Patents

Literature

30results about How to "Reduce susceptibility to interference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acceleration sensor having a damping device

ActiveUS20120031185A1Increased susceptibilityReduce susceptibility to interferenceAcceleration measurement using interia forcesSeismic massClassical mechanics

A micromechanical acceleration sensor is described which includes a substrate and a seismic mass which is movably situated with respect to the substrate in a detection direction. The micromechanical sensor includes at least one damping device for damping motions of the seismic mass perpendicular to the detection direction.

Owner:ROBERT BOSCH GMBH

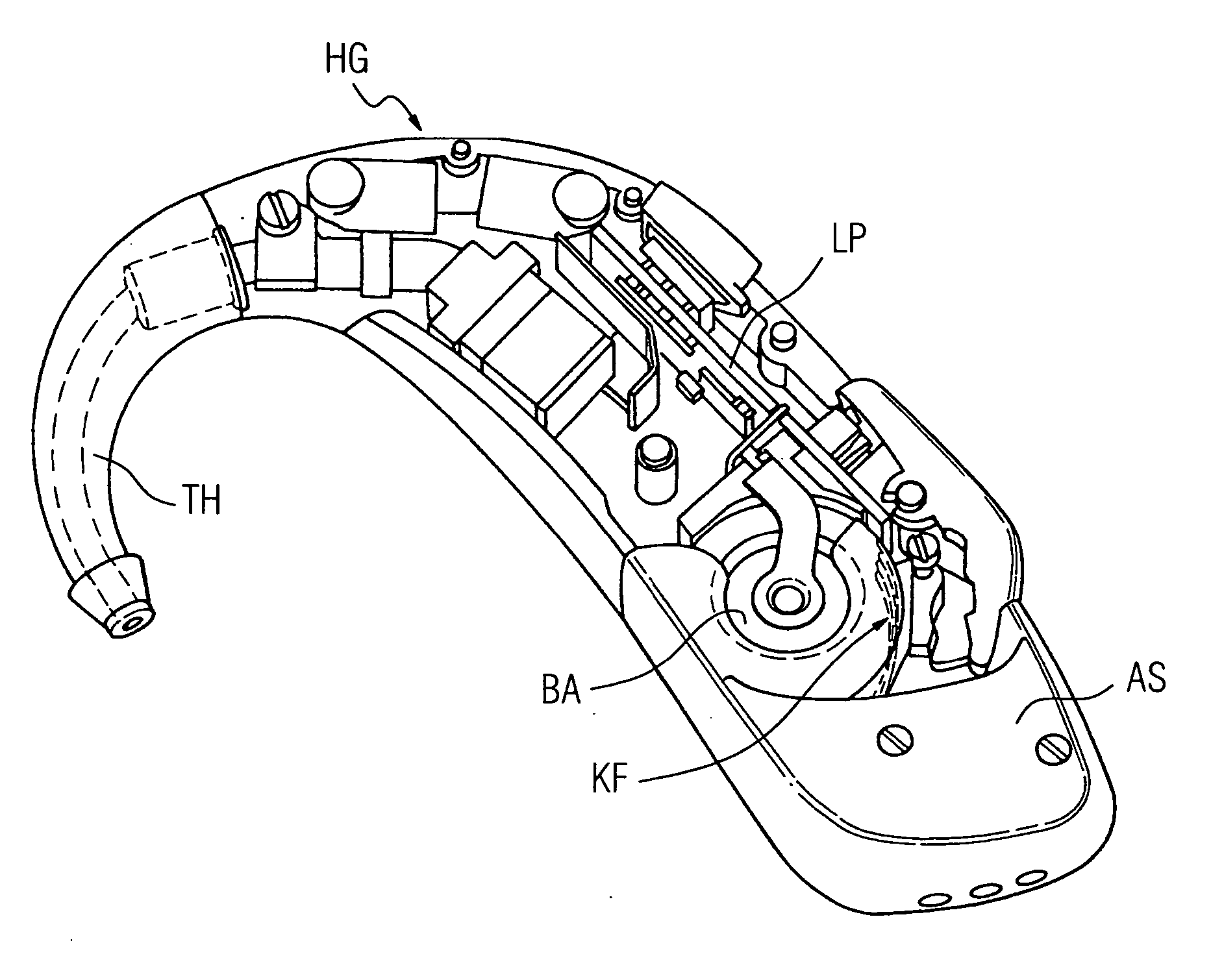

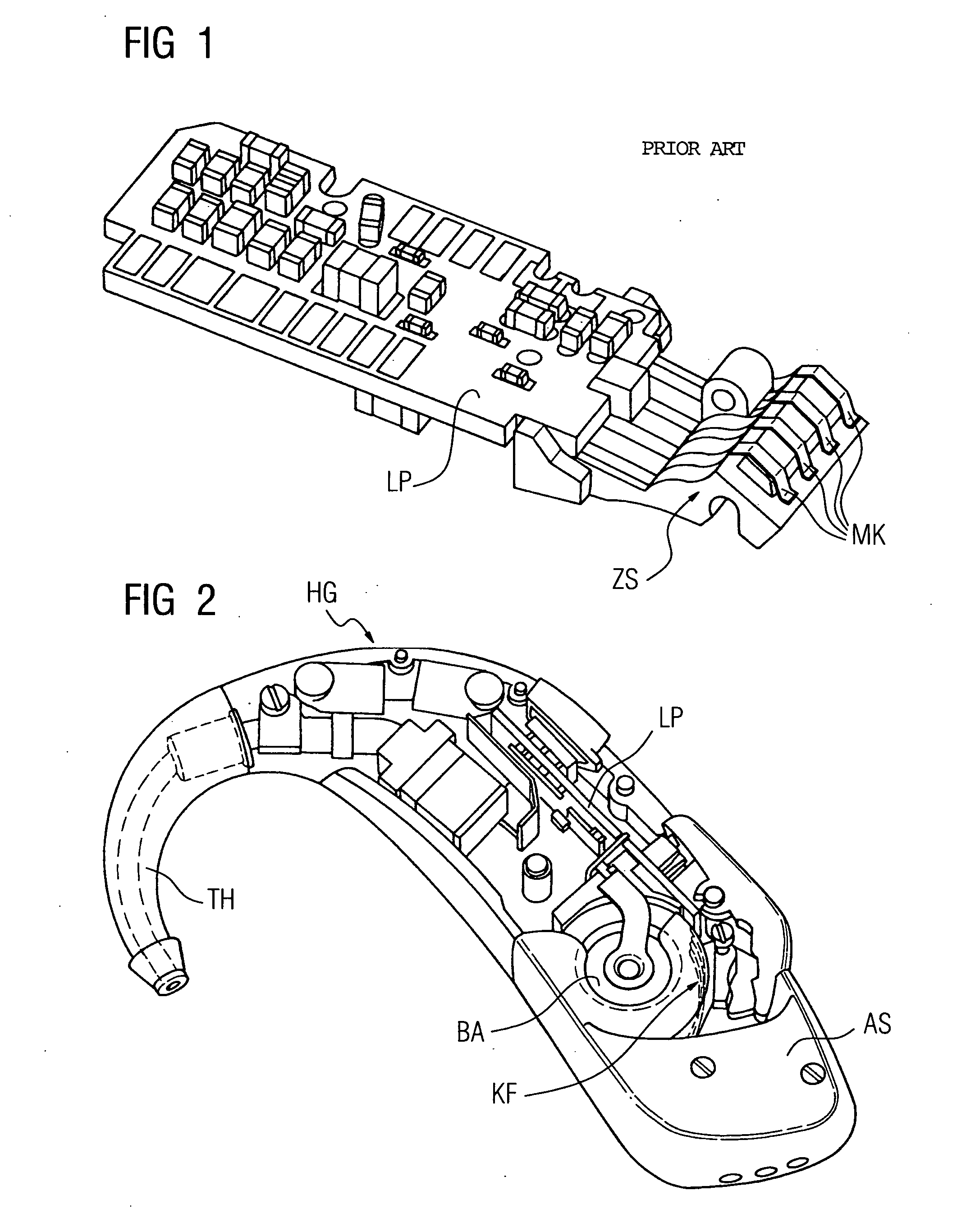

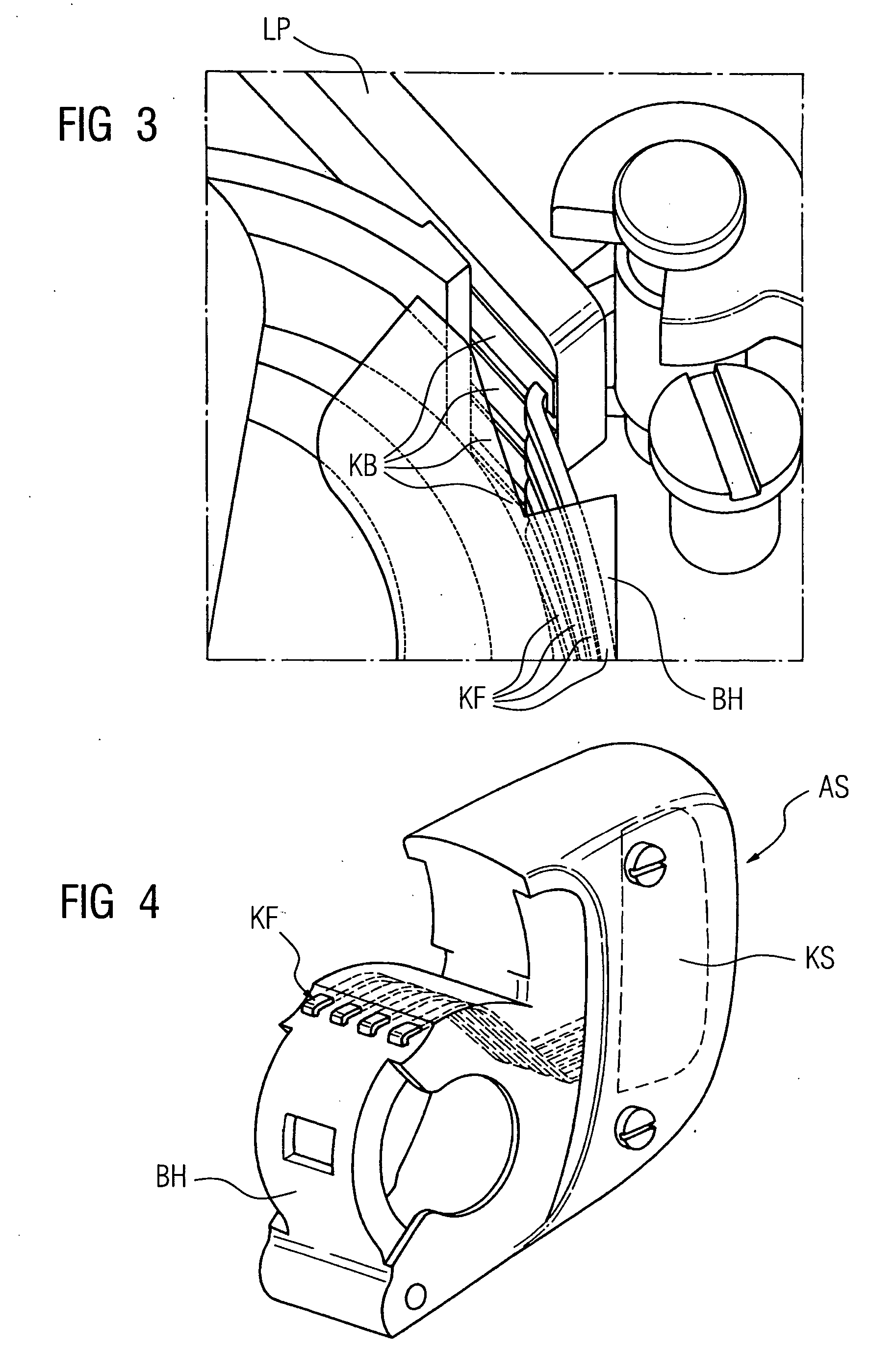

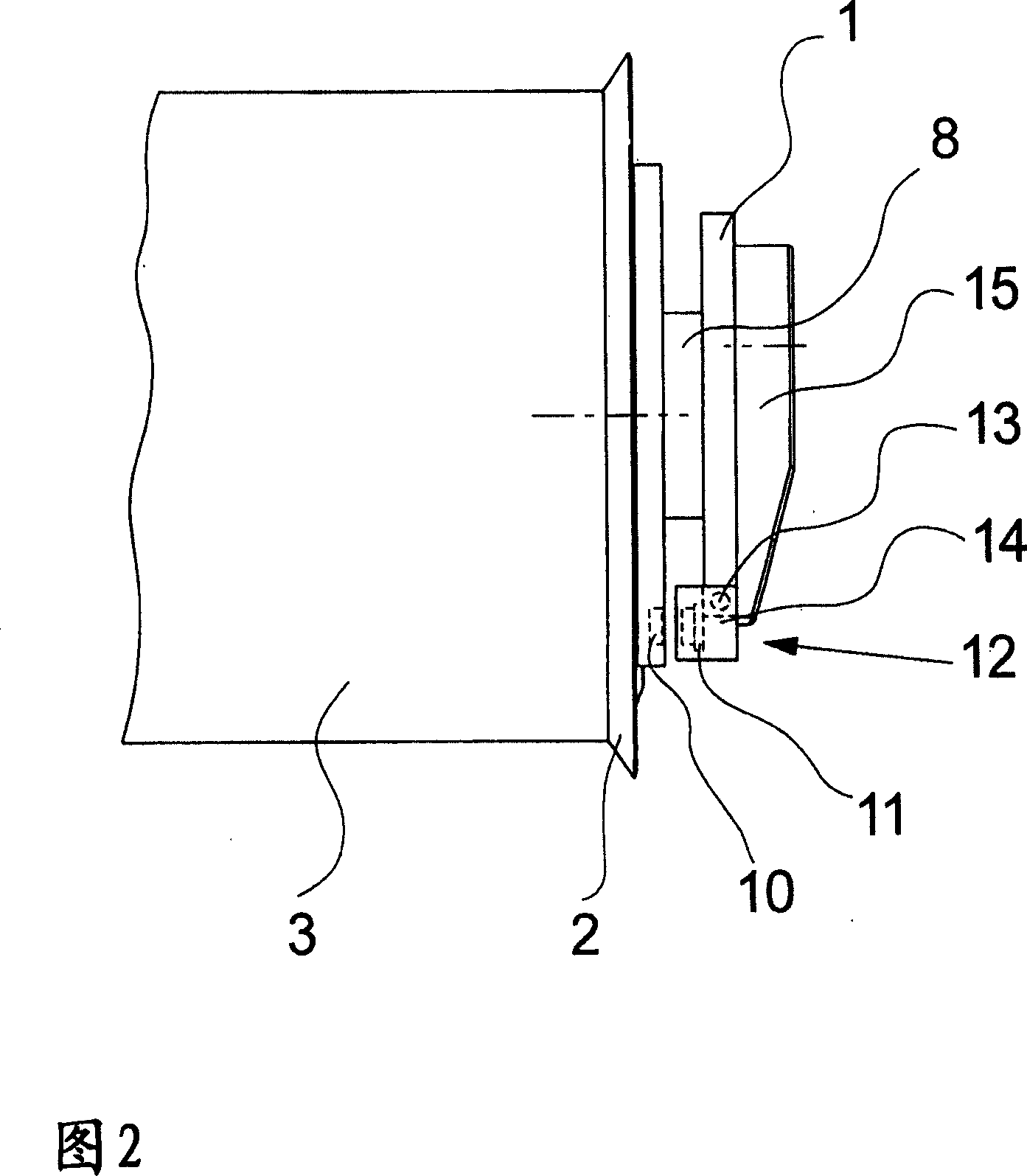

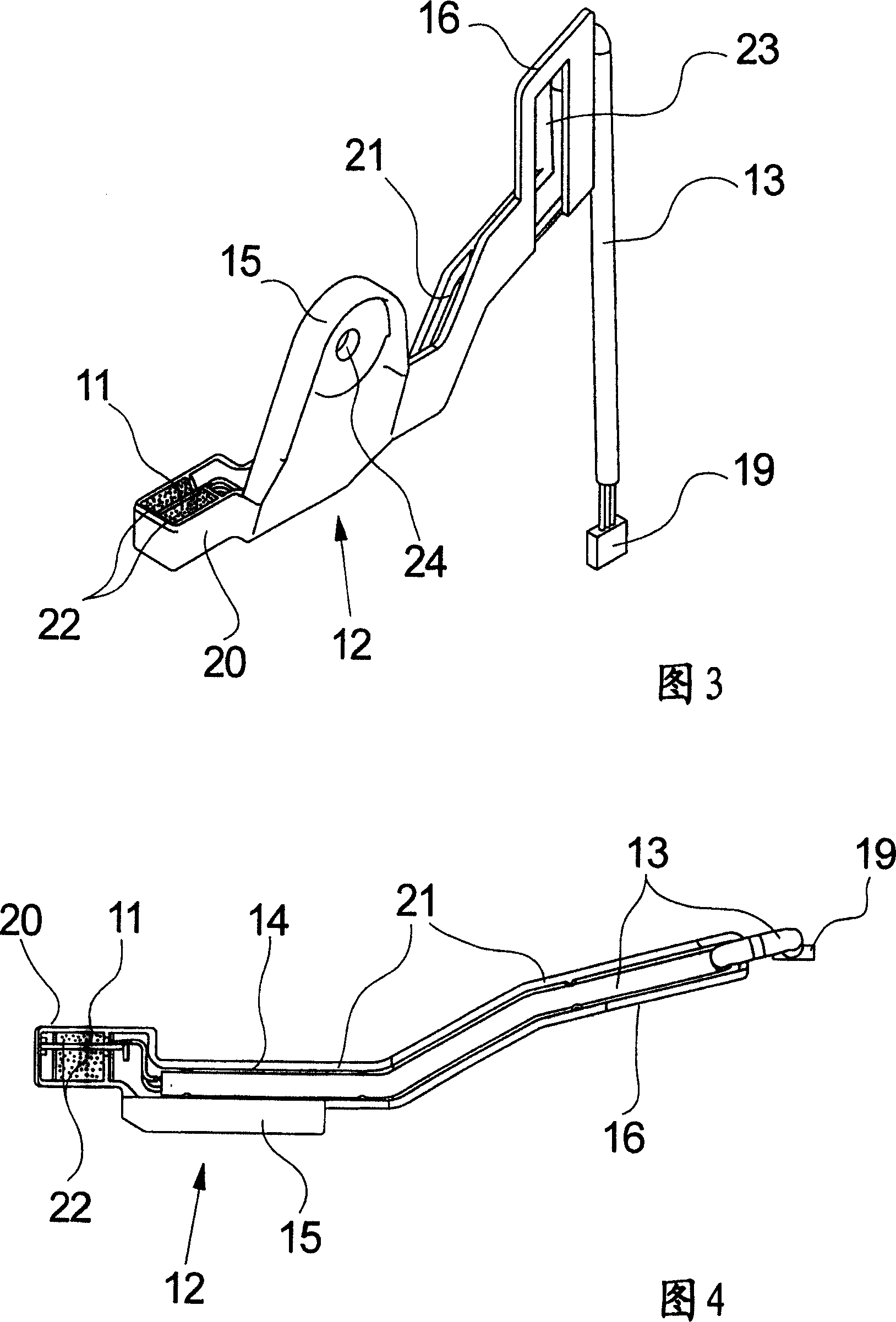

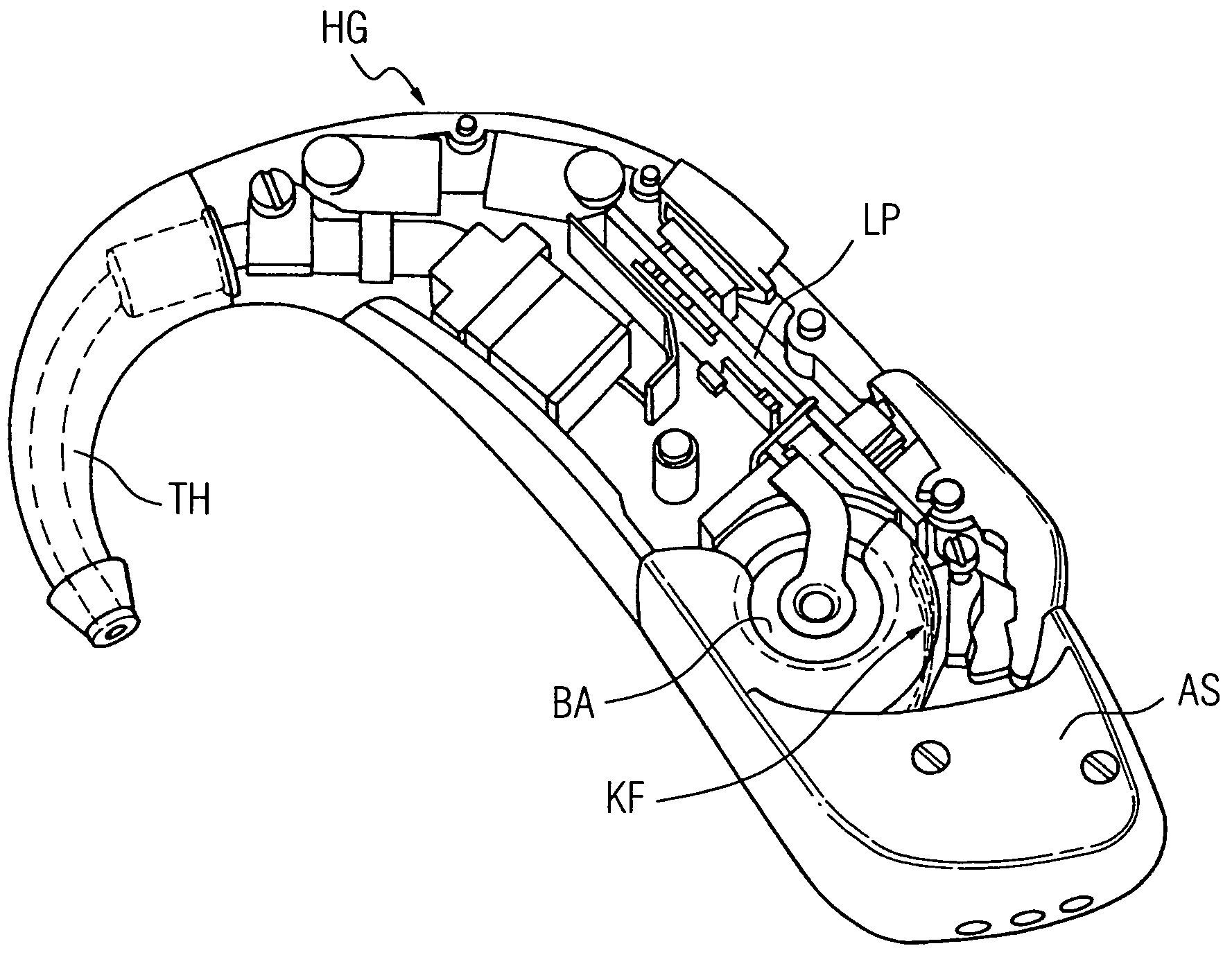

