Medium thickness detection device and method

A medium thickness and detection device technology, which is applied to the authenticity inspection of banknotes, handling coins or valuable banknotes, instruments, etc., can solve the problems of error, cost increase, and not strictly equal radii, etc., to reduce processing costs and reduce processing costs. Accuracy requirements, the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

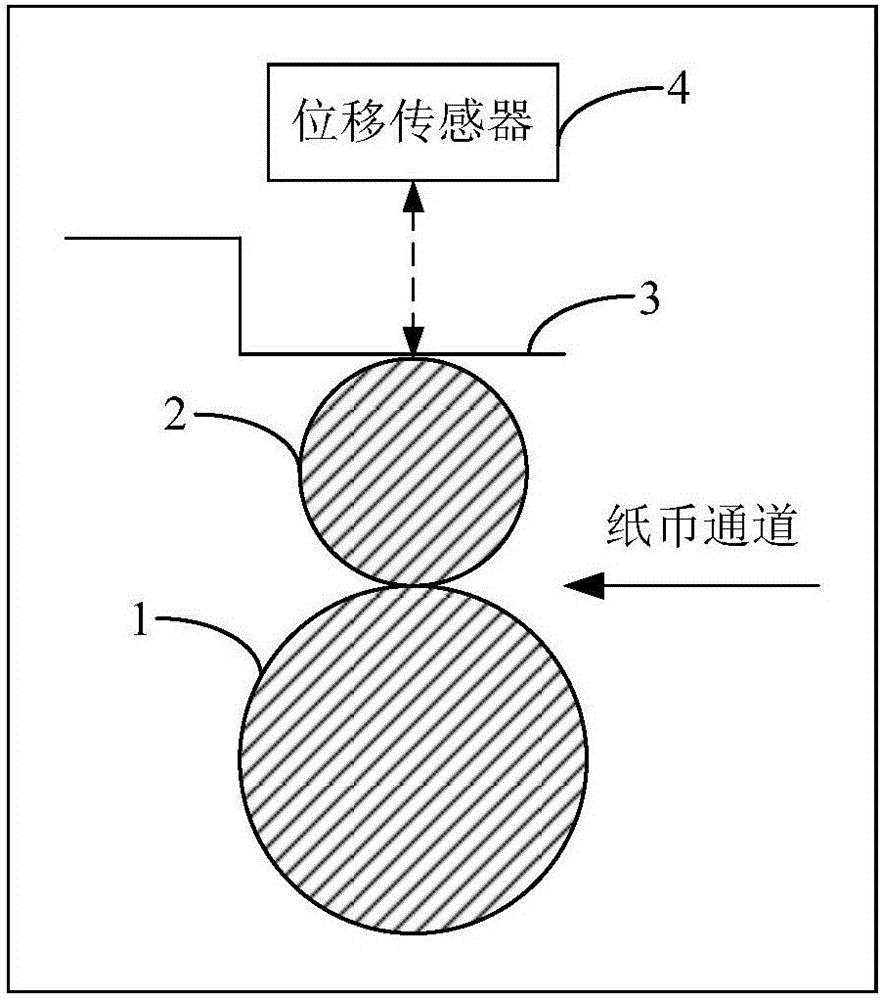

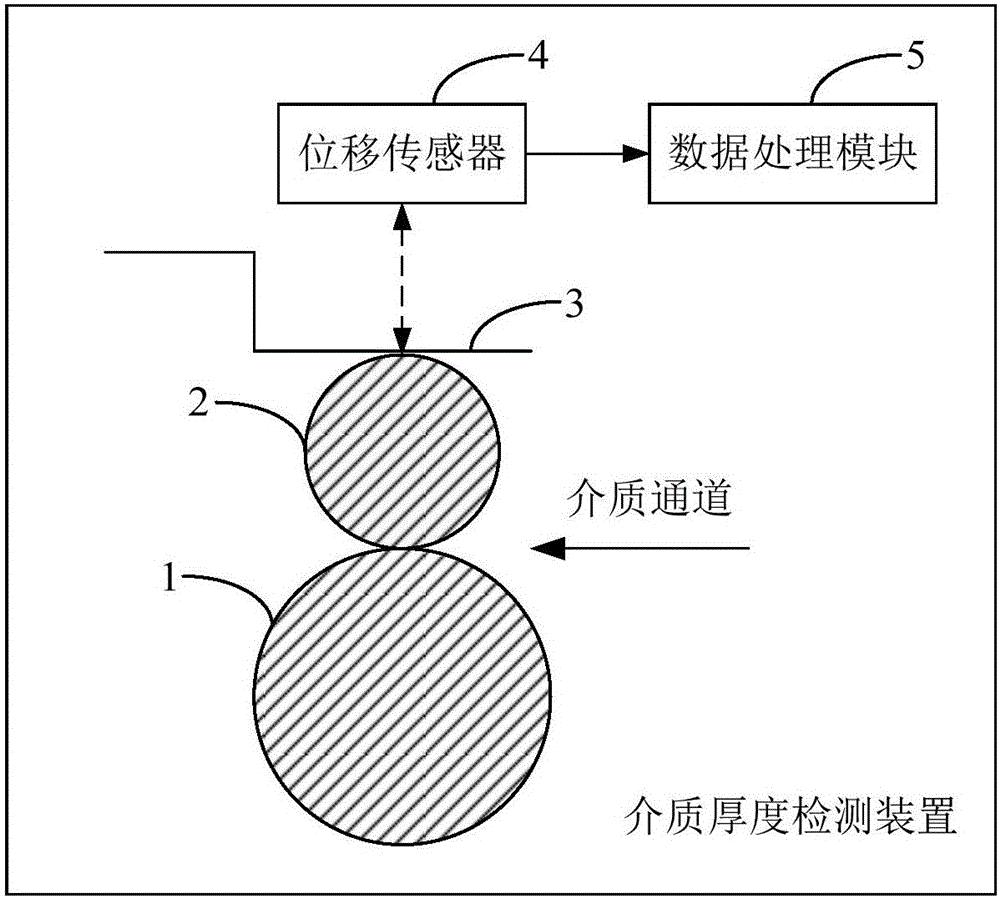

[0018] The first embodiment of the present invention provides a medium thickness detection device. The medium thickness detecting device can be applied to banknote checking modules of automatic cash machines and other financial automatic equipment to detect the thickness of banknotes.

[0019] figure 2 The structure of the cross section of the medium thickness detection device provided by the first embodiment of the present invention is shown, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0020] A medium thickness detection device connected to a motor (not shown in the figure), including a driving shaft 1, a floating shaft 2, a shrapnel 3 and a displacement sensor 4, the driving shaft 1 and the displacement sensor 4 are relatively fixed, and the floating shaft 2 and the shrapnel 3 are sequentially arranged between the driving shaft 1 and the displacement sensor 4, the floating shaft 2 is in contact with...

