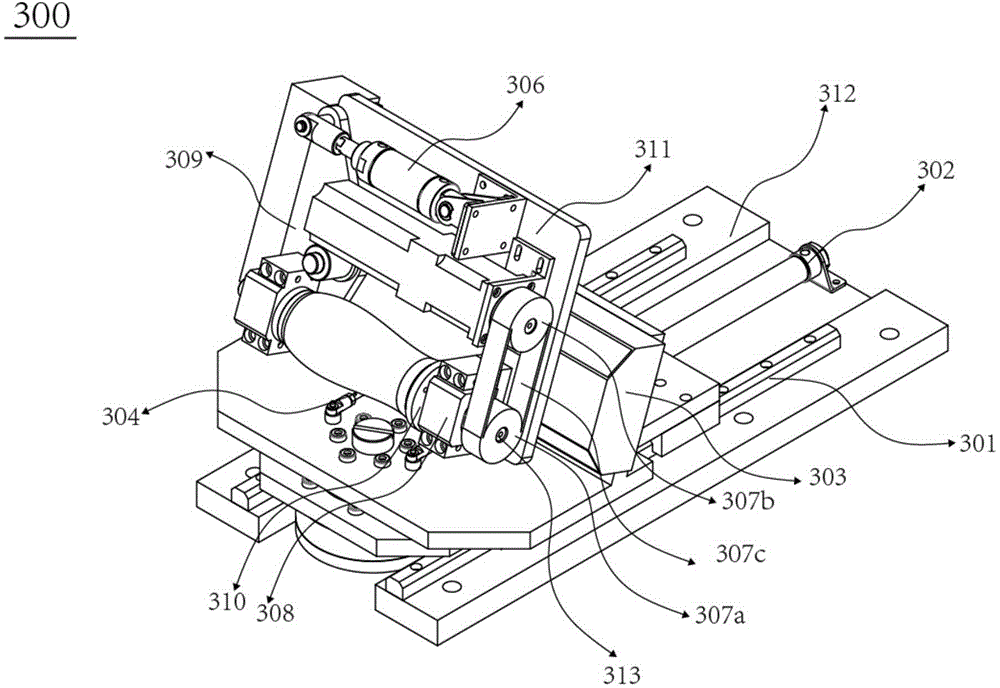

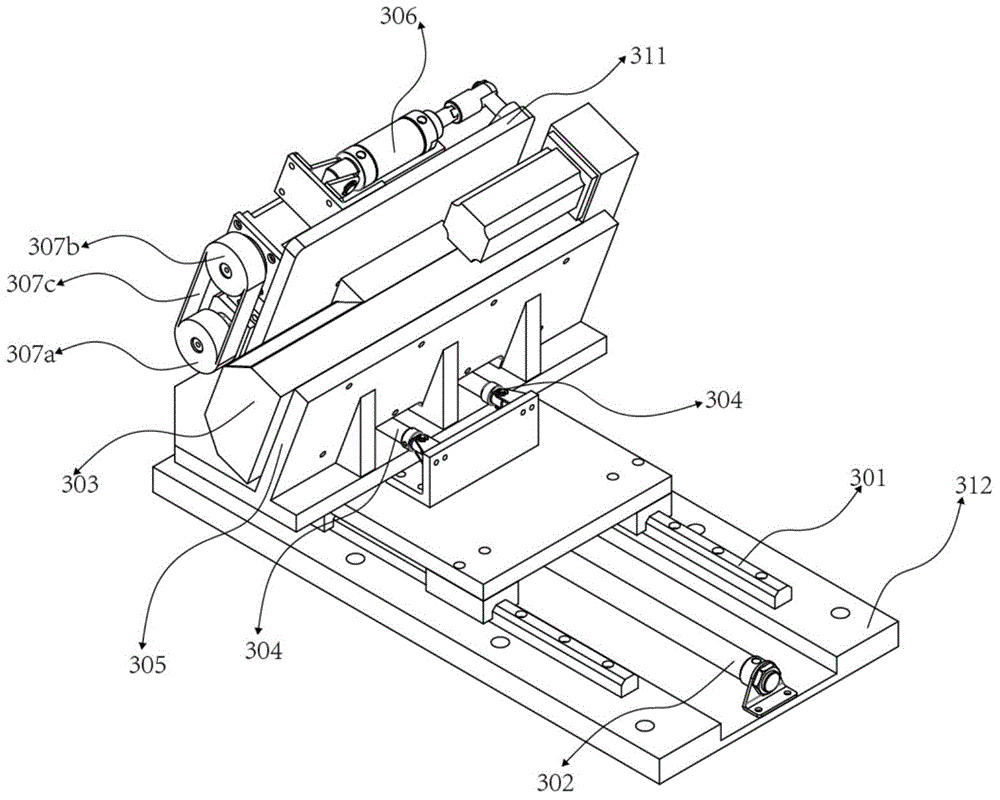

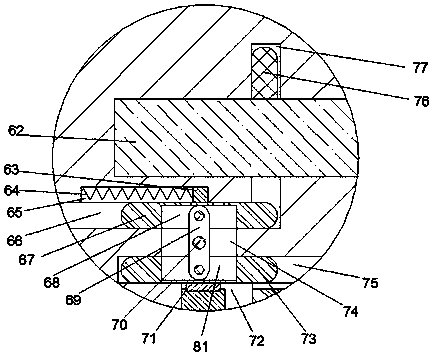

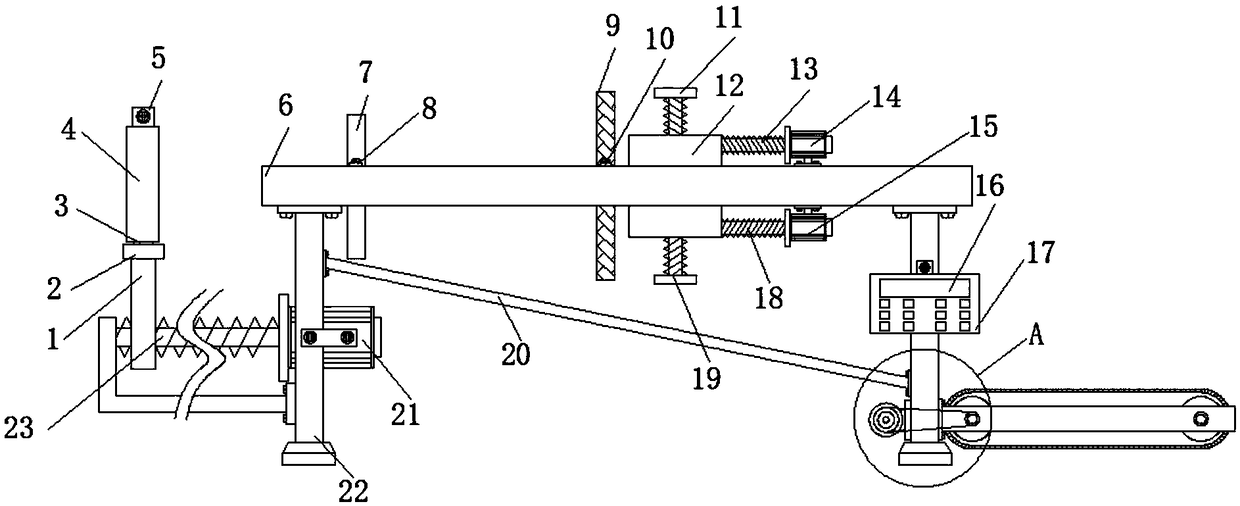

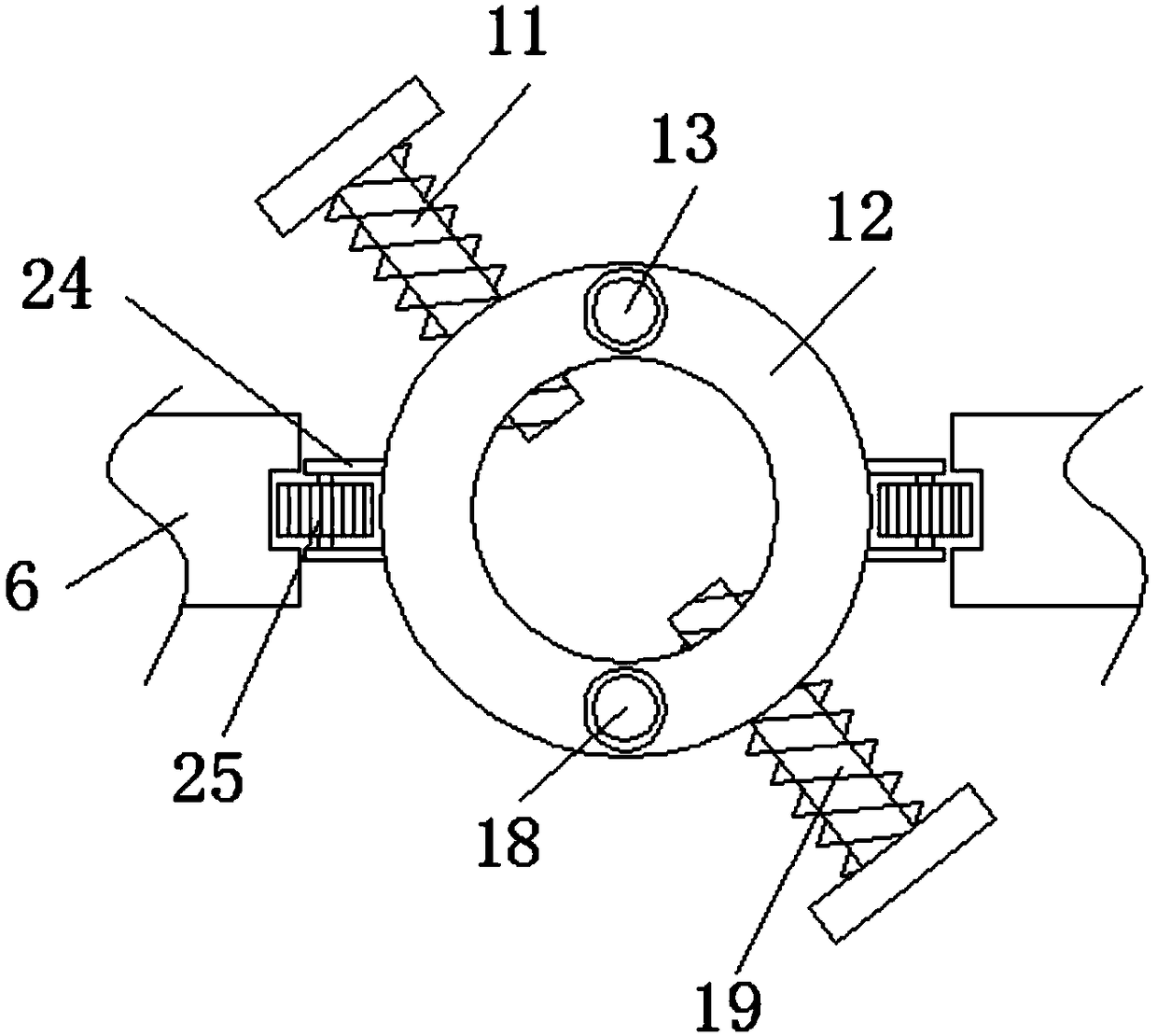

Rotary multi-angle automatic polishing system and polishing method thereof

ActiveCN104308710ARealize fixed tighteningRealize multi-angle and multi-face rotationPolishing machinesAutomatic grinding controlMechanical engineering

The invention discloses a rotary multi-angle automatic polishing system and a polishing method thereof. The rotary multi-angle automatic polishing system comprises a working stand, a polishing device, a clamping device and a control device, wherein the polishing device is provided with a hinge plate, a polishing component and a polishing driving device for driving the polishing component to operate; the clamping device is provided with a clamping component, a push driving device and a translation driving device; the clamping component is hinged to the working stand; the push driving device is used for driving the clamping component to rotate towards the polishing component along a plane perpendicular to a rotating shaft; the translation driving device is used for driving the clamping component to move reciprocally along the axial direction of the rotating shaft; the clamping component is also provided with a rotating device and a rotation driving device; the rotation driving device is used for driving the rotation device to rotate; the clamping component is hinged to the hinge plate; the clamping device is also provided with a rotation driving device for driving the clamping component to rotate reciprocally towards the polishing component relative to the hinge plate. According to the rotary multi-angle automatic polishing system, multi-angle continuous polishing can be realized, the polishing is accurate, the health of workers is protected, and the cost is low.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

Method for outdoor fishing, transporting and temporarily rearing before artificial reproduction of salmons

InactiveCN103109766AIncrease production quantityClimate change adaptationPisciculture and aquariaMortality rateFishing

The invention relates to a method for outdoor fishing, transporting and temporarily rearing before artificial reproduction of the salmons, and aims to solve the problems that due to the fact that the salmons during current parent salmon fishing, transporting and temporarily rearing processes are high in death rate, cost of artificial reproduction is high, breeding parent salmons are insufficient in quantity and production quantity of larvae of the salmons is affected. The method includes: outdoor fishing, transporting and temporarily rearing. The survival rate during salmons storing in river reaches to 95%, the survival rate during transporting reaches to 100%, and the survival rate during temporarily rearing reaches to 98%, and the survival rate of the total processes reaches to more than 93%, so that production quantity of the larvae of the salmons is obviously increased. The method is used for outdoor fishing, transporting and temporarily rearing before artificial reproduction of the salmons.