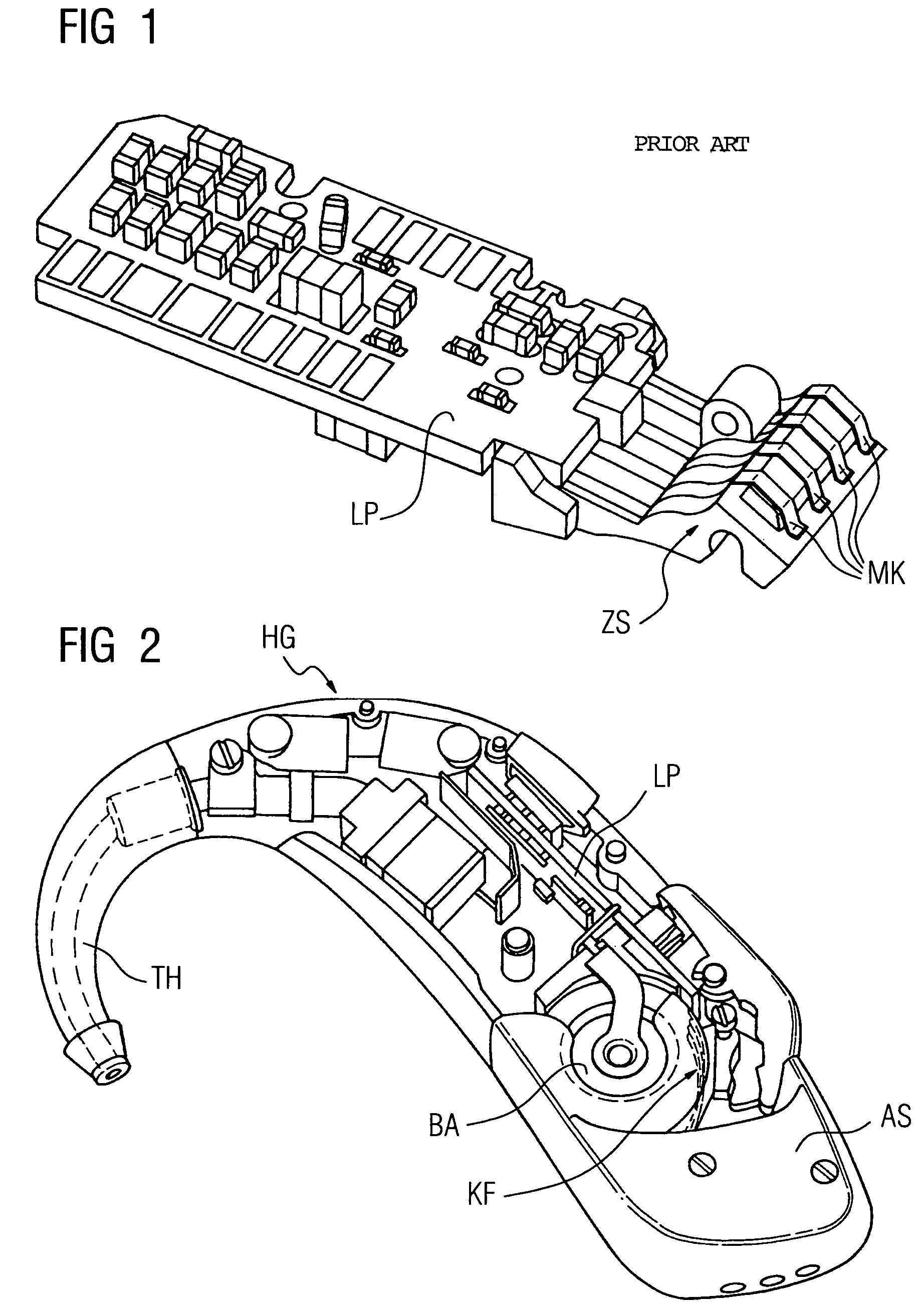

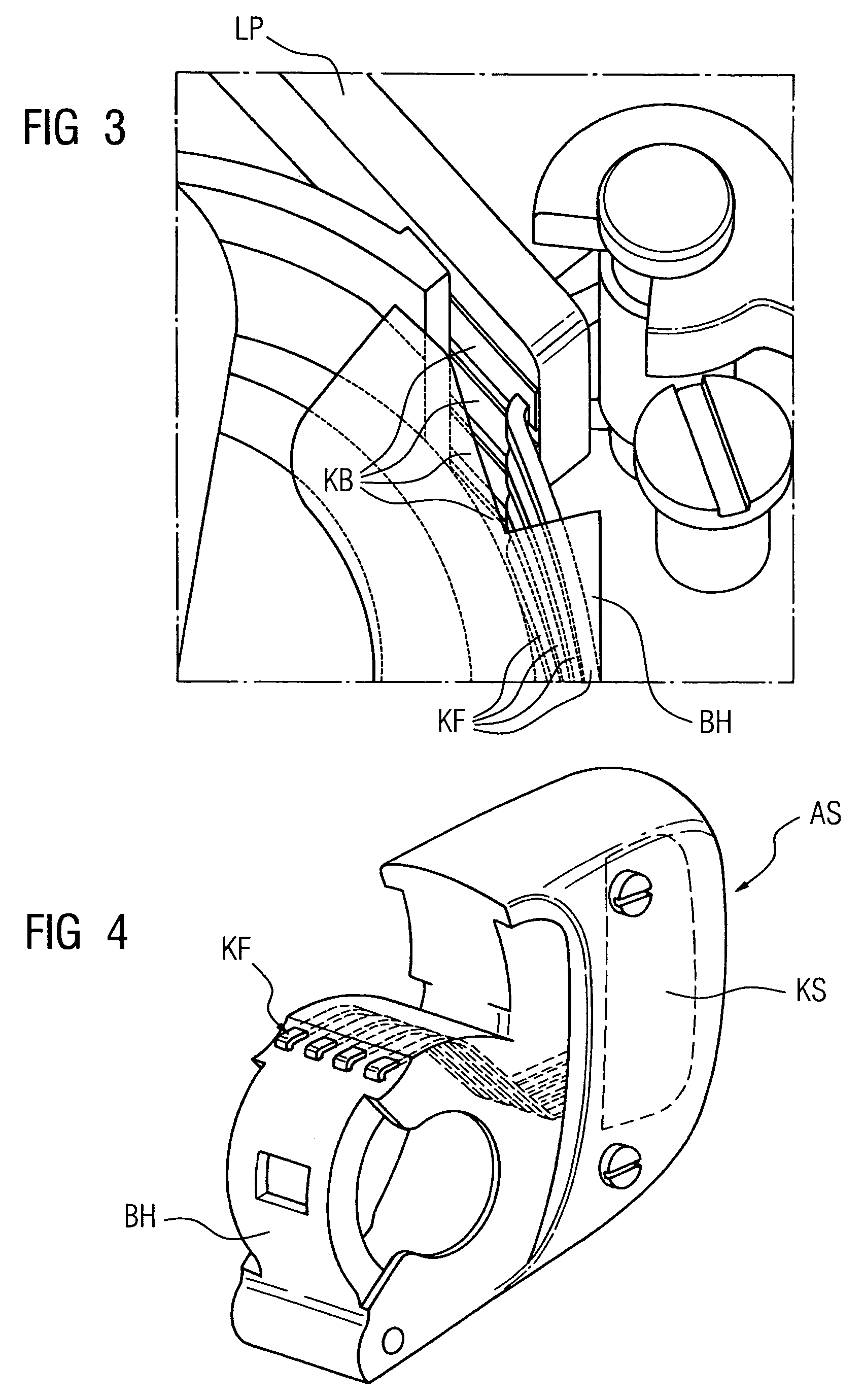

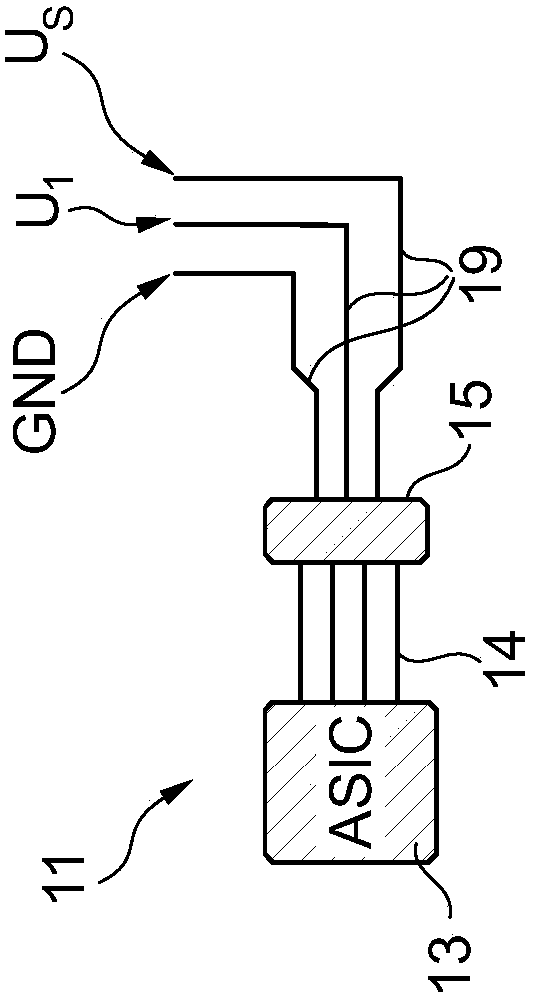

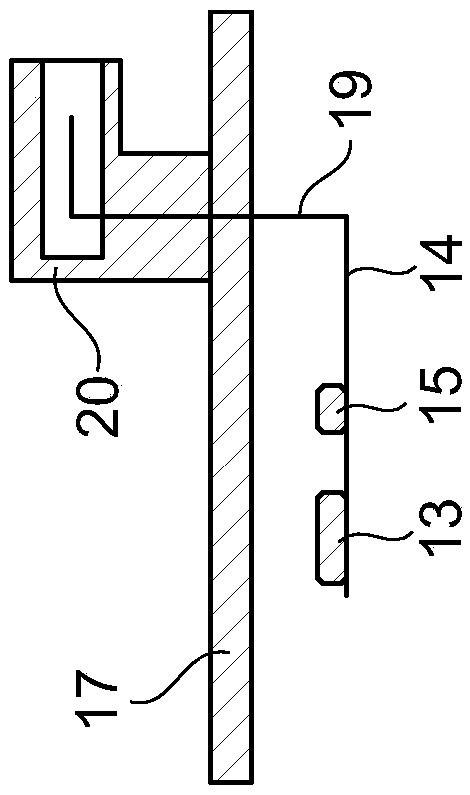

Audio shoe contact for a hearing device

ActiveUS20070047751A1Easy to assembleReduce susceptibility to interferenceHearing aids housingEngineeringHearing apparatus

