Patents

Literature

191results about How to "Tooling structure is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

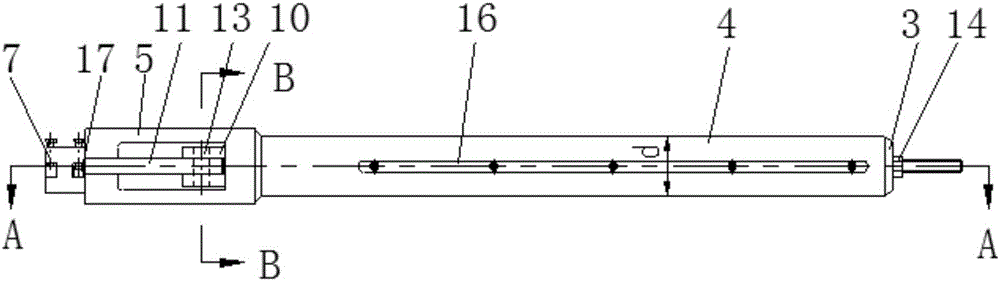

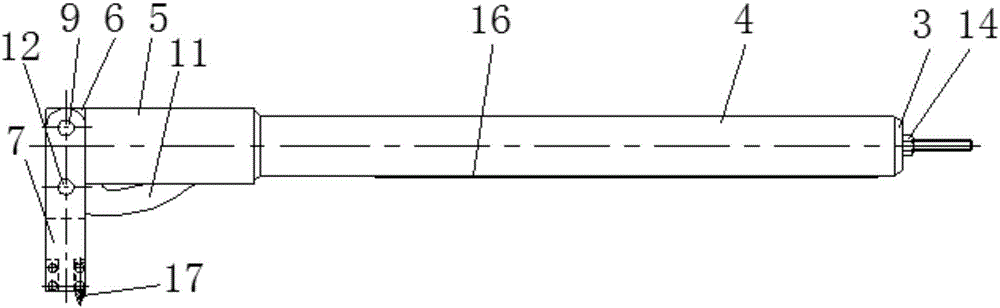

Machining technology of elongated thin-wall C-shaped tubular parts

ActiveCN103846624AImprove processing qualityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringCylindrical grinding

The invention discloses a machining technology of elongated thin-wall C-shaped tubular parts and belongs to the technical field of machining precision parts. The machining technology comprises the steps of blanking, hot and cold processing, aging strengthening, rough machining, finish machining and through groove machining, wherein the blanking comprises bar material cutting, the rough machining comprises inner hole drilling and outer circle rough turning, the finish machining comprises outer circle finish turning, inner circle grinding and end surface cutting, the elongated thin-wall C-shaped tubular parts are machined by selecting a bar material, the machining quality and efficiency of the parts can be greatly increased through a concise and practical process route, and the technical difficulties of elongated shaft machining, thin-wall piece machining, deep hole machining, main guide rail groove machining and the like which relate to the elongated thin-wall C-shaped tubular parts can be solved.

Owner:GUIZHOU ZUNYI CHI YU PRECISION MACHINERY MFG

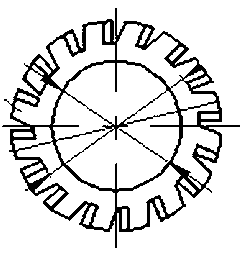

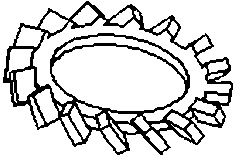

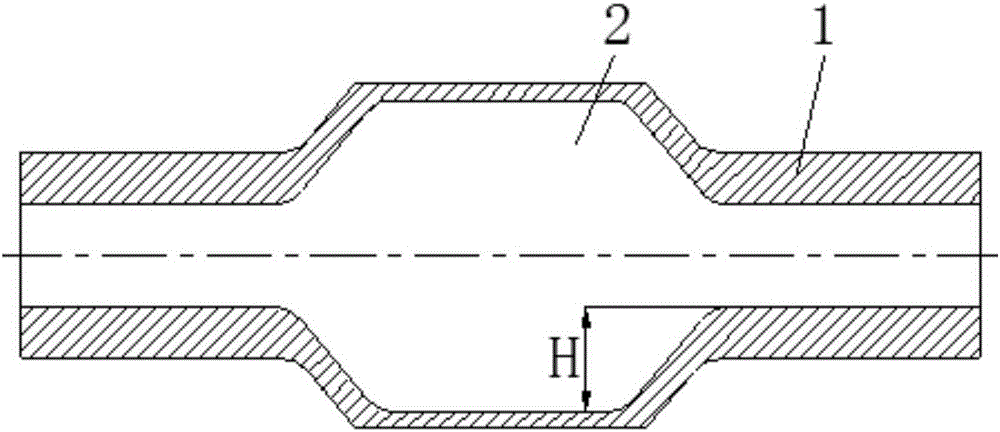

Processing crafts and tools of serrated lock washers external teeth

ActiveCN102974689AEasy loading and unloadingPrecise positioningShaping toolsTooth partManufacturing engineering

The invention discloses processing crafts and tools of serrated lock washers external teeth. According to the tools, a middle guide pillar mould base is adopted, and forming of parts is achieved by utilizing a manner that mold inserts provided with sawteeth are pressed mutually, wherein the mold inserts are arranged on end heads of an upper mold and a lower mold. In the process of machining of serrated lock washers external teeth part products, once tooth-pressing forming of the part products can meet the requirements of size and a performance test, and technological process is optimized by utilizing the crafts and the tools. And quality of the products machined by the crafts is guaranteed, and part-taking process is very convenient. The tools are simple in structure, flexible in machining method, accurate and reliable in positioning, and high in production efficiency, and the parts are convenient to assemble and disassemble. Guiding functions and valve of use for reference can also be provided for those internal serrated washer products which are large in types and varieties and specifications, small in batch and short in production cycle. And new product development of other similar structures can also be enlightened, and the processing crafts and the tools of the serrated lock washers external teeth are worthy of being popularized.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

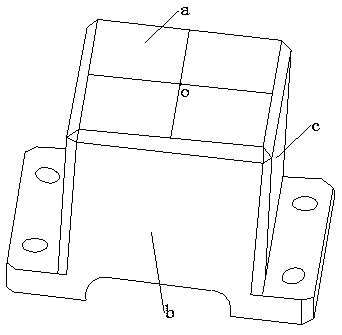

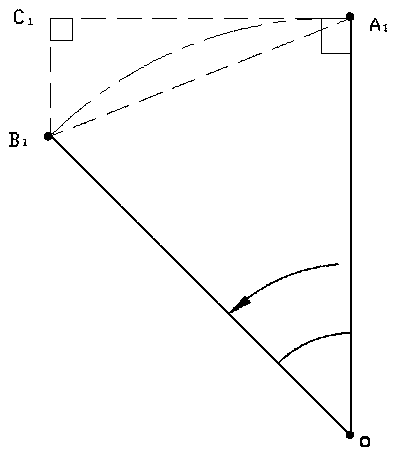

Zero calibration method of five-axis numerical control machine tool

ActiveCN109483322ARealize back to zero calibration workRealize automatic zero return calibrationAutomatic control devicesFeeding apparatusNumerical controlReturn-to-zero

The invention discloses a zero calibration method of a five-axis numerical control machine tool. The method can be used for completing calibration through three steps that first, a return-to-zero calibration tool is installed; second, a linear shaft is subjected to return-to-zero calibration; and third, a rotating shaft is subjected to return-to-zero calibration. The calibration tool is simple instructural design, the linear shaft and the rotating shaft of the five-axis numerical control machine tool can be subjected to return-to-zero calibration, an actual rotating angle value of a C shaft is calculated according to the moving track so as to complete calibration, and in a similar way, return-to-zero calibration of an A shaft is achieved by utilizing a calibration surface c. The zero calibration method is simple in tool structure and simple in calibration step, a related calculating method is simple, and the problems in the prior art are well solved.

Owner:SHANDONG POLYTECHNIC

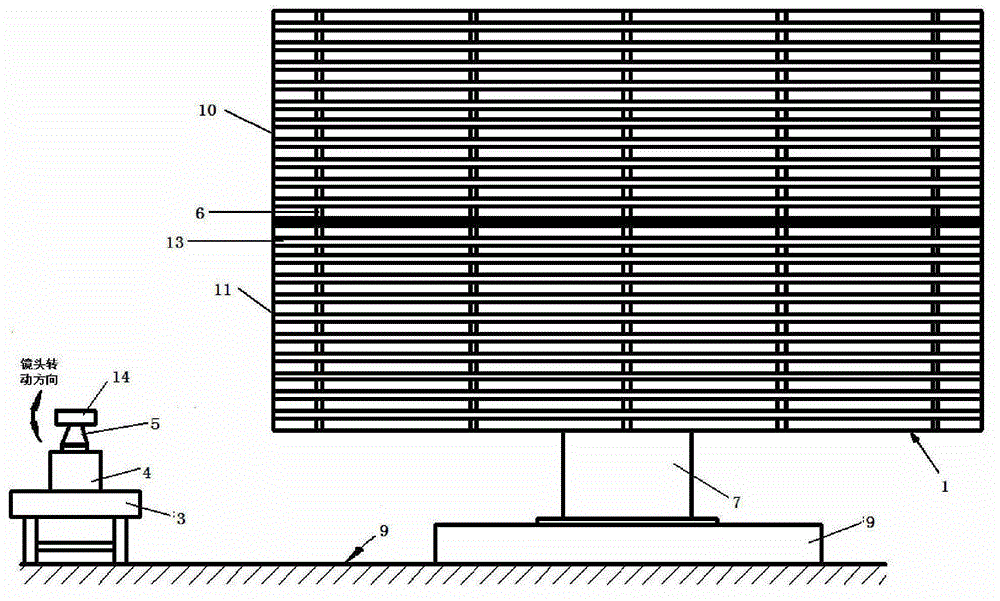

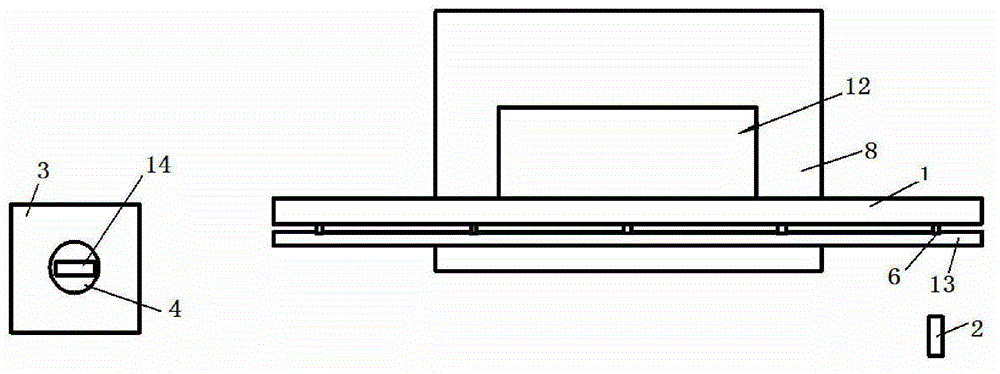

Installation precision detection method for planar array antenna surface

InactiveCN102749068AImprove detection accuracyReduce labor intensityIncline measurementTheodoliteEngineering

The invention discloses an installation precision detection method for a planar array antenna surface. A level-1'' level gauge is arranged just in front of an antenna skeleton; the side surface of an antenna is provided with a universal swivel table; a level-1'' theodolite is erected on the universal swivel table; and an antenna is detected by the theodolite, a depthometer and the level gauge. The installation precision detection method for the planar array antenna surface, which is disclosed by the invention, has the advantages of high detection precision, convenience and rapidness in detection, simple detection system structure, easiness in disassembling and assembling and the like.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

Method for manufacturing titanium alloy straightener blade

The invention discloses a method for manufacturing a titanium alloy straightener blade. The process flow comprises the following steps: A, preparing blanks; B, machining peripheral screw holes; C, milling a first reference surface; D, machining small positioning holes and milling a connecting surface; E, performing pre-connection pretreatment on the connecting surface; F, performing pre-connection assembly; G, performing diffusion bonding; H, performing post-connection milling; I, machining long oblique circular holes; J, performing post-connection treatment. The straightener blade manufactured with the method for manufacturing the titanium alloy straightener blade has the advantages of smooth surface, low cost and firmness in connection; moreover, the yield of the straightener blade manufactured by using the method is higher.

Owner:北京智创联合科技股份有限公司

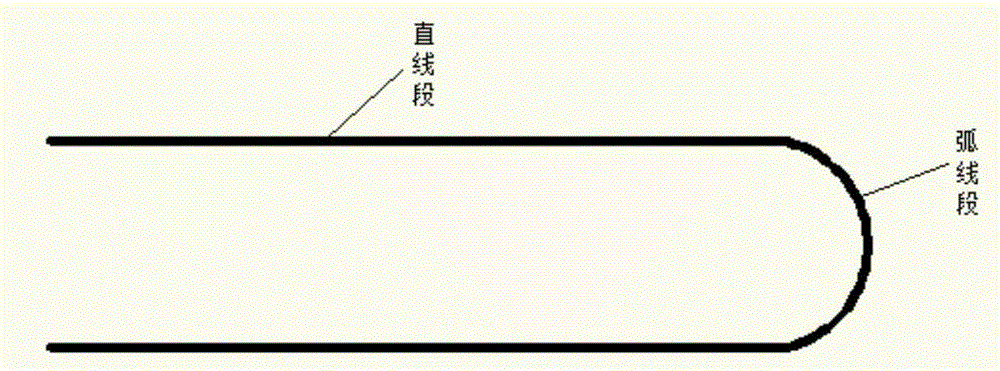

Machining method of high-precision and large-diameter ultralong and ultrathin shell

The invention relates to a machining method of a high-precision and large-diameter ultralong and ultrathin shell. The machining method comprises the following steps: (1) a rod is machined to a think-wall shell through a reverse extruding mode; (2) a spun blank having a size accordant with design requirements is obtained through machining; (3) a large-diameter ultralong and ultrathin aluminum alloy / aluminum base composite shell linear section part is obtained through multi-spinning travel and multipass strong spinning; (4) the annealing or solution treatment is performed for the shell linear section part in the step (3); (5) the acid washing is performed; (6) an arc part at the end part of the shell is machined with high precision; and (7) the whole inner and outer surfaces of the shell are polished to obtain a large-diameter ultralong and ultrathin aluminum alloy / aluminum base composite shell with high size precision and excellent performance. The large-diameter ultralong and ultrathin aluminum alloy / aluminum base composite shell, machined by the method, is higher in size precision, uniform and small in structure, excellent in comprehensive performance, high in material utilization rate, simple in tool and labor-saved in formation.

Owner:有研金属复材技术有限公司

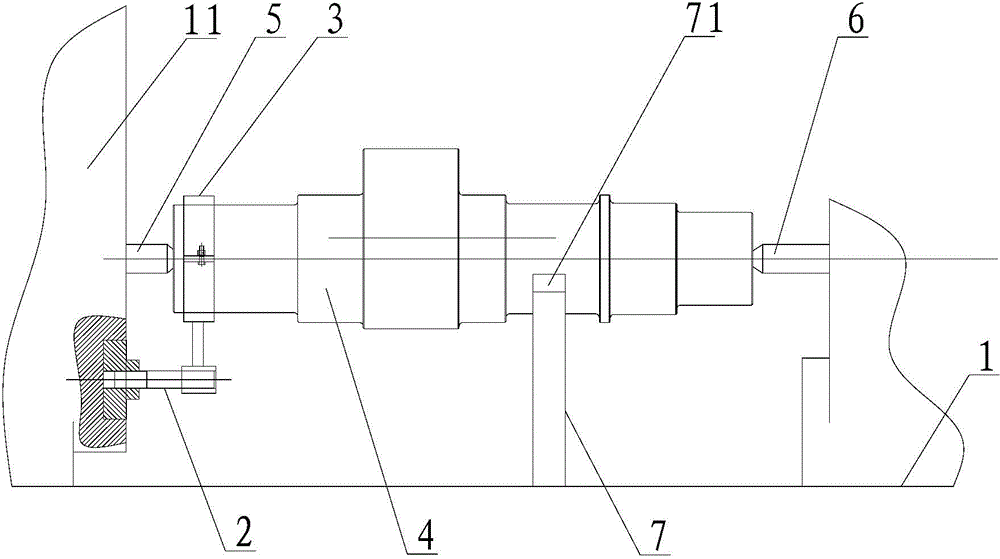

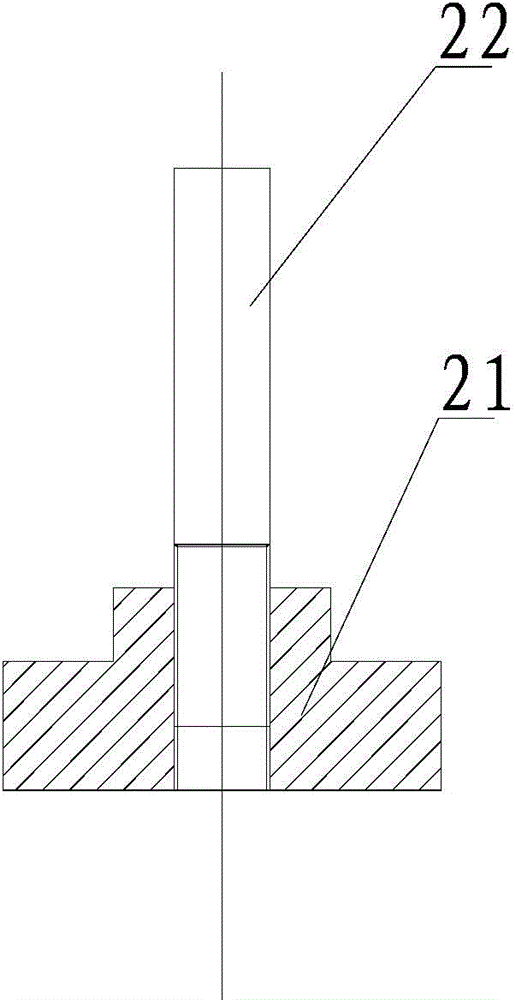

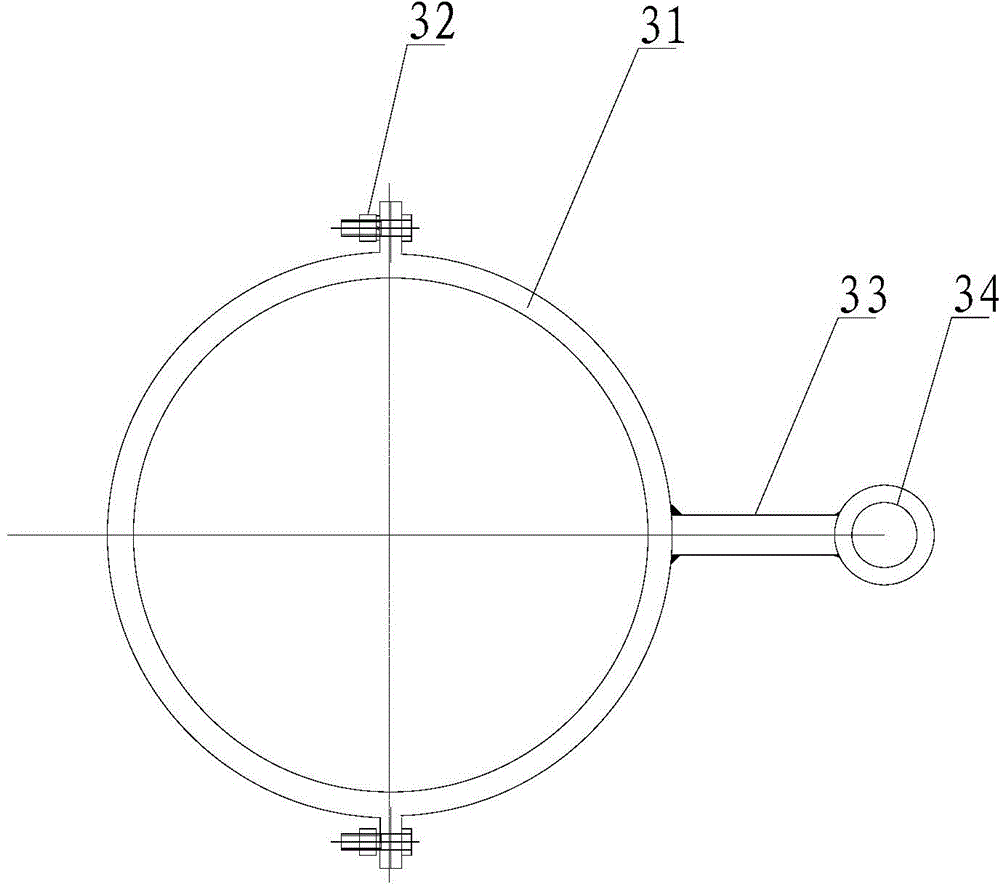

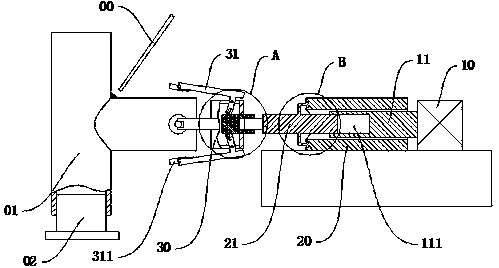

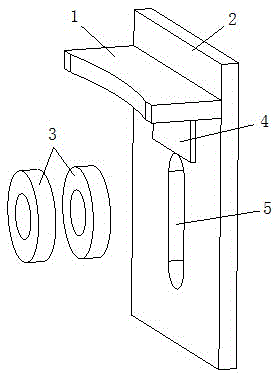

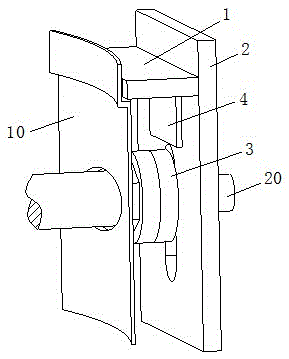

Eccentric shaft machining tool and method

InactiveCN103600270ASimple toolingTooling structure is simpleRevolution surface grinding machinesGrinding drivesLathe faceplateEngineering

The invention provides an eccentric shaft machining tool and method. The eccentric shaft machining tool comprises a deflector rod assembly fixed on a machine tool, a hoop assembly fixed on the deflector rod assembly, a front grinder apex and a rear grinder apex, wherein the hoop assembly is used for fixing an eccentric shaft in the radial direction; the front grinder apex and the rear grinder apex are fixed on the machine tool and used for positioning the eccentric shaft in the axial direction; the deflector rod assembly is fixed on a disc chuck at the front end of the machine tool; the disc chuck drives the eccentric shaft to rotate for grinding through the deflector rod assembly and the hoop assembly in the rotating process. The eccentric shaft machining tool is simple in structure, low in cost, capable of being combined with a general machine tool for use, wide in application range and high in efficiency.

