Automatic assembly tool and method for spring clamp ring of automotive seat headrest guide sleeve

A spring collar and automatic assembly technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems of unfavorable large-scale production, high labor intensity of workers, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

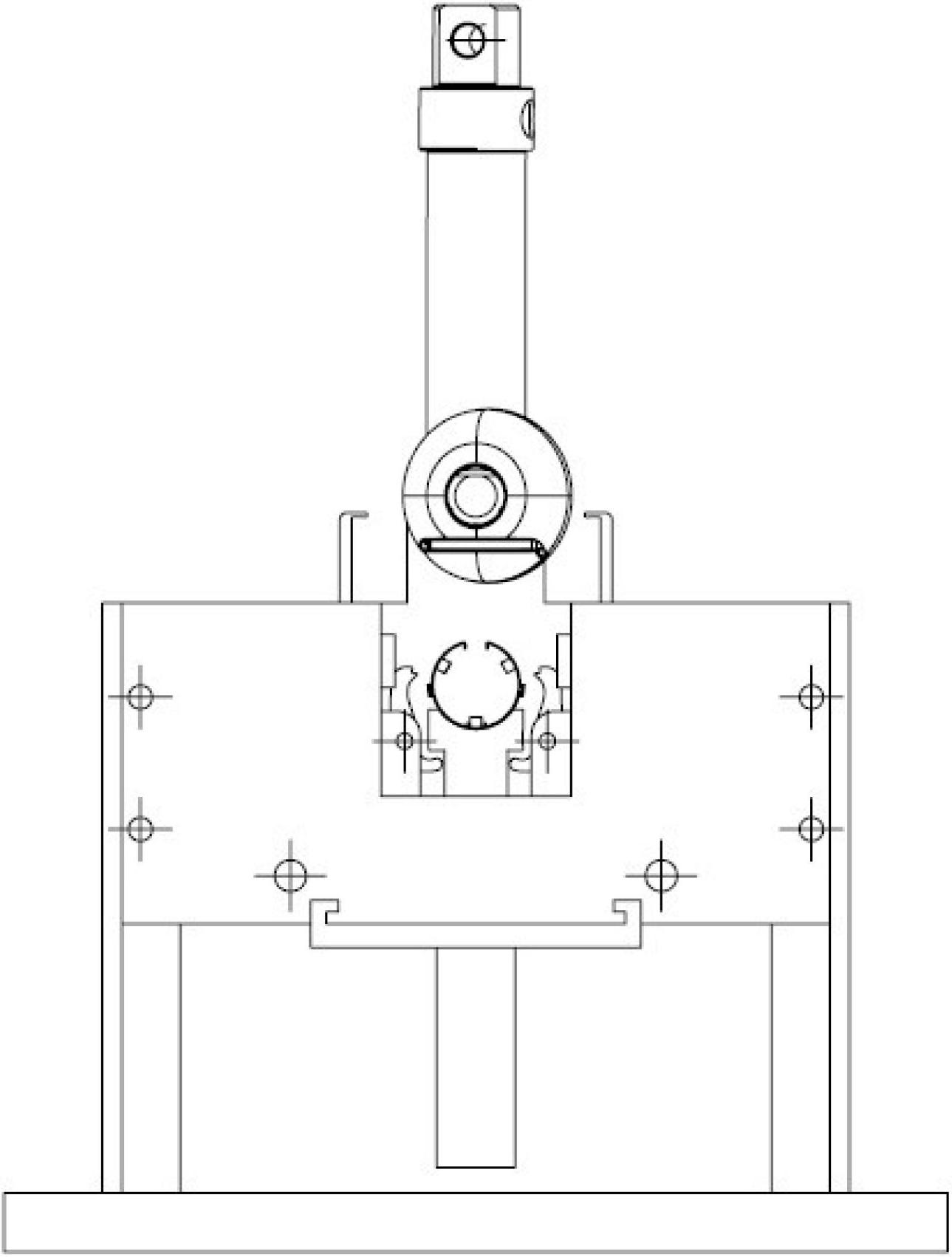

Image

Examples

Embodiment 1

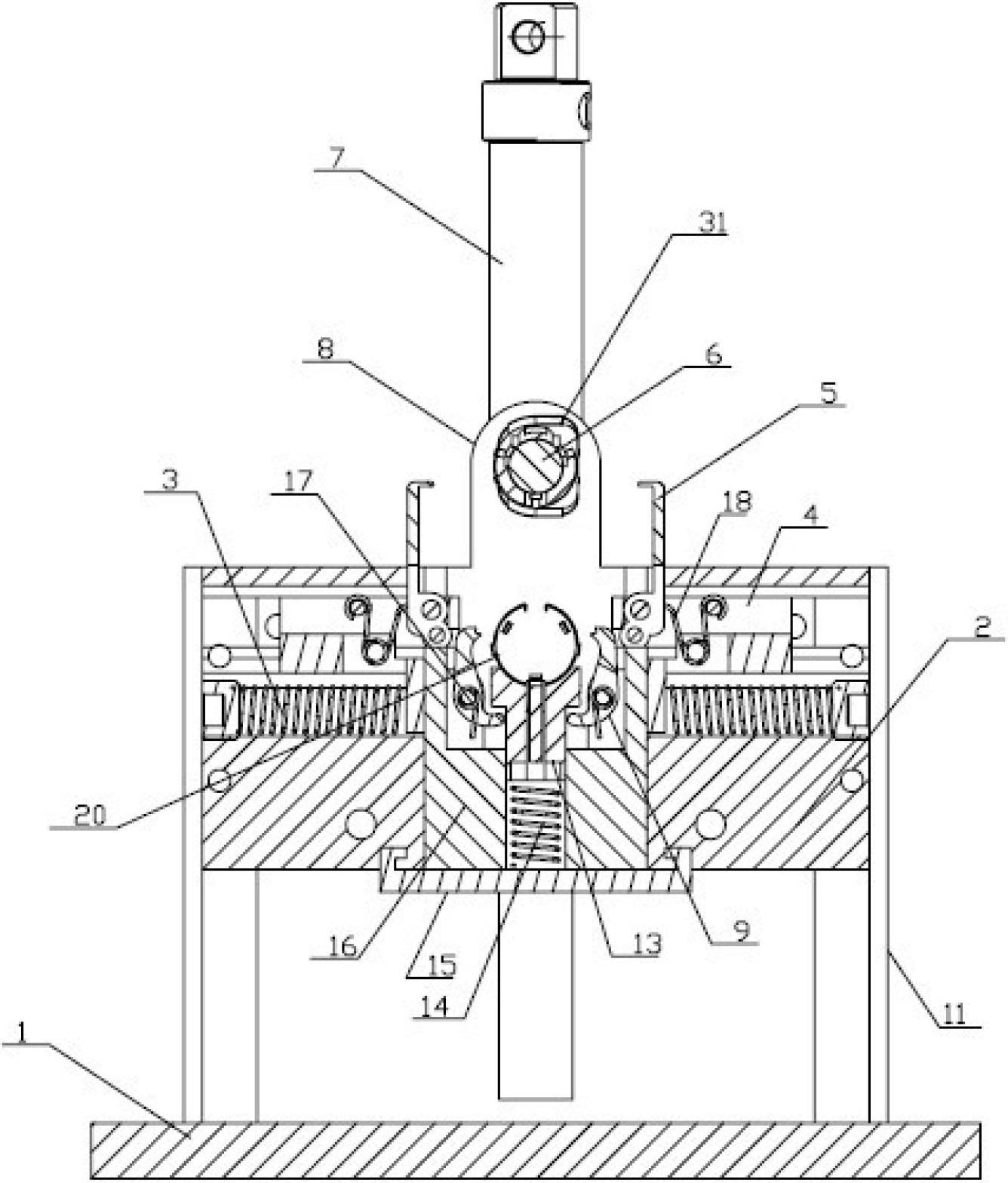

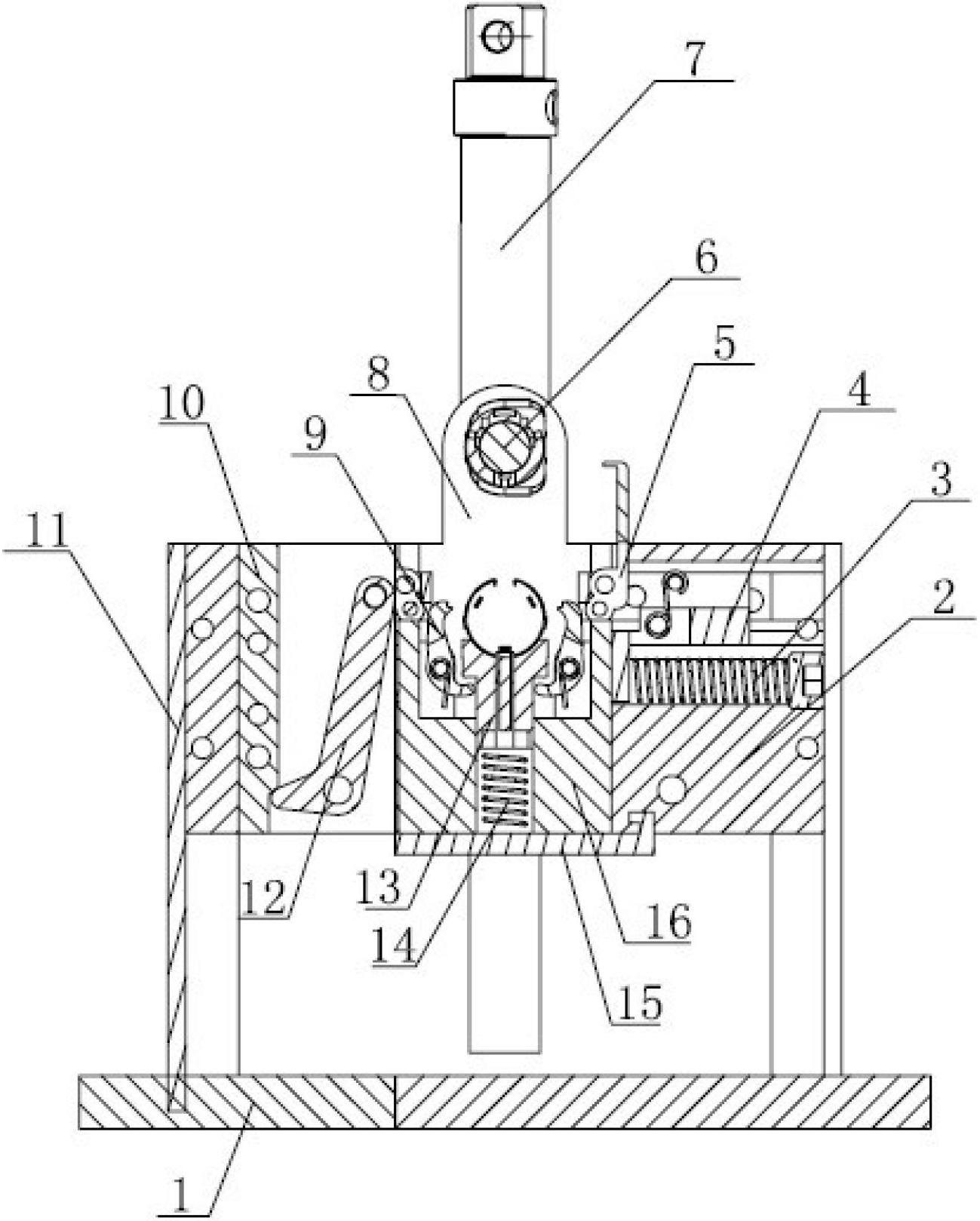

[0028] The spring collar needs to be assembled to the guide sleeve of the seat headrest. The specific assembly steps are as follows:

[0029] (a) First place the opening of the spring collar 20 on the upper end of the spring collar fixing seat 13, and install and fix the seat headrest guide sleeve 31 on the product fixing pin 6;

[0030] (b) The direct push cylinder 7 starts to move, pushes the assembly sliding block 8 to slide downward in the main fixed seat 11, and drives the shovel base 10 to push the lever 12 downward to rotate, and the lever 12 makes the hook linkage block 4 slide to both sides, Simultaneously, drag hook 5 rotates 90 degrees to the inside and hooks the upper edge of the opening of spring collar 20 and pulls to both sides, so that the opening of spring collar 20 is enlarged;

[0031] (c) Assemble the sliding block 8 to drive the seat headrest guide sleeve 31 to continue to move down so that the seat headrest guide sleeve 31 is put into the spring collar 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com