Owner:HEILONGJIANG RIVER FISHERY RES INST CHINESE ACADEMY OF FISHERIES SCI

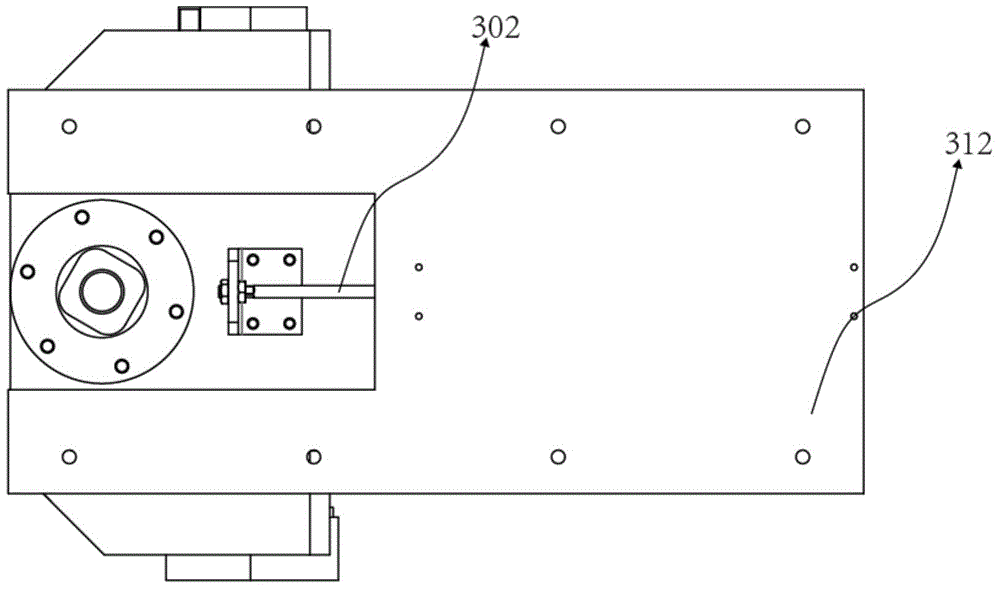

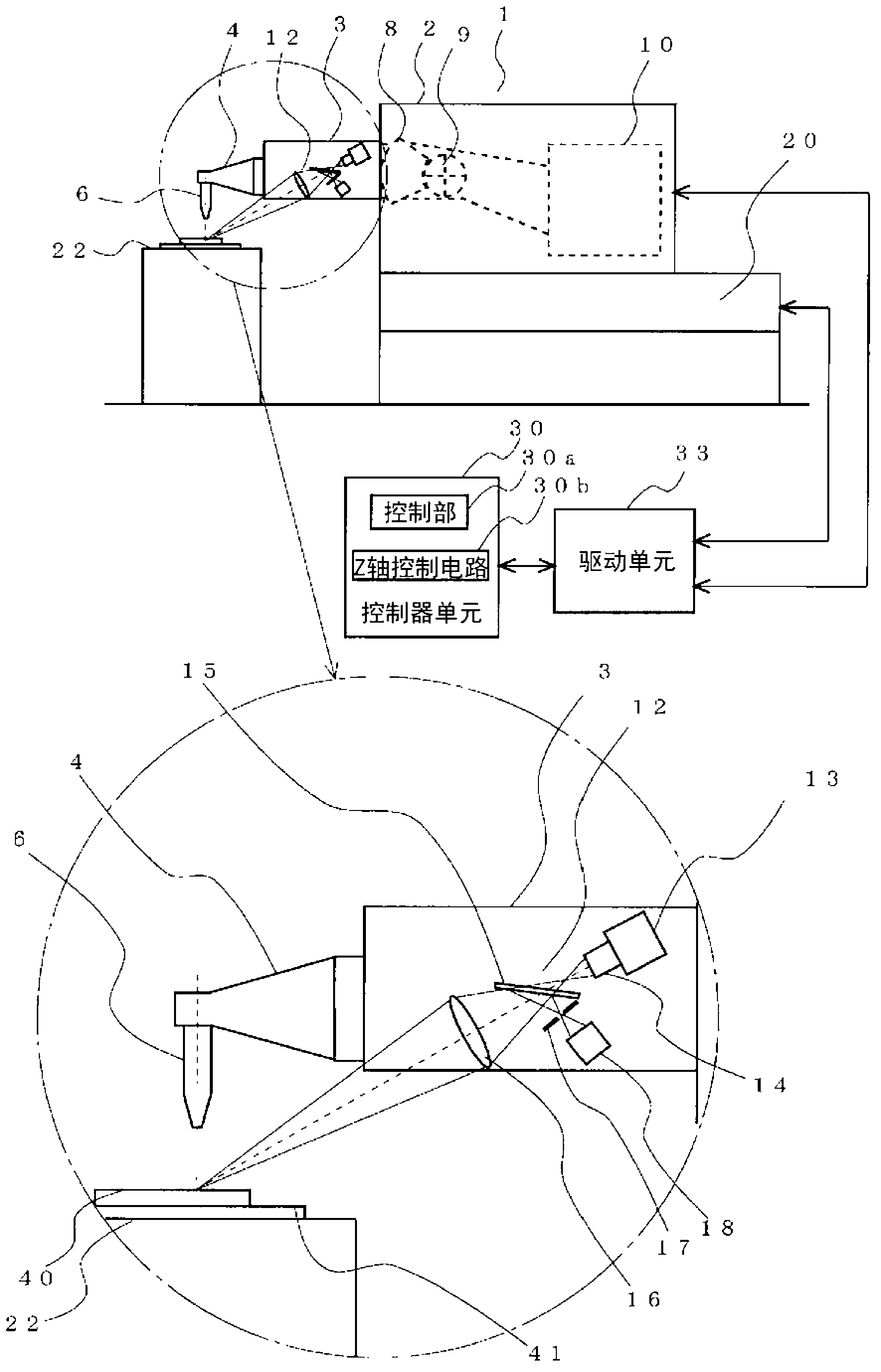

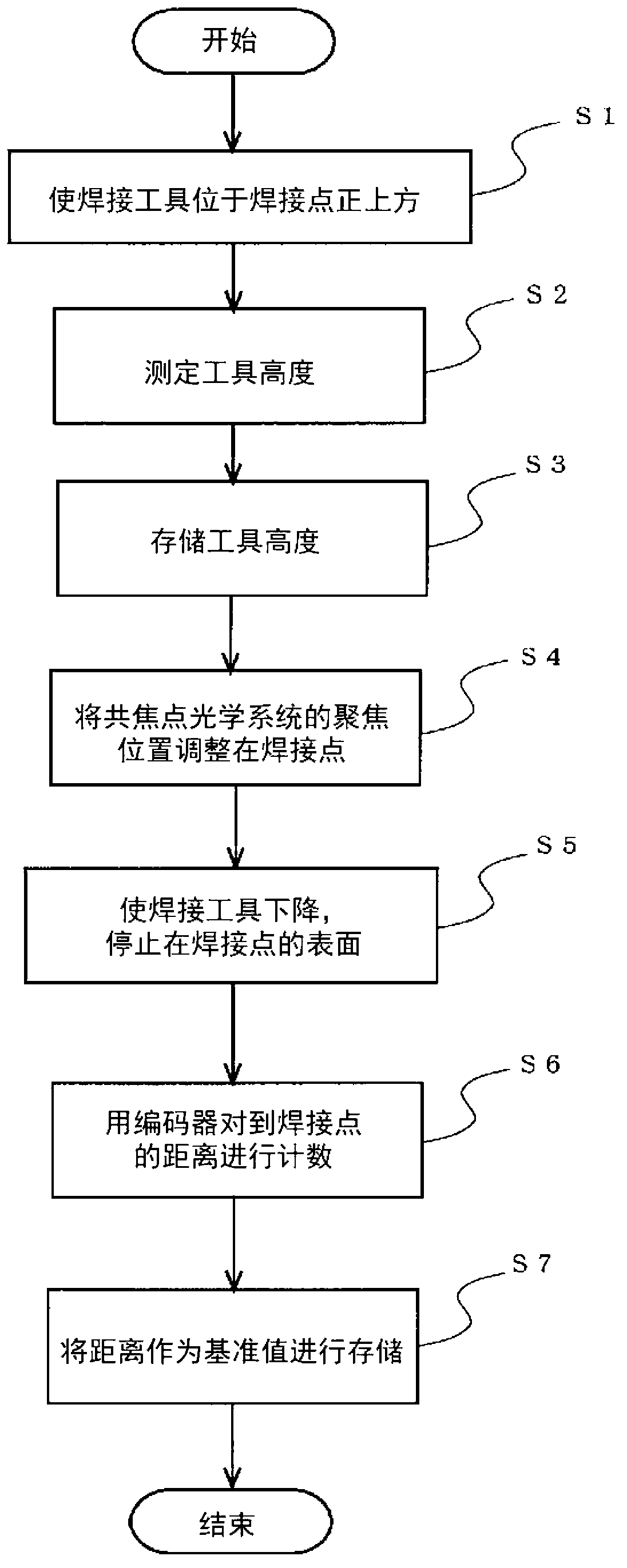

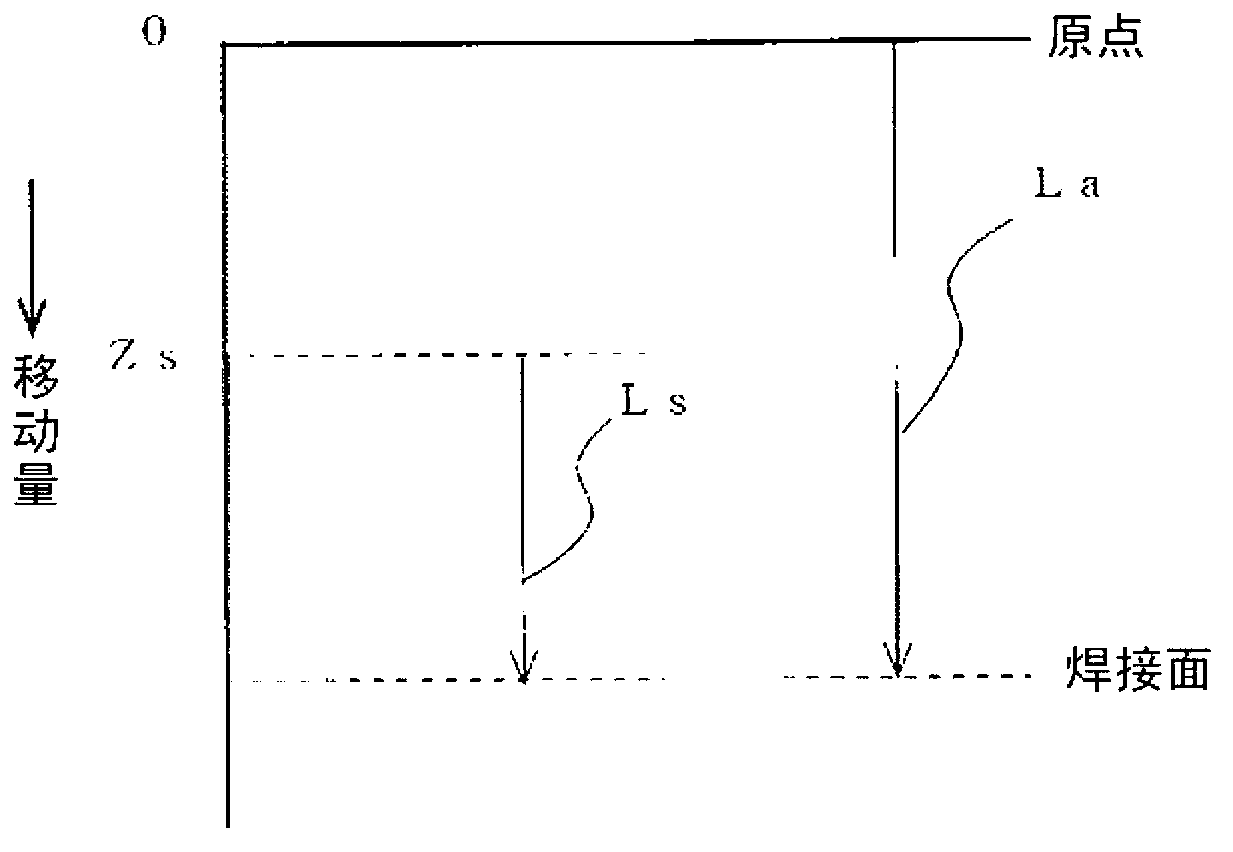

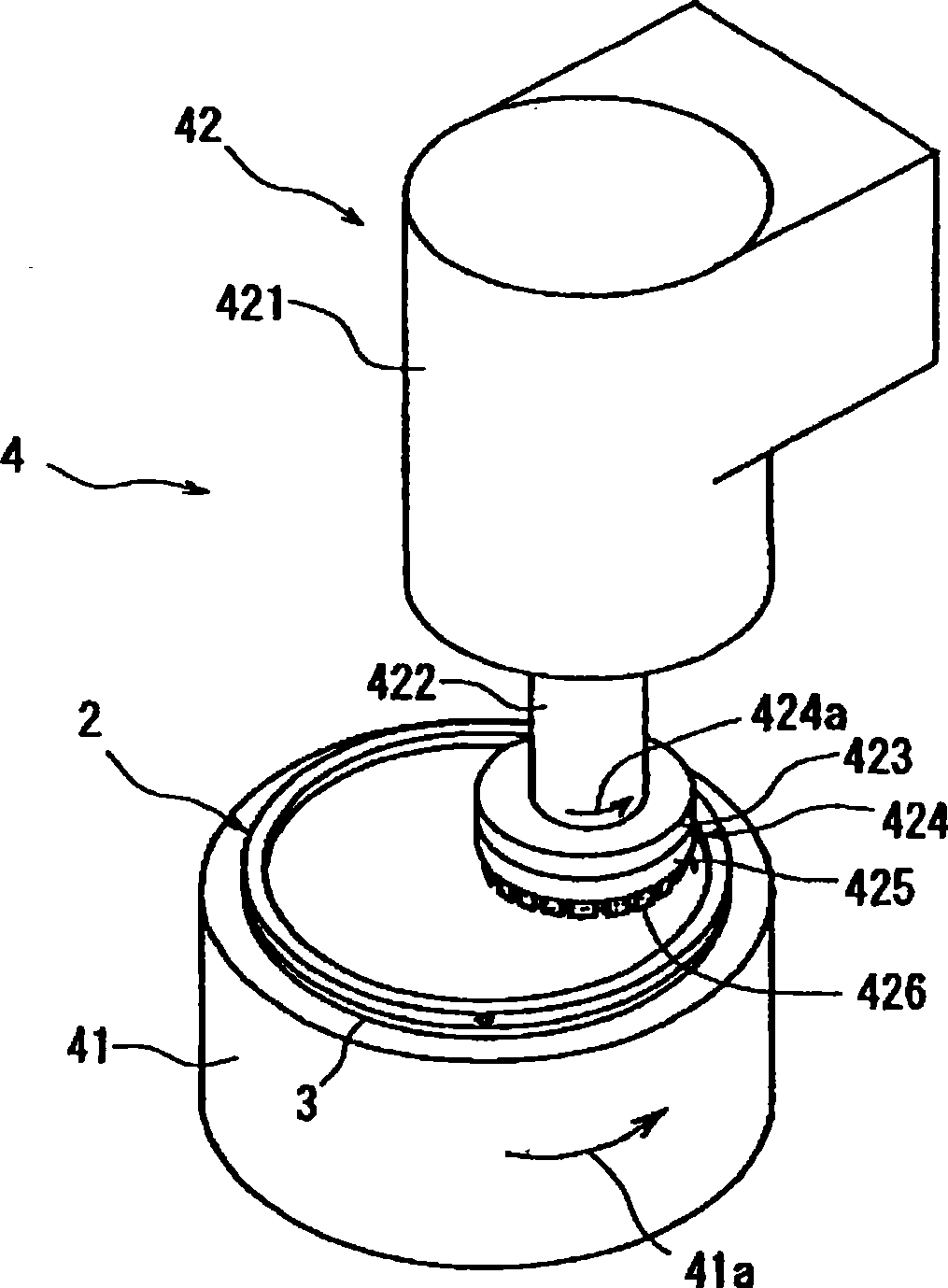

Bonding device

ActiveCN103262229AIncrease production quantitySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringHigh velocity

The purpose of the invention is to provide a bonding device that is capable of bonding at high speed without measurement of a bonding point height before a search operation or before bonding. The invention comprises: a confocal point optical system mounted on a bonding arm capable of swinging in the up / down direction and detecting the focused focal point of a bonding point positioned on a surface of a part to be bonded; a bonding tool that bonds and is integrally mobile with the bonding arm; and a position detection means that detects the position of the bonding tool. Control is provided so that the bonding tool descends a specified distance (focused focal point reference descent amount), from a bonding tool position the position detection means detected during the descent of the bonding tool, said bonding tool position being detected by means of focused focal point detection by the confocal point optical system, to a preset bonding point, and stops on the bonding point.