Owner:SANY AUTOMOBILE MFG CO LTD

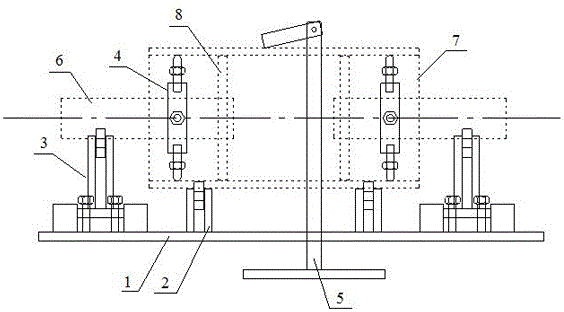

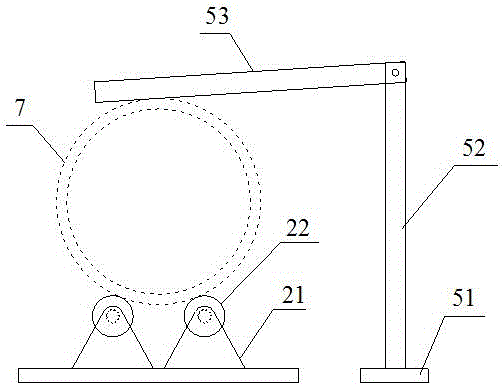

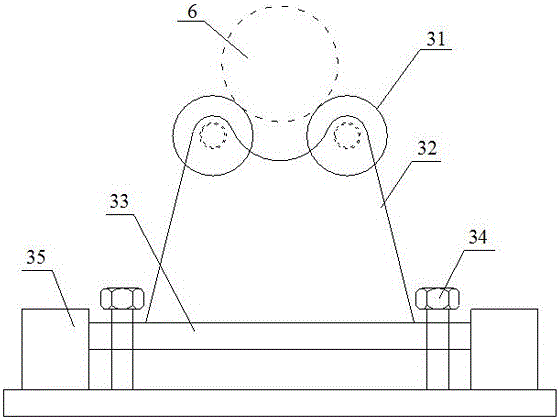

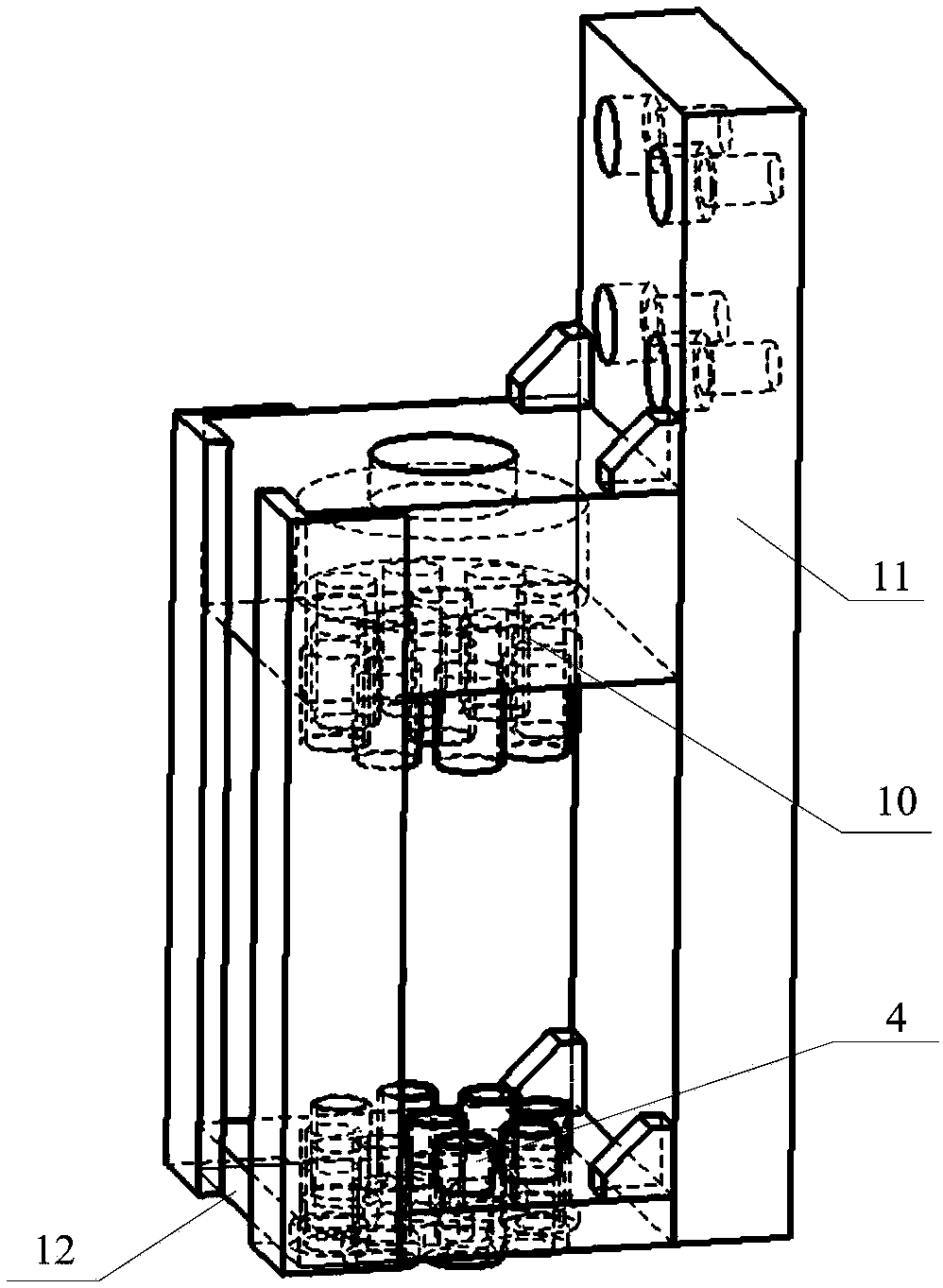

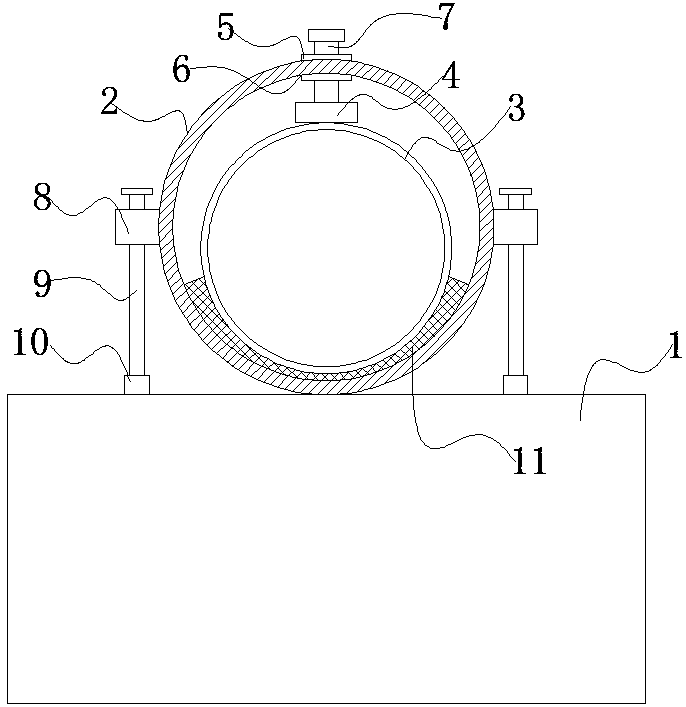

Roller assembly auxiliary tool

ActiveCN106584009AGuaranteed sizeTooling structure is simpleWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a roller assembly auxiliary tool. The roller assembly auxiliary tool comprises a base, a roller barrel locating mechanism, a roller shaft locating mechanism and a coaxial adjusting mechanism. The coaxial adjusting mechanism is located between a roller shaft and a roller barrel. The roller barrel locating mechanism comprises a roller barrel locating support and roller barrel locating rolling wheels. The roller barrel locating support is fixed to the middle of the base. The roller barrel locating rolling wheels are installed on the roller barrel locating support. The roller shaft locating mechanism comprises roller shaft locating rolling wheels, a roller shaft supporting seat, a roller shaft support bottom plate, a height adjusting bolt and limiting blocks. The roller shaft locating rolling wheels are fixed to the roller shaft supporting seat. The roller shaft supporting seat is installed on the roller shaft support bottom plate. The roller shaft support bottom plate is provided with the height adjusting bolt. The limiting blocks are located around the roller shaft support bottom plate and are welded to the two ends of the base. The roller assembly auxiliary tool can improve roller assembly precision and efficiency significantly and has the advantages of being simple in structure, reasonable in design, convenient to operate, low in cost and the like.

Owner:南通远洋船舶配套有限公司

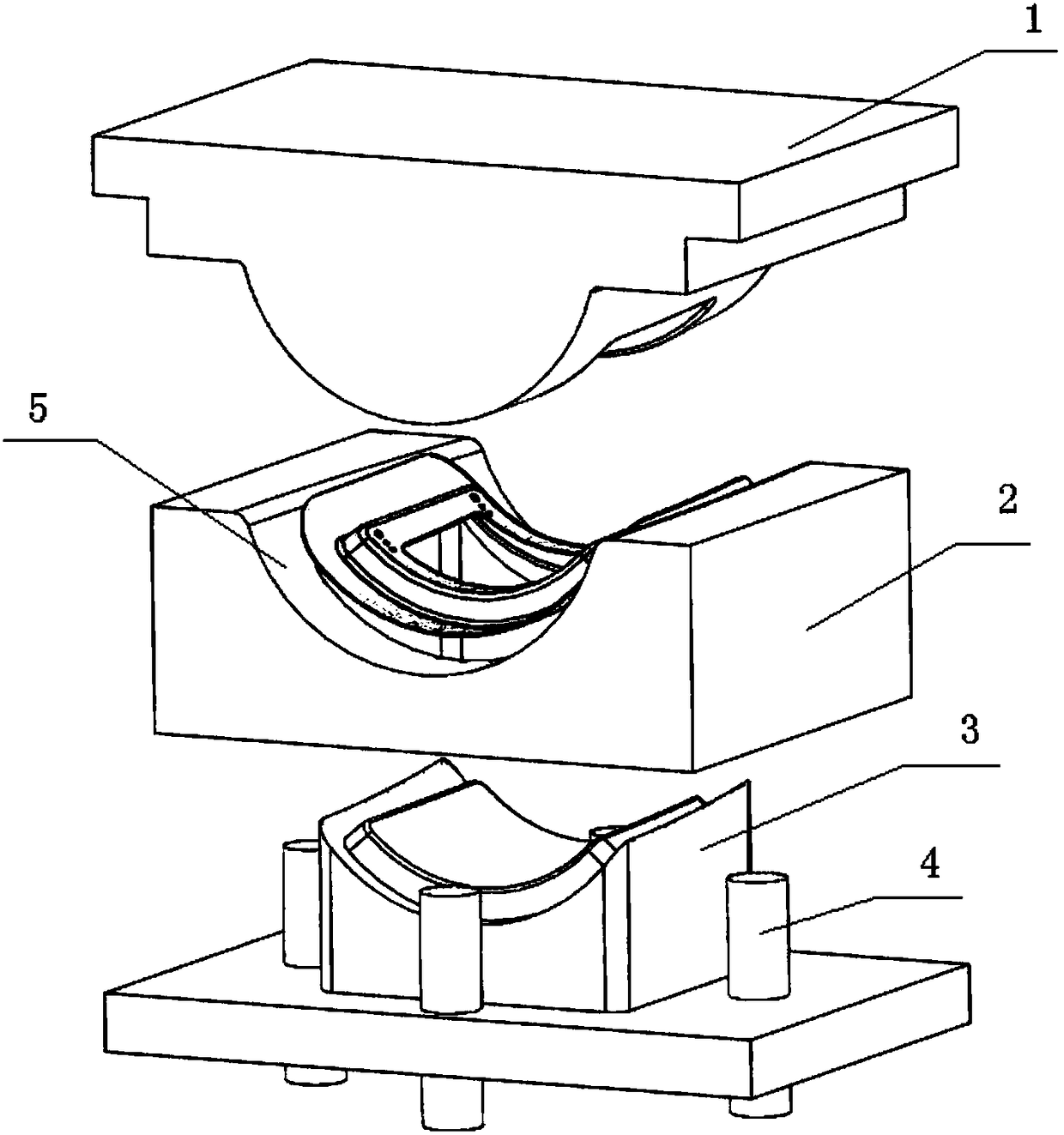

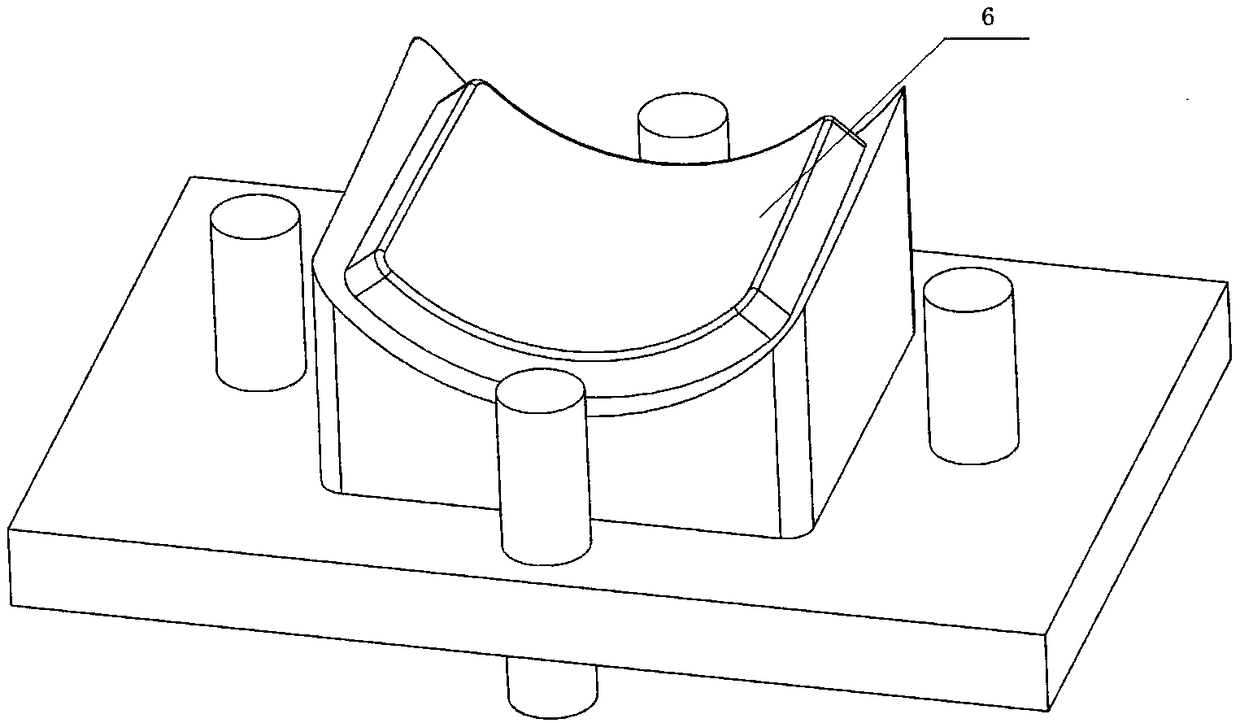

Titanium alloy box-shaped part hot drawing method

InactiveCN108145006ASolving Precise Forming ChallengesSimple structureHollow articlesTitaniumTitanium alloy

The invention elates to a titanium alloy box-shaped part hot drawing method, relates to the technical field of titanium alloy hot formation, can realize hot drawing and pressing formation of parts with such difficult deformation materials as titanium alloys and with box-shaped sinks on special-shaped curved surfaces, and solves the difficulties of low forming precision of the parts and easy wrinkling and cracking during forming. Through novel and reasonable mold structural design, different molded surfaces of the parts are formed in once forming process by adopting a two-pass drawing scheme. The tool structure is simple; the operation and the use are convenient; the batch production cost is reduced; the production efficiency is improved; and the precise forming difficulties of titanium alloy parts with complicated molded surfaces are solved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

