Cooling fan and assembly method thereof

一种散热风扇、组装方法的技术,应用在泵装置、机电装置、电动组件等方向,能够解决组装不便、无法确保电路板绝缘效果、轴向高度无法缩减等问题,达到降低轴向高度、提升组装便利性、佳定位功效的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

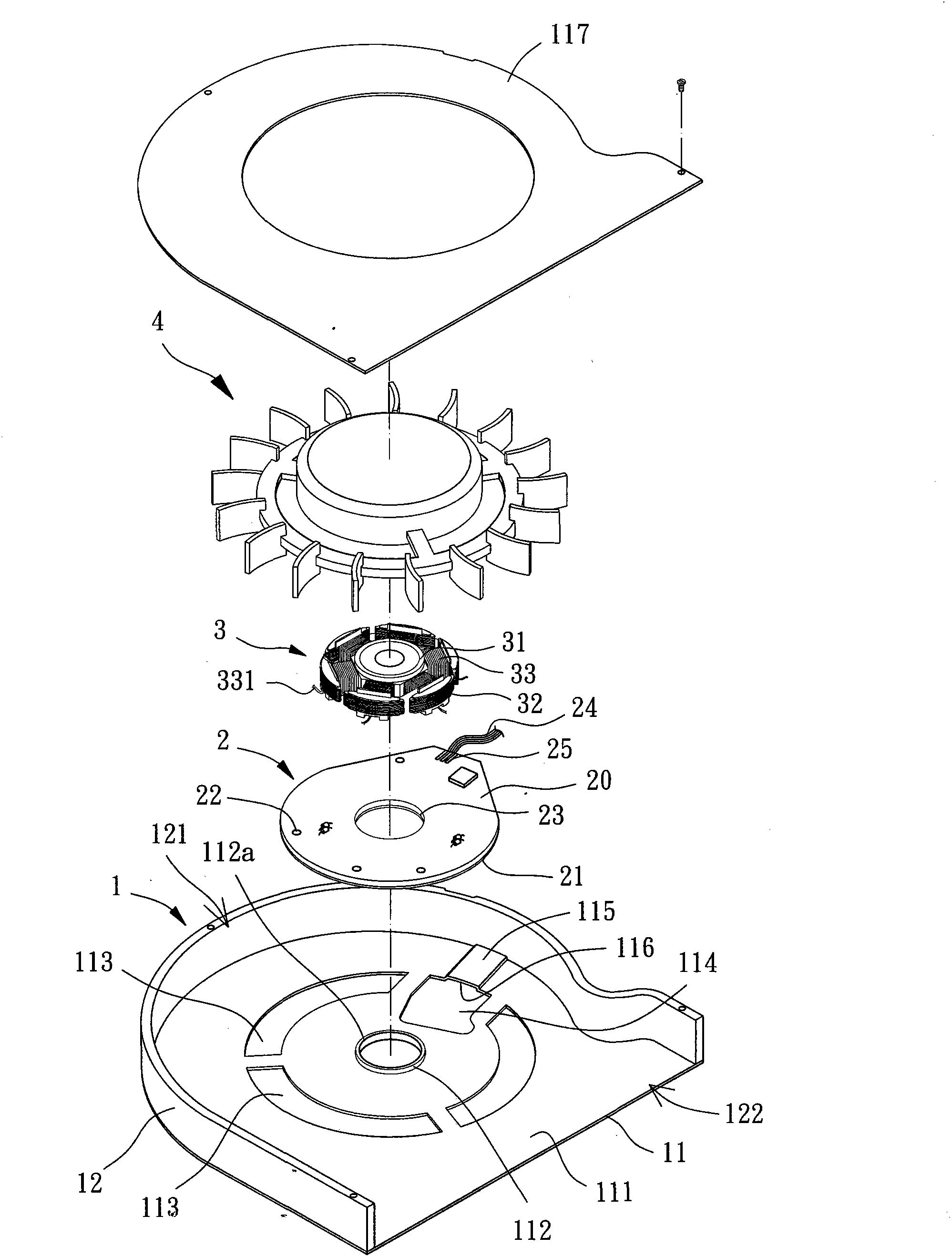

[0074] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

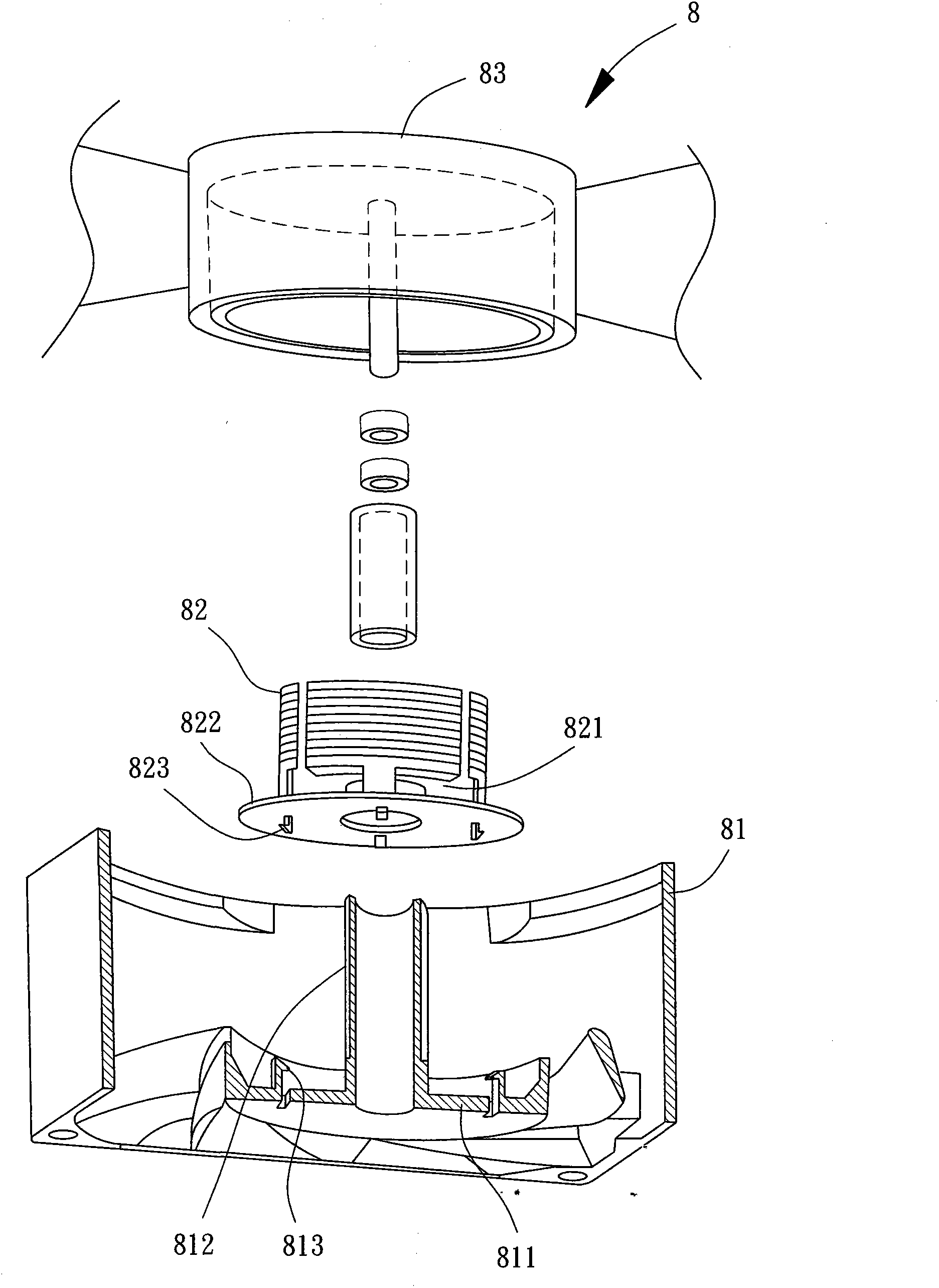

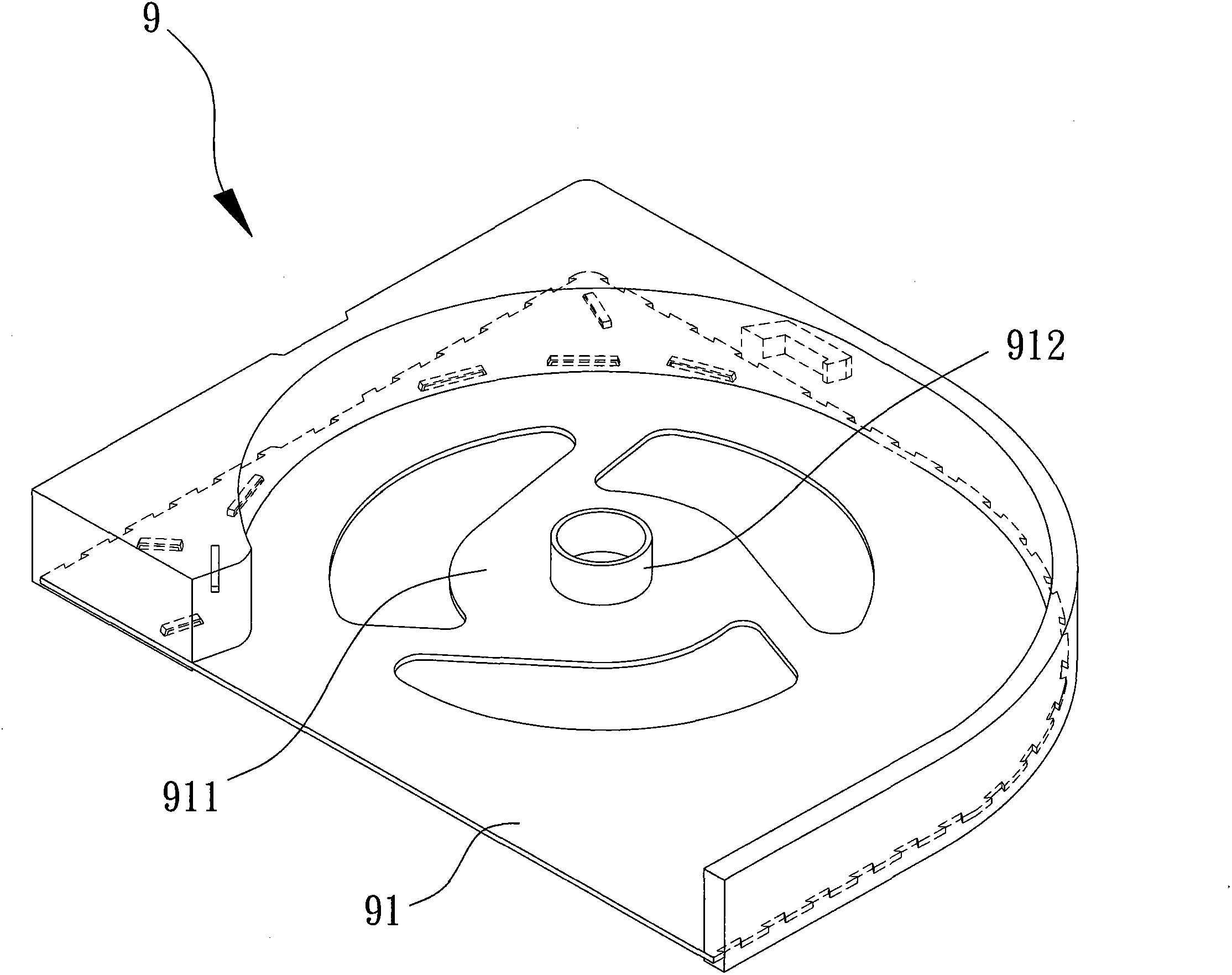

[0075] Please refer to image 3 As shown, the cooling fan of the present invention at least includes a fan frame 1 , a circuit board 2 , a stator coil assembly 3 and a fan wheel 4 . The fan frame 1 can be combined with the circuit board 2, the circuit board 2 is used for external power supply or drive circuit, the stator coil group 3 is combined inside the fan frame 1 and used to electrically connect the circuit board 2, the fan wheel 4 The stator coil set 3 can be rotatably combined to drive the fan wheel 4 to rotate by using the stator coil set 3 .

[0076] The fan frame 1 includes a metal base 11 and a side wall 12 . The metal base 11 has a joint surface 111 and a joint portion 112, the joint portion 112 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com