Tool and method for assembling of carbon fiber composite cross beams of standardized CRH train equipment compartment

A composite material and carbon fiber technology, which is applied in the field of carbon fiber composite material beam assembly tooling for standardized EMU equipment cabins, can solve the problems of low efficiency, high cost, and the quality of the beam cannot be guaranteed, and achieves simple manufacturing, simple implementation, and low processing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

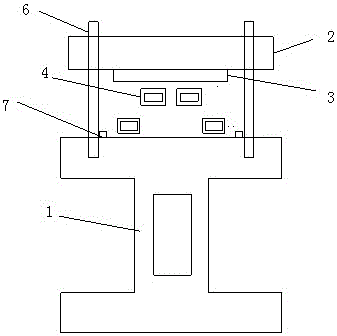

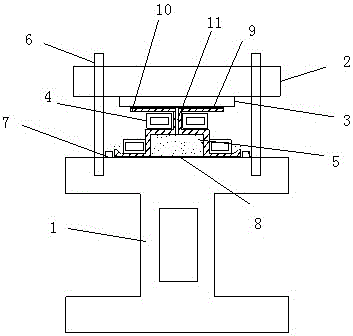

[0021] A standardized EMU equipment cabin carbon fiber composite beam assembly tooling, such as figure 1 , comprising a bottom platform 1, a positioning plate 2, an end-blocking foam 5, a side equalizing plate 4 and a top equalizing plate 3, the positioning plate 2 and the bottom platform 1 are respectively provided with bolt holes, and the positioning plate 2 is connected to the bottom platform 1 through bolts 6 The top surface, the top surface of the bottom platform 1 is provided with more than one limit hole, the limit hole is provided with a limit block 7, and the positioning platen 2 and the bottom platform 1 are respectively provided with a sealing foam 5 and more than two side parts. Pressure equalizing plate 4, top equalizing plate 3.

[0022] The bottom platform 1 is provided with a lower skin 8 with rubber, and a web 10 of a beam is arranged on the lower skin 8 with glue, and an upper skin 9 with glue is arranged on the top of the web 10 of the beam, and an upper ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com