Owner:KAIJOO KK

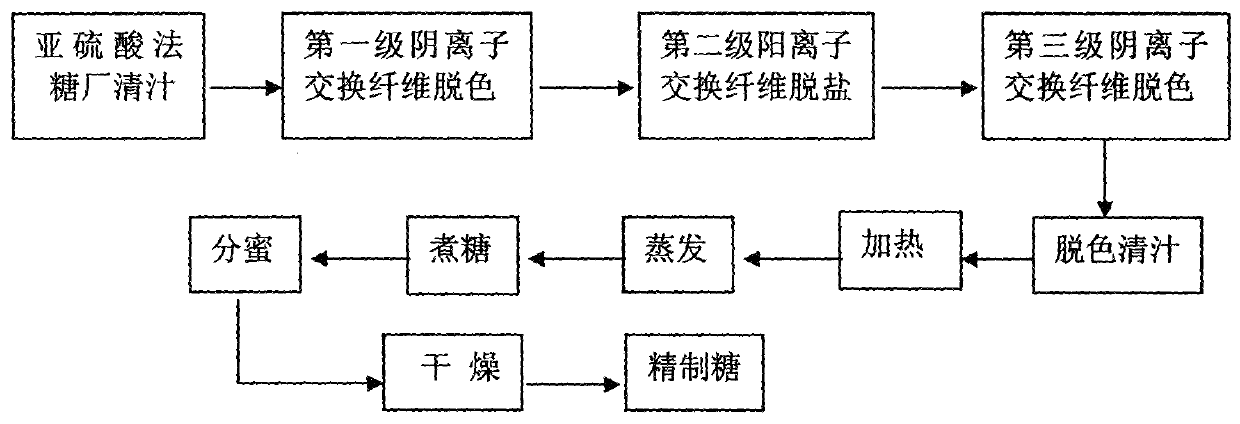

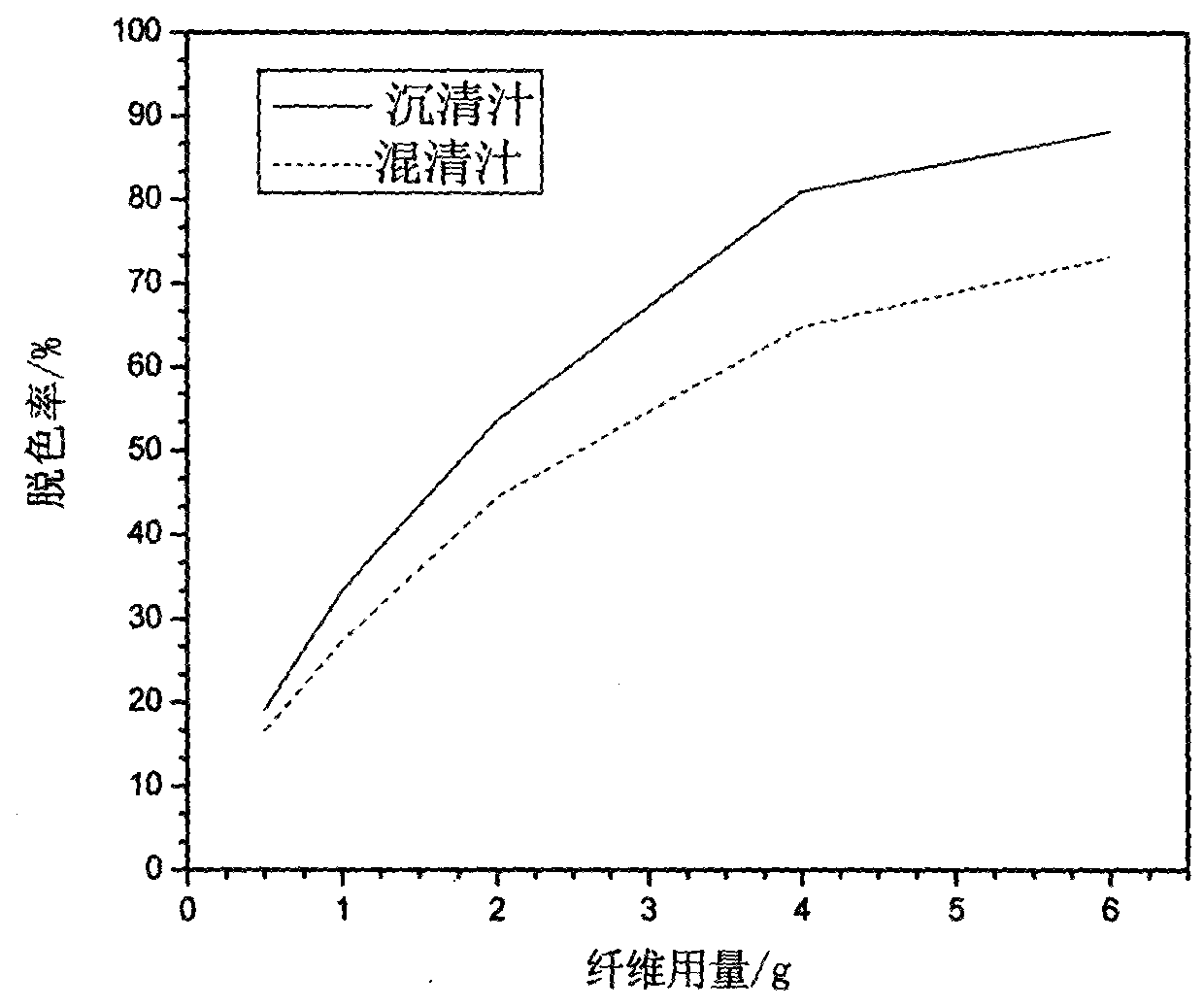

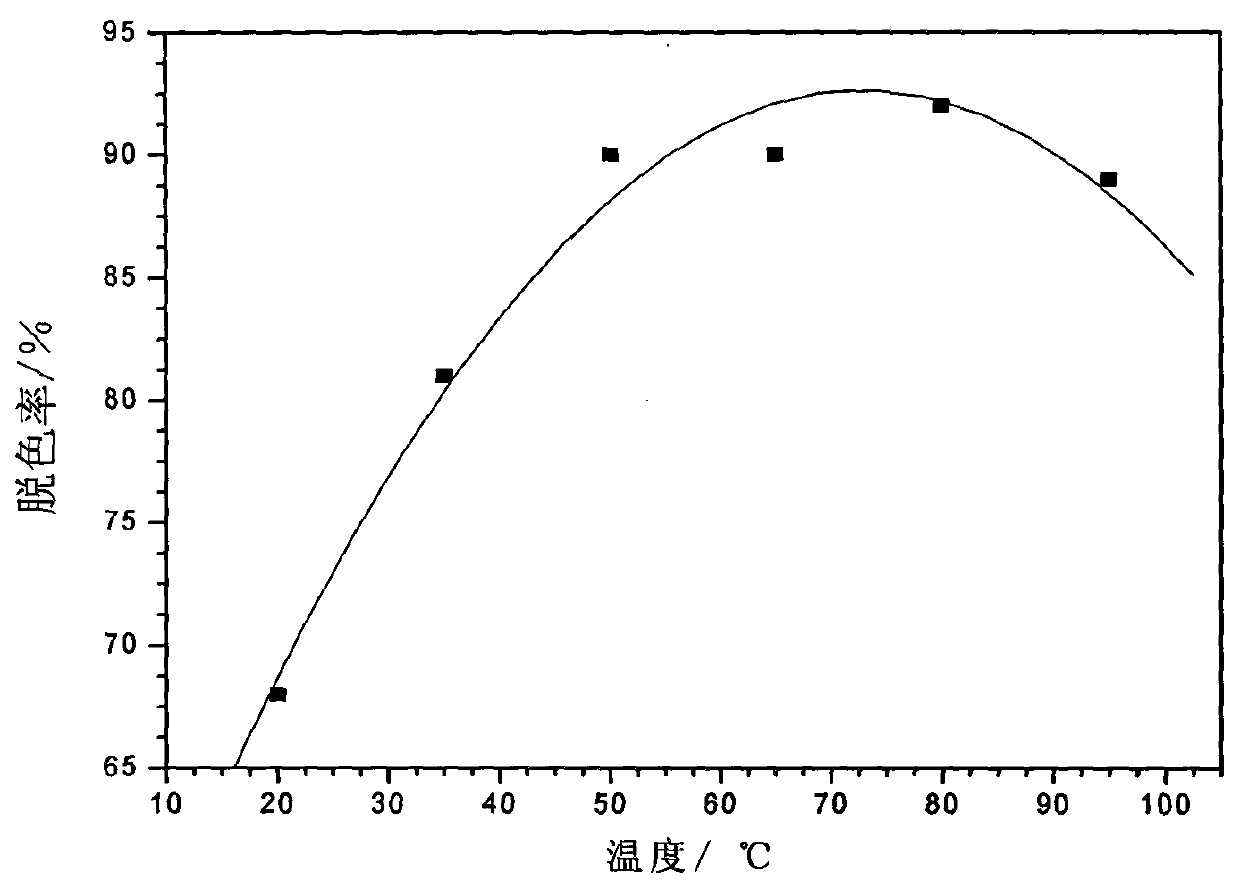

Method for producing refined sugar through ion-exchange fiber high efficiency decolorization one-step method

InactiveCN104195271AGuaranteed uniformityQuality assurancePurification using ion-exchange materialsFiberThree stage

The invention provides a method for preparing refined sugar through an ion-exchange fiber high efficiency decolorization one-step method. The method comprises the following steps: (1) conducting pre-treatment on sugar juice obtained through sugar preparation by a sulfurous acid method and a carbonic acid method; (2) conducting negative-positive-negative three-stage pillar exchange decolorization by adopting ion-exchange fiber until the sugar juice reaches the requirements of a refined sugar clear juice, and collecting into a clear juice box; (3) unloading sugar; (4) evaporating the refined sugar clear juice; (5) boiling sugar; (6) conducting help-crystallization and purging. According to the method provided by the invention, on the basis of the conventional sugar preparation process, the ionic fiber exchange process is added, the two-step method is replaced by the one-step method, and the refined sugar is prepared by directly using the sugar juice obtained through sugar preparation by the sulfurous acid method and the carbonic acid method, so that the technology is simple, the quality index of the sugar juice is improved, the product quality is good, the energy is saved, and the environmental pollution is reduced.

Owner:桂林正翰科技开发有限责任公司

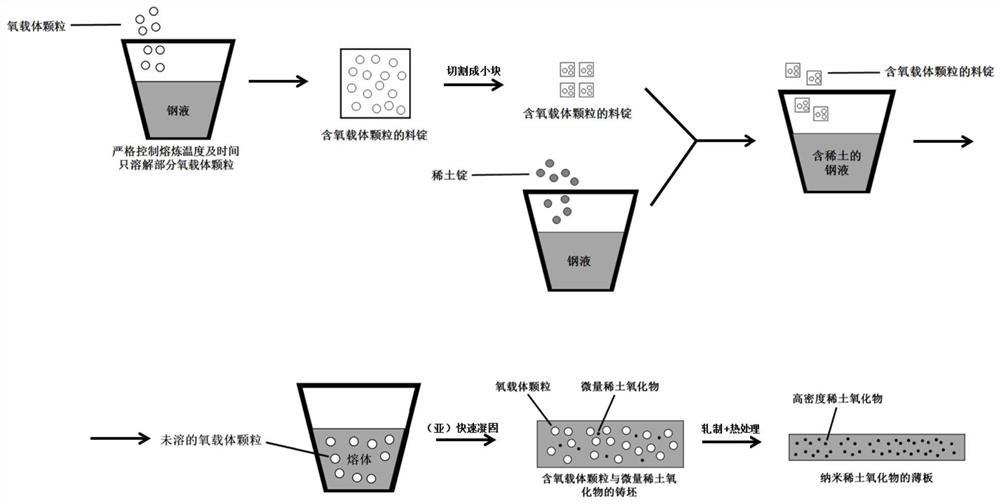

Preparation method of high-density oxide dispersion strengthened steel

The invention discloses a preparation method of high-density oxide dispersion strengthened steel, and belongs to the field of metal material preparation. The method comprises the following steps that1, a steel base body is placed in a container to be smelted into molten steel, after the steel base body is completely smelted, oxygen carrier particles are added into the molten steel, smelting is continued to be conducted to enable the oxygen carrier particles and the molten steel to be mixed, and cooling is conducted to obtain a material ingot; 2, a steel base body is placed in a container to be smelted into molten steel, and after the steel base body is completely smelted, rare earth elements are added into the molten steel to form molten steel containing the rare earth