Embodiment 2

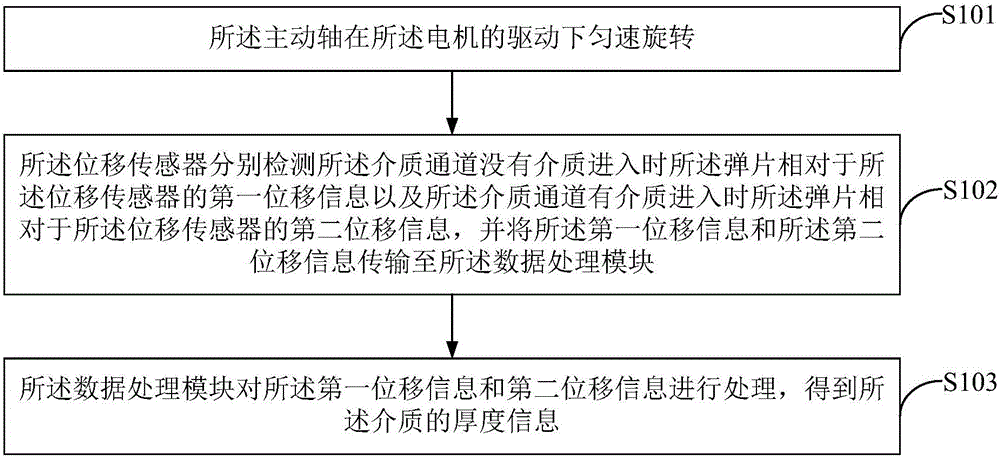

[0032] The second embodiment of the present invention provides a medium thickness detection method based on the medium thickness detection device provided in the first embodiment above.

[0033] image 3 A flow chart of the method for detecting the thickness of a medium provided by the second embodiment of the present invention is shown, and for the convenience of description, only the parts related to the embodiment of the present invention are shown.

[0034] Such as image 3 As shown, a medium thickness detection method, comprising:

[0035] In step S101, the drive shaft rotates at a constant speed driven by the motor.

[0036] In step S102, the displacement sensor respectively detects the first displacement information of the shrapnel relative to the displacement sensor when there is no medium entering the medium channel and the second displacement information of the shrapnel relative to the displacement sensor when the medium channel has medium entering, and combines th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com