A hearing device with an audio shoe is to be designed in a simpler and less interference-susceptible manner. To this end, provision is made for an audio shoe to comprise contact springs of such type that directly contact the circuit boards of a hearing device. A contact intermediate piece between the audio shoe and the circuit board of the hearing device can thus be dispensed with. Furthermore, contact problems caused by the intermediate piece can hereby be avoided and the assembly cost for the hearing device reduced.

Owner:SIVANTOS PTE LTD

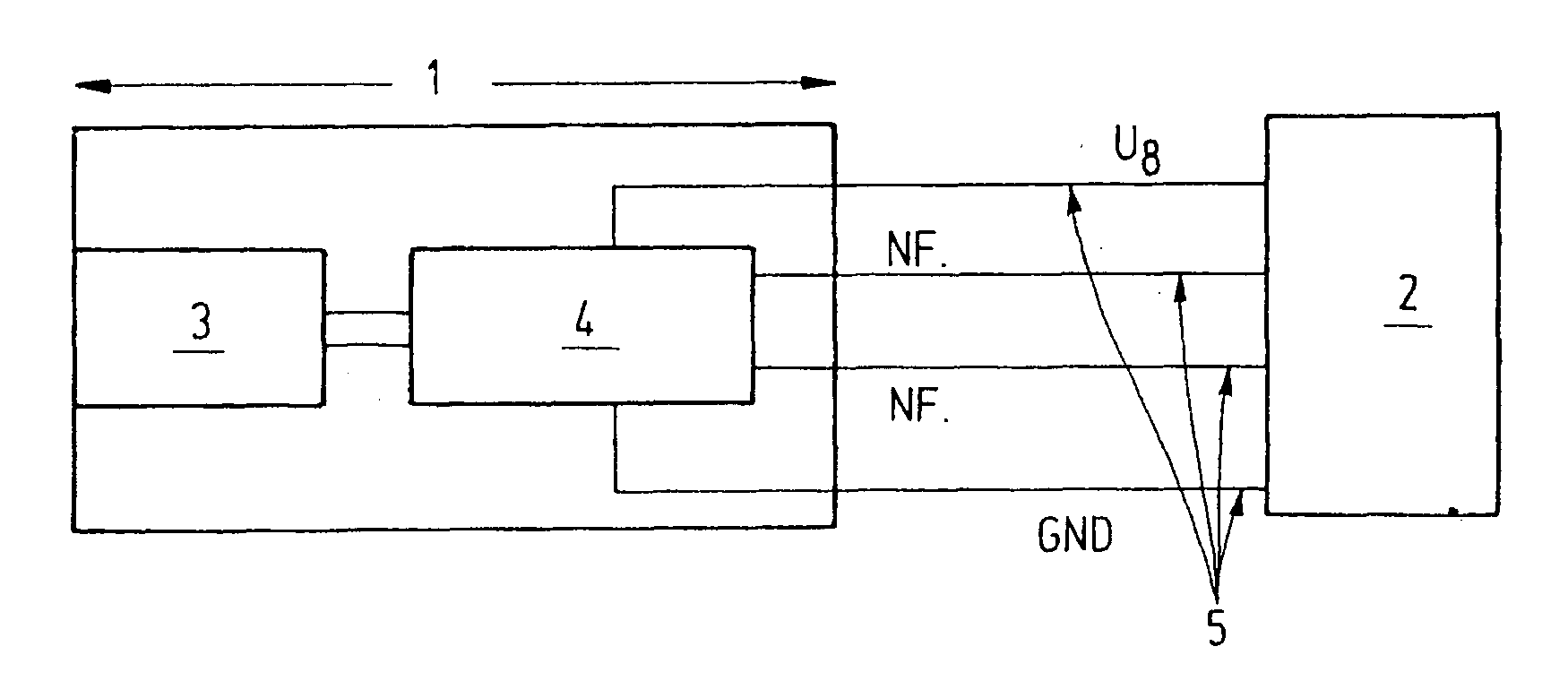

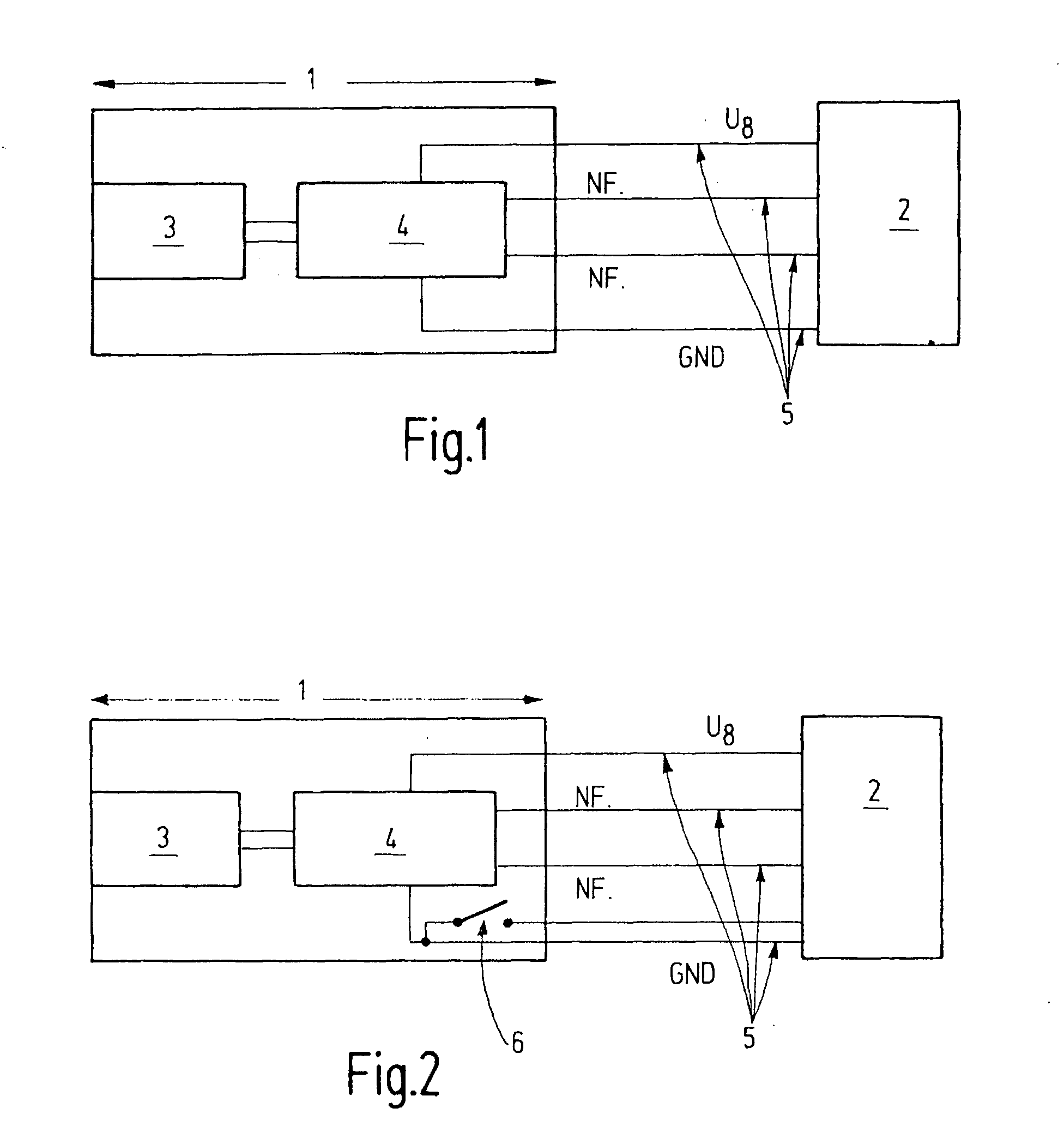

Microphone Having an Output Signal Amplifier

InactiveUS20080317262A1Less susceptible to interferenceReduce sensitivityMicrophonesFrequency response correctionElectrical conductorSignal-to-noise ratio (imaging)

A microphone is described including a microphone housing having a microphone capsule disposed therein. The microphone is connected via a microphone cable to an audio system, and has an integrated amplifier that raises the signal output level. The integration of a preamplifier into the microphone advantageously reduces the microphone's susceptibility to interference. In contrast to conventional preamplifiers, the preamplifier does not, or not exclusively, operate as an impedance converter, but instead amplifies the output voltage. As a consequence, the signal-to-noise ratio is advantageously increased even in the presence of interference. The preamplifier can be provided with energy via a battery or accumulator mounted in the microphone, or advantageously from the audio system via additional conductors in the microphone cable.