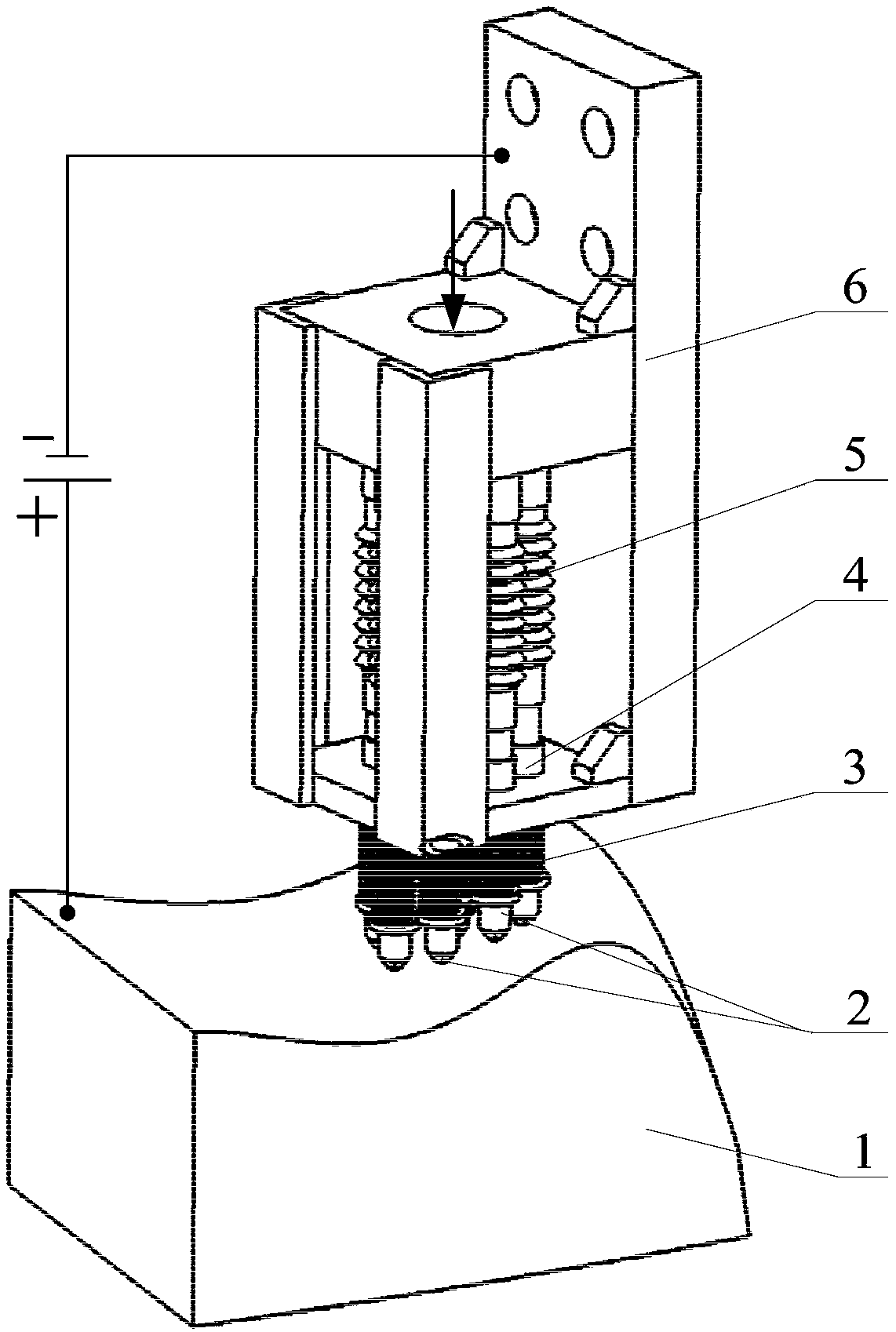

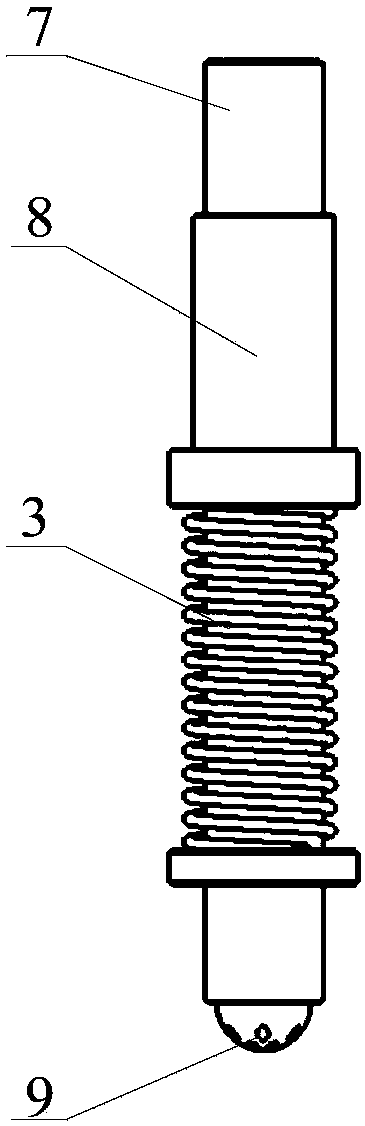

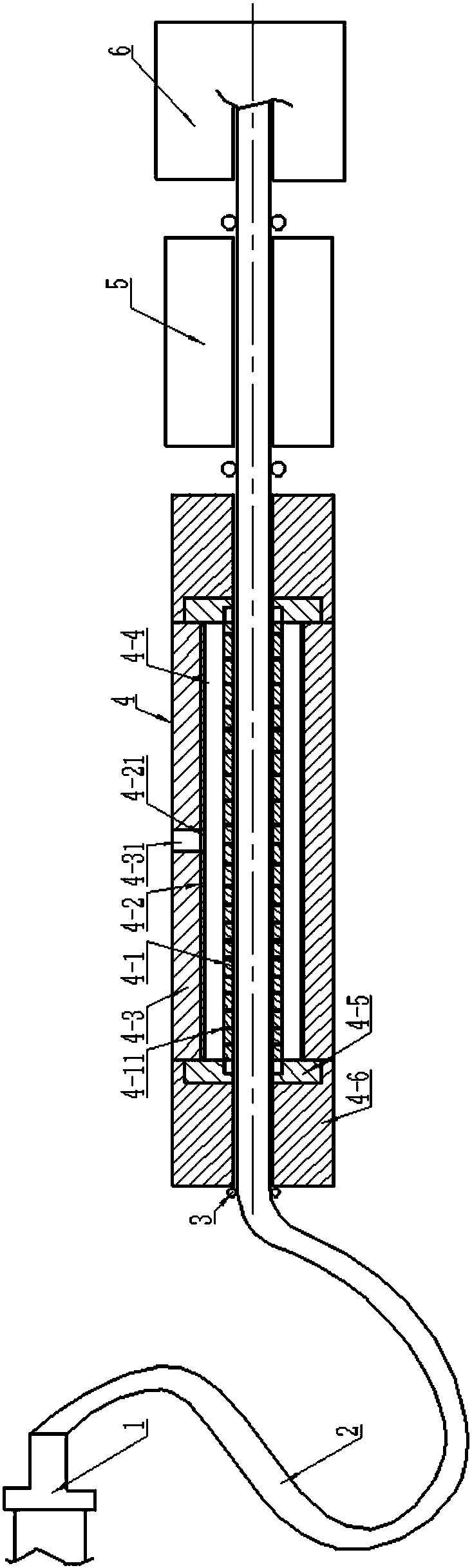

Multi-pipe floating complex curved surface self-finding track electrolytic processing device and method

ActiveCN108213623AUniform and stable flowLow skill level requiredMachining working media supply/regenerationNumerical controlElectrolysis

The invention relates to a multi-pipe floating complex curved surface self-finding track electrolytic processing device and method, and belongs to the field of electrolytic processing. The method is characterized in that an inner liquid spraying tube electrode group can be floated up and down on the surface of a curved surface part according to a specified processing track under the action of springs and a guide device, and the method can be used for electrolytic processing of workpieces with complex outer surfaces; and in addition, due to the fact that the multi-pipe liquid spraying processing is adopted, the flow field of a processing area is more stable compared with a single-pipe liquid spraying process. The processing device comprises the following components of group tube electrodes,the springs, elastic soft infusion tubes, a clamp body, a guide tube and the like. The method and the device has important significance in improving the electrolytic processing efficiency and stability and reducing the difficulty of programming and operation of numerical control machining the curved surface part.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Welding tooling

ActiveCN108747195ATooling structure is simpleLow costWelding/cutting auxillary devicesAuxillary welding devicesMotor drivePipe fitting

The invention discloses a welding tooling, and belongs to the field of welding. The welding tooling comprises a clamping and holding device, a guider, and a power device, wherein the clamping and holding device is used for clamping a pipe fitting welded at one end to another pipe fitting, the guider is used for driving the clamping and holding device to move in the axis direction of the clamped pipe fitting, and the power device is used for driving the clamping and holding device to rotate, wherein the rotation of the clamping and holding device and the movement of the clamping and holding device in the axis direction of the clamped pipe fitting form compound motion, the movement track of the compound motion is a reversing intersecting line of the intersection line dislocating arrangement,any point of the intersection line always penetrating through the welding position during the process of the movement. The Welding tooling used a motor drive the rotation, with the help of a guide chute curve generation and opposite movement track of the intersecting line, so that the movement track of the two cancels each other out, eventually compound motion track is always located in a circle,so that the welding gun under the condition of without moving, the welding is finished, the tooling structure is relatively simple, the cost is low, the welding efficiency can be effectively improved.

Owner:江苏中唱特种设备有限公司

Machining method for bulged cavity part

The invention discloses a machining method for a bulged cavity part. The machining method comprises the following steps: (1) clamping a round toolbar in a clamp hole, and firmly mounting a mounting handle on a tool rest of a horizontal lathe; (2) mounting and clamping a big-step bulged cavity part on the horizontal lathe and well aligning; (3) dismounting a nut, and propelling a long bolt into the inner hole of the round toolbar, wherein the long bolt sequentially drives a slider and a connecting plate to advance, so that a longitudinal toolbar and the round toolbar are longitudinally parallel, and through translation of the tool rest, a bent inner hole turning toolbar enters the inner hole of the big-step bulged cavity part; and then backing the long bolt to enable the longitudinal toolbar and the round toolbar to be longitudinally perpendicular, tightening the nut, and fixing the long bolt in the longitudinal direction; and (4) starting up the horizontal lathe, through translation of the tool rest, enabling a turning tool of the bent inner hole turning toolbar to move onto the inner surface of the bulged inner hole of the big-step bulged cavity part, performing tool setting, and then feeding for turning. The machining method is simple in tool and convenient to operate.

Owner:MCC SFRE HEAVY IND EQUIP

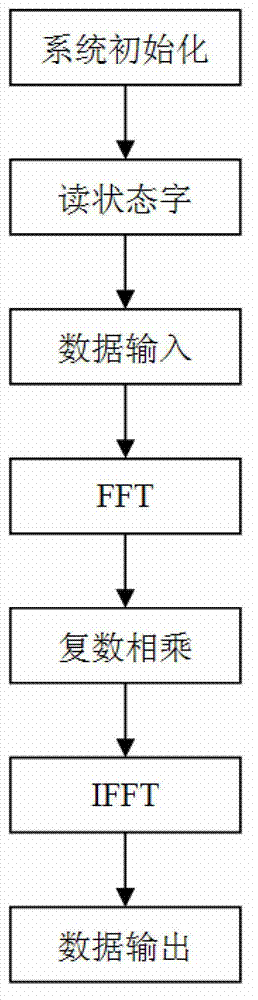

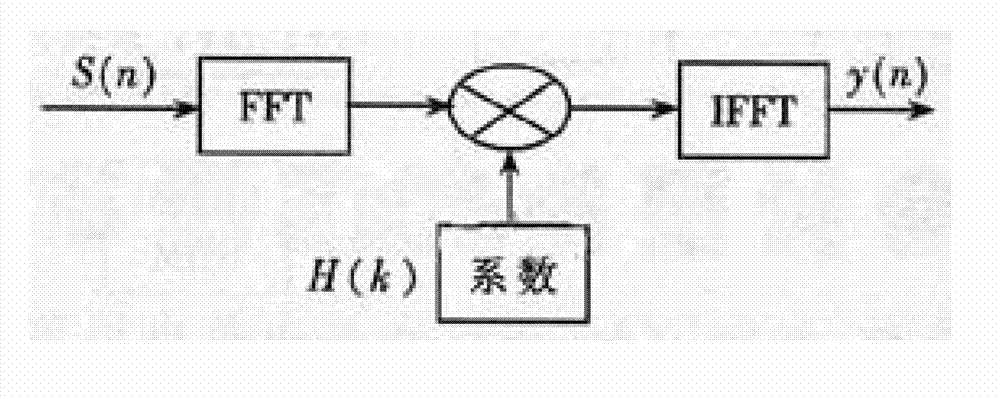

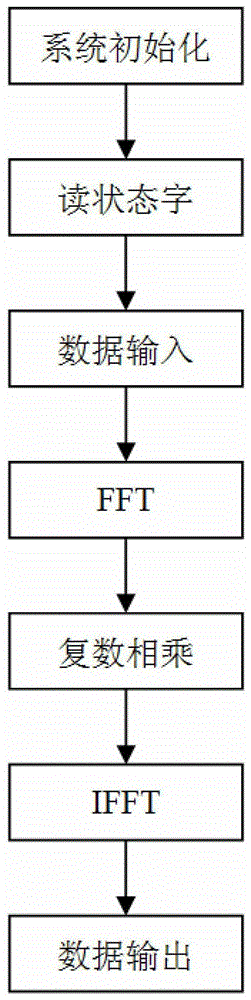

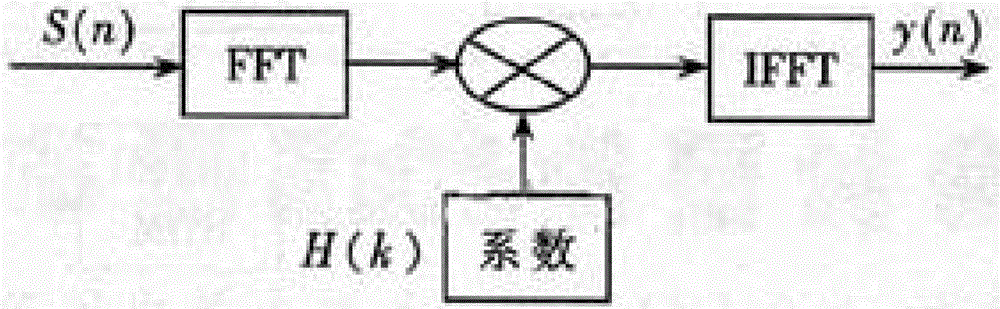

High-speed real-time pulse compression algorithm

ActiveCN103926567ATooling structure is simpleEasy to adjustWave based measurement systemsFourier transform on finite groupsRapid pulse

The invention discloses a high-speed real-time pulse compression algorithm. The algorithm comprises reading a state character, and selecting parameters such as a frequency modulation signal, a distance and the like; reading the frequency modulation signal; converting integer numbers into floating numbers; performing fast Fourier transform (FFT); performing complex multiplication on an FFT result and the weight of a corresponding parameter; performing FFT; performing normalization operation, and converting the floating numbers into the integer numbers; and writing a pulse pressure signal and storing the signal. The high-speed real-time pulse compression algorithm has the advantages of small calculation complexity, highly-efficient and rapid pulse compression, and the like.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

