Heat radiation fan and method of manufacture

A heat dissipation fan and manufacturing method technology, applied in the direction of electromechanical devices, electrical components, magnetic circuits, etc., can solve the problems of many assembly steps, lack of tight connection between bearing and center column, shaking or vibration, etc., and achieve simplified assembly steps , Improve structural reliability and reduce assembly cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be made below in conjunction with the embodiments with reference to the accompanying drawings.

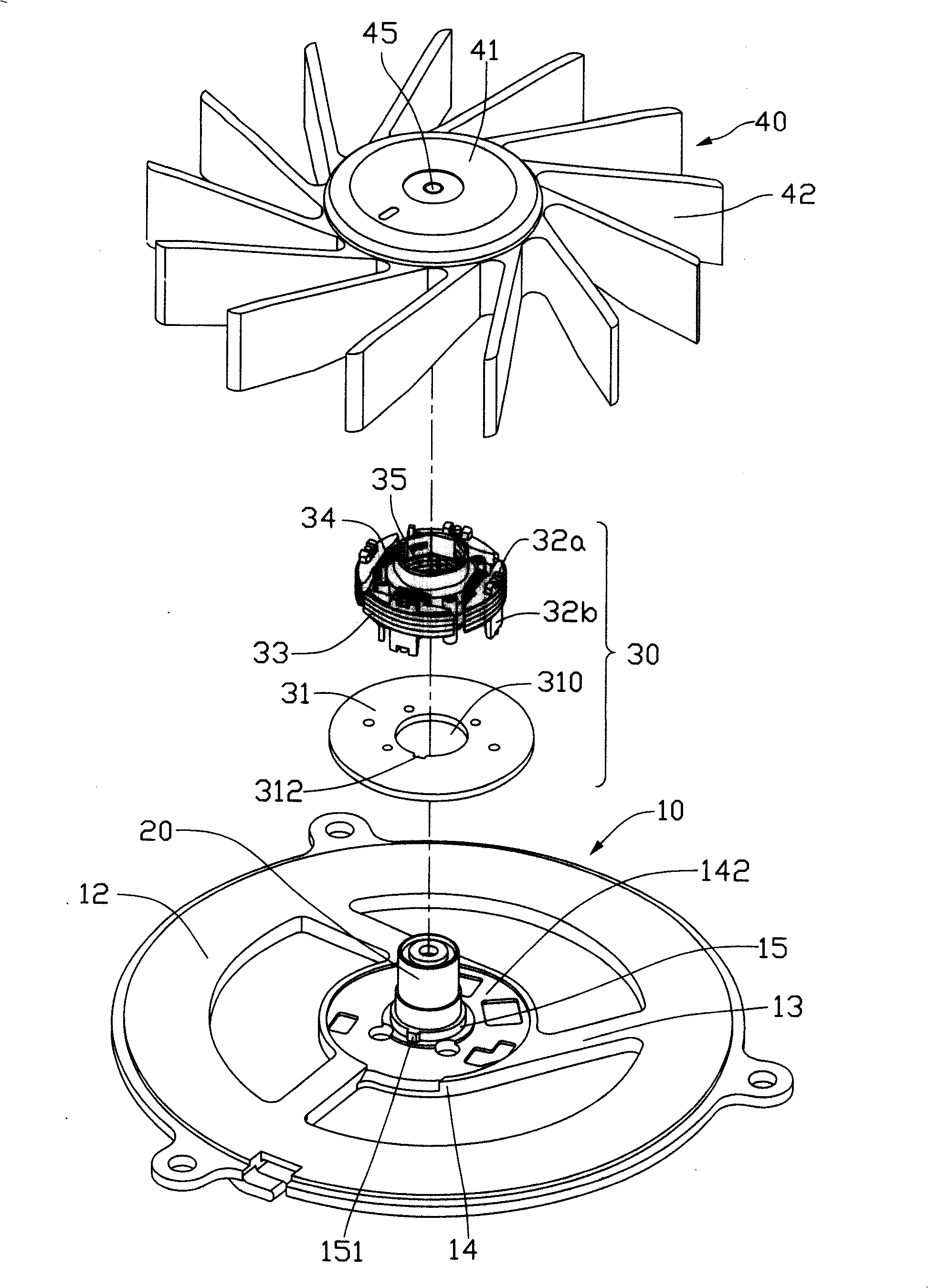

[0021] like figure 1 As shown, the cooling fan of this embodiment includes a fan frame 10 , a bearing system 20 disposed in the center of the fan frame 10 , a set of stator 30 disposed outside the bearing system 20 and a rotor 40 surrounding the periphery of the stator 30 .