Owner:ROBERT BOSCH GMBH

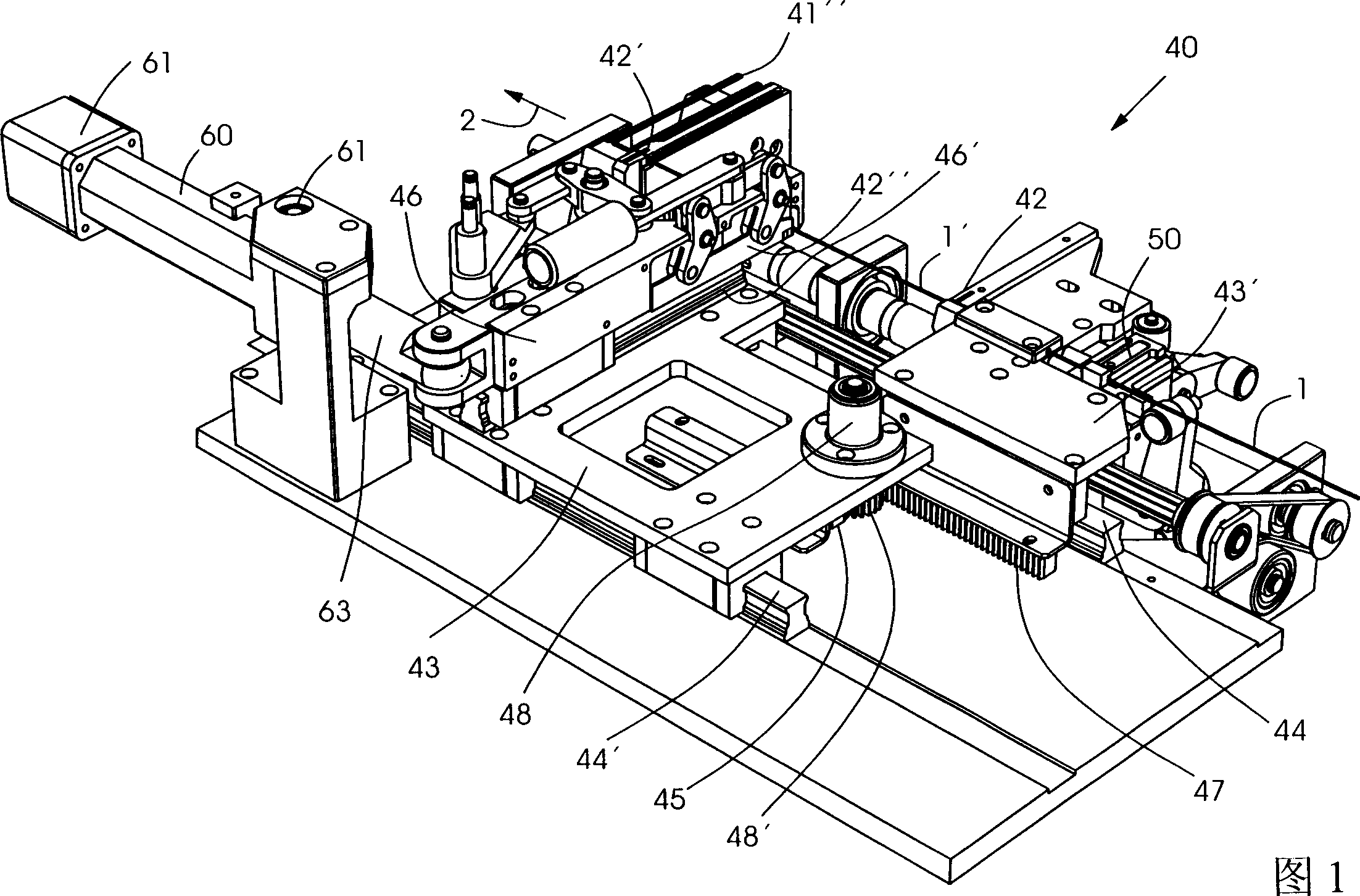

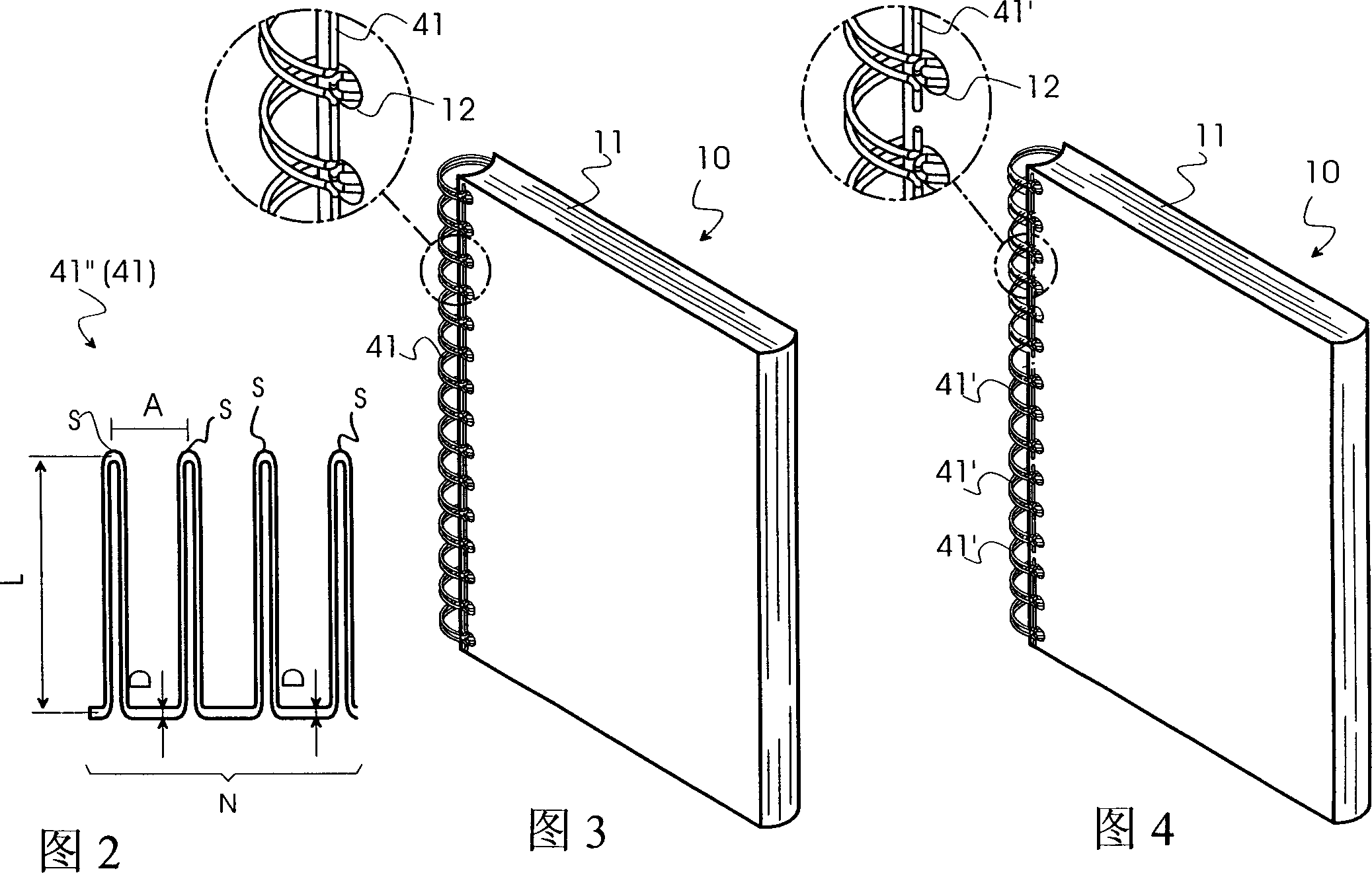

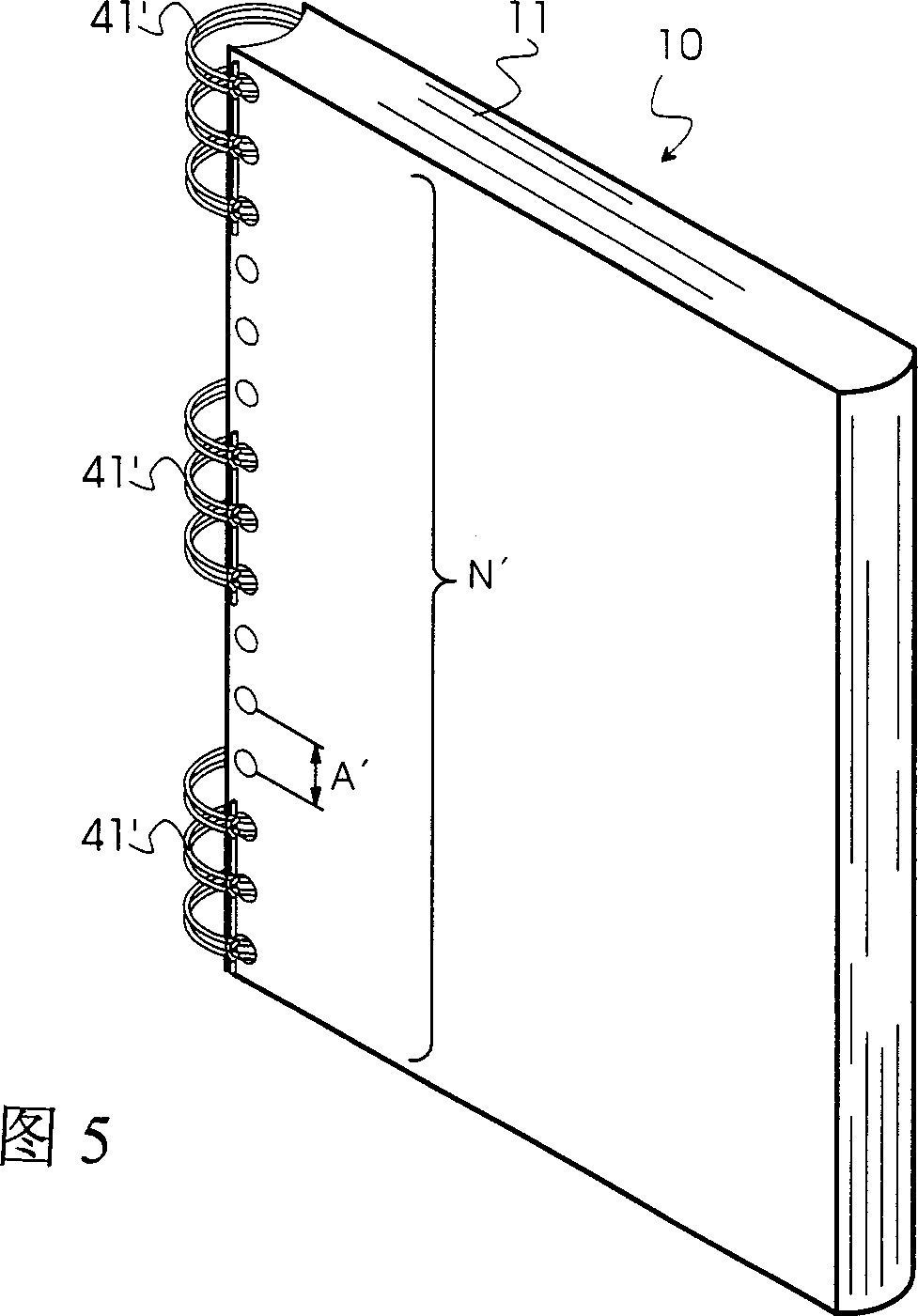

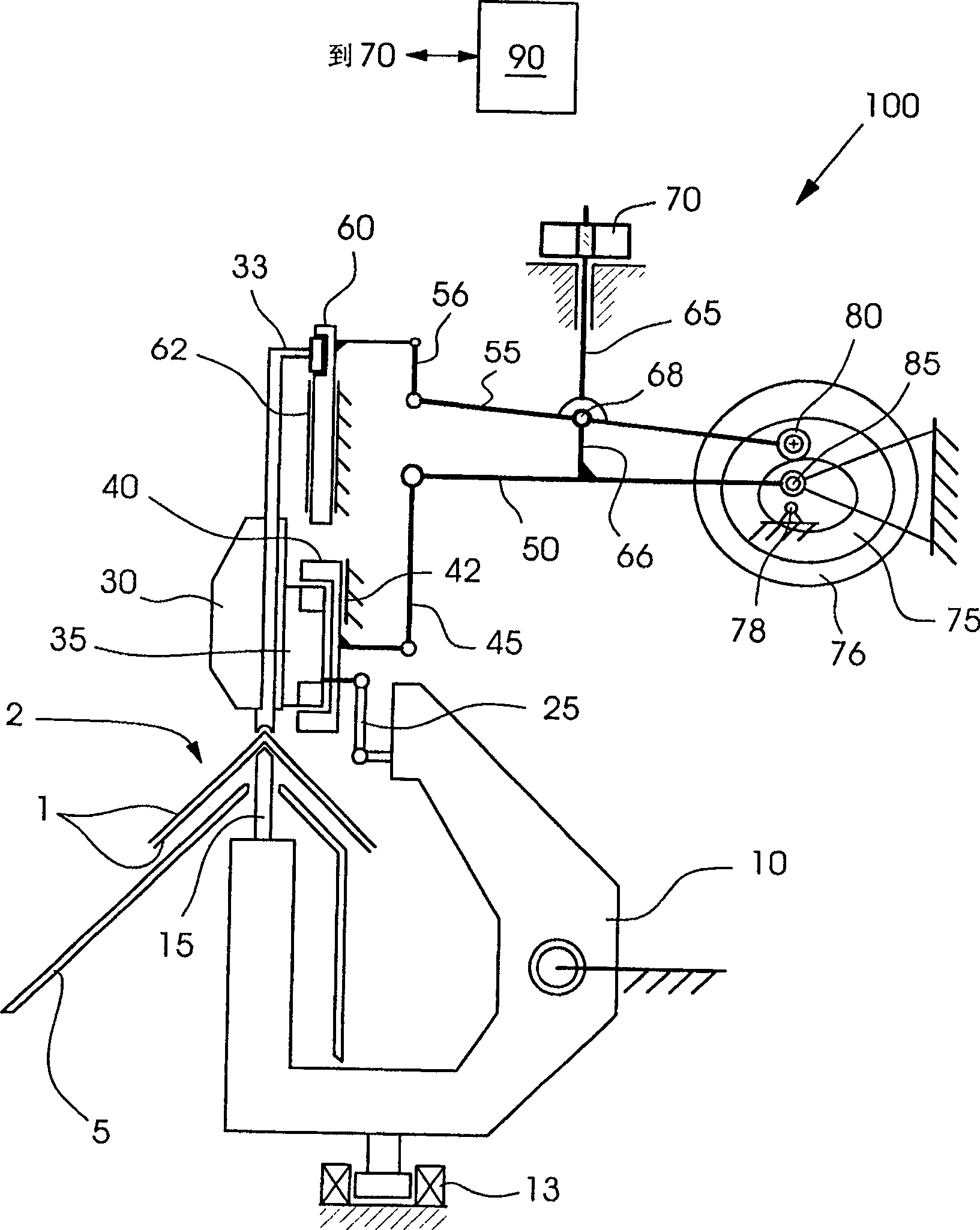

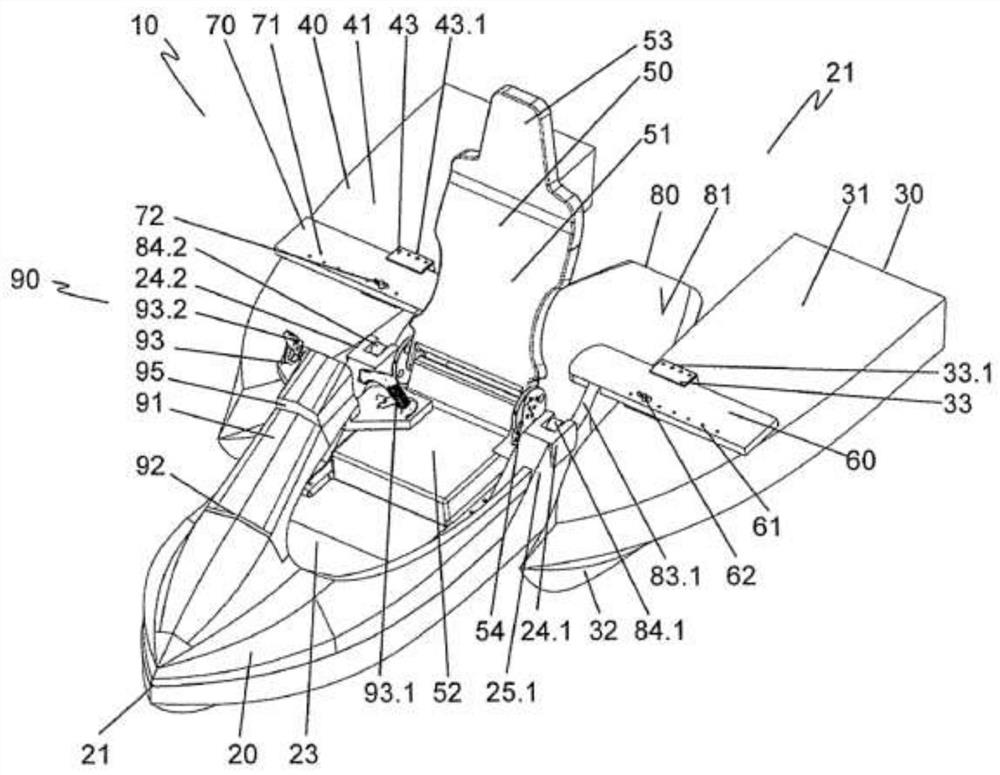

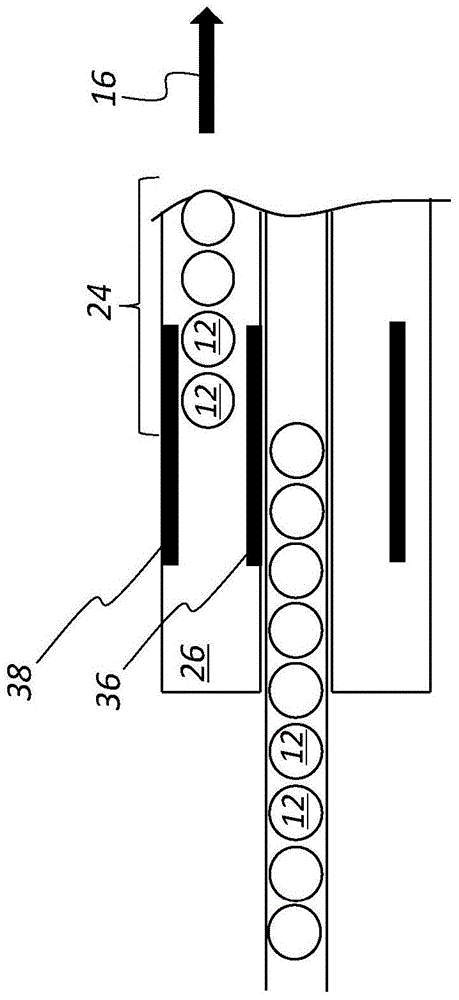

Apparatus for making metallic wire binding parts

