Large-scale MIMO antenna structure and manufacturing process

A large-scale, antenna technology, applied in the field of massive MIMO antenna structure and manufacturing process, can solve the problems of difficult control of relative displacement and spacing, low welding reliability, etc., to achieve the effect of reducing mass, simplifying assembly steps, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means realized by the present invention clear, the present invention will be further described below in conjunction with the accompanying drawings.

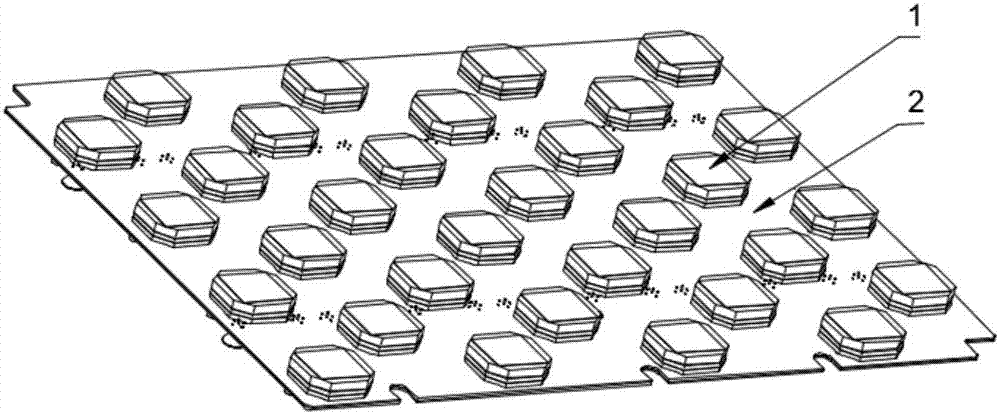

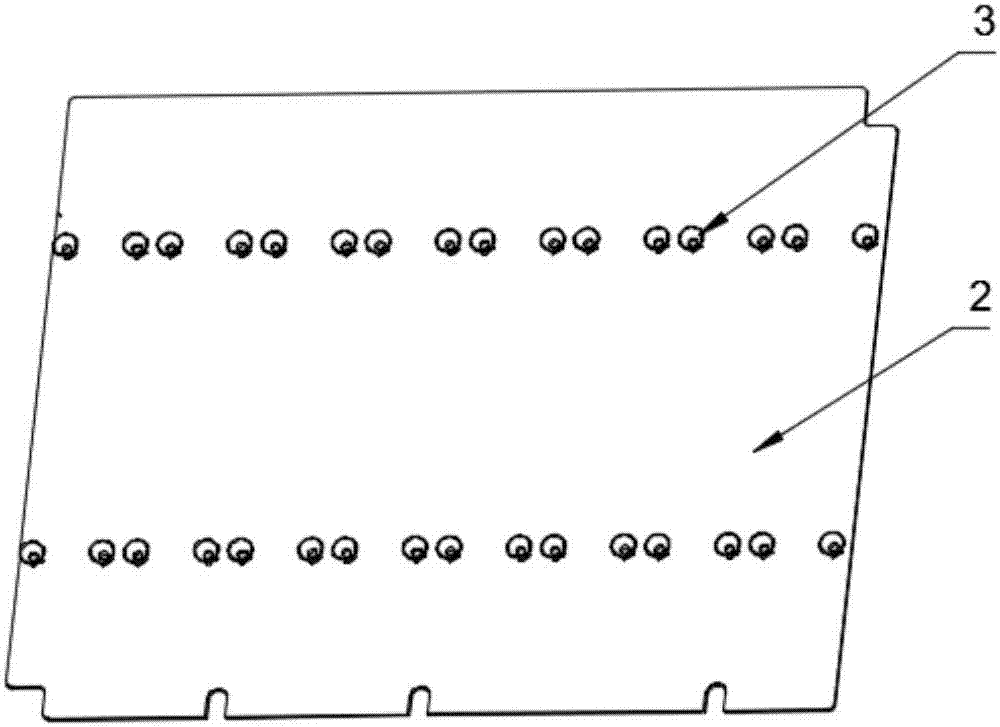

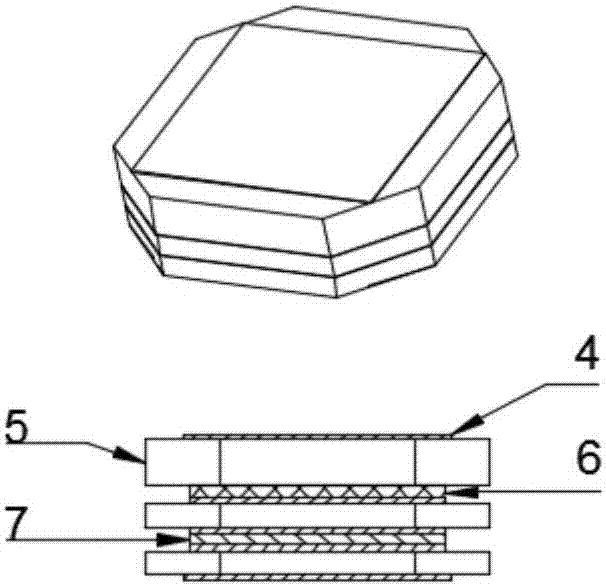

[0028] like Figure 1 to Figure 6 As shown, a large-scale MIMO antenna structure includes a PCB substrate 2 and N×N antenna units 1; the PCB substrate 2 includes two layers of PCB substrate dielectric boards 12, and the interlayer formed by the two layers of PCB substrate dielectric boards is In the middle layer, the metal is laid on the upper surface 13 of the PCB substrate, the metal is laid on the lower surface 16 of the PCB substrate, and the transmission line structure is laid on the middle layer. The transmission line structure includes the middle layer metal signal line 14 and the middle layer metal ground 15, which penetrate the two layers of PCB substrate media A plurality of metallized via holes 11 of the board 12 communicate with the metal laid on the upper surface 13 of the PCB su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com