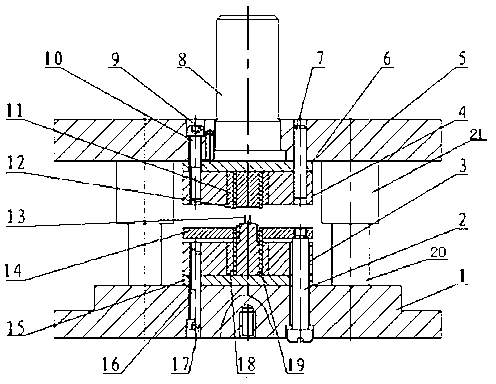

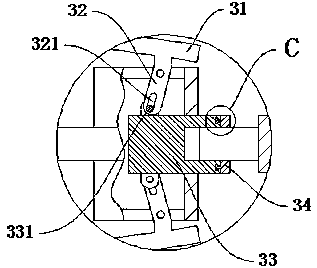

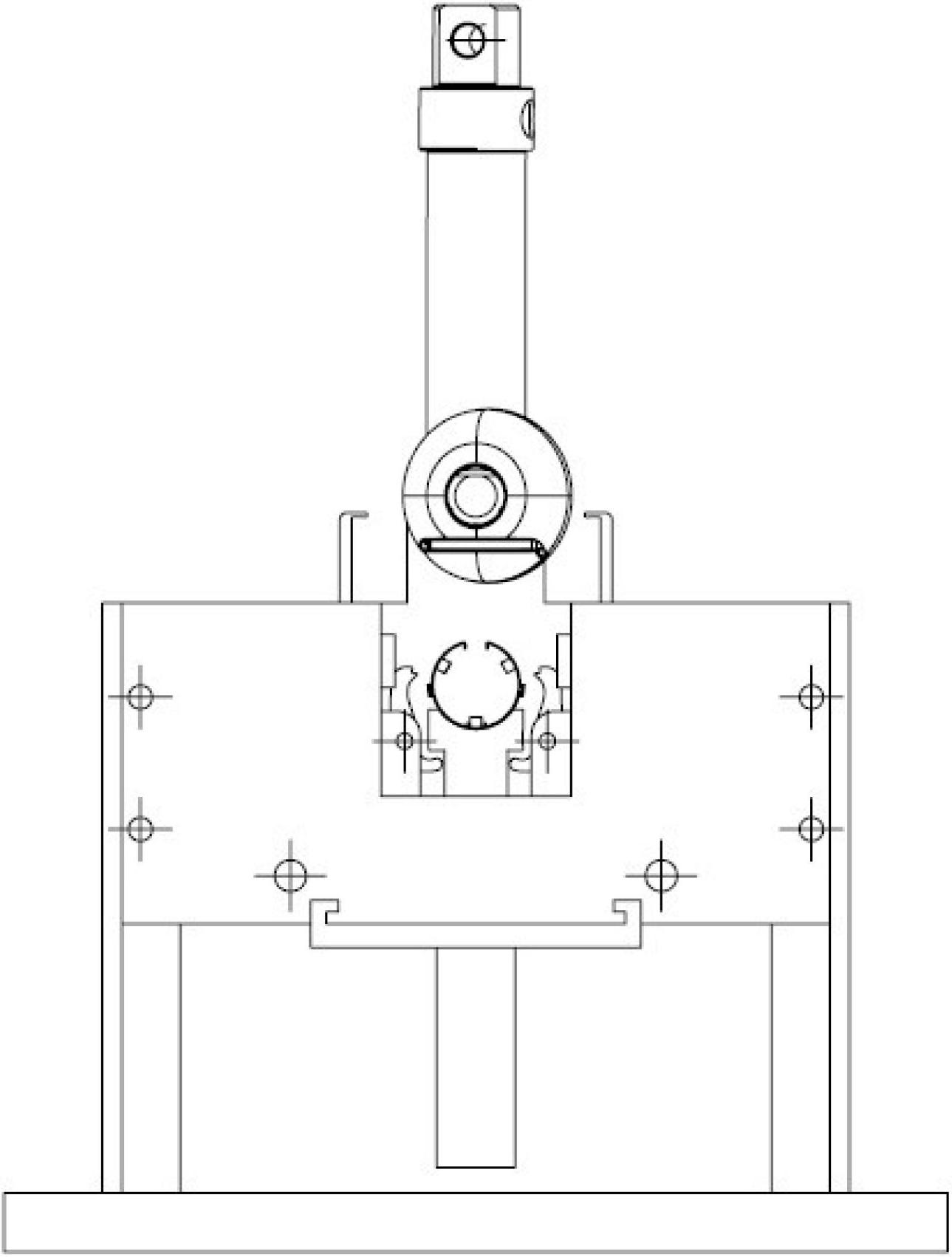

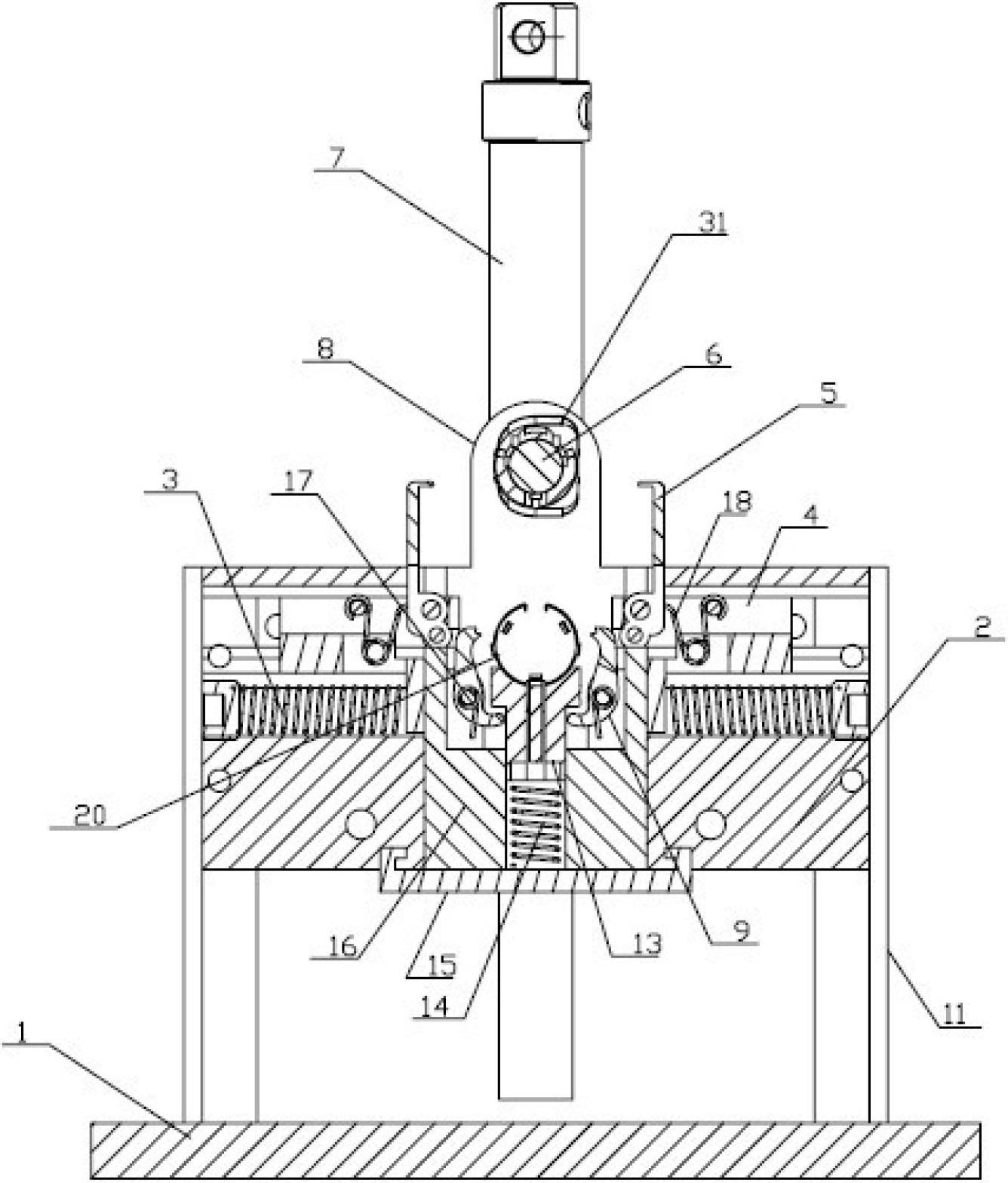

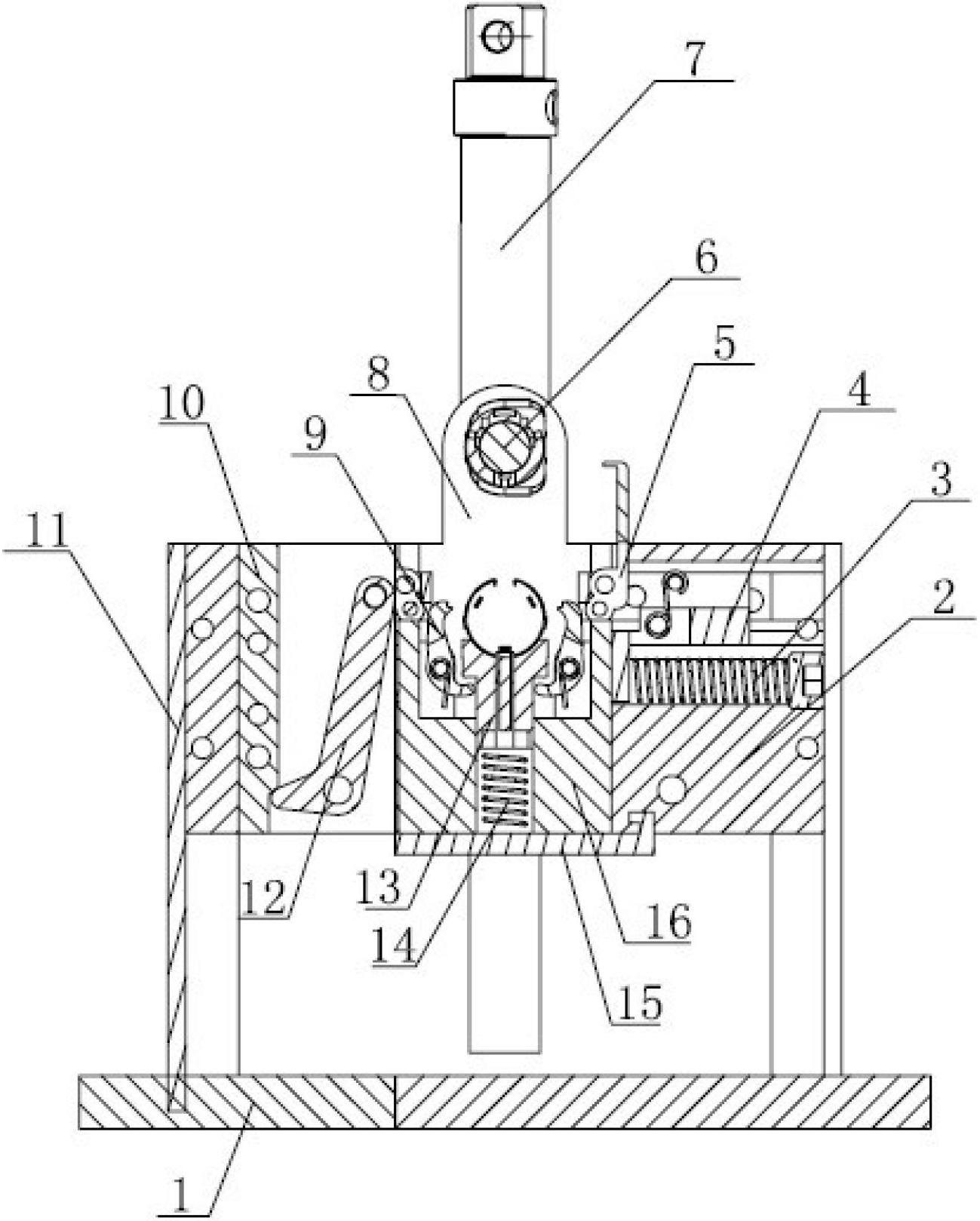

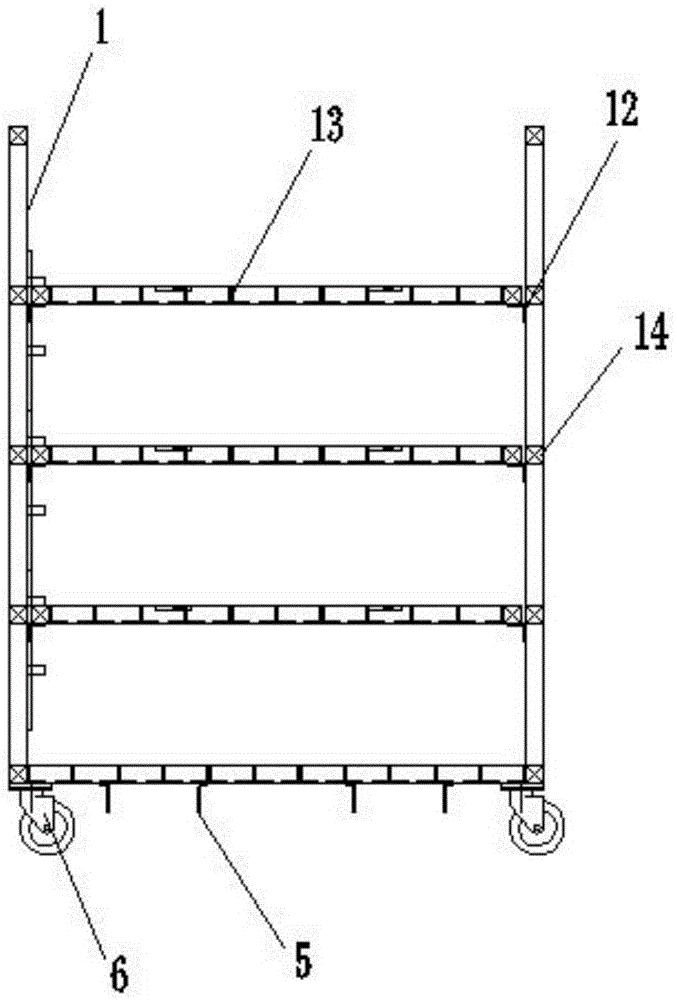

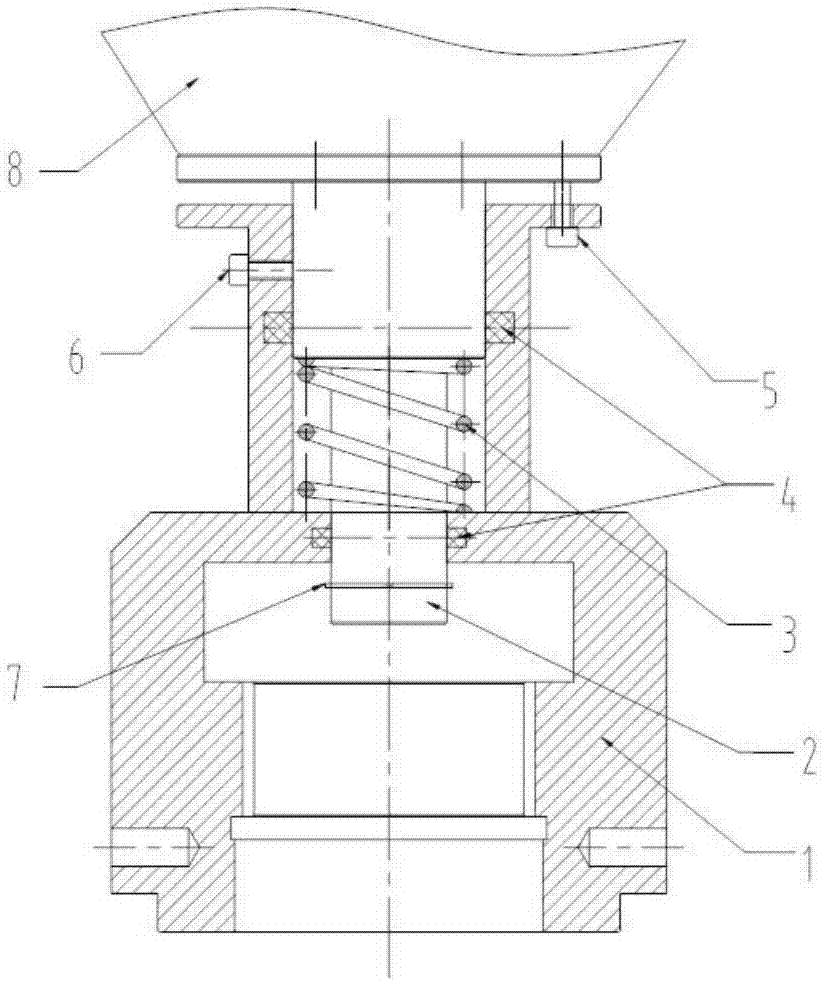

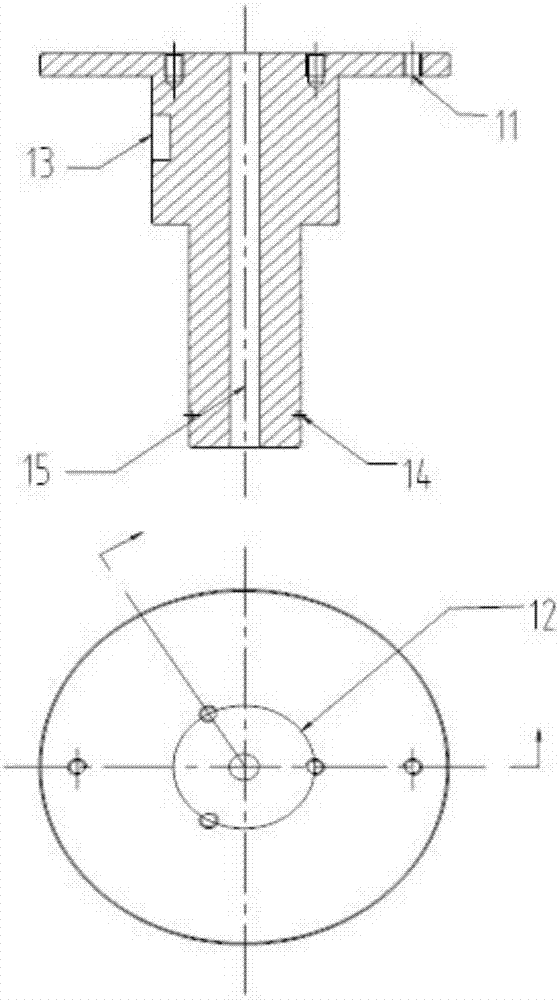

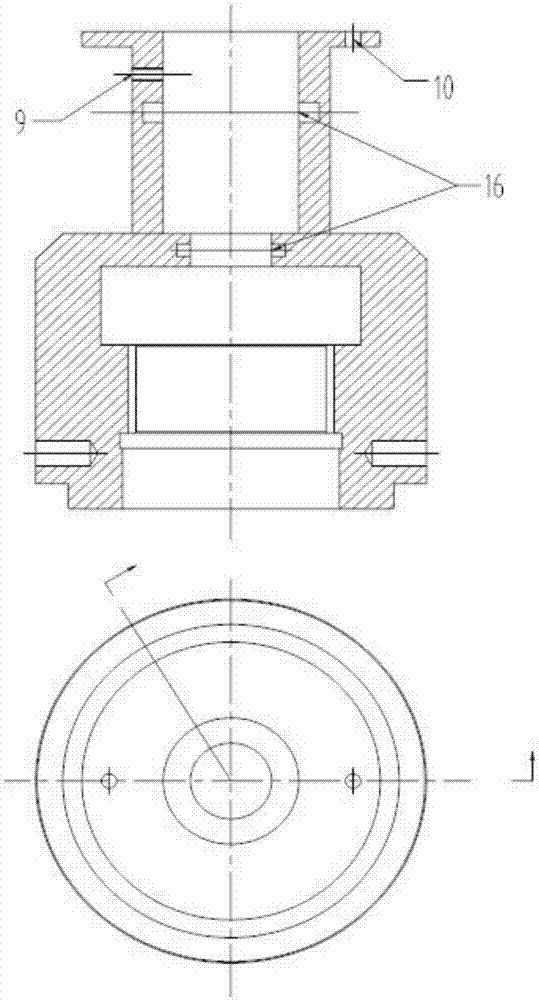

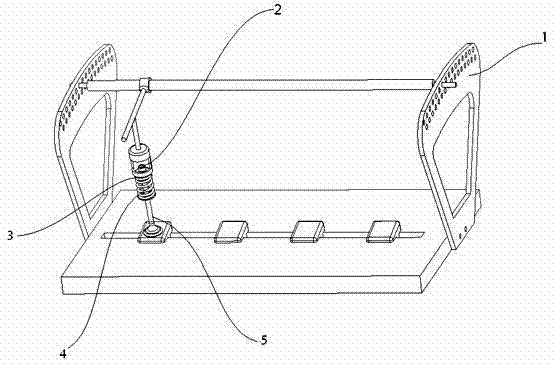

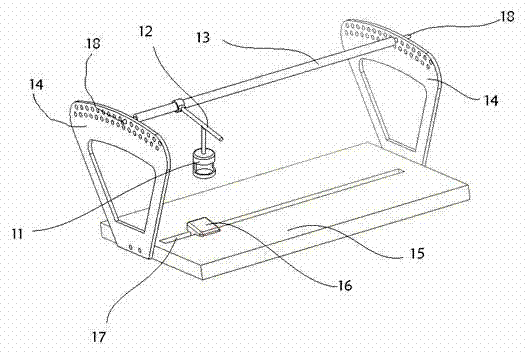

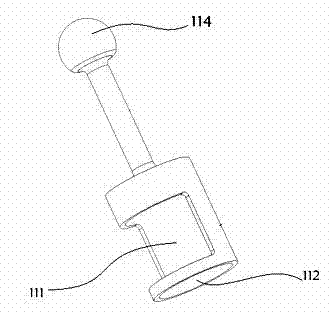

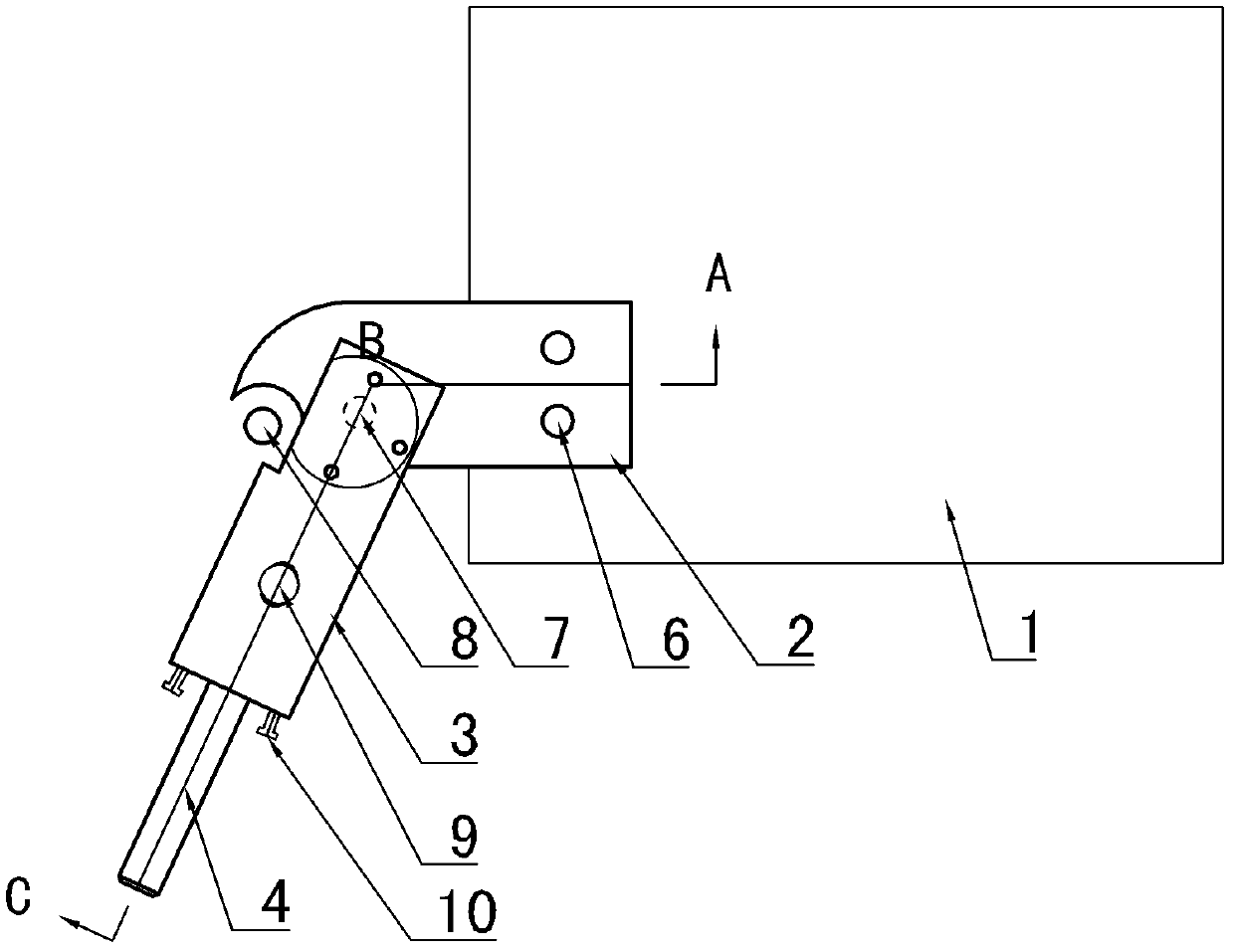

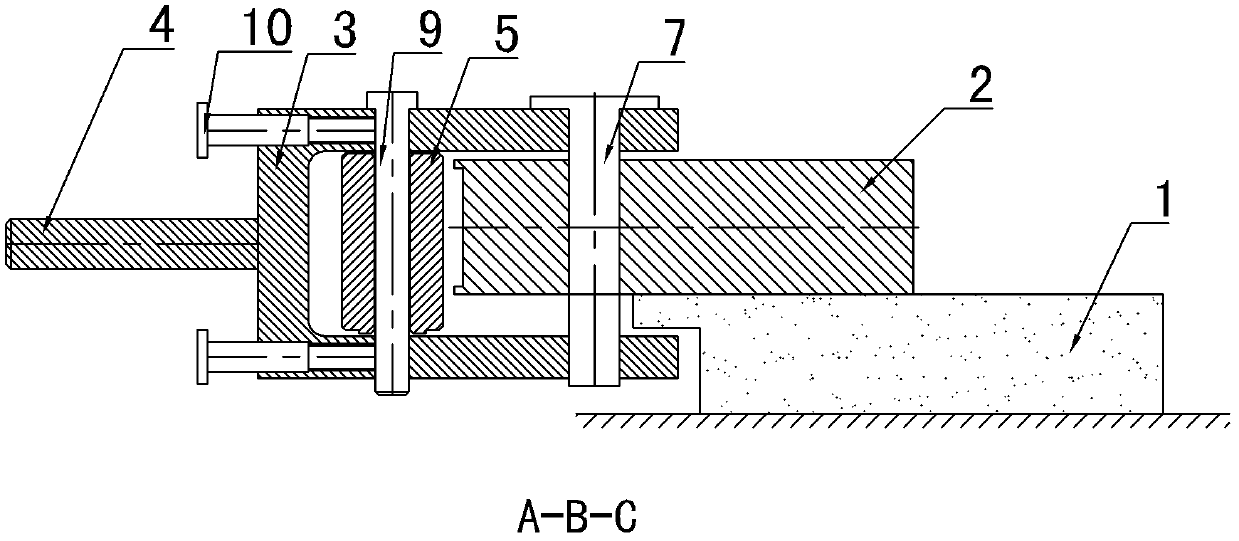

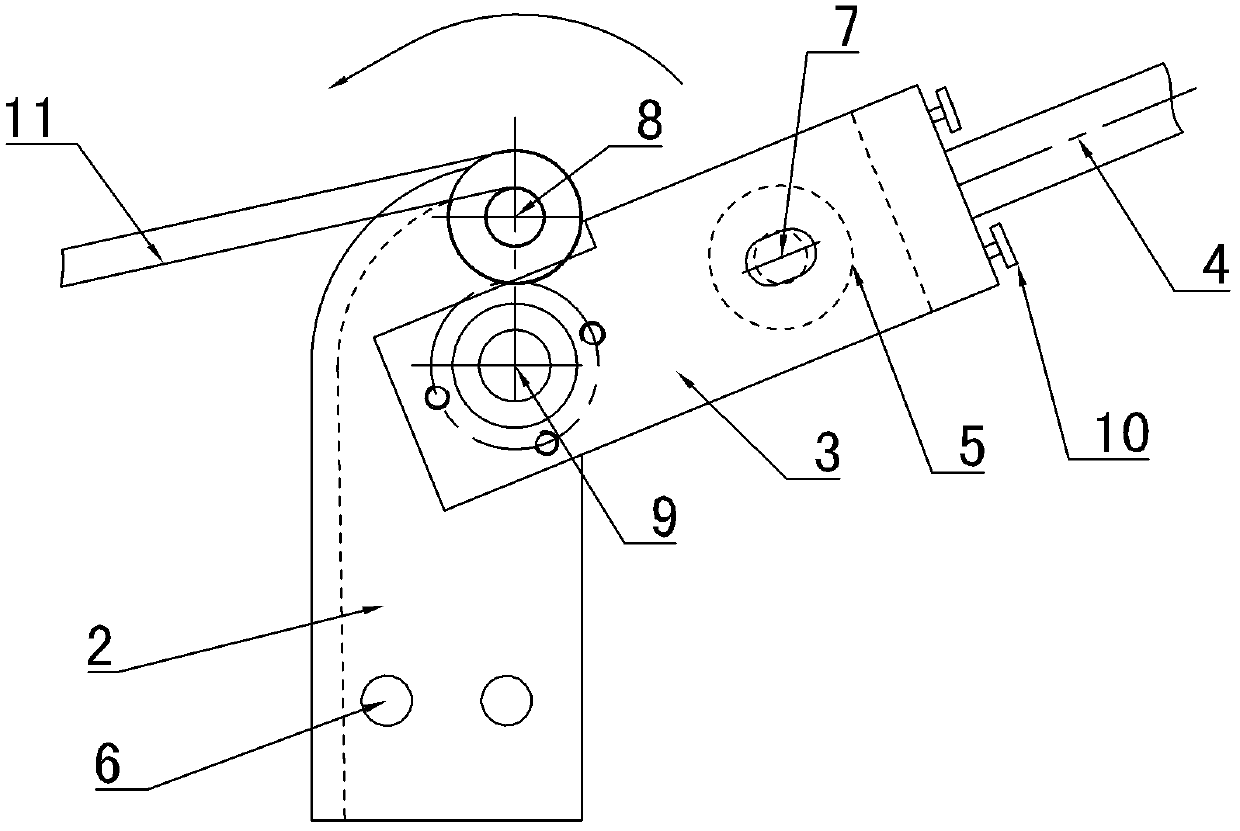

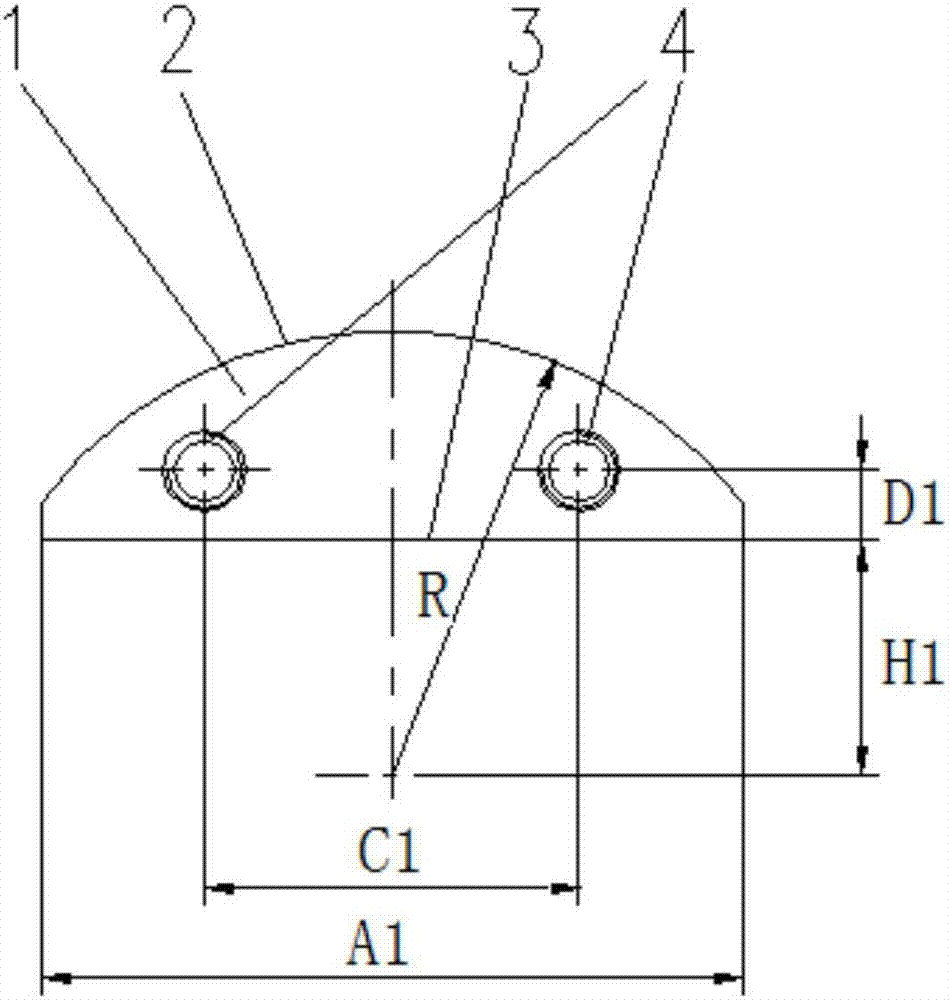

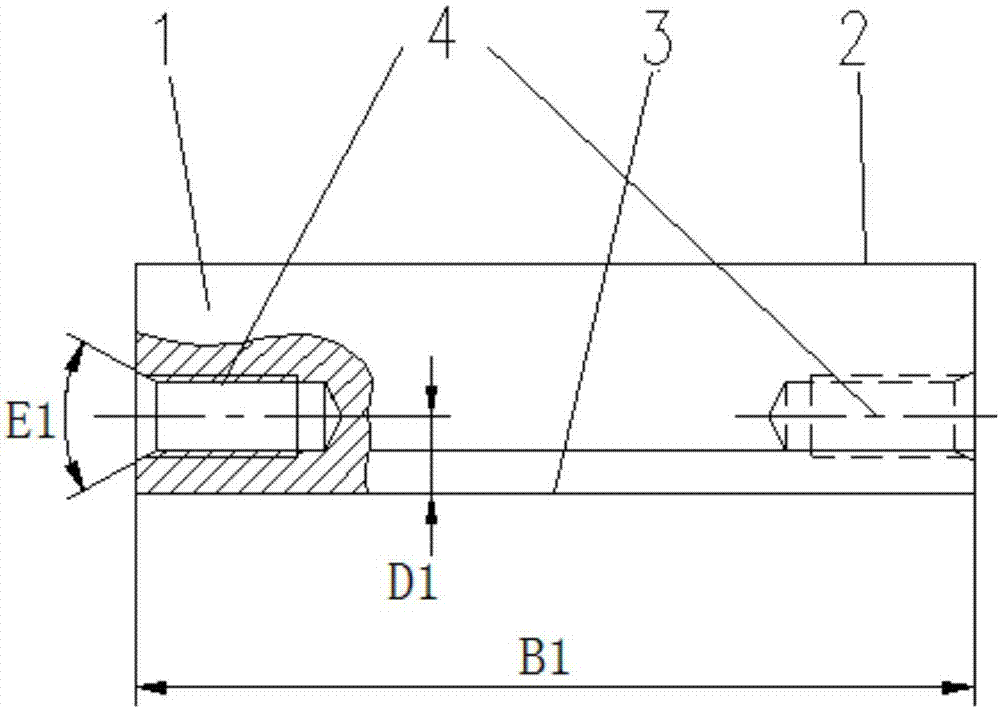

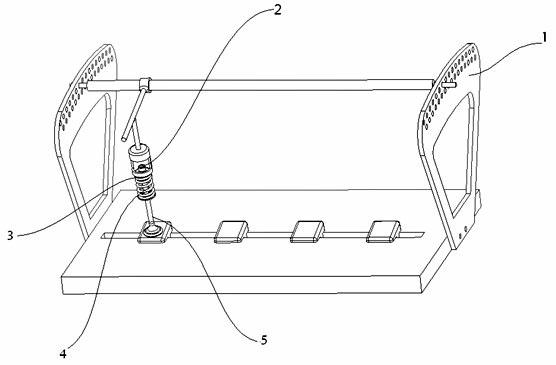

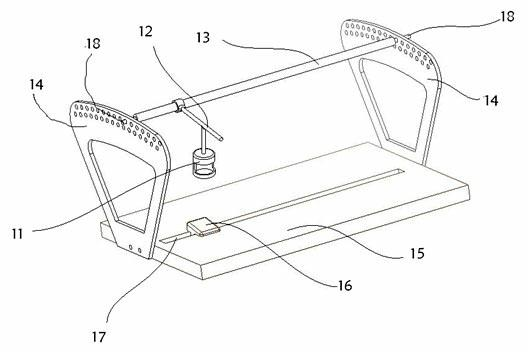

Automatic assembly tool and method for spring clamp ring of automotive seat headrest guide sleeve

ActiveCN102658476ARealize high-volume assembly productionReduce labor intensityMetal working apparatusCouplingEngineering

The invention relates to an automatic assembly tool and method for a spring clamp ring of an automotive seat headrest guide sleeve. The automatic assembly tool comprises a bottom plate (1), an assembly sliding block (8) and an assembly seat (2); a main fixing seat (11) and the assembly sliding block (8) are vertically mounted on the upper surface of the bottom plate (1); a straight push air cylinder (7) is vertically mounted at the back side of the main fixing seat (11); the lower end of the straight push air cylinder (7) is connected with the assembly sliding block (8); a shovel base (10) and a deflector rod (12) are symmetrically and vertically mounted on two sides of the assembly sliding block (8); the assembly seat (2) is fixedly mounted in the front of the main fixing seat (11); drag hook coupling blocks (4) and drag hooks (5) are mounted on both of hollow sliding chutes on two sides of the inner side of the assembly seat (2); a spring clamp ring fixing seat (13) is placed at the upper end of the middle of a middle base block (16); and spring clamp ring assembly swaying blocks (9) are mounted on two sides of the spring clamp ring fixing seat (13). The tool provided by the invention is simple in structure, high in degree of automation and high in production efficiency, and is convenient to use.

Owner:NINGBO JIFENG AUTO PARTS

Quick clamping tool for pipe fitting

InactiveCN108581538AEasy to operateTooling structure is simplePositioning apparatusMetal-working holdersEngineeringArchitectural engineering

