Auxiliary tool for installing foreside windscreen of passenger car

A front windshield and installation auxiliary technology is applied in the field of passenger car front windshield installation auxiliary tooling, which can solve the problems of high labor intensity, easy slipping and inconvenient operation for workers, so as to reduce labor intensity, improve production efficiency, and operate convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

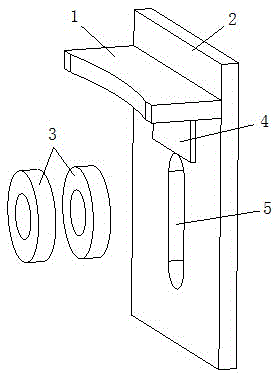

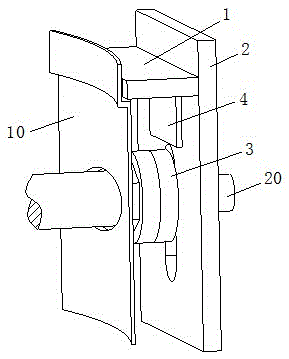

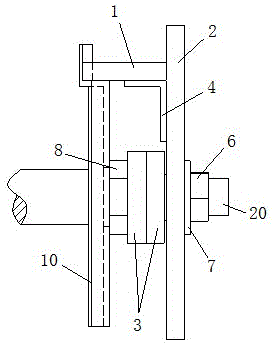

[0018] Such as figure 1 , figure 2 , image 3 The shown auxiliary tool for installing the front windshield of a passenger car includes a flat plate 1 arranged horizontally, one end of the flat plate 1 is a plane, and this end is connected with a vertical plate 2 perpendicular to the flat plate 1, and the other end of the flat plate 1 is an arc surface , and the radian of the curved surface coincides with the radian of the front windshield 30, the thickness of the plate 1 coincides with the gap reserved by the front windshield sealant, and the vertical plate 2 and the wiper output shaft set on the front wall skin 10 20 is fixed, and a spacer 3 for adjusting the horizontal position of the flat panel 1 is provided between the cowl skin 10 and the vertical panel 2 .

[0019] Such as Figure 4 As shown, the structure of the cowl skin is an existing structure, and the struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com