Method for establishing temporary support moulding bed system for steel structure assembly

A temporary support and establishment method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult control of internal dimensions, irregular appearance, failure to meet construction requirements, etc., and achieve significant cost control and reduction Auxiliary materials used in construction and the effect of improving predictability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

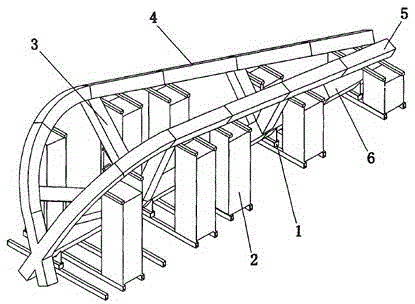

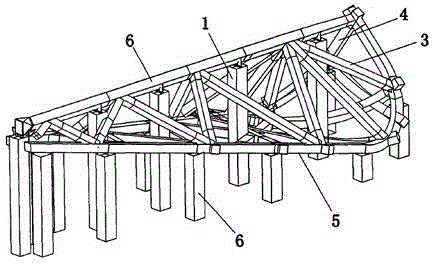

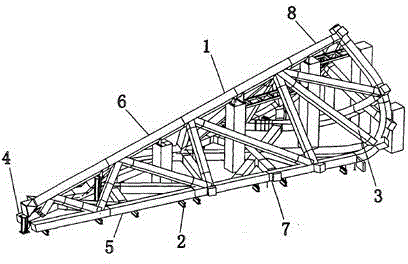

[0024] The invention provides a method for establishing a temporary support tire frame system for assembling large-scale steel structure building units. The method is: using computer three-dimensional modeling software to first establish a three-dimensional simulation of the large-scale steel structure that needs to be assembled. Model, and according to the simulation model to determine the assembly posture of the steel structure unit body and assembly segmentation; then according to the assembly posture optimization of the unit body to establish the assembly coordinate system, output the three-dimensional appearance control point of each characteristic appearance of the structure to be assembled under the assembly coordinate system Finally, according to the three-dimensional coordinate system and the assembly posture of the steel structure unit, a temporary support frame system that does not interfere with the unit members is designed.

[0025] The present invention adopts fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com