The invention discloses a quick clamping tool for a pipe fitting. The quick clamping tool for the pipe fittings comprises a cutting support table; a large-diameter steel pipe is disposed on the cutting support table; the to-be-cut pipe fitting is inserted inside the large-diameter steel pipe, and the top end of the to-be-cut pipe fitting is pressed through a pressing block in an abutting mode; thetop face of the pressing block and the bottom end of a bolt are fixedly connected in a welded mode; a through hole is formed in the top end of the large-diameter steel pipe, a first threaded block isfixedly welded in the formed through hole and connected with the bolt in a threaded mode; second threaded blocks are welded to the outer walls of the left side and the right side of the large-diameter steel pipe and connected with a screw rod in a threaded mode; the bottom end of the screw rod is connected with a third threaded block in threaded and locked mode; and the third threaded block is fixedly welded on the cutting support table. By adoption of the technical scheme, the tool is simple in structure, low in manufacturing cost, convenient to assemble and install, capable of pressing theto-be-cut pipe fitting quickly and conveniently and wide in application range.

Owner:张多梅

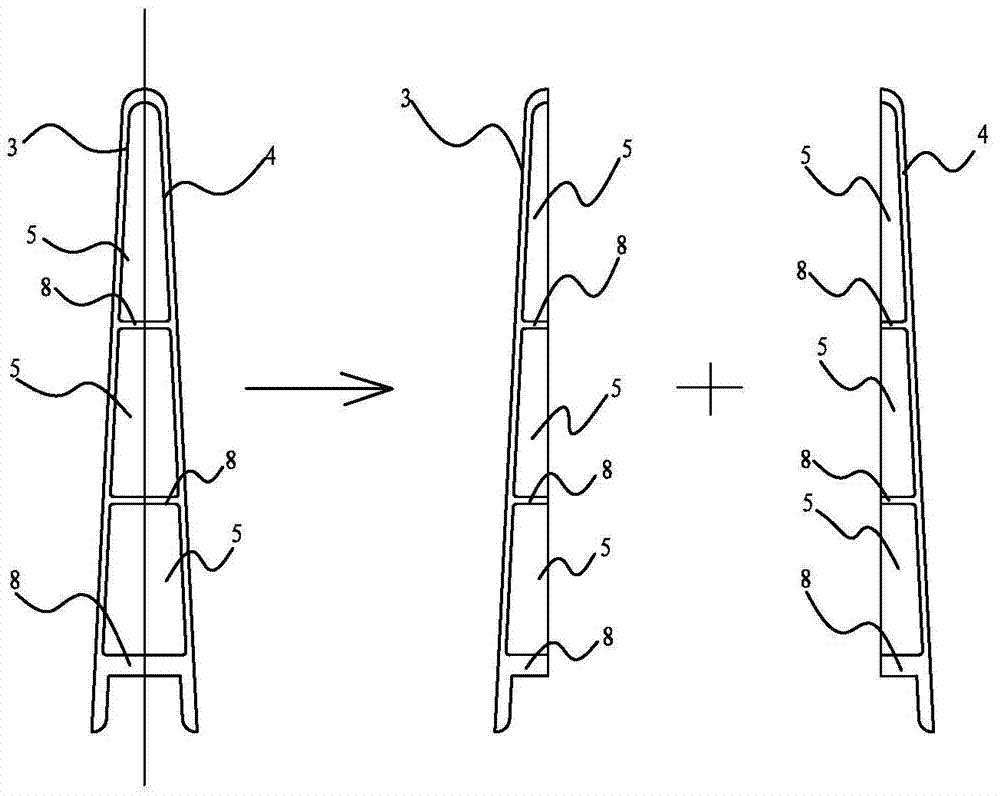

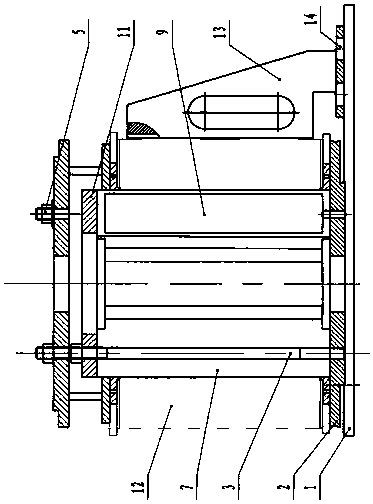

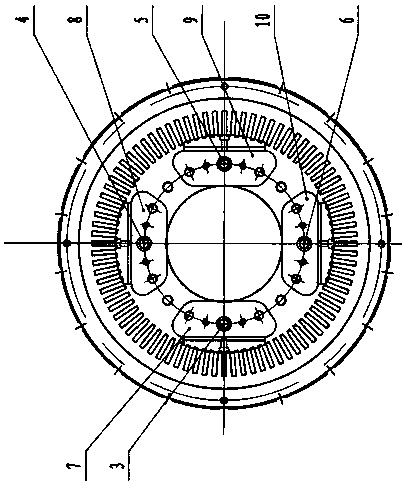

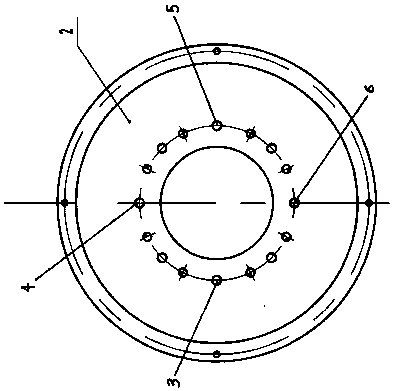

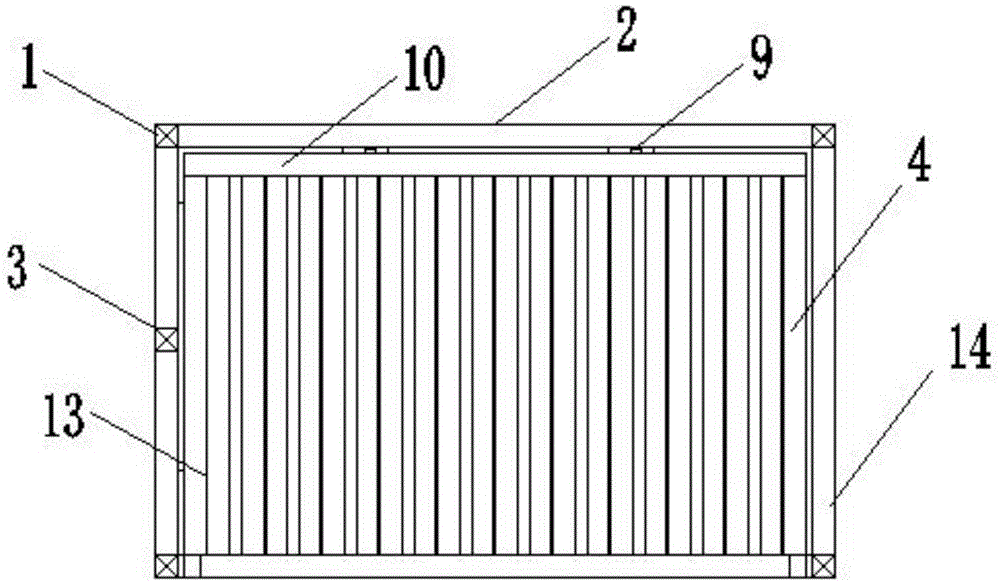

Wind driven generator stator iron core lamination forming tool and a lamination forming method

PendingCN111327165AImproving Lamination Weld Forming QualityReduce the probability of scratchesManufacturing stator/rotor bodiesEngineeringElectric generator

The invention discloses a wind driven generator stator iron core lamination forming tool and a lamination forming method, and solves the problem that an integral silicon steel sheet iron core is difficult to separate from an integral positioning support cylinder in an existing stator iron core lamination tool. An integral positioning support cylinder of a laminated silicon steel sheet iron core isdecomposed into four arc-shaped laminated positioning support plates, a spacing gap is formed between every two adjacent arc-shaped laminated positioning supporting plates, and after stator iron coresilicon steel sheets are laminated, the fixing mechanisms of the arc-shaped laminated positioning supporting plates are dismounted, so that the four arc-shaped laminated positioning supporting platesare in a movable state, and the laminated stator iron core can be conveniently separated from the stator iron core; and the silicon steel sheet excircle positioning vertical plate (13) is matched with a silicon steel sheet laminated excircle positioning groove (21) formed in the excircle of the stator core silicon steel sheet (12), so that the positioning rib embedding grooves in the laminated silicon steel sheets are aligned. The quality of the iron core is improved, and the scratching probability of the inner side wall of the iron core is reduced.

