Micro approximate U-shaped scraper clamping plate regulating mechanism

An adjustment mechanism and scraper technology, applied in the field of coating machines, can solve problems such as poor straightness accuracy, simple structure, and poor quality of coated products, and achieve the effect of reducing processing accuracy, simple and ingenious structure, and stable and reliable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

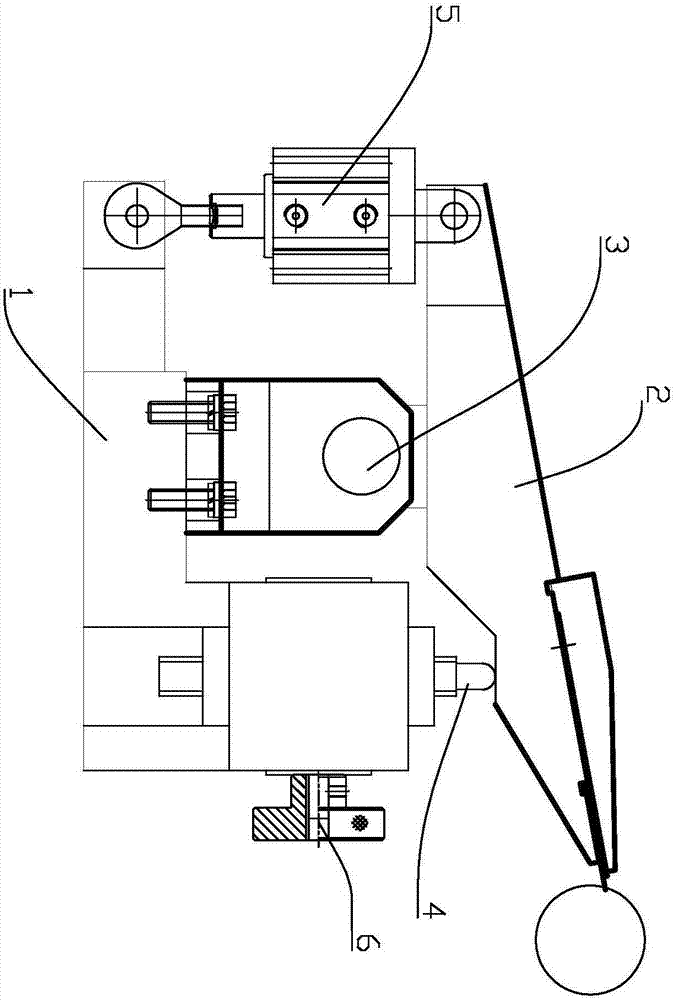

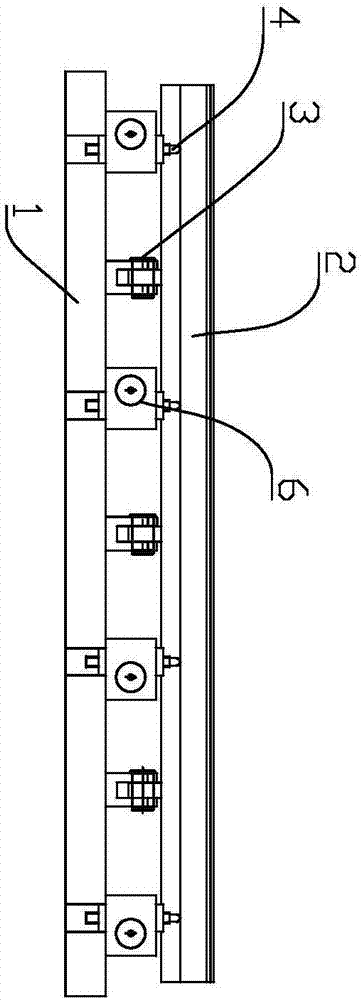

[0019] refer to Figure 1 ~ Figure 2 , the present invention is a dimple scraper splint adjustment mechanism, comprising:

[0020] mount 1;

[0021] The scraper splint 2 is pivotally connected to the mounting base 1 through a pivot 3 in the middle;

[0022] A plurality of adjusting rods 4 are installed on the mounting base 1 and located on one side of the pivot 3, and each adjusting rod 4 can be independently raised and lowered relative to the mounting base 1;

[0023] The force applying device 5 is installed on the mounting base 1 , and the force applying device 5 is used to drive the scraper splint 2 to always be in contact with the adjusting rod 4 .

[0024] The present invention can adjust the height of the adjustment rod 4 according to the straightness of the scraper splint 2, and then the scraper splint 2 is pressed against the adjustment rod 4 by the force applying device 5 to realize the correction of the straightness of the scraper splint 2 and reduce the processing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com