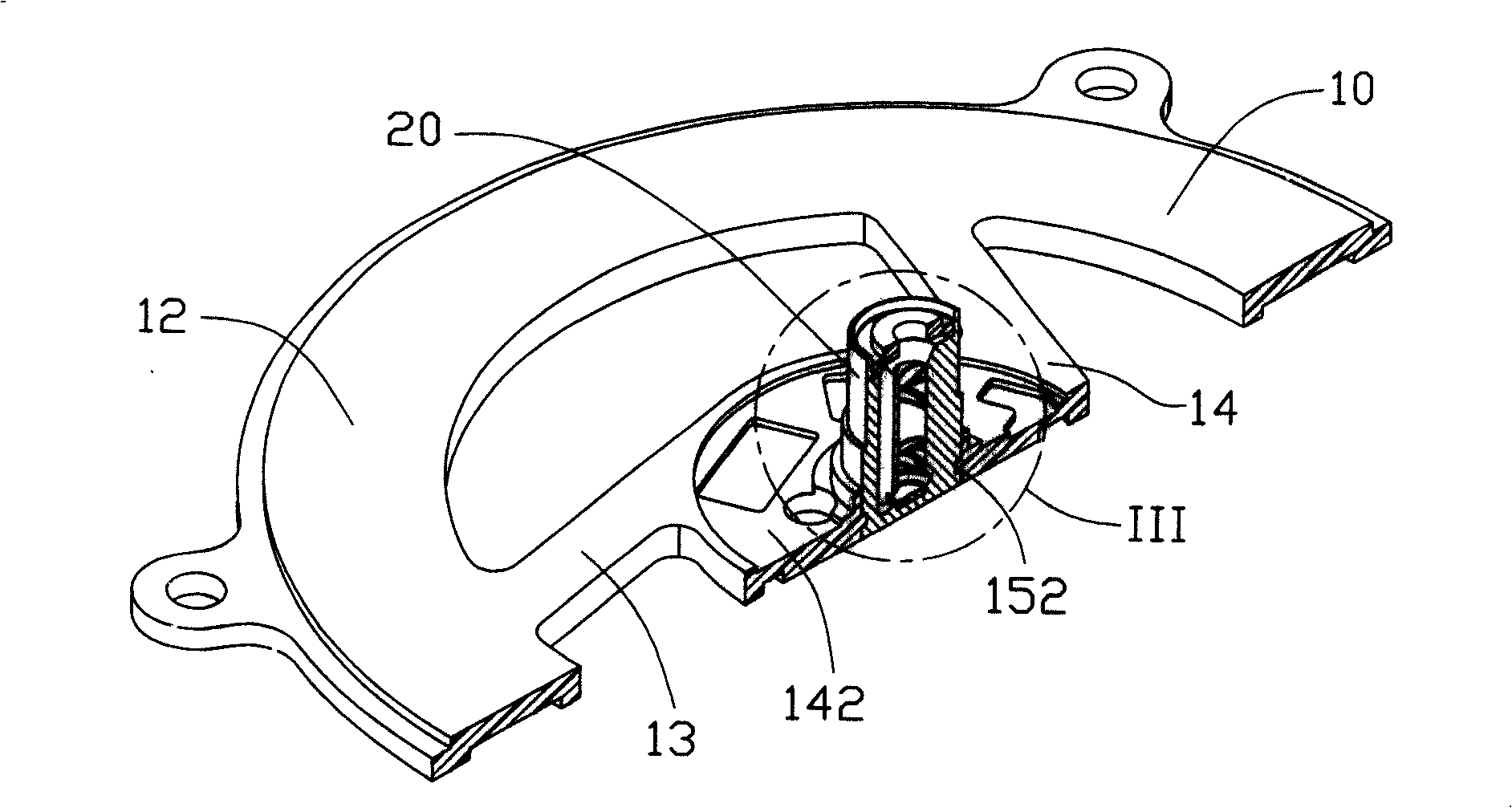

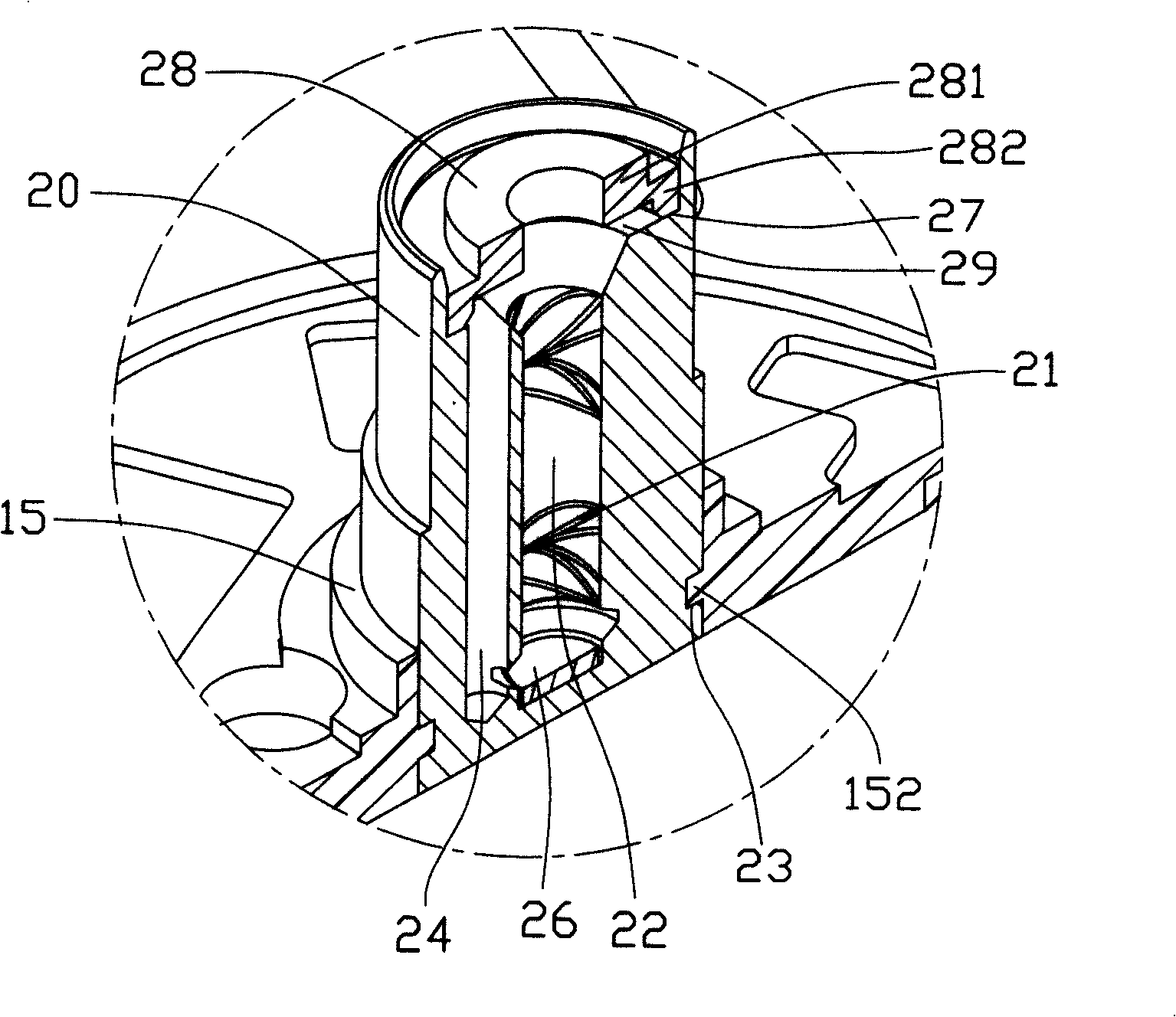

[0022] In this embodiment, the fan frame 10 includes a circular outer frame 12 , a support portion 14 located at the center of the outer frame 12 , and several ribs 13 connected between the outer frame 12 and the support portion 14 . The support portion 14 is disc-shaped, and a middle portion thereof is slightly recessed downward to form a disc-shaped receiving portion 142 . The center of the receiving portion 142 extends upwards to form a central column 15 , the central column 15 is cylindrical in shape, and the bottom end of the bearing system 20 is embedded and fixed in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com