Owner:CSIC ELECTRICAL MACHINERY SCI & TECH

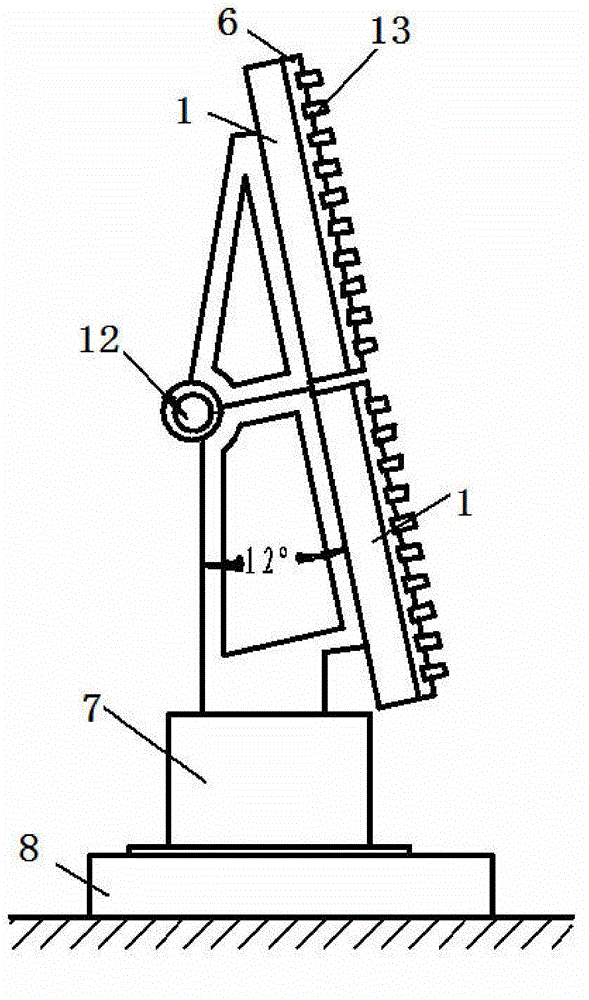

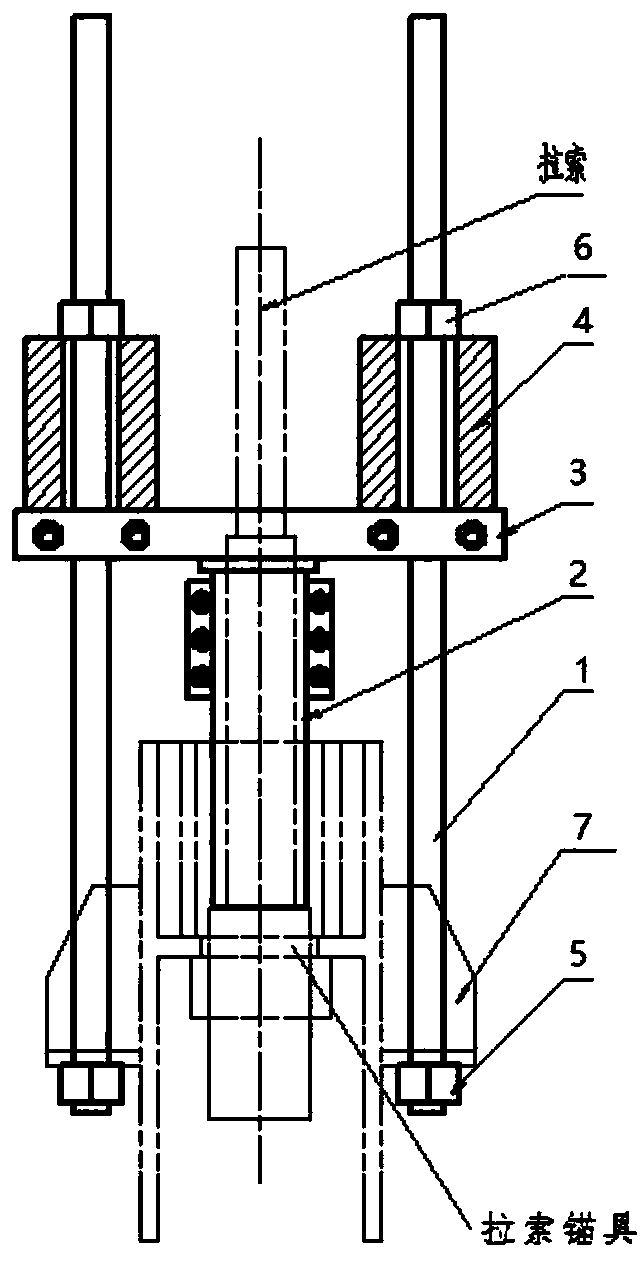

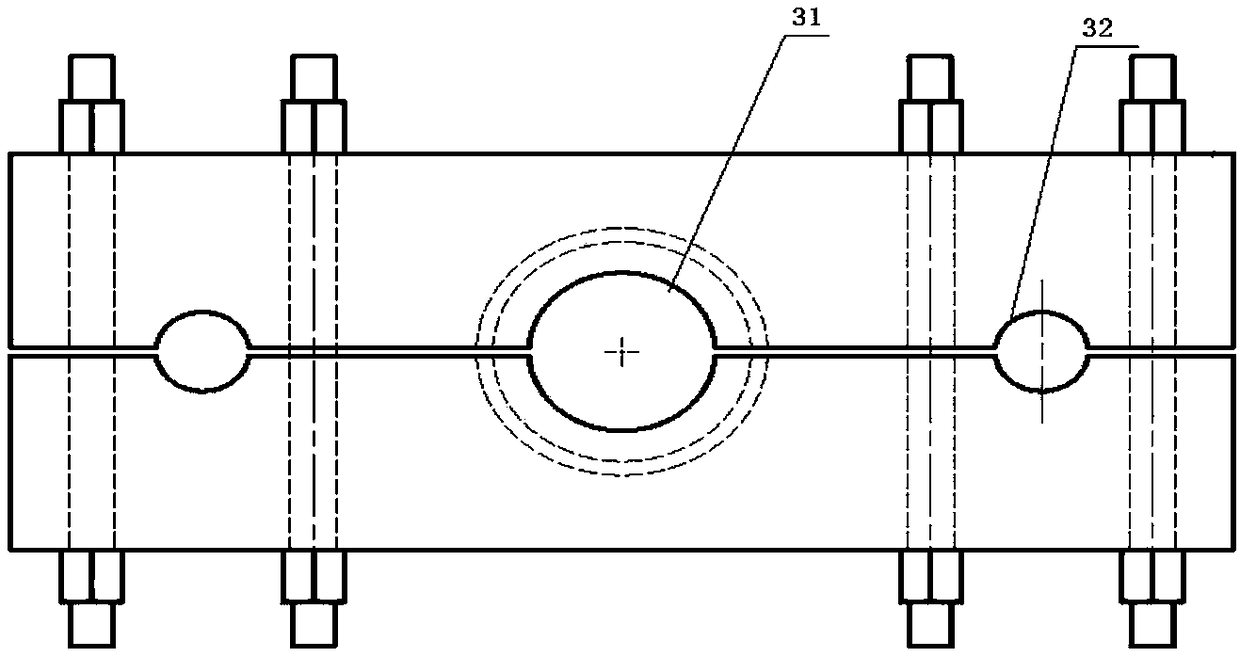

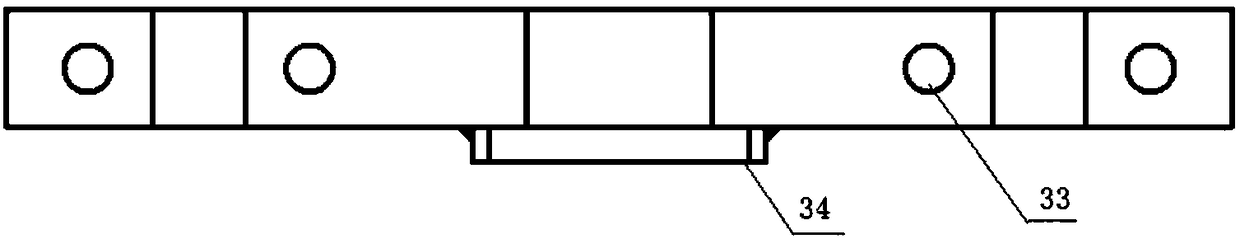

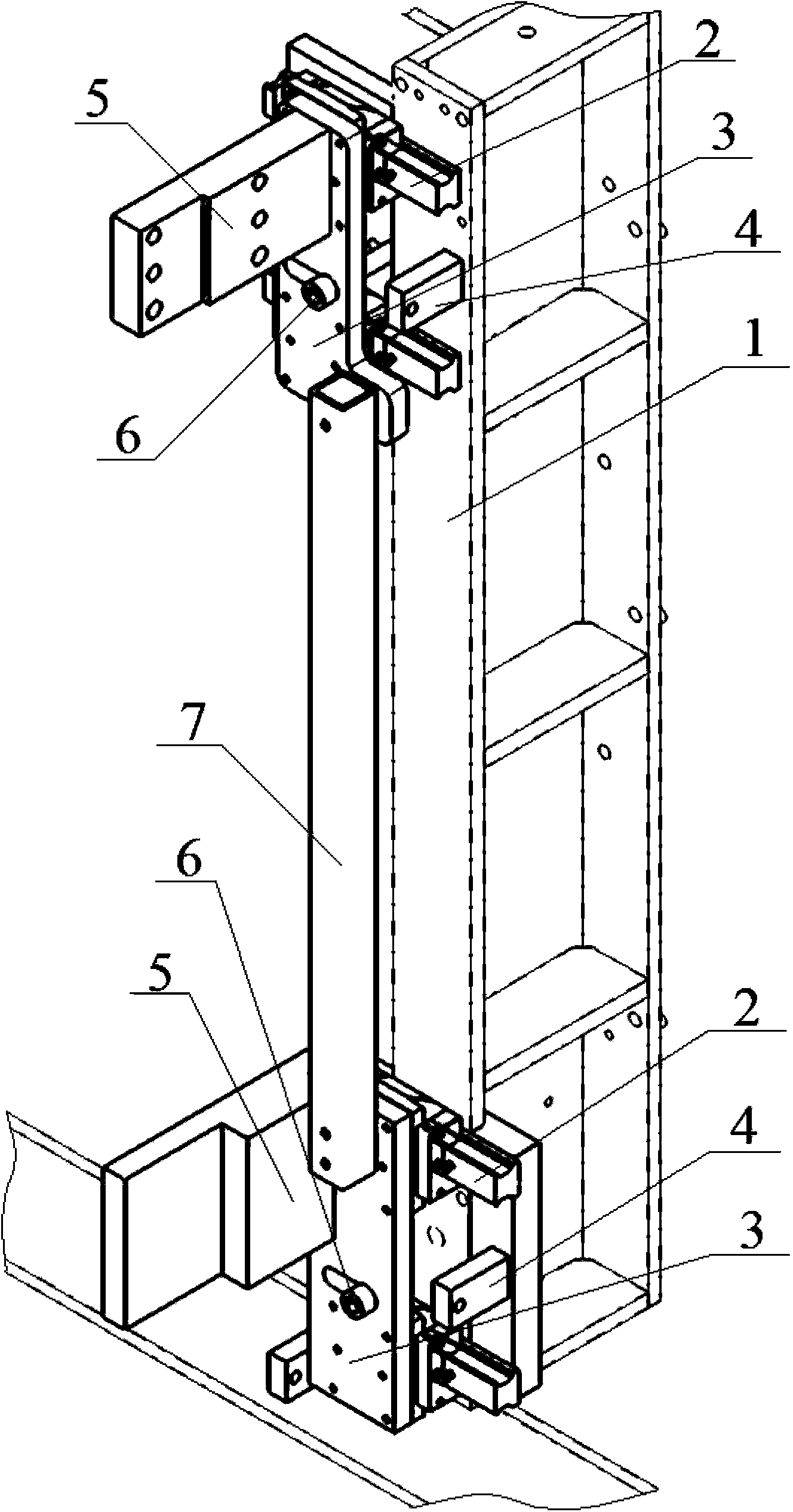

Tooling device for tensioning steel anchor box inhaul cable and tensioning method thereof

PendingCN108589553ATooling structure is simpleEasy to operateBridge erection/assemblyEngineeringCable tension

The invention provides a tooling device for tensioning an inhaul cable. The tooling device comprises a tensioning rod, a tensioning cylinder, a shoulder pole beam and a jack. The tooling device is characterized in that the tensioning cylinder is a two-half combined structure; the shoulder pole beam is connected to the upper end of the tensioning cylinder by adopting a fixing structure, the shoulder pole beam is of a two-half combined structure, a groove hole is formed in the middle of the shoulder pole beam, the inhaul cable penetrates through the groove hole, round holes and screw holes are formed in the two sides of the shoulder pole beam, the tensioning rod penetrates through the round holes, and bolts penetrate through the screw holes; and the tensioning cylinder is provided with a lugplate structure, a concave or convex rabbet structure is arranged at the upper end of the tensioning cylinder, and the groove hole of the shoulder pole beam is provided with a concave or convex rabbet structure. The invention further provides a tensioning method for the steel anchor box inhaul cable. The tooling device is simple in structure, simple to operate, safe and reliable, and the rabbet structure has the advantage of connecting the inhaul cable in a centering mode. In the process of inhaul cable tension, the structural characteristics of a steel anchor box and a conventional inhaul cable are not changed, and the advantages of the steel anchor box and the conventional inhaul cable are combined.

Owner:LIUZHOU OVM ENG

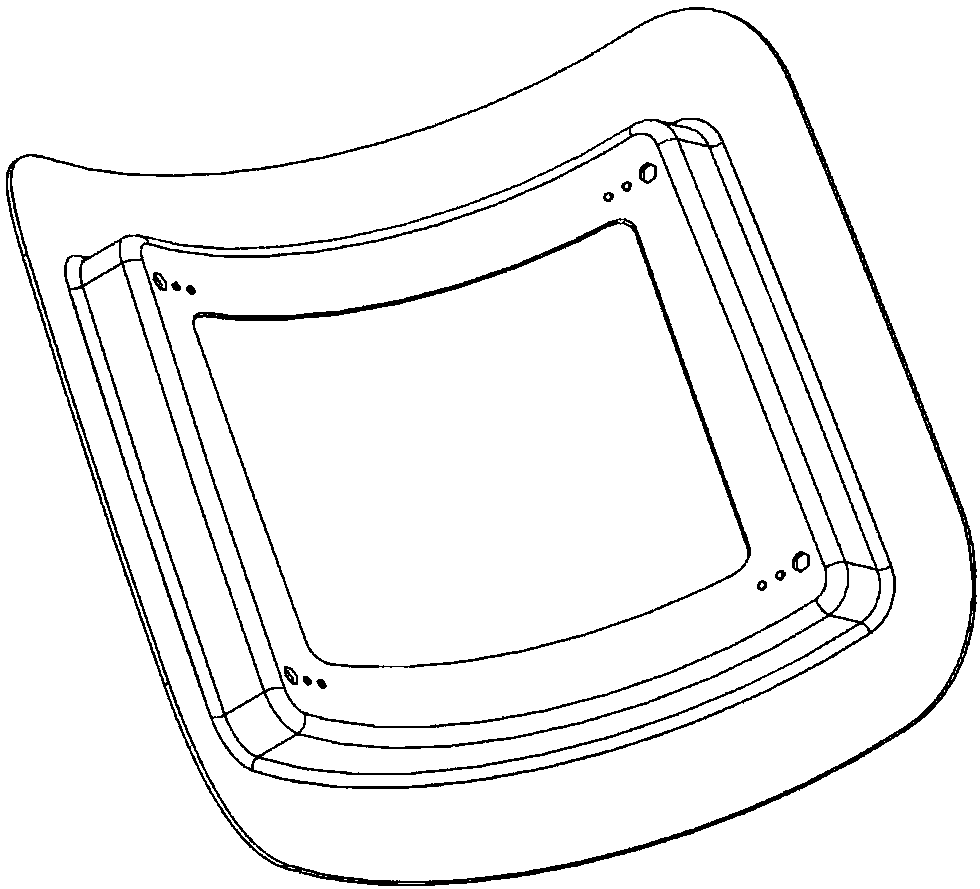

Auxiliary tool for installing foreside windscreen of passenger car

The invention relates to an auxiliary tool for installing a foreside windscreen of a passenger car. The auxiliary tool comprises a horizontal plate which is horizontally arranged, one end of the horizontal plate is a plane and is connected with a vertical plate perpendicular to the horizontal plate, the other end of the horizontal plate is a cambered surface, and the radian of the cambered surface is matched with that of the foreside windscreen; the thickness of the horizontal plate is matched with a gap reserved at gap filling glue of the foreside windscreen, the vertical plate is fixed with a windscreen wiper output shaft arranged on a front wall outer panel, and a gasket for regulating the horizontal position of the horizontal plate is arranged between the front wall outer panel and the vertical plate. According to the auxiliary tool, the horizontal plate supports the foreside windscreen, the vertical plate is fixed with the front wall outer panel, and the gasket arranged between the front wall outer panel and the vertical plate regulates the planar height of the horizontal plate, so that installation of the foreside windscreen becomes easier, more convenient, more flexible and safer; meanwhile, the tool is simple in structure, convenient to operate and capable of reducing the labor intensity of workers and improving the production efficiency.

Owner:ANHUI ANKAI AUTOMOBILE

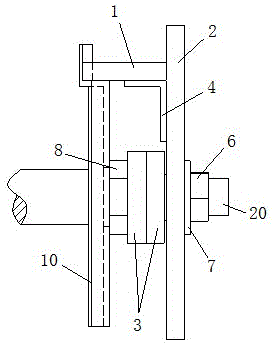

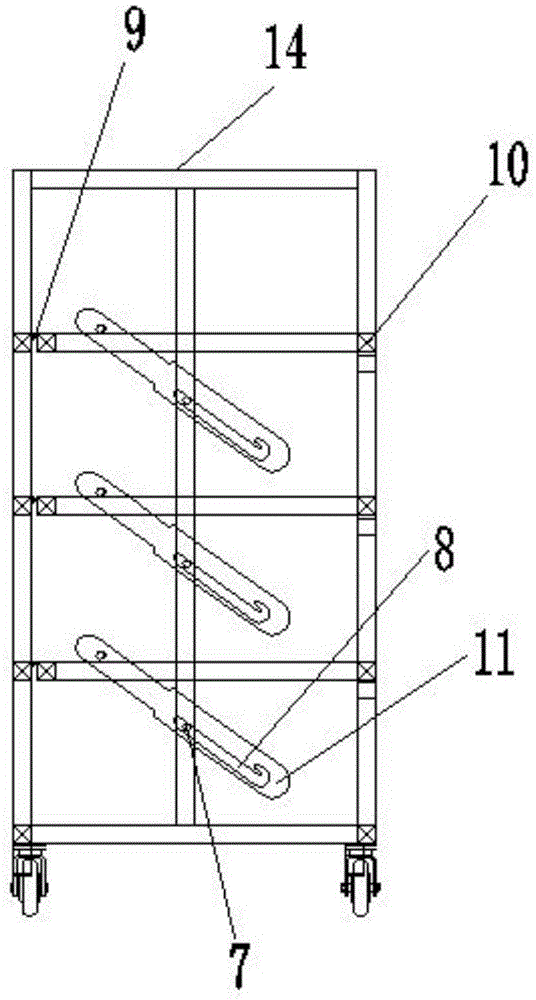

Transfer and storage goods shelf for U-shaped parts of passenger car

ActiveCN105666448AConvenient statisticsEasy accessWork tools storageOther workshop equipmentStructural engineeringTransverse beam

The invention discloses a transfer and storage goods shelf for U-shaped parts of a passenger car.The transfer and storage goods shelf comprises four layers of rectangular frameworks fixed on four standing columns, wherein a turning framework is arranged in each of the upper three layers of rectangular frameworks; each turning framework is composed of inner transverse beams and inner longitudinal beams which are oppositely arranged two to two, one inner transverse beam on one side of each layer of the turning framework is rotatably connected with a transverse beam of the corresponding rectangular framework through two hinges, the opposite inner transverse beams of each layer of the turning framework and the opposite transverse beams of the bottommost-layer rectangular framework are provided with a plurality sets of two opposite bending plates; one side of each layer of the turning framework is provided with a support plate which is provided with a J-shaped support sliding groove.According to the transfer and storage goods shelf, the bending plates are designed according to the shape of the U-shaped parts, the U-shaped parts are directly put into the bending plates, therefore, transfer is convenient, workshop counting is also convenient, the space is saved to store more workpieces, and the parts are conveniently taken by personnel; the whole tool is simple in structure, convenient to operate and suitable for storage and transfer of the U-shaped parts arranged on a framework of the passenger car.