elements; 3, the material ingot is added into the molten steel containing the rare earth elements to be smelted to enable the material ingot to be dissolved, oxygen carrier particles in the material ingot are partiallydissolved to obtain a melt, and the melt is cooled to obtain a casting blank; and 4, the casting blank is subjected to rolling and heat treatment to obtain ODS steel. According to the preparation method, the ODS steel with the nano rare earth oxide with extremely high density can be prepared, and the performance of the prepared ODS steel is greatly improved.

Owner:SHANGHAI UNIV

Automatic feeding mechanism for tungsten carbide heating reduction furnace

ActiveCN111570817ASpread evenlyGood smoothing qualityCharge manipulationConveyor partsCarbideEngineering

The invention provides an automatic feeding mechanism for a tungsten carbide heating reduction furnace. The automatic feeding mechanism for the tungsten carbide heating reduction furnace comprises a conveying device, a weighing and discharging device, a smoothing device, a boat stacking device, a lifting device, a boat pushing device and a heating reduction furnace, wherein the conveying device, the weighing and discharging device, the smoothing device, the boat stacking device, the lifting device, the boat feeding device and the heating reduction furnace are arranged in sequence. The conveying device is used for receiving boats and conveying the boats to the subsequent device. The boats are provided with the upper boat and the lower boat. Footstands are arranged on two sides of the bottomof the upper boat, supporting seats are arranged on two sides of the top of the lower boat, the weighing and discharging device is used for receiving and weighing tungsten powder and discharging thetungsten powder into the boats, the smoothing device is used for smoothing the tungsten powder in the boats, the boat stacking device is used for stacking the upper boat to the lower boat, the liftingdevice is used for lifting the boats to the boat sending device, and the boat pushing device is used for pushing the boats into the heating reduction furnace. The automatic feeding mechanism for thetungsten carbide heating reduction furnace has reasonable structural design and high degree of automation, realizes an efficient, high-quality, and safe feeding process of the heating reduction furnace, the production efficiency is effectively improved, the labor intensity of personnel is reduced, and hidden safety dangers to personnel is avoided.

