Machining method for bulged cavity part

A processing method and cavity technology, which are applied in metal processing equipment, manufacturing tools, turning equipment, etc., can solve the problems of no tooling, turning, and the difficulty of bulging inner cavity parts with large steps, and achieve the effect of convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

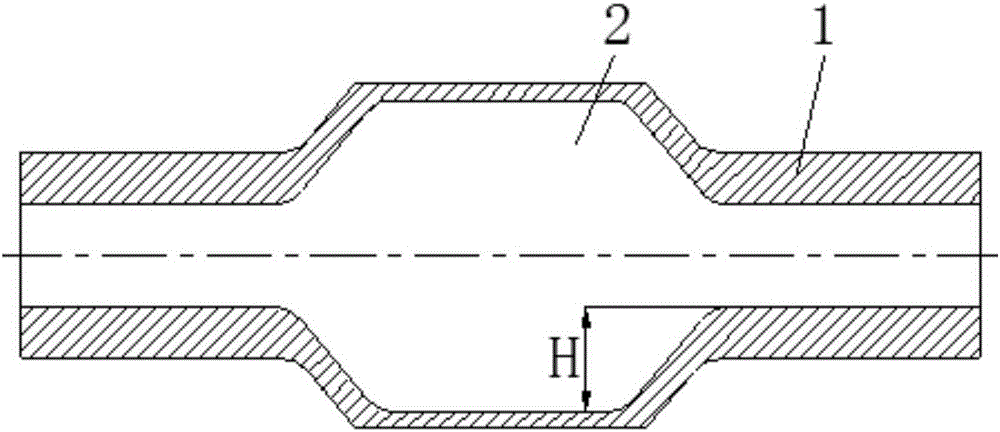

[0025] refer to figure 1 , is the cross-sectional structure of the large step bulging inner cavity part 1 of the processing object of the present invention. On the large step bulging inner cavity part 1, the bulging inner hole 2 needs to be processed, and the step size H of the bulging inner hole 2 is greater than 100mm. In the process of processing, the rigidity and convenience of access of the tooling into the large-step bulging inner cavity part 1 should be ensured, and the turning of the bulging inner hole 2 should be completed.

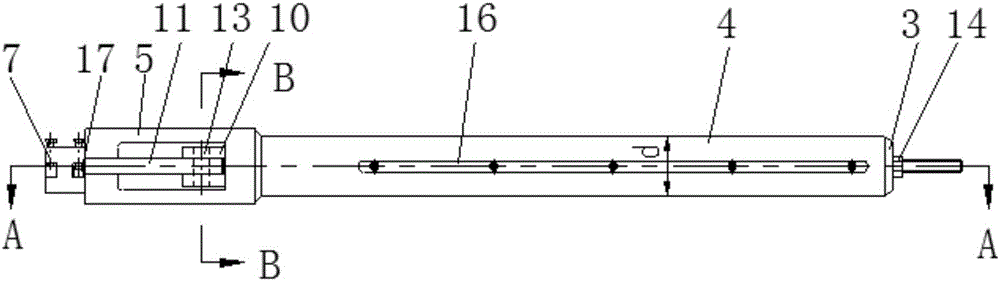

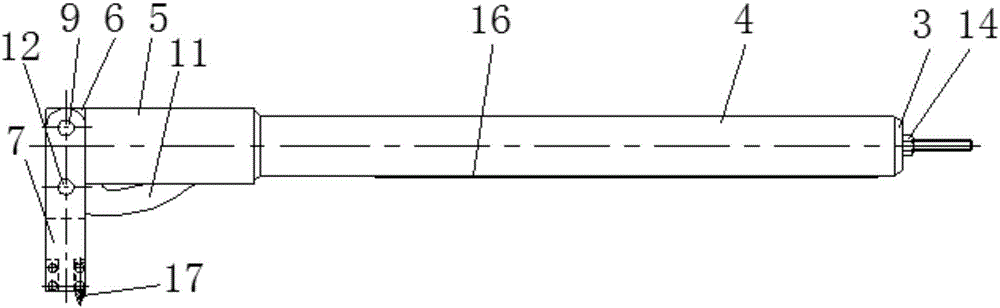

[0026] The tooling structure adopted by the method of the present invention is to include a bent type inner hole turning tool holder and a clip, and the two are matched together to complete the turning of the processing object.

[0027] refer to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com