Owner:ANHUI ANKAI AUTOMOBILE

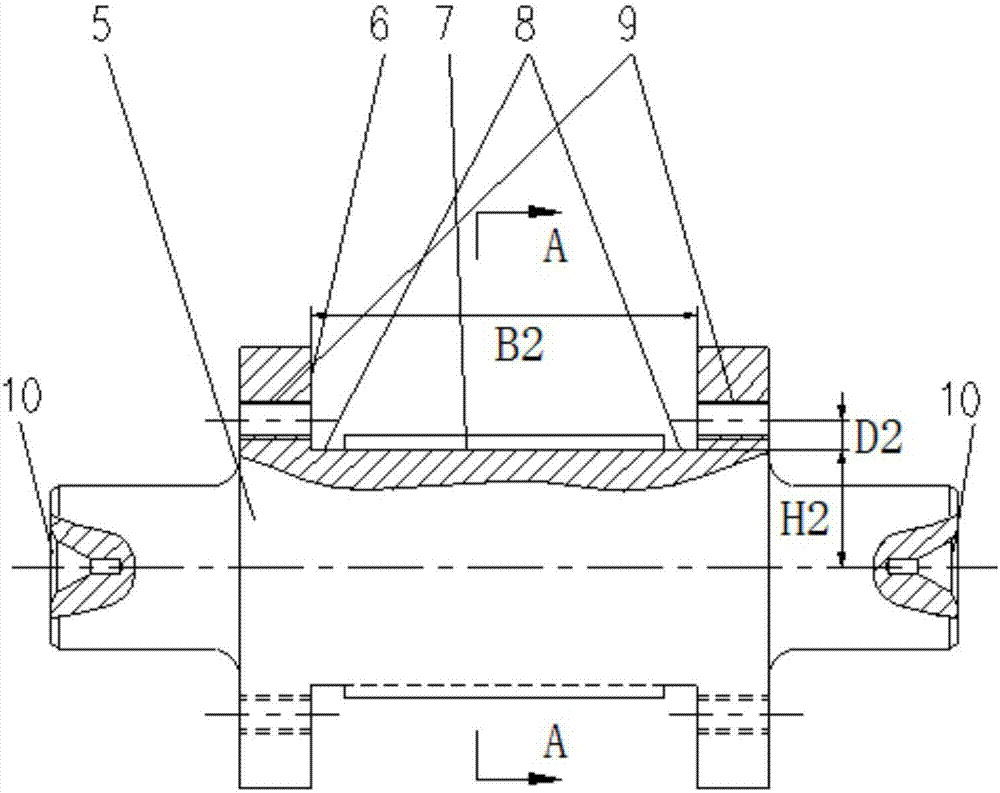

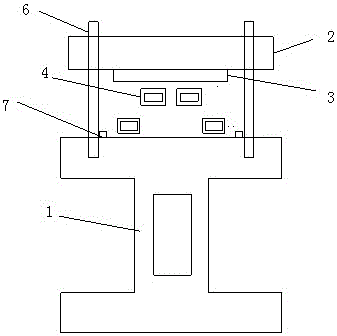

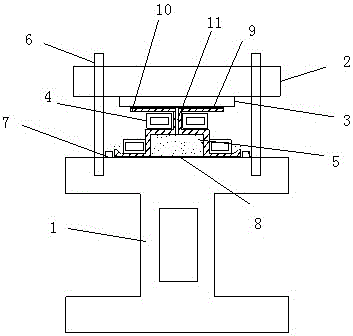

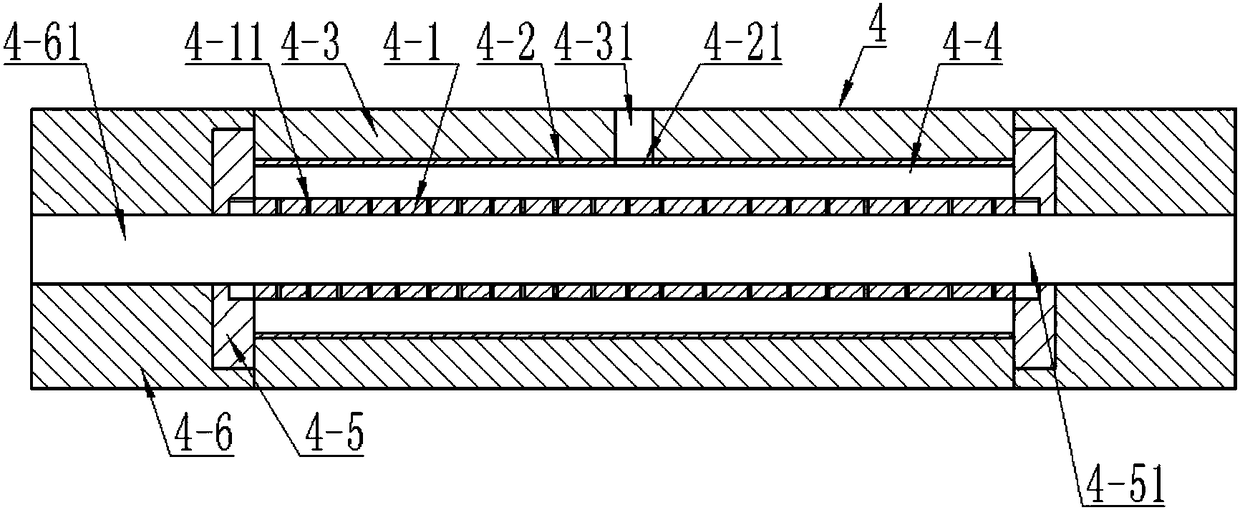

Large-caliber optical part elastic chucking tool and method for numerical-control grinding and polishing

ActiveCN107363726AAppropriate flexibilityFit tightlyOptical surface grinding machinesGrinding work supportsNumerical controlMachined surface

The invention belongs to the technical field of machining of optical elements, and particularly relates to a large-caliber optical part elastic chucking tool and method for numerical-control grinding and polishing. By utilizing a clamp fixing apparatus, a foundation support and a spring, a large-caliber optical part is elastically installed and clamped, and the large-caliber optical part elastic chucking tool is suitable for the numerical-control grinding and polishing of an optical surface. The tool is simple and reasonable in structure and convenient to operate, and not only has a vacuum sealing function, but also can enable the optical part to have appropriate elasticity in the machining process. By adopting the apparatus and the chucking method, the close lamination of a machined surface and a polishing (accurate grinding) disc can be realized, the technical bottle neck that the numerical-control grinding and polishing cannot be adopted for the large-caliber optical surface can be solved, and the labor intensity is alleviated.

Owner:TIANJIN JINHANG INST OF TECH PHYSICS

Engine valve locking piece assembling and disassembling tool

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

High-speed real-time pulse compression algorithm

ActiveCN103926567BTooling structure is simpleEasy to adjustWave based measurement systemsFourier transform on finite groupsRapid pulse

The invention discloses a high-speed real-time pulse compression algorithm. The algorithm comprises reading a state character, and selecting parameters such as a frequency modulation signal, a distance and the like; reading the frequency modulation signal; converting integer numbers into floating numbers; performing fast Fourier transform (FFT); performing complex multiplication on an FFT result and the weight of a corresponding parameter; performing FFT; performing normalization operation, and converting the floating numbers into the integer numbers; and writing a pulse pressure signal and storing the signal. The high-speed real-time pulse compression algorithm has the advantages of small calculation complexity, highly-efficient and rapid pulse compression, and the like.

Owner:ANHUI BOWEI CHANGAN ELECTRONICS

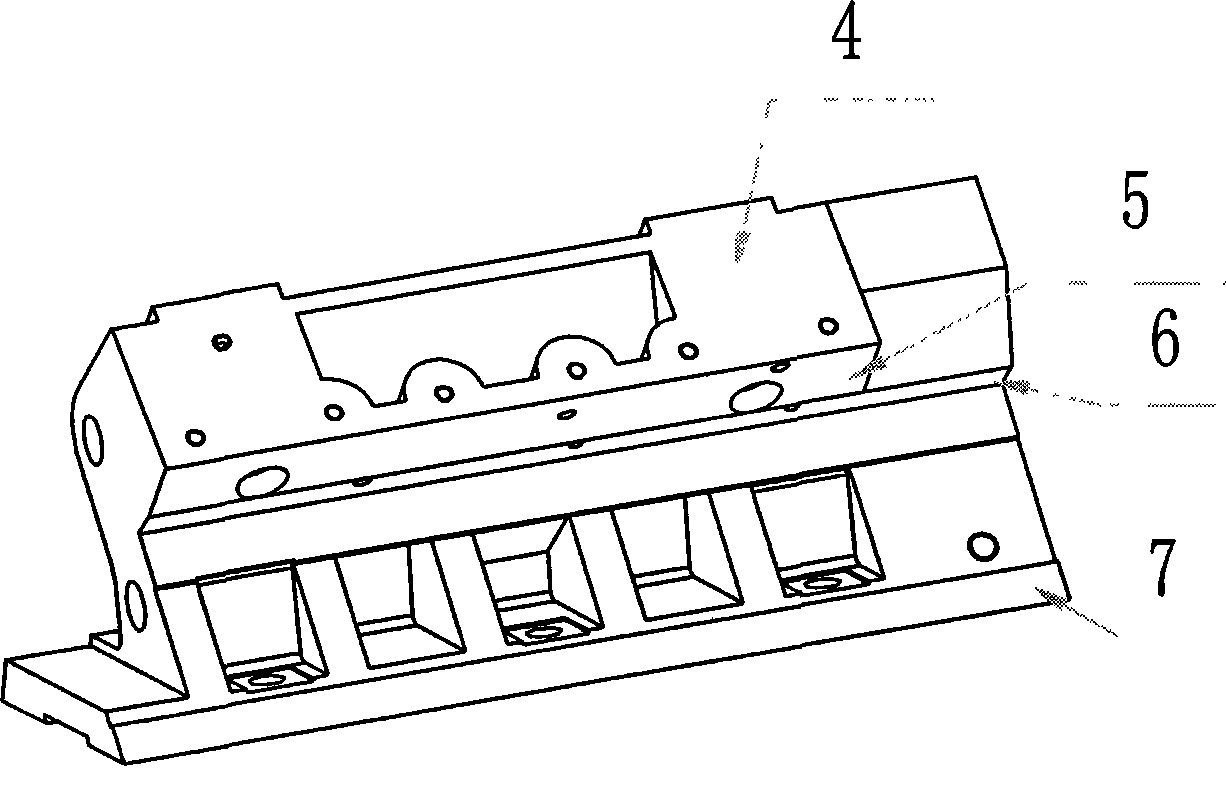

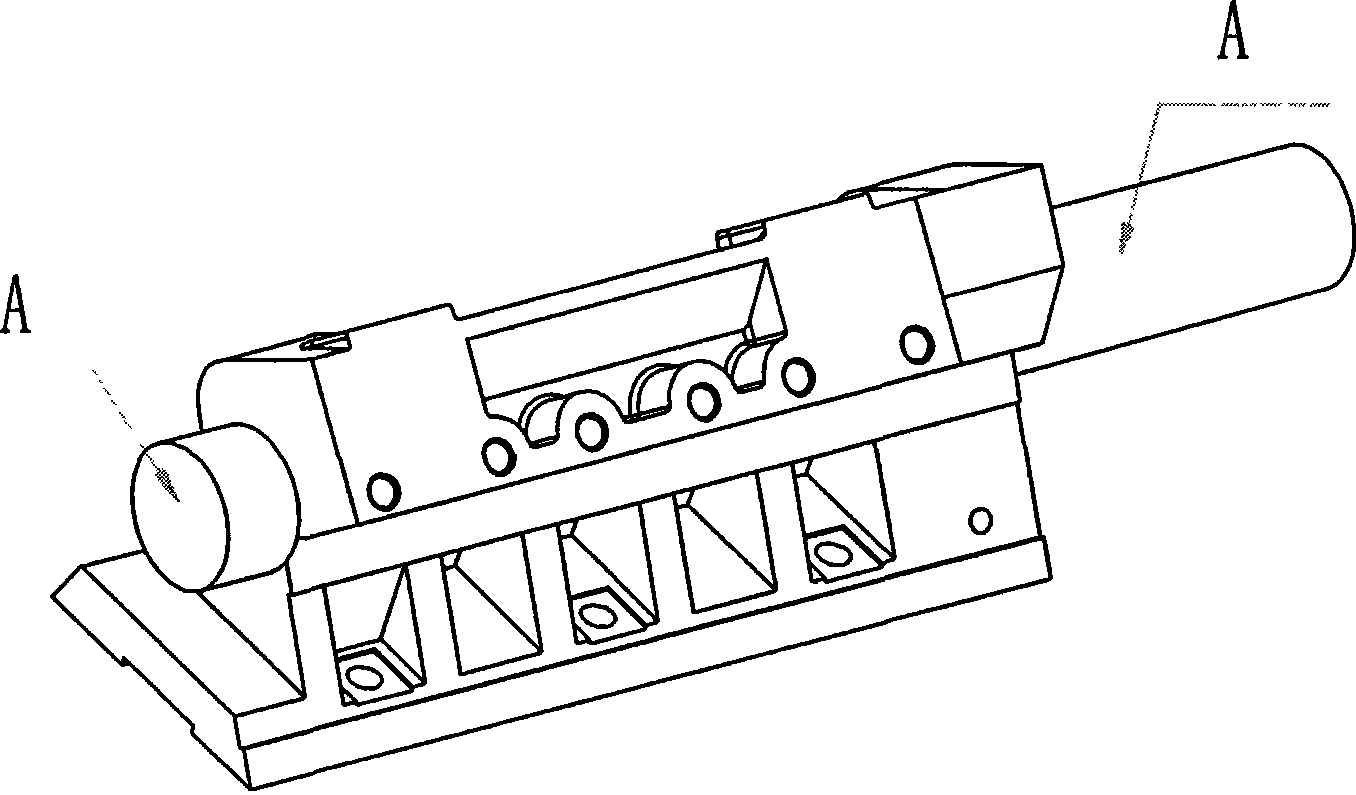

Assembling tooling simultaneously applicable to die-cutting machine and gilding press

ActiveCN104339300ATooling structure is simpleEasy to operateMetal-working hand toolsWall plateEngineering

The invention relates to an assembling tooling simultaneously applicable to a die-cutting machine and a gilding press. The assembling tooling comprises a support, four linear guide ways, two sliding blocks, two fixing blocks and a connecting rod, two linear guide ways are fixed at the upper end of the support, the other two linear guide ways are fixed at the lower end of the support, the two sliding blocks are in sliding joint with the linear guide ways located at upper and lower ends of the support respectively, the two fixing blocks are vertically fixed on the sliding blocks respectively, the connecting rod is fixedly arranged between the two sliding blocks in a connecting mode so as to limit synchronous movement of the two sliding blocks, the fixing blocks are used for fixing machine wall plates of a to-be-assembled machine, and the positions of the sliding blocks on the linear guide ways are adjusted so as to be adapted to the machine widths of the die-cutting machine and the gilding press. Compared with assembling toolings in the prior art, the assembling tooling simultaneously applicable to the die-cutting machine and the gilding press has the advantages that simple and convenient switching between two machine types can be performed so that the tooling can conveniently assemble the two types of machines, and the assembling efficiency is generally increased by the aid of reduced switching time of the tooling.

Owner:BOBST SHANGHAI

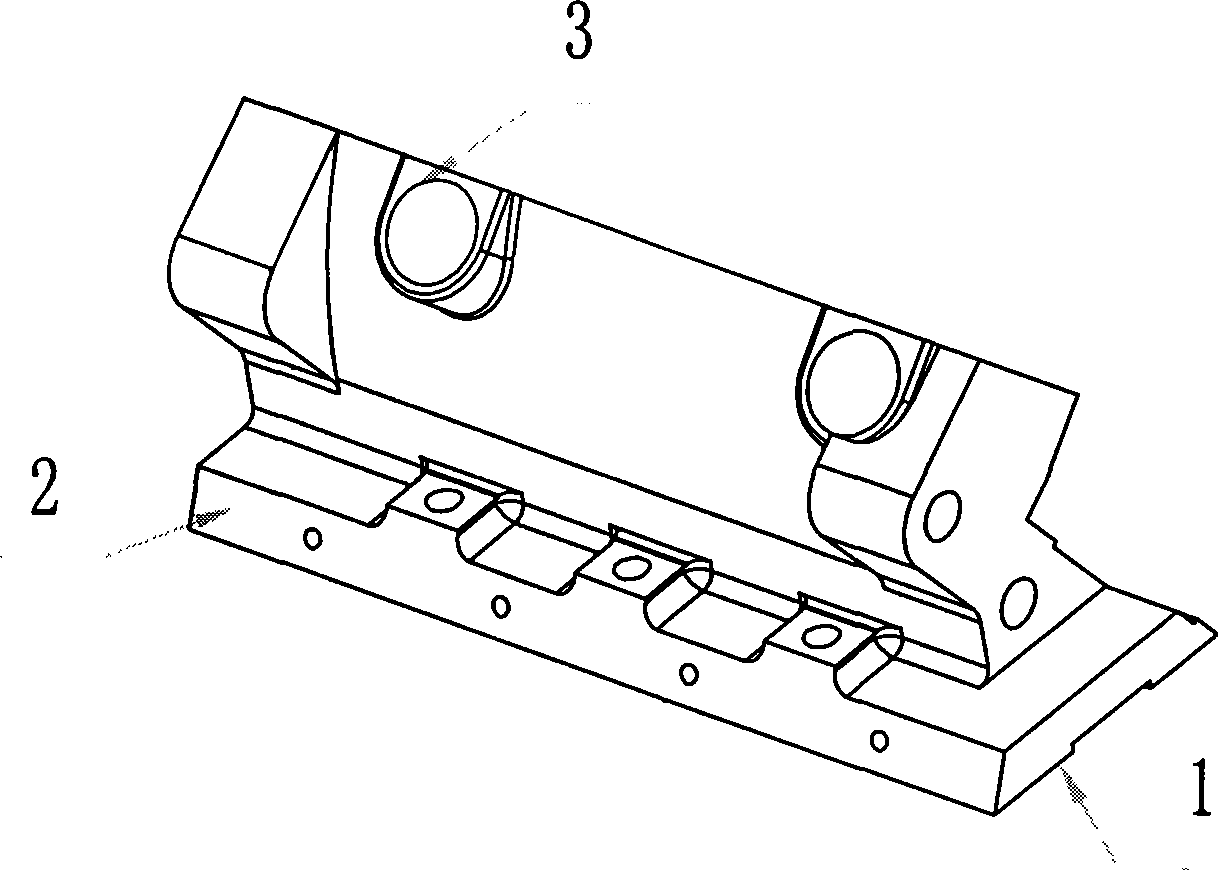

Rolling tool for rolled piece of reed of plate spring

The invention relates to a rolling tool for a rolled piece of a reed of a plate spring, which belongs to the field of manufacturing equipment of automobile parts and comprises a worktable (1). The rolling tool is characterized in that a rolling device is fixed at the side edge of the worktable (1) and comprises a rolling module (2), a pin roll (7), a swing mechanism and a vertical column (8). One end of the rolling module (2) is fixed on the worktable (1), and the other end of the rolling module (2) extends out of one end of the worktable and is in rotary connection with the swing mechanism through the pin roll (7). The rolling module (2) is a rectangle with an arced end. A semicircular groove is arranged at the inner side of the arc of the end part. The vertical column (8) is vertically fixed inside the semicircular groove. According to the rolling tool for the rolled piece of the reed of the plate spring, the reed can be rolled, so that the reed can have arc-shaped angle, and the rolling to the reed that cannot be completed by press punching can be realized, and the rolling tool is convenient and rapid to use and more economical and practical.

Owner:山东海华汽车部件制造有限公司

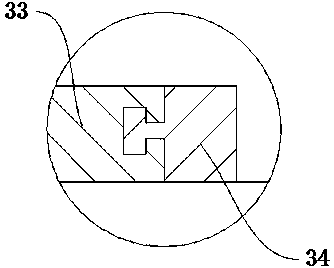

Technique for processing poly-angle part blade supporting seat

InactiveCN101502892AImprove machining accuracyIncrease productivityMilling equipment detailsProcess supportEngineering

The invention discloses a processing technology of a multi-angle part blade support seat. The technology comprises the following steps: firstly confirming a device required by the processing and designing a positioning fixture and a cutter in use according to the device; the two end surfaces of the blade support seat are provided with a coaxial cylindrical process support; arranging the blade support seat on the positioning fixture based on the coaxial cylindrical process support; taking the central line of the process support as the rotary axle center, selecting the process support and one processing surface of the blade support seat as calculation benchmark, carrying out the conversion among angles and data on design angles and dimensions of all surfaces of the blade support seat and forming the manufacturing process angle and dimension chain among all surfaces; taking the central line of the process support as the rotary axle center, rotating all manufacturing process angles in turn and processing other surfaces and through holes or screwed holes on the surfaces; finally milling the process support and the two end surfaces and processing the screw thread holes of the two end surfaces. The invention, due to the adoption of the auxiliary process support, has the advantages of high processing accuracy, simple tooling structure and high production efficiency.

