Swash plate type axial piston pump or motor

A swash plate plunger pump and motor technology, applied in the hydraulic field, can solve problems affecting the overall efficiency of the swash plate plunger pump, oil leakage friction loss, harsh manufacturing precision, etc., to ensure assembly accuracy and overall efficiency , reduce oil leakage, easy to manufacture and implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to understand the above-mentioned purpose, features and advantages of the present invention more clearly, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] In the following description, many specific details are set forth in order to fully understand the present invention, but the present invention can also be implemented in other ways different from those described here, therefore, the present invention is not limited to the specific embodiments disclosed below limit.

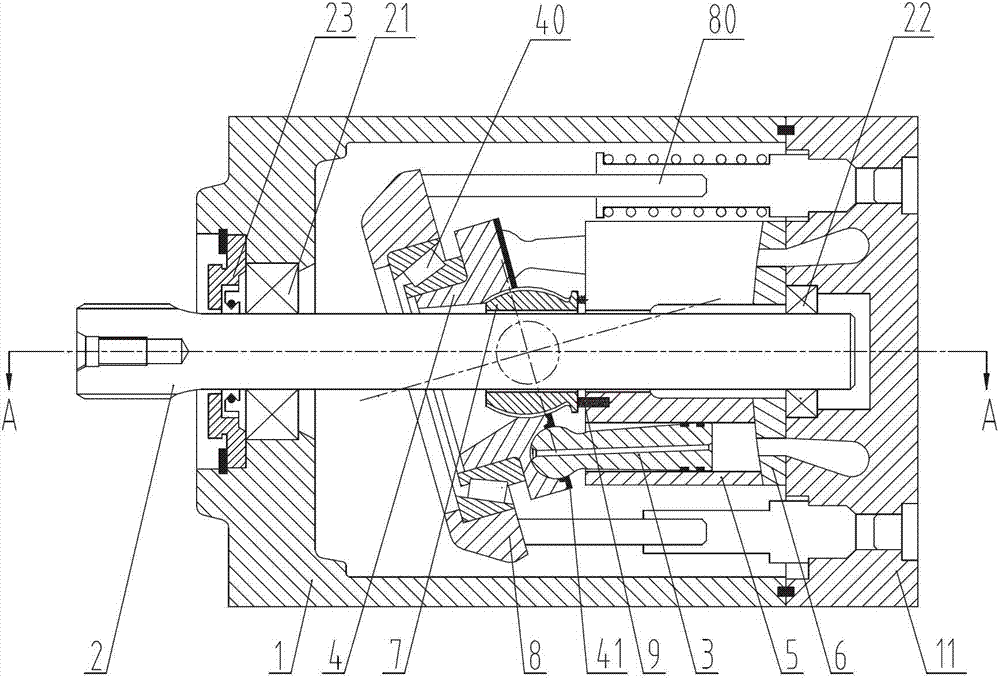

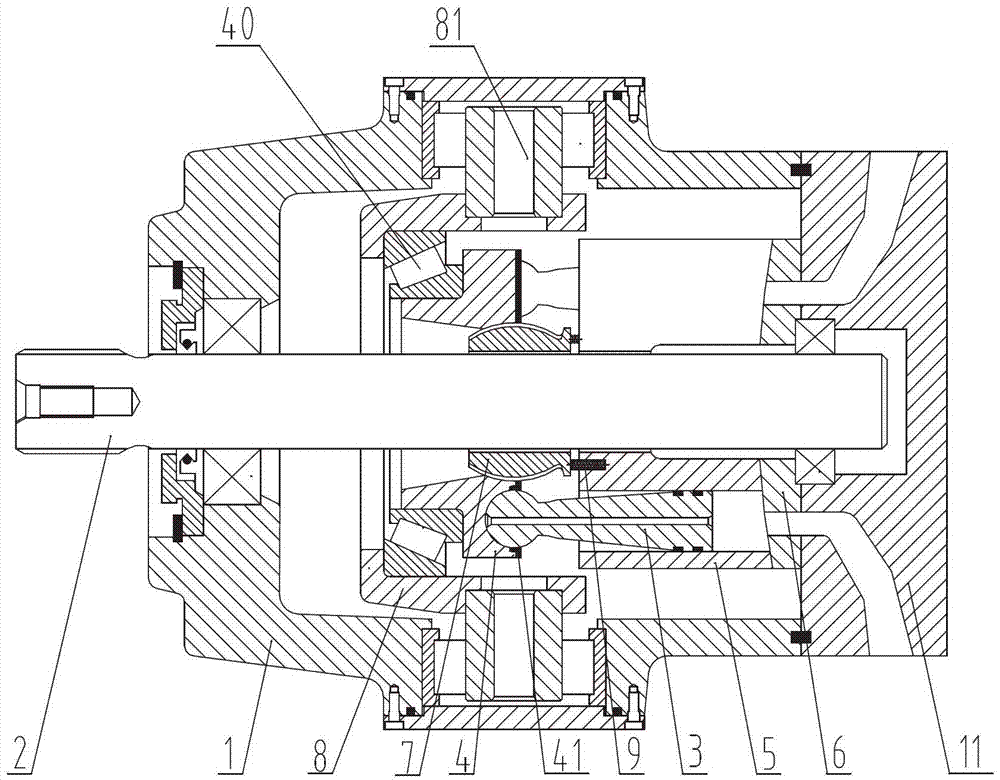

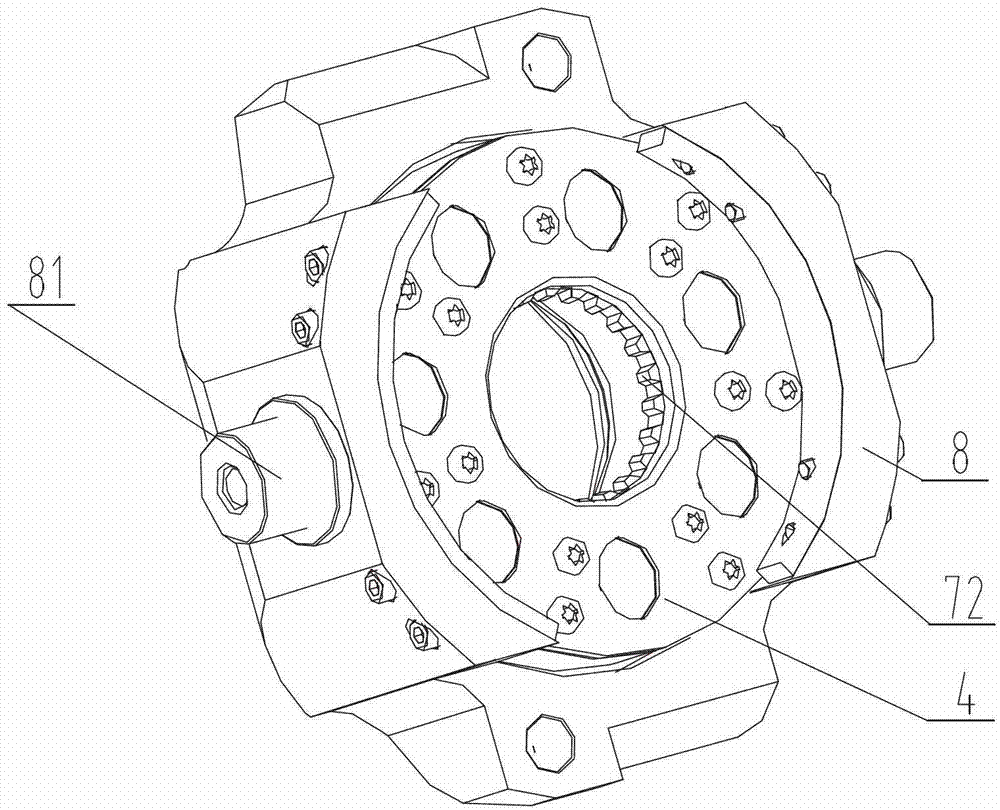

[0044] figure 1 with figure 2 Shown is a schematic structural view of a swash plate type plunger pump or motor according to an embodiment of the present invention, the swash plate type piston pump or motor at least includes a housing 1, a main shaft 2, a plunger assembly 3, a swash plate 4, and a cylinder body 5. The distribution plate 6 and the connection part 7.

[0045] The casing 1 acts as a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com