Rolling tool for rolled piece of reed of plate spring

A reed and ear rolling technology, which is applied in the field of auto parts manufacturing equipment, can solve problems such as reed ear rolling and bending, and achieve the effect of saving space, simple design, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

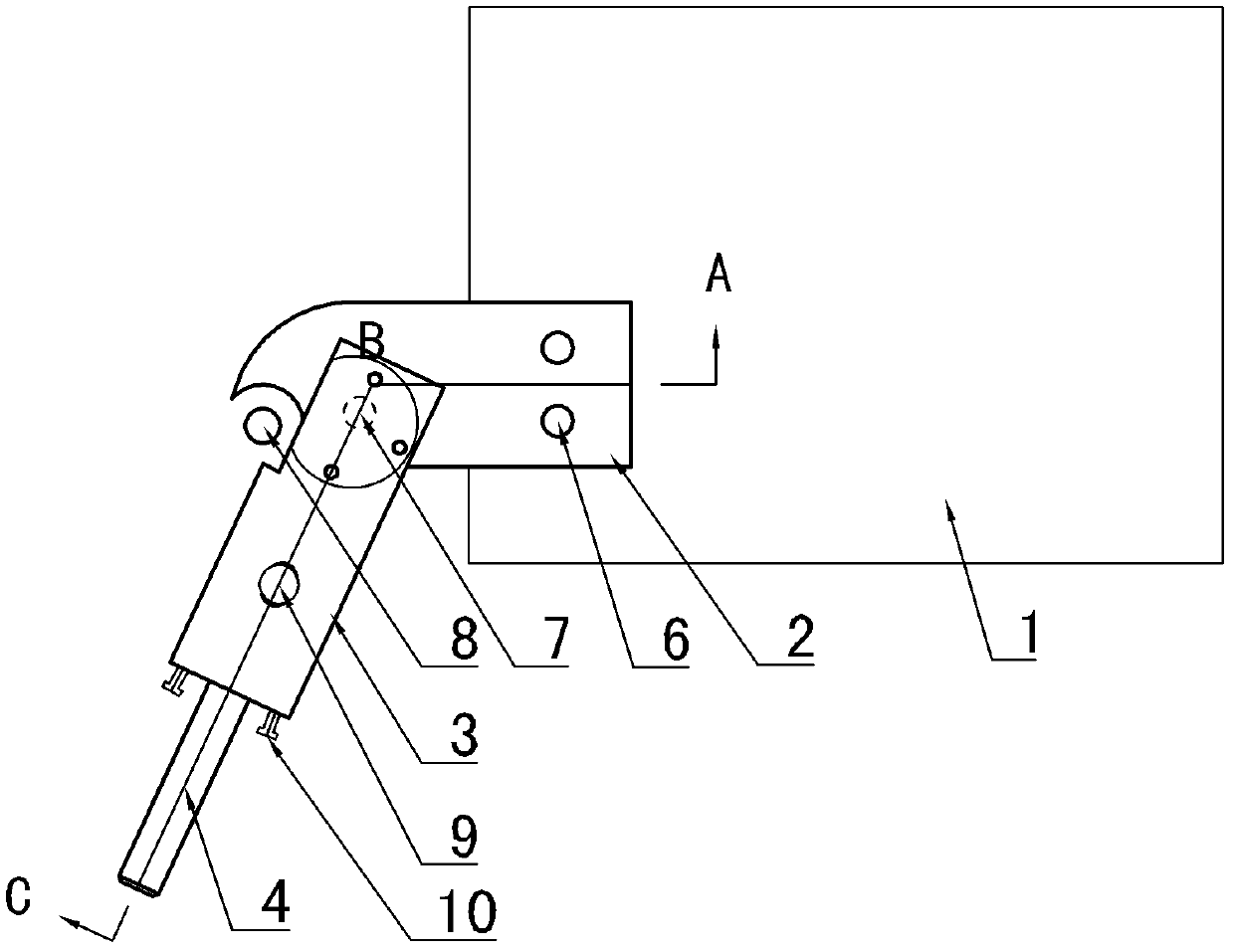

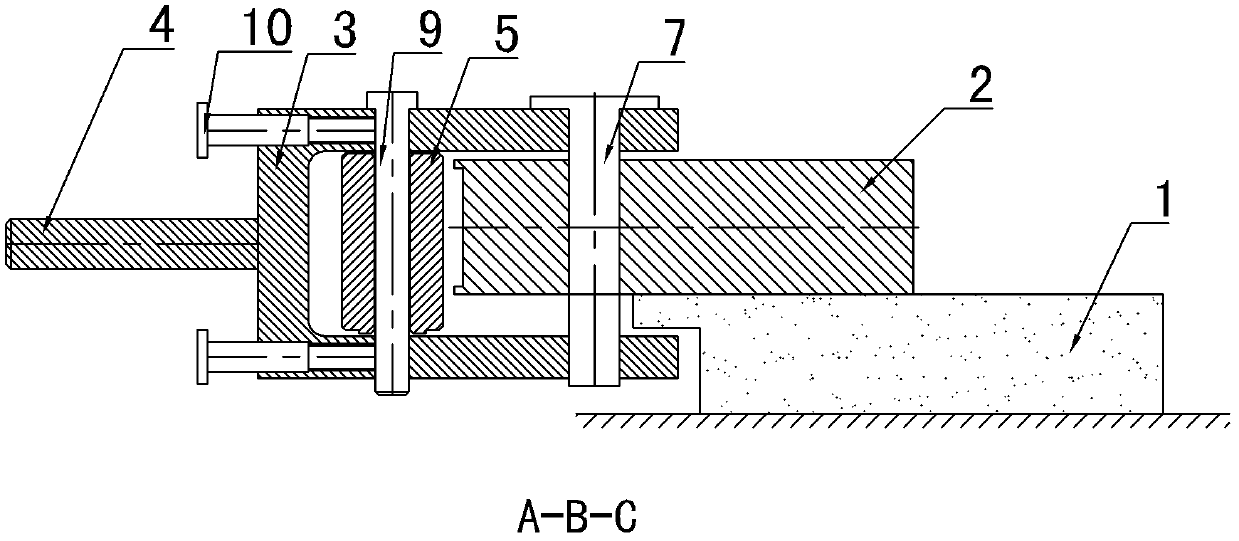

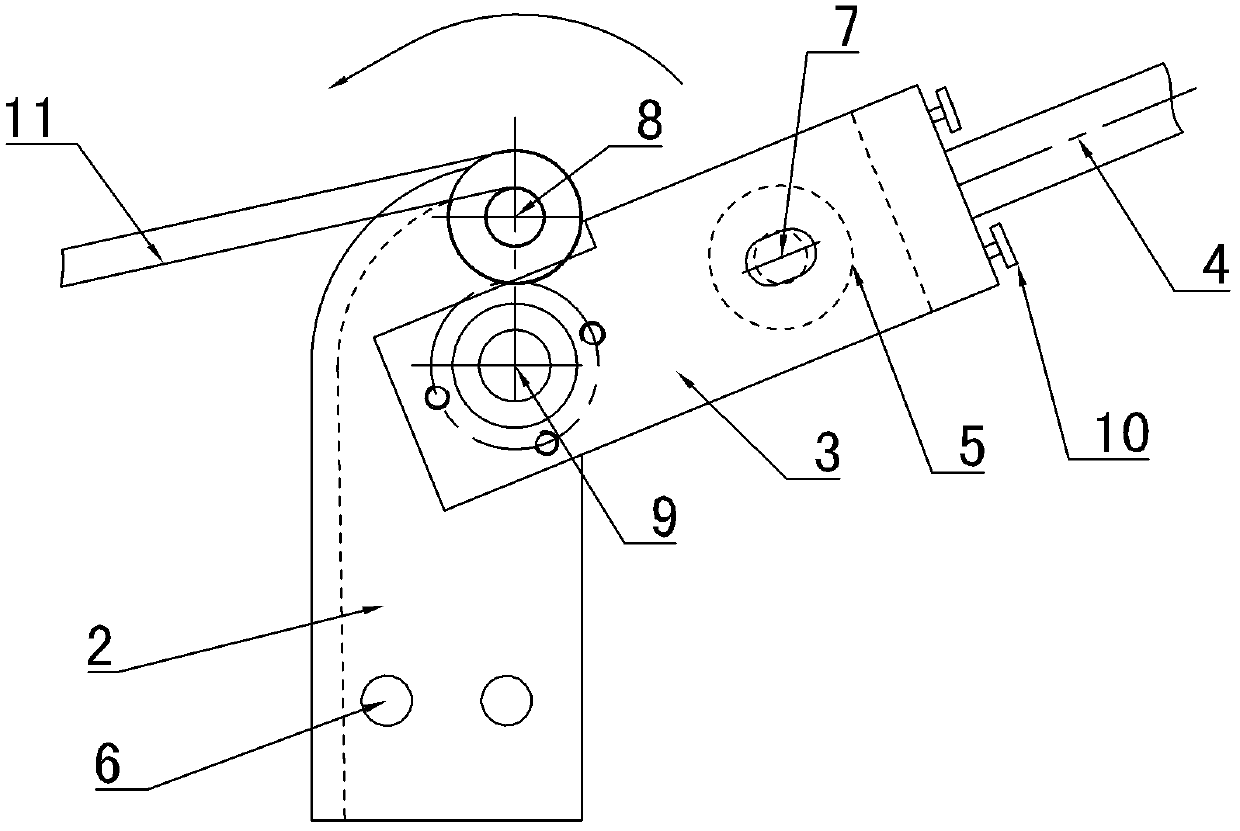

[0018] Refer to attached Figure 1~2 : The leaf spring and reed ear rolling tooling includes a workbench 1, and a bending device is fixed on the side of the workbench 1. The bending device includes a bending module 2, a pin shaft 7, a swing mechanism and a column 8. One end of the bending module 2 is fixed on the workbench 1 by the fixing bolt 6 on the upper part, and one end of the other end protruding from the workbench is rotatably connected with the swing mechanism through the pin shaft 7. There is a semicircular groove on the inner side of the shape, and the column 8 is vertically fixed in the semicircular groove. The reed to be bent is fixed on the bending module 2 through the column 8, and the rotating and swinging mechanism cooperates with the bending module 2 to complete the bending of the reed. .

[0019] The swing mechanism comprises a U-shaped iron block 3 and a swing bar 4, the upper end of the U-shaped iron block 3 is provided with a hole for installing the pin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com