Owner:SUZHOU SUFOMA MACHINERY

Machining method for semicircular inserts

The invention discloses a machining method for semicircular inserts. The machining method comprises the steps that 1, the parts, except the less half cylindrical surfaces, of semicircular insert workpieces are machined to the needed amount; 2, the two semicircular insert workpieces treated in the step 1 are installed in two installing grooves of a mandrel body, a jacking bolt is screwed into each jackscrew hole, the jacking bolts at the two ends are pre-tightened, and the two semicircular insert workpieces are installed on the mandrel body simultaneously every time; 3, the mandrel body on which the two semicircular insert workpieces are installed is clamped on a common lathe, turning is conducted on the less half cylindrical surfaces after aligning is conducted, and the moderate margin is reserved; and 4, the mandrel body and the two semicircular insert workpieces are clamped on a common cylindrical grinding machine, the less half cylindrical surface is ground to the size required by the workpieces, and then the semicircular inserts are obtained. According to the machining method, adopted tools and lathe equipment are simple, the machining cost is low, the working efficiency is high, and the finished product rate is obviously increased.

Owner:MCC SFRE HEAVY IND EQUIP

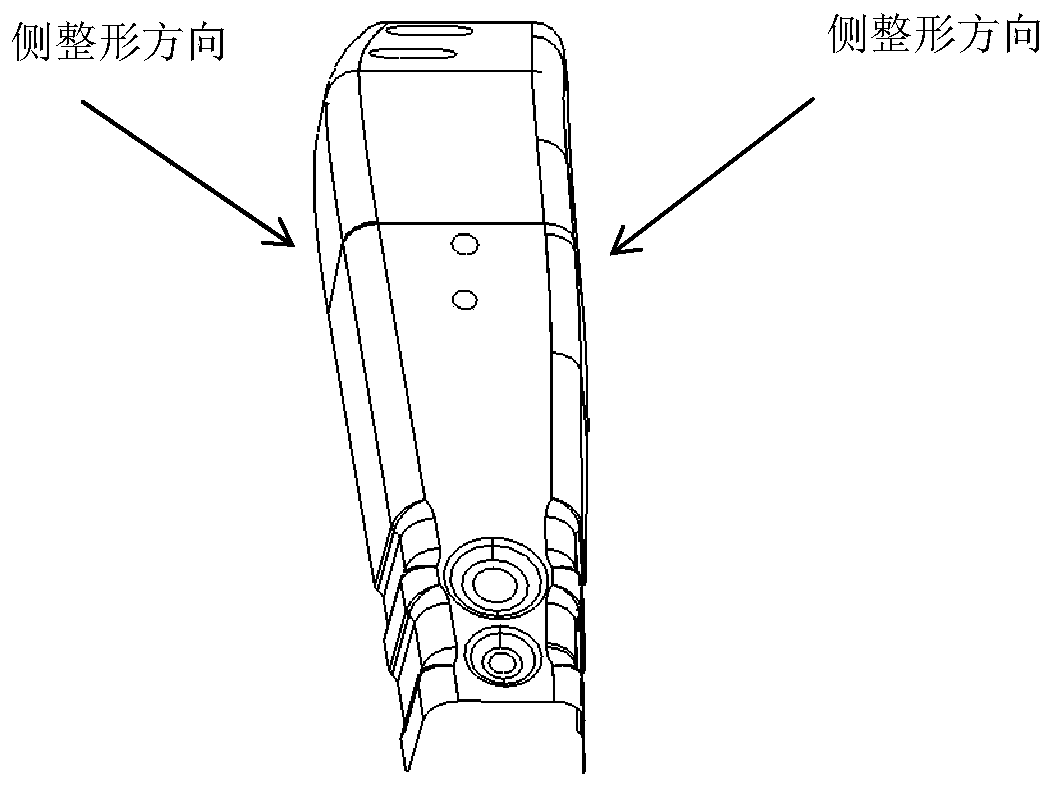

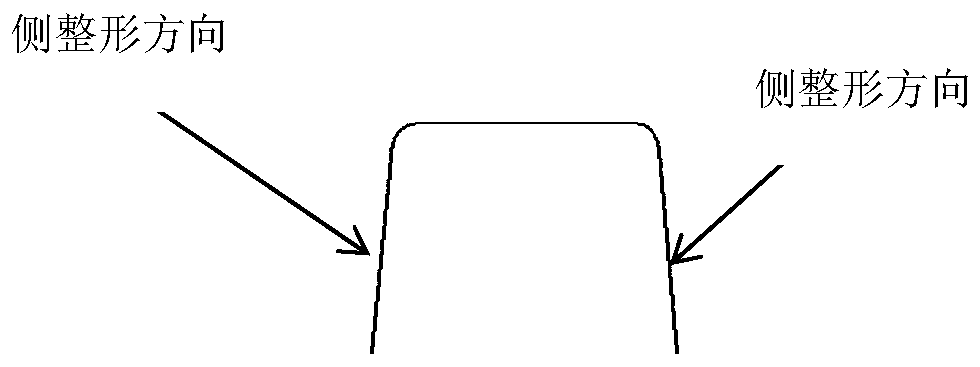

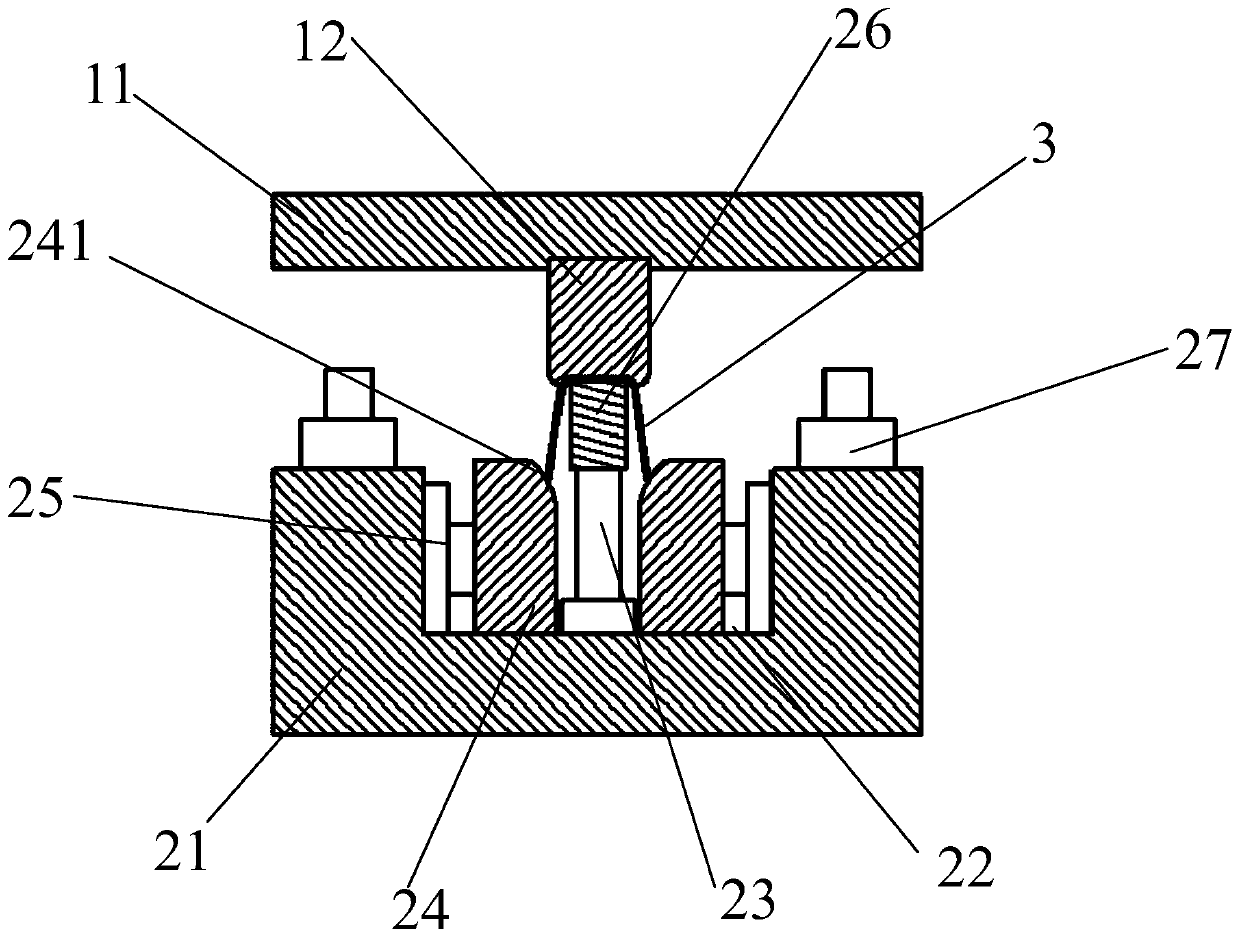

U-shaped beam shaping tool and corresponding shaping method

InactiveCN110449490AReduced commissioning timeReduce the difficulty of debuggingShaping toolsLoad-supporting pillarsShaped beamEngineering

The invention discloses a U-shaped beam shaping tool and relates to the technical field of vehicles. The U-shaped beam shaping tool comprises an upper die body, and a lower die body matched with the upper die body. The upper die body comprises an upper die base. An upper die core is connected to the bottom of the upper die base. The lower die body comprises a lower die base. A groove opened upwards is formed in the upper end face of the lower die base. A jacking mechanism, lower die shaping cutter blocks and side pushing mechanisms are arranged in the groove. The jacking mechanism is installedat the bottom end of the groove. A carrier core is arranged on the top of the jacking mechanism. The lower die shaping cutter blocks are arranged on the left side and the right side of the jacking mechanism. The side pushing mechanisms are connected to the back ends of the lower die shaping cutter blocks. A height adjustable upsetting block is arranged on the upper end face, connected with the groove, of the lower die base. The invention further discloses a U-shaped beam shaping method. According to the tool and the method, the former side shaping or front shaping technology is changed into adriving extrusion technology, on the condition of ensuring the product quality, debugging time and difficulty can be shortened and reduced substantially, the adopted tool is simple in structure and low in investment cost, and parts of multiple specifications can be produced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

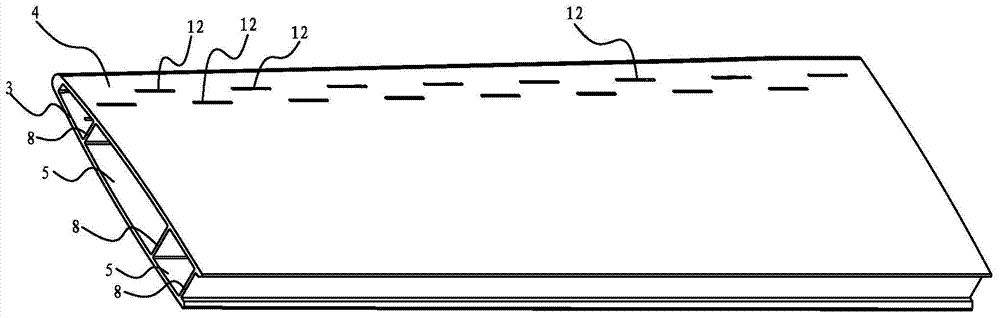

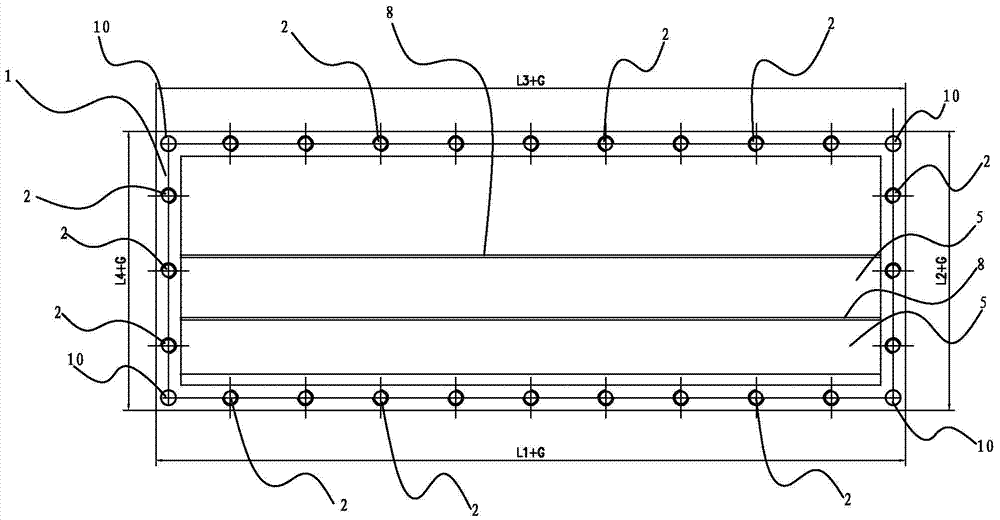

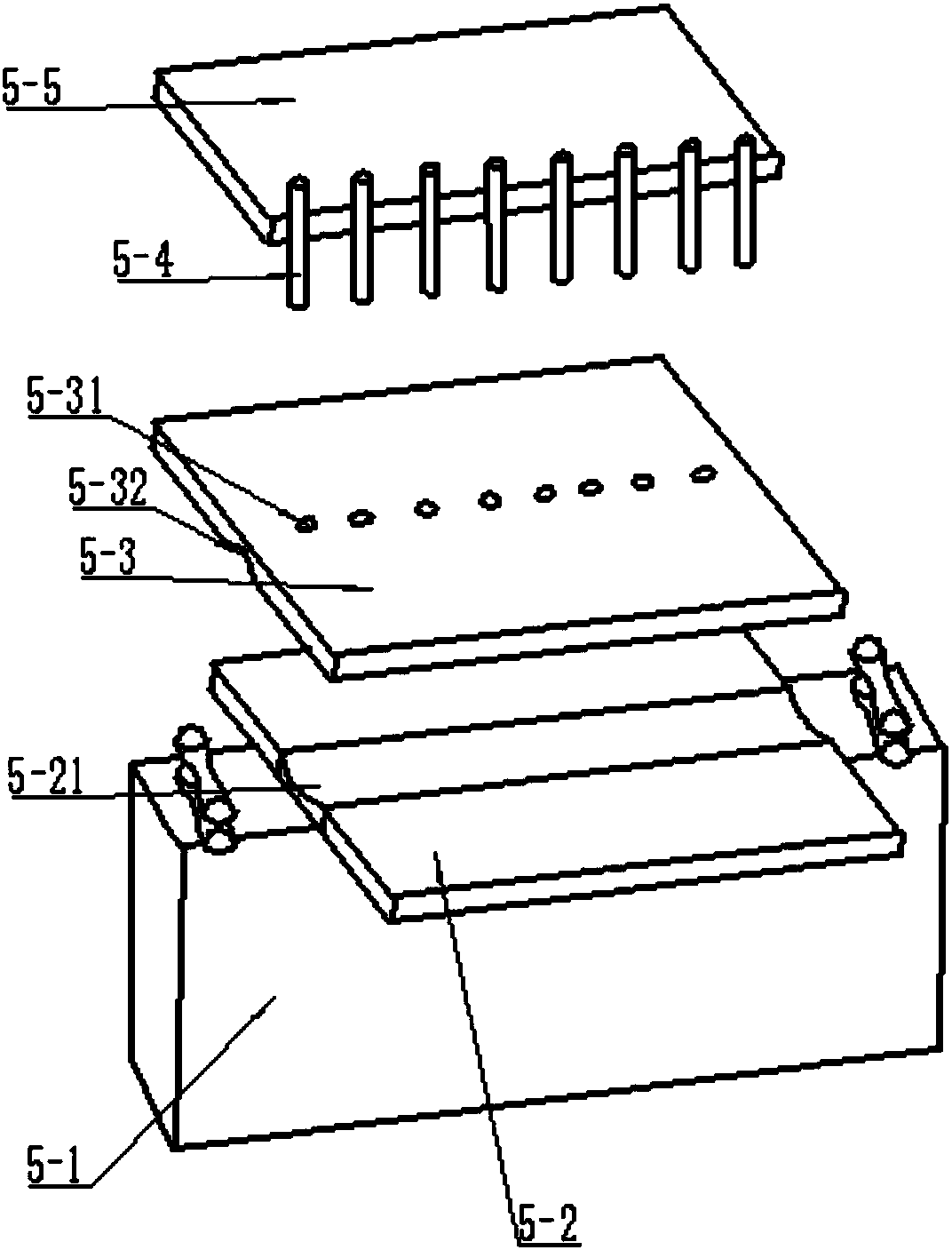

Tool and method for assembling of carbon fiber composite cross beams of standardized CRH train equipment compartment

ActiveCN105904721AGuaranteed assembly accuracyTooling structure is simpleManufacturing cost reductionEngineering

The invention provides a tool and method for assembling of carbon fiber composite cross beams of a standardized CRH train equipment compartment. The tool for the assembling of the carbon fiber composite cross beams of the standardized CRH train equipment compartment comprises a base platform, a positioning press plate, a piece of end seal foam, side portion balance plates and a top balance plate; bolt holes are formed in the positioning press plate and the base platform correspondingly; the positioning press plate is connected to the top surface of the base platform through bolts; one or more limit holes are formed in the top surface of the base platform; limit blocks are arranged in the limit holes; and the end seal foam, the side portion balance plate and the top balance plate are arranged between the positioning plate and the base platform correspondingly. The tool is a novel practical tool formed by machining and combining with the steel serving as the raw material. The tool for the assembling of the carbon fiber composite cross beams of the standardized CRH train equipment compartment has the advantages of being simple in structure, easy to manufacture, easy to implement, low in manufacturing cost, high in assembling precision and the like. The assembling precision of structural elements is guaranteed, the manufacturing cost is greatly lowered, and the manufacturing cycle is greatly shortened at the same time.

Owner:HENGSHEN

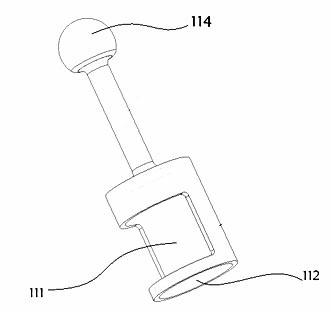

Engine valve locking piece assembling and disassembling tool

The invention provides an engine valve locking piece assembling or disassembling tool comprising a pressure head, a compression rod, an adjusting sliding rod, a dividing disc, a flat base and a cushion block, wherein the flat base has a large plane on which a guide slot is arranged, one or a plurality of cushion blocks are freely arranged in the guide slot in a slippage manner; each cushion block is a wedge, the wedge surface faces upwards and is vertical to an valve axis; the dividing disc is vertically fixed on two sides of the flat base, at least one row of holes are distributed on the upper end position of the dividing disc in a sector shape; two ends of the adjusting sliding rod are fixed in the corresponding holes on the dividing disc by lock pins; one end of the compression rod is provided with holes which are hinged with the adjusting sliding rod; the pressure head is connected below the middle part of the compression rod, a T-shaped structure is formed by the pressure head and the compression rod, and the lower part of the pressure head has a sleeve structure. By utilizing a lever principle, the engine valve locking piece assembling or disassembling tool reduces assembling pressure, adjusts the assembling angle through the scales of the dividing disc, so that the locking piece is simply and easily assembled or disassembled, other parts can be ensured not to be collided and crushed, and the whole assembling is more easily realized.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Perforating method for perforating one row of holes in hose

InactiveCN108162050AElasticQuality is not affectedMetal working apparatusLiquid nitrogen coolingEngineering

The invention relates to a perforating method for perforating one row of holes in a hose. The perforating method includes the following steps that 1, a hose to be perforated is obtained, the diameterof the hose is 6-25 mm, and the two ends of the hose to be perforated are blocked after the hose to be perforated is filled with water; 2, the hose filled with water is placed in a liquid nitrogen cooling device to be cooled until the water in the hose is frozen to ice; 3, a to-be-perforated section of the hose is placed in a front-face perforating device to be perforated; 4, the perforated hose is moved forwards into a hose collecting device to wait for ice melting, and meanwhile, the next to-be-perforated section is placed in the front-face perforating device; and 5, the step 4 is repeated until the whole hose is perforated. A core mold is no longer needed for the front-face perforating device for the hose, the structure is simple, the perforating quality is good, the roundness of the holes can be guaranteed, and it is guaranteed that the hose cannot be broken through.

Owner:史倩萌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com