Owner:湖南蓝天机器人科技有限公司

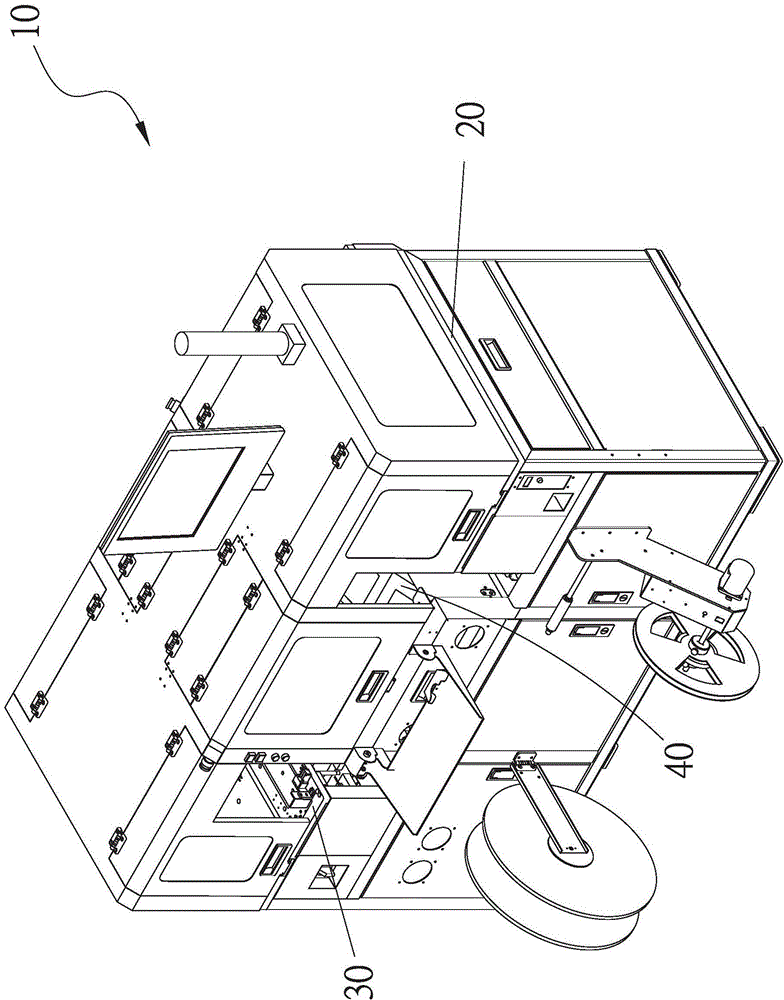

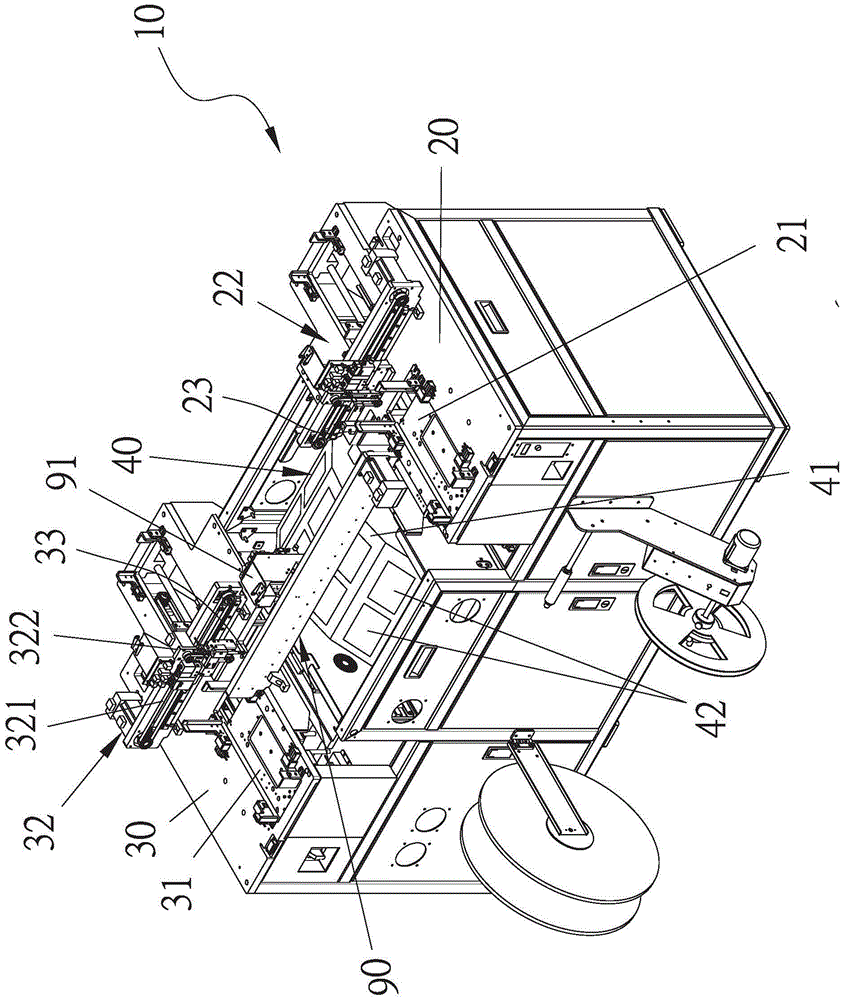

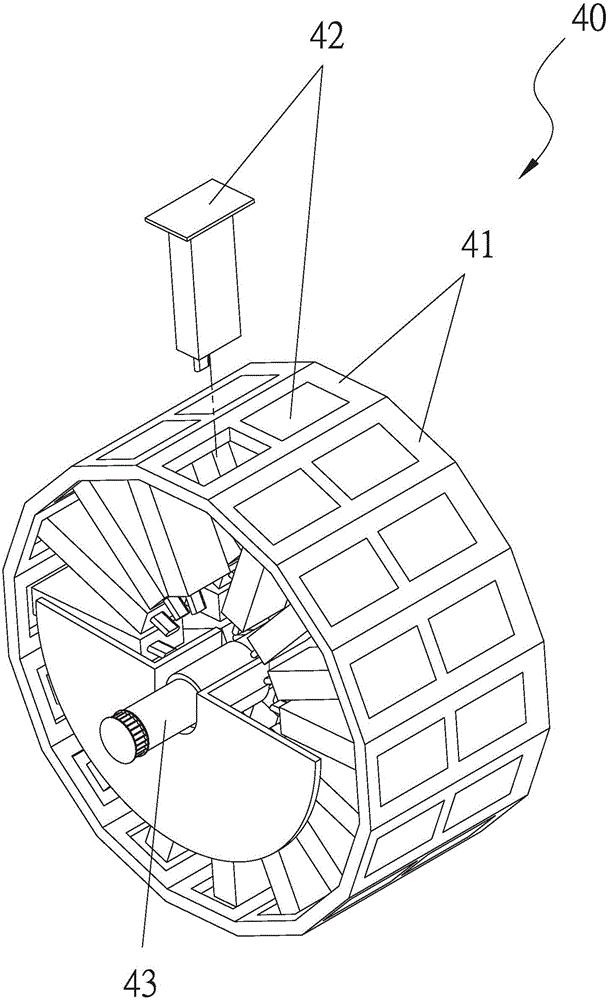

Drum type chip burning equipment

ActiveCN105654148AIncrease the number of placementsIncrease production quantityConveying record carriersBurn unitsEngineering

The invention relates to drum type chip burning equipment comprising a burning unit. A first working platform, a second working platform, a drum type burning device, and a material taking device are arranged in the burning unit; a material placing part and a feeding device are arranged at the first working platform; and a conveying device is arranged on the second working platform. The drum type burning device is arranged between the first working platform and the second working platform by a shaft; a plurality of plane parts are arranged at the drum type burning device in an annular mode; and at least one burning machine is arranged at each plane part. According to the invention, the multiple plane parts are arranged at the drum type burning device in an annular mode and each plane part is provided with at least one burning machine; and the drum type burning device is arranged between the first working platform and the second working platform by the shaft. The feeding device can place ICs without burning processing in sequence and the conveying device can take ICs with completed burning in sequence. Therefore, an effect of increasing of the number of placed ICs can be realized by using the drum type burning device and thus the produced number can be increased; and an objective of boosting of the production speed can be achieved.

Owner:王安松

Pressure device for correction of dental bracket grooves

ActiveCN110773598AImprove operational efficiencyIncrease production quantityEngineeringMouth opening

Owner:VICHNET COMM SCI & TECH

Manufacturing system for vacuum glass

The invention relates to a manufacturing system for vacuum glass. The system comprises a high-temperature heating box, a low-temperature sealing box and a vacuum pump, wherein a communicated hot air pipe is arranged between the high-temperature heating box and the low-temperature sealing box; the low-temperature sealing box consists of a movable sealing box cover and a pumping box; and the movable sealing box cover and the pumping box are arranged hermetically. The manufacturing system for vacuum glass consists of the high-temperature heating box and the low-temperature sealing box, and a hot air pipeline of the low-temperature sealing box is communicated with a pipeline of the high-temperature heating box, therefore the waste heat of the high-temperature heating box can be fully utilized by a low-temperature vacuum furnace so as to remove moisture from a vacuum glass vacuum cavity. The manufacturing system for vacuum glass has the advantages of environment friendliness, energy conservation and capabilities of removing the moisture from the vacuum glass and improving the quality of vacuum glass; moreover, the entire manufacturing system is combined organically, so that continuous production of vacuum glass is facilitated, and the production efficiency is increased.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

Rubber cock cap for internal combustion engine and use method thereof

InactiveCN109228092AControl wall thicknessIncrease production quantityExternal combustion engineEconomic benefits

The invention discloses rubber cock cap for an internal combustion engine and a use method thereof. The rubber cock cap comprises a machine frame, wherein a raw material falling cavity is arranged inthe machine frame; a raw material outlet cavity is arranged above the raw material falling cavity; a communicated raw material conveying cavity is arranged at the right side of the raw material falling cavity; a communicated processing cavity is arranged at the right side of the raw material conveying cavity; a finished product falling cavity which is communicated with the processing cavity, has adownward opening and is communicated with the outside is arranged under the processing cavity; a communicated pushing plate translation cavity is arranged at the left side of the raw material conveying cavity; a second pushing plate translation cavity is arranged above the first pushing plate translation cavity. The device structure is simple; the operation is convenient; through the device, therubber formation realizes the process automation; a discharging device can complete the simple single discharging by a simple mechanical structure; the ductility of the device is high; users can increase the production quantity of the cock caps at the same time according to requirements; the economic benefits are increased.