InactiveCN1365897ASave materialFast bindingWire ringsFiling appliancesLoop lengthMechanical engineering

The flat loop-shaped wire binding element is bent into a C-shape in a segment fashion. Bending is carried out using a device (90) with two bending units (95, 95), each with at least one retaining part (91, 91), at least one support (92, 92) and at least one bending beam (93, 93), the two bending units being individually movable along the wire loops in a controlled manner. Two O-shaped dies (94, 94) are used to bend the C-shapes into O-shapes, which are used to hold brochure sheets together.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

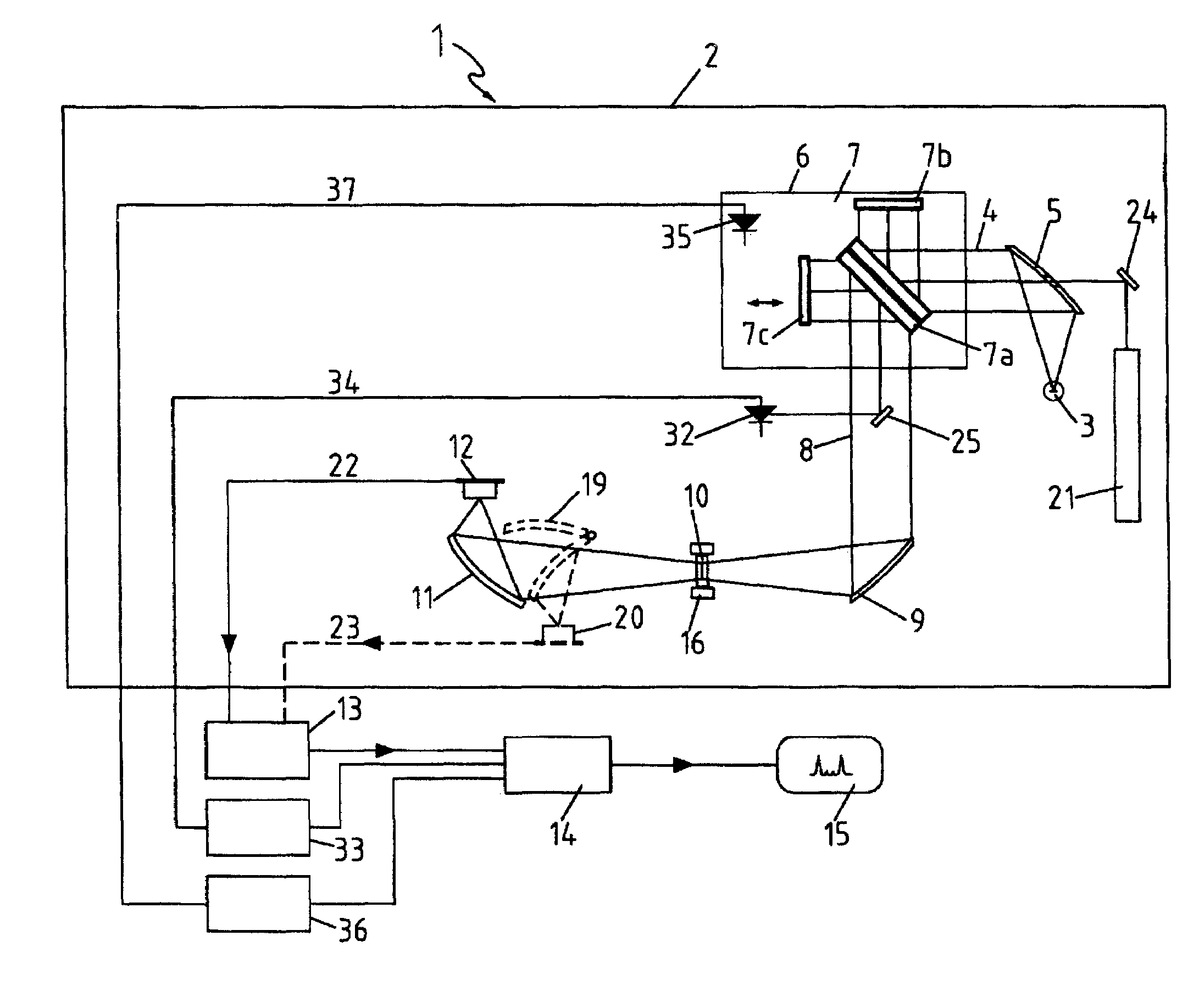

