Punching equipment for punching sheet of motor iron core, punching method of ultrathin iron-based sheet and manufacturing method of motor iron core

A manufacturing method and technology of ultra-thin iron, used in the manufacture of stator/rotor bodies, electrical components, electromechanical devices, etc., can solve the problems of tearing, poor processability, difficult mass production, etc., to reduce wear and grinding frequency, reduce The requirements of machining accuracy and the effect of reducing machining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

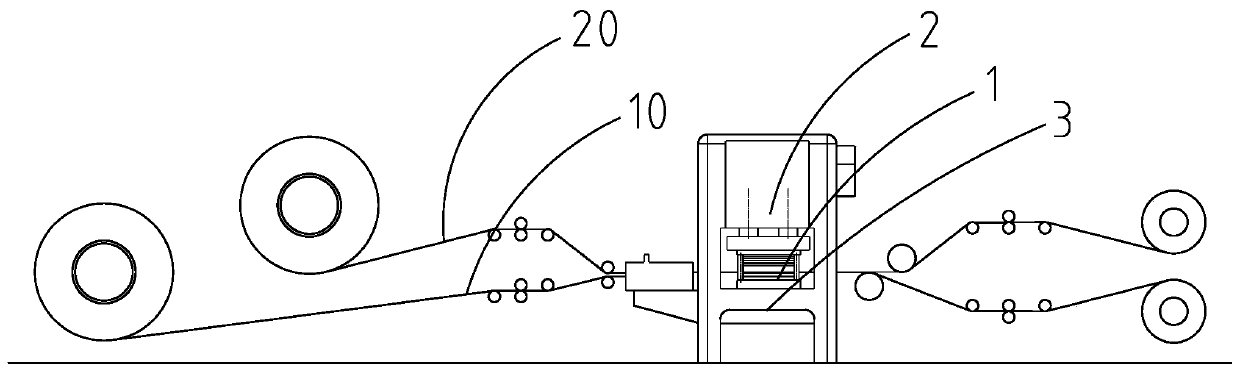

[0041] In this embodiment, the ultra-thin iron-based strip material 20 with a thickness of 0.025±0.005 mm is used, and the conventional silicon steel strip material 10 with a thickness of 0.35 mm is used for auxiliary punching. The specific method for manufacturing the motor core is as follows:

[0042] Use a normal 0.35mm non-oriented silicon steel sheet punching machine, set the accuracy of the supporting mold and the matching punching gap between the upper and lower molds according to the needs, and drive the upper mold 2 to lift through the driving mechanism of the punching machine. The driving mechanism of the punching machine is an existing structure, so no detailed introduction is given. The lower mold 1 has a lower mold pressing mechanism for fixing the silicon steel strip 10, and the upper mold 2 has a glue dispensing mechanism for glue spraying and lamination between layers. The machine tool has a silicon steel strip feeding mechanism (sending + pulling), and an ultra...

Embodiment 2

[0054] In this embodiment, the ultra-thin iron-based strip material 20 with a thickness of 0.1±0.005 mm is used, and the conventional silicon steel strip material 10 with a thickness of 0.25 mm is used to assist stamping. The specific method for manufacturing the motor core is as follows:

[0055] Use a normal 0.25mm non-oriented silicon steel sheet punching machine tool, set the accuracy of the supporting mold and the matching punching gap between the upper and lower molds according to the needs, and drive the upper mold 2 to lift through the punch drive mechanism. The punch drive mechanism is an existing structure, so no detailed introduction is given. The lower mold 1 has a lower mold pressing mechanism for fixing the silicon steel strip 10, and the upper mold 2 has a glue dispensing mechanism for glue spraying and lamination between layers. The machine tool has a silicon steel strip feeding mechanism (sending + pulling), and an ultra-thin iron base strip feeding system (sen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com