Owner:俞李娜

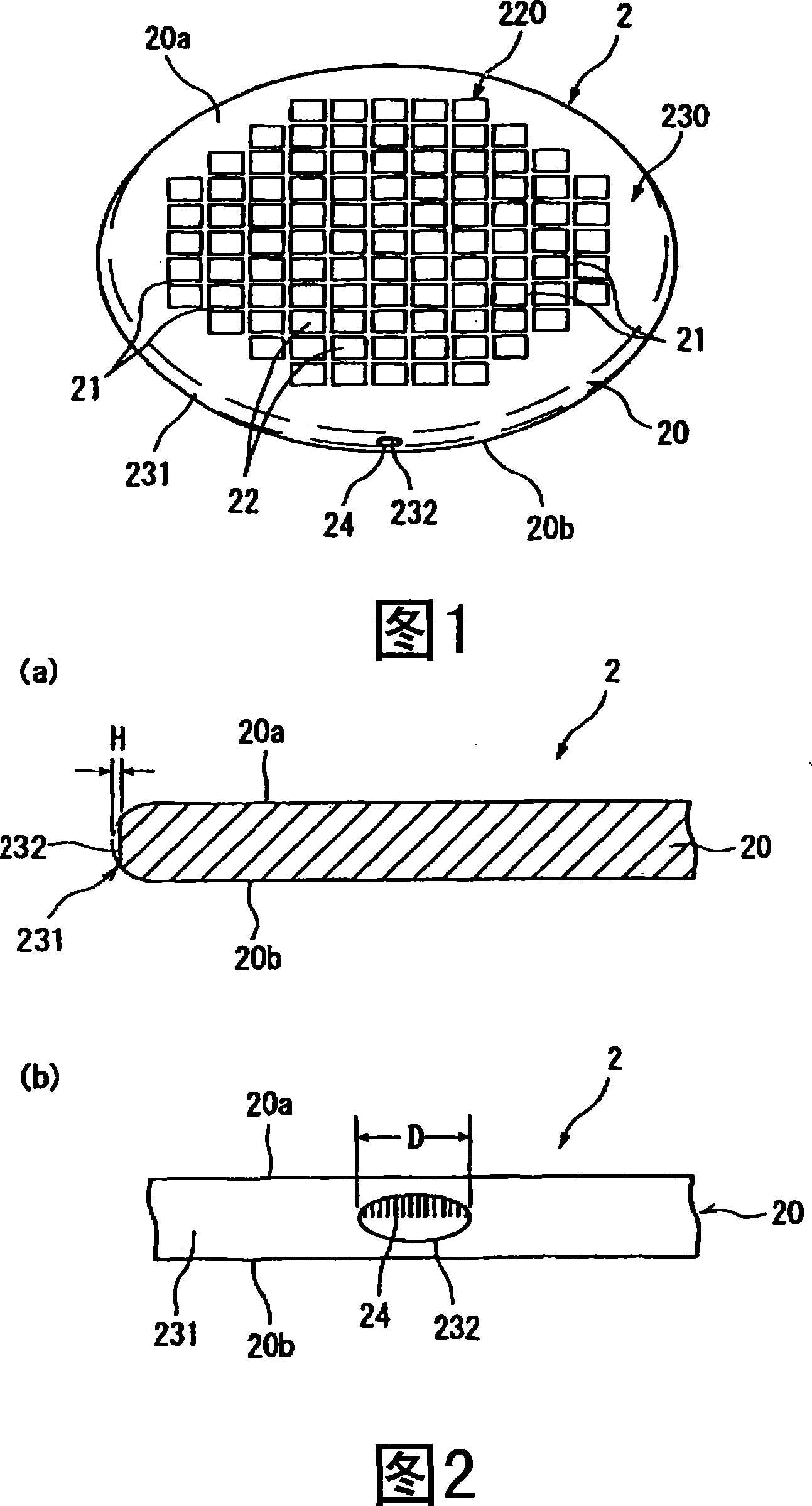

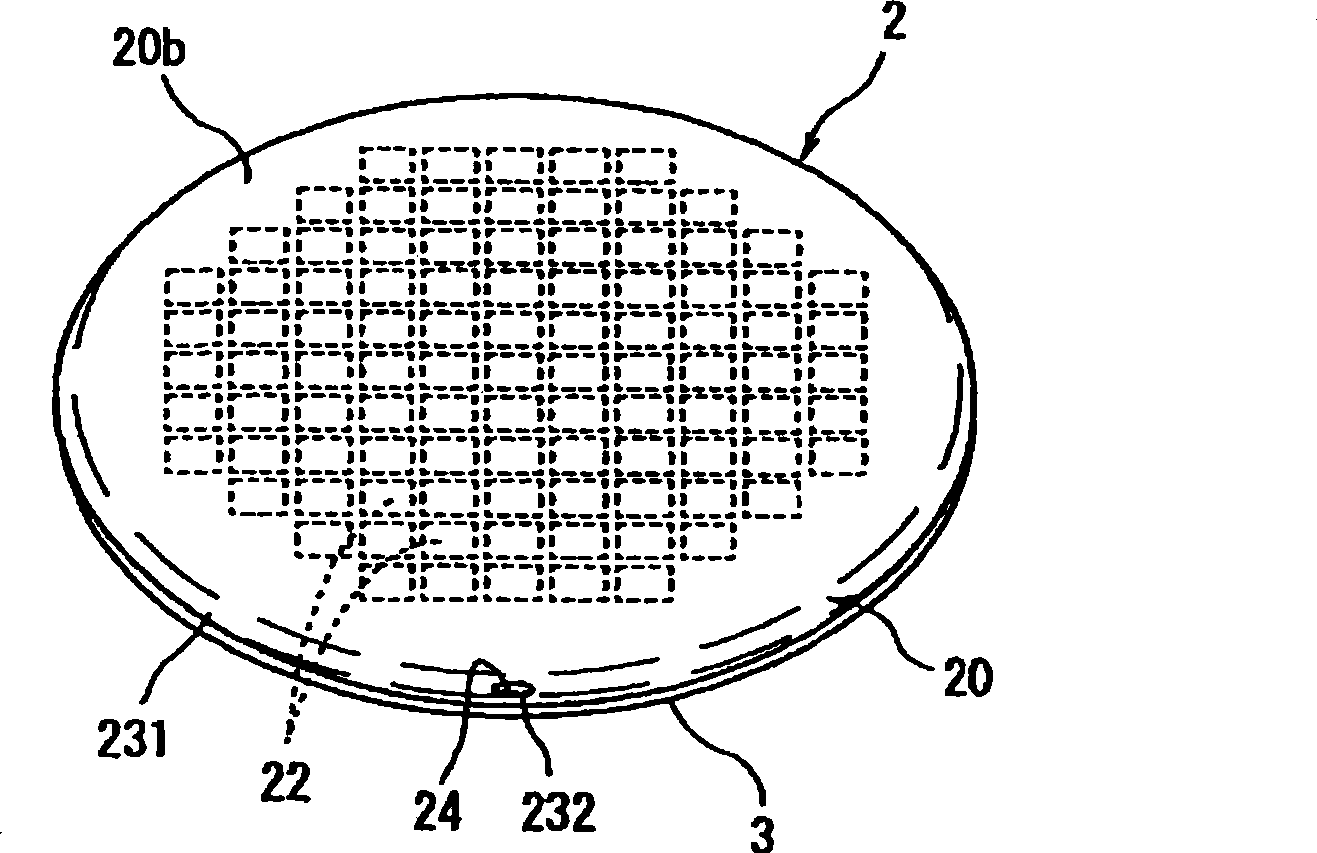

Wafer

ActiveCN101383339AGuaranteed widthIncrease production quantitySemiconductor/solid-state device detailsSolid-state devicesCrystal orientationEngineering

A wafer having a device region, where a plurality of devices is formed, and an outer peripheral surplus region, which surrounds the device region, on the face of a circular wafer substrate is disclosed. A chamfered portion whose cross-sectional shape defines an arc-shaped surface in a range from the face to the back of the wafer substrate is formed in an outer peripheral end portion of the outer peripheral surplus region of the wafer substrate. A flat surface orthogonal to the face and the back is formed in the chamfered portion as a mark showing the crystal orientation of the wafer substrate. An identification code for specifying the wafer substrate is printed on the flat surface.

Owner:DISCO CORP

Plug cap for internal combustion engine

InactiveCN109130047AControl wall thicknessIncrease production quantityExternal combustion engineEconomic benefits

The invention discloses a plug cap for an internal combustion engine. The plug cap comprises a machine frame, wherein a raw material receiving cavity is arranged in the machine frame; a raw material outlet cavity is arranged on the raw material receiving cavity; a raw material conveying cavity which communicates with the raw material receiving cavity is arranged on the right side of the raw material receiving cavity; a processing cavity which communicates with the raw material conveying cavity is arranged on the right side of the raw material conveying cavity; a finished product receiving cavity which is communicated with the processing cavity and external environment is arranged under the processing cavity, and the opening of the finished product receiving cavity faces downwards; a firstpush plate translation cavity which is communicated with the raw material conveying cavity is arranged on the left side of the raw material conveying cavity; a second push plate translation cavity which is parallel to the first push plate translation cavity is arranged above the first push plate translation cavity. The plug cap disclosed by the invention is simple in structure and convenient to operate, and has the advantages that the automatic process of rubber shaping is realized; a discharge device is arranged, so that simple single discharge can be completed by a simple mechanical structure; the ductility is high, so that the production quantity of the plug caps can be increased as required by users, and the economic benefits can also be increased.

