Machining method for semicircular inserts

A processing method and technology for inserts, which are applied to the processing field of semicircular inserts, can solve the problems of low yield, high processing cost and low efficiency of semicircular inserts, and achieve high yield, low processing cost and simple tooling structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

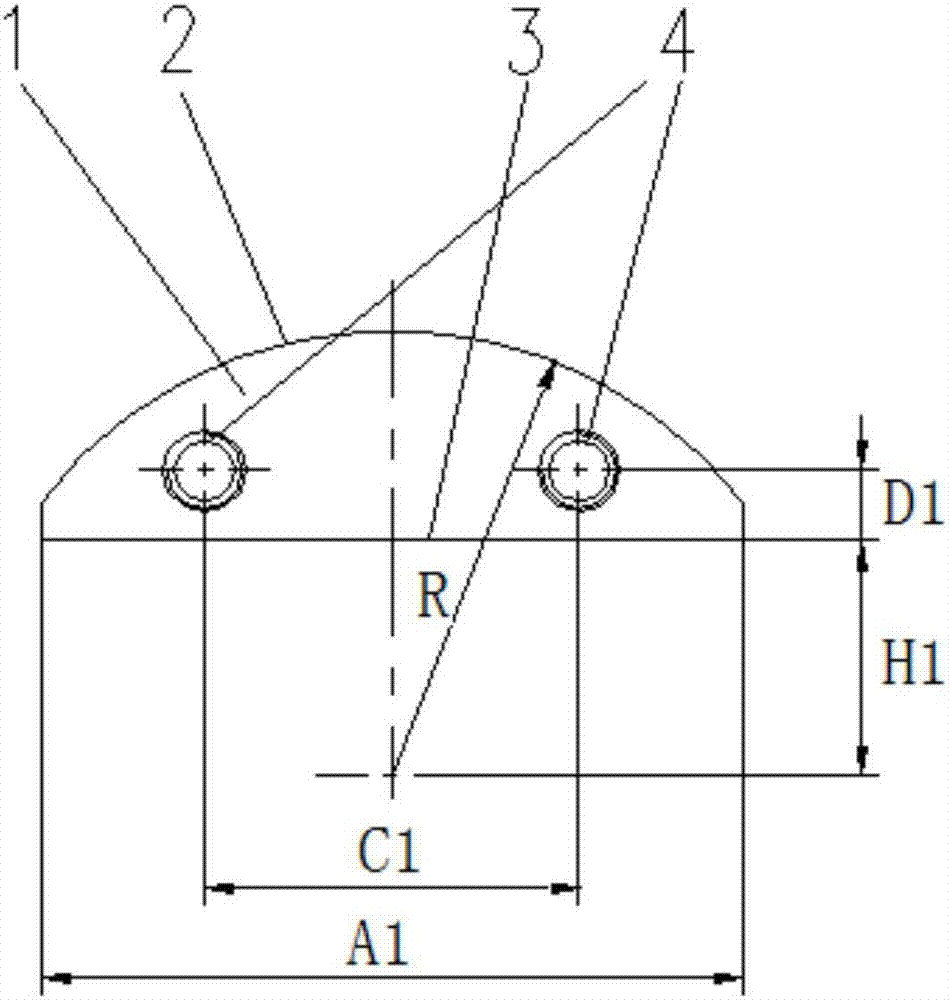

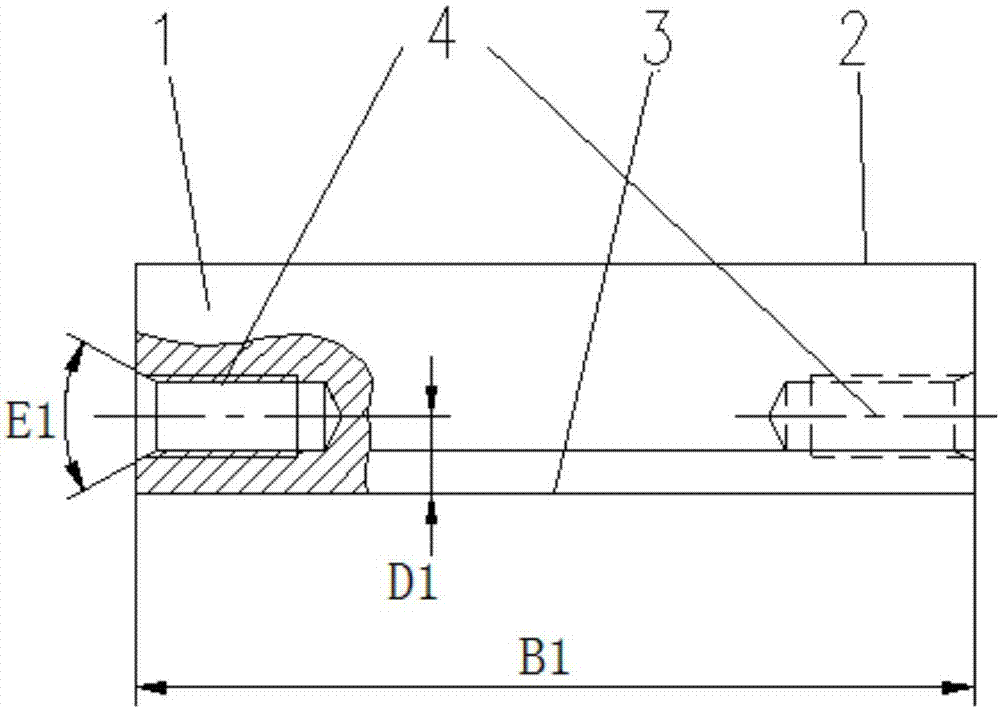

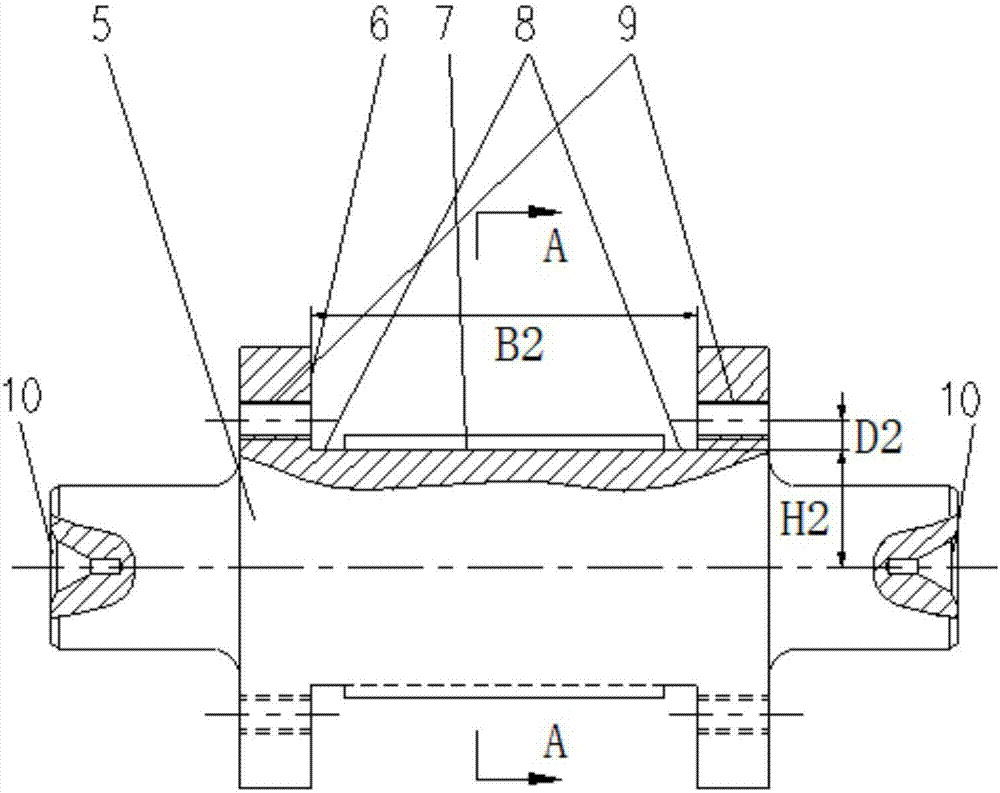

[0028] refer to figure 1 and figure 2 , the structure of the finished product of the processing object semicircle insert of the present invention is that a semicircular insert workpiece 1 is provided with a less semi-cylindrical surface 2 with a radius of R, the radius R of the less semicylindrical surface 2, and the lower plane where the center of the radius R is located The vertical distance H1 of 3 has relatively strict size requirements, and its tolerance requirements are usually within 0.08mm; the width of semicircular insert workpiece 1 is A1 (see figure 1 ), the length is B1 (see figure 2 ), there are two screw holes 4 on both ends of the length of the semicircular insert workpiece 1, the distance between the two screw holes 4 on each end face is C1, and the distance between the axis center line of each screw hole 4 and the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com