Permanent magnet motor driven vertical lathe

A permanent magnet motor and vertical lathe technology, applied in the field of CNC machine tools, can solve problems such as low machining accuracy, high energy consumption, and complicated operation, and achieve the effects of improving stability, convenient maintenance, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

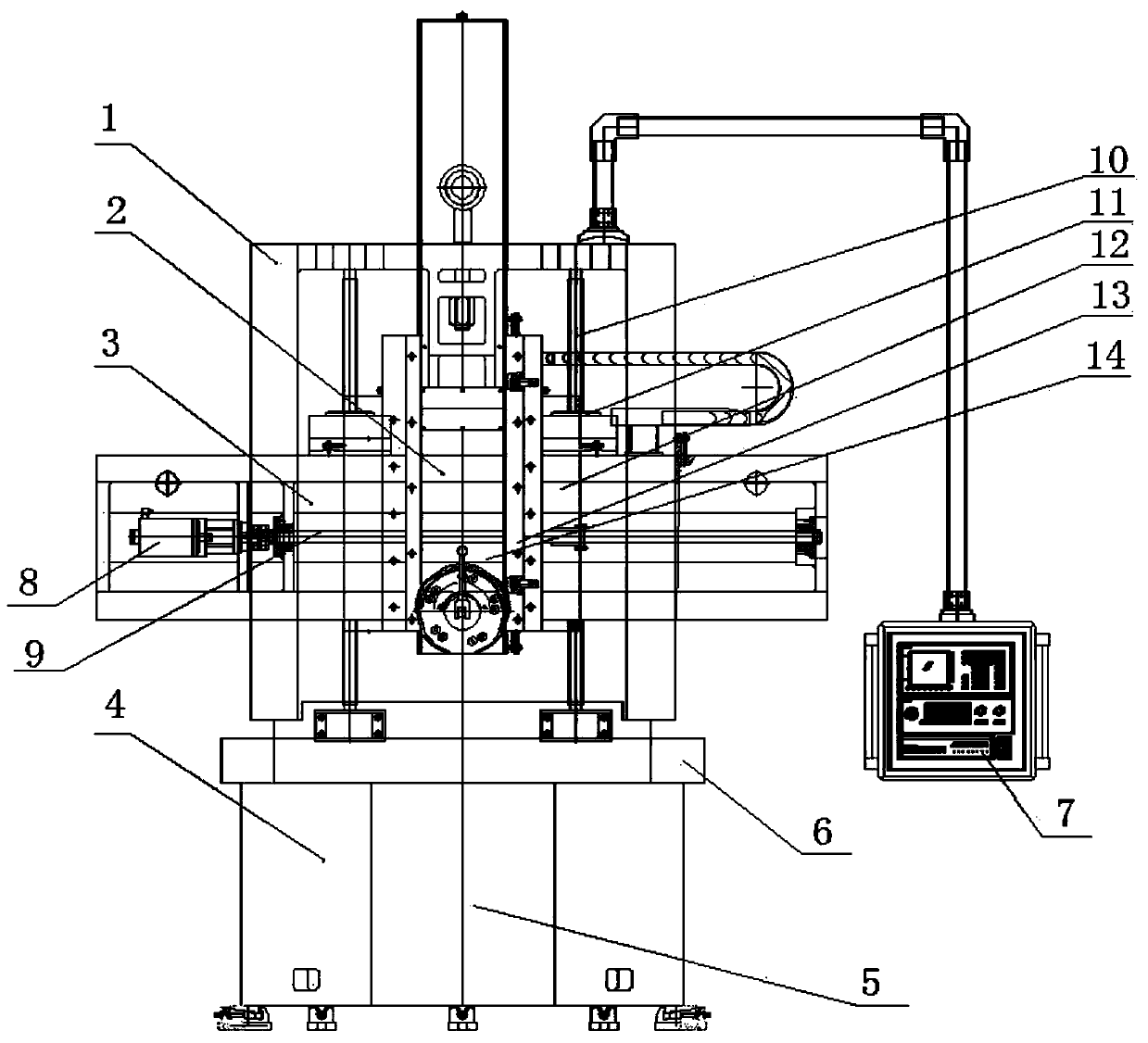

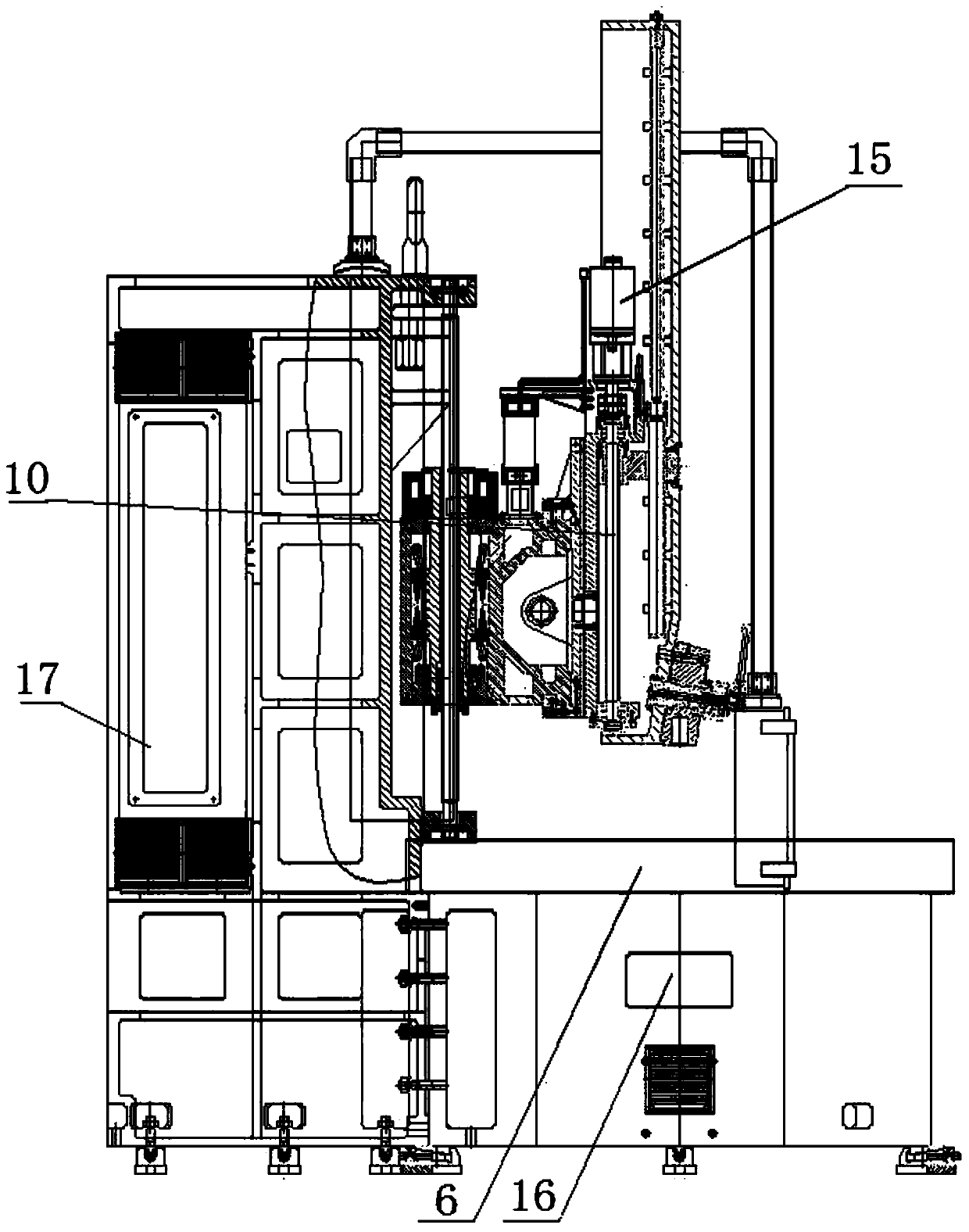

[0013] The structure of a permanent magnet motor driven vertical lathe of the present invention is as follows: figure 1 and figure 2 As shown, the bed 1 is installed on the upper part of the base 4, and the workbench 6 is installed on the upper part of the base 4 at the front of the bed 1. The workbench 6 is connected to the permanent magnet motor 8 located in the base 4. Installed coaxially with the workbench 6, the encoder 16 is directly connected coaxially with the workbench 6 at 1:1; the front side of the bed 1 is provided with a guide rail, and the front side of the bed 1 slides to install the beam 3 through the guide rail, and the rear side of the beam 3 is connected to lift Lead screw 10, lifting screw 10 is connected with vertical servo motor 15; beam slide seat 12 is installed on the front side of cross beam 3, and cross beam slide seat 12 is connected with horizontal servo motor 8 through horizontal lead screw 9, and vertical tool holder is installed at the front of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com