Owner:俞李娜

Bamboo slicer convenient for positioning and regulating slicing amount

The invention discloses a bamboo slicer convenient for positioning and regulating slicing amount. The bamboo slicer comprises a main body, wherein one side of the main body is equipped with a pullingring; the top of the pulling ring is rotatably connected with a top fixed rod; the bottom of the pulling ring is rotatably connected with a bottom fixed rod; the two sides of the pulling ring are equipped with slide wheel fixed plates; the inner parts of the slide wheel fixed plates are rotatably connected with slide wheels; one side, adjacent to the slide wheel fixed plates, of the pulling ring is rotatably connected with a top lead screw and a bottom lead screw; the bottom lead screw is positioned below the top lead screw; and one side, away from the pulling ring, of the bottom lead screw isequipped with a bottom motor. According to the bamboo slicer disclosed by the invention, a movable rod, a top plate, a top rod, a pushing ring, a pushing motor, a pushing lead screw, a top fixed rod,a pulling ring, a top lead screw, a top motor, a bottom motor, a bottom lead screw, a bottom fixed rod, a slide wheel fixed plate and a slide wheel are arranged, so that working strength of a user isreduced, and safety guarantee of the user is improved.

Owner:黄琴

Manufacturing process of vacuum glass

ActiveCN102295404BQuality improvementRealize continuous productionGlass reforming apparatusGlass productionEngineeringMoisture

The invention relates to a manufacturing process of vacuum glass, which comprises the following steps: (1) sheet binding, that is, cutting an upper and a lower piece of flat glass into sheets, placing a supporting substance between the two pieces of glass, placing a low-melting glass powder or a binder between the upper and the lower piece of flat glass, welding and mounting an air exhaust glass tube at the side edge or the side surface of the angle part, wherein the air exhaust glass tube is a sealed glass tube; (2) heating for edge sealing in a high-temperature heating box; (3) orderly placing the glass with a sealed edge into a clamping frame which is fixedly mounted on a bottom plate in an air exhaust box of a low-temperature heating furnace; (4) vacuum pumping, that is, starting a vacuum pump, performing vacuum pumping of a cavity in the vacuum glass to reach a set vacuum degree, performing hot-melt sealing of the air exhaust tube by an electrically-fusing electrode, cooling to room temperature, taking the product out of the furnace to obtain the vacuum glass. In the manufacturing process of vacuum glass, the air exhaust tube mounted in the high-temperature heating box is a blind-hole tube, and thus during the cooling process after the edge sealing of the vacuum glass, outdoor air is prevented from entering the vacuum glass cavity; the air in the cavity is maintained to be dry; the specific gravity of the air in the cavity is decreased; the vacuum degree in the cavity is increased; during the vacuum pumping of the cavity, the air exhausting efficiency is increased; procedures for removing moisture in the cavity is reduced; and the quality of the vacuum glass is guaranteed.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

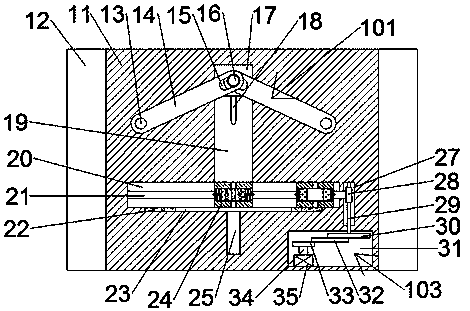

The improved structure of mold components that greatly improves the casting precision of lightweight aluminum pistons

ActiveCN111421114BPrevent side swingEliminate distractionsFoundry mouldsFoundry coresClassical mechanicsStructural engineering

The invention relates to an improved structure of a mold assembly for greatly improving the casting precision of lightweight aluminum pistons, which is applied to mass production of high-precision lightweight aluminum pistons. It includes outer mold, pin hole mold, slider mold and core mold. The mandrel includes a piston mandrel centerpiece. The central part of the piston mandrel consists of a quadrangular pyramid column and a supporting platform connected with the quadrangular pyramid column. It is characterized in that the support rail opens the groove along the center line, the bottom of the pin hole mold has a straight rod, the straight rod is as wide as the through groove and extends into the through groove; the upper part of the pin hole mold has a T-shaped guide rail groove, and the upper part of the outer mold cavity With T-shaped guide rail, the T-shaped guide rail groove is set on the T-shaped guide rail. The pin hole die has a lower pressing block for the pin hole. The quadrangular pyramid column and the supporting platform are fastened and connected by bolts with chord sections. The end face hole of the bolt is connected with the side hole of the bolt, and a deep hole of the square pyramid column is opened on the lower end surface of the square pyramid column. It has the advantages of avoiding various abnormal wear and tear of the pin hole mold, greatly enhancing the anti-turbulence performance, and improving the precision of the thickness of the radial casting involved in the slider mold during production.

Owner:HUAMIN NANPING AUTOMOBILE FITTINGS GROUP

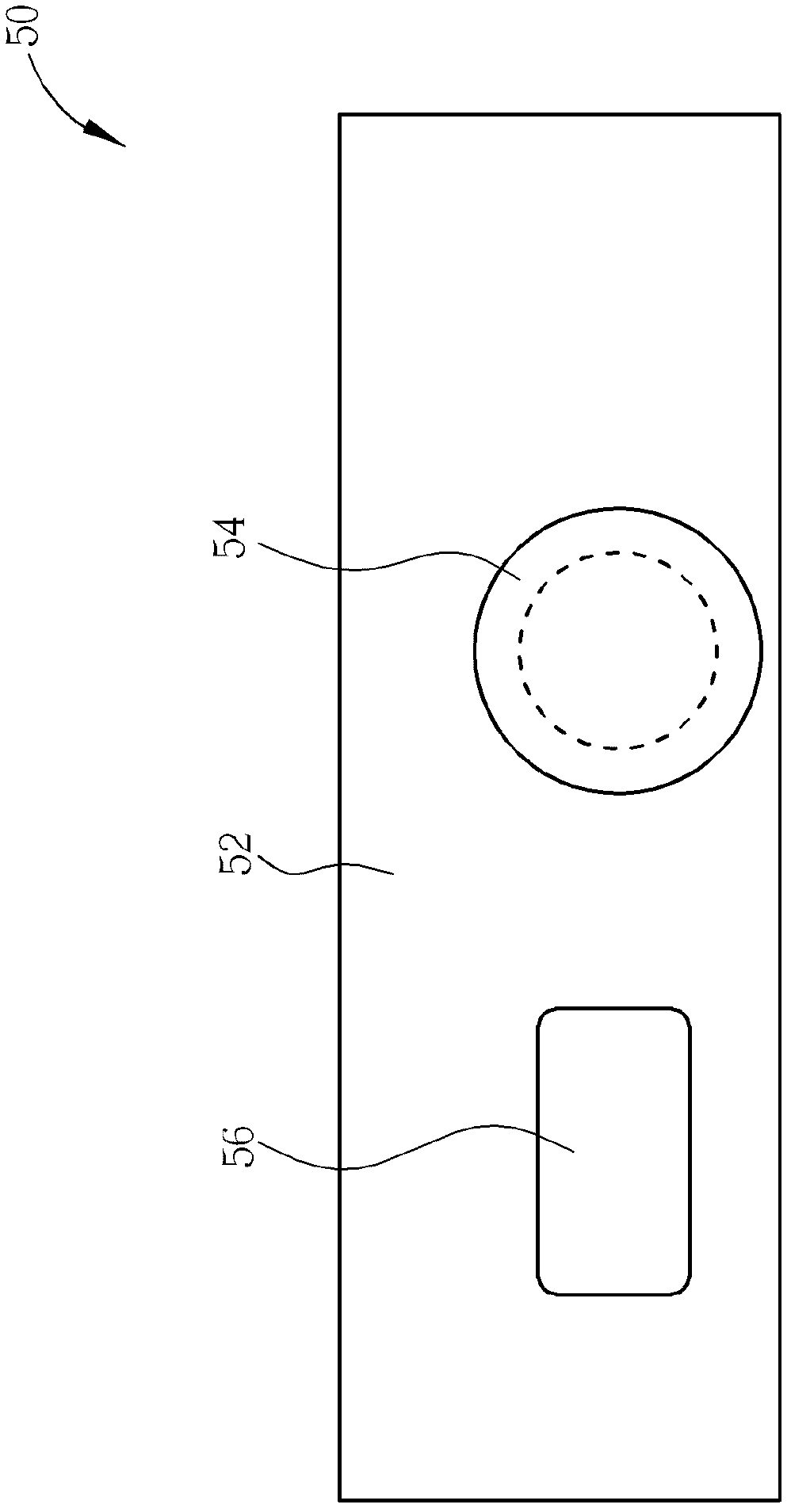

Lithium-ion secondary battery

ActiveUS8876917B2Increase production quantityDifficult to identifyAssembling battery machinesFinal product manufactureLithiumEngineering

A lithium-ion secondary battery is provided where the production process line that fabricated it can be identified. The lithium-ion secondary battery includes a jelly roll, a positive electrode tab, a negative electrode tab, a positive electrode can, and a lid. The jelly roll is made by rolling the positive electrode and the negative electrode with an interposed separator, and is contained in the casing. The positive electrode tab has one end connected to the positive electrode of the jelly roll and the other end connected to the lid. The negative electrode tab has one end connected to the negative electrode of the jelly roll and the other end connected to a terminal provided on the lid. The other end of the negative electrode tab has a shape with a cut at a cut angle determined in accordance with the production process line that fabricated the lithium-ion secondary battery.

Owner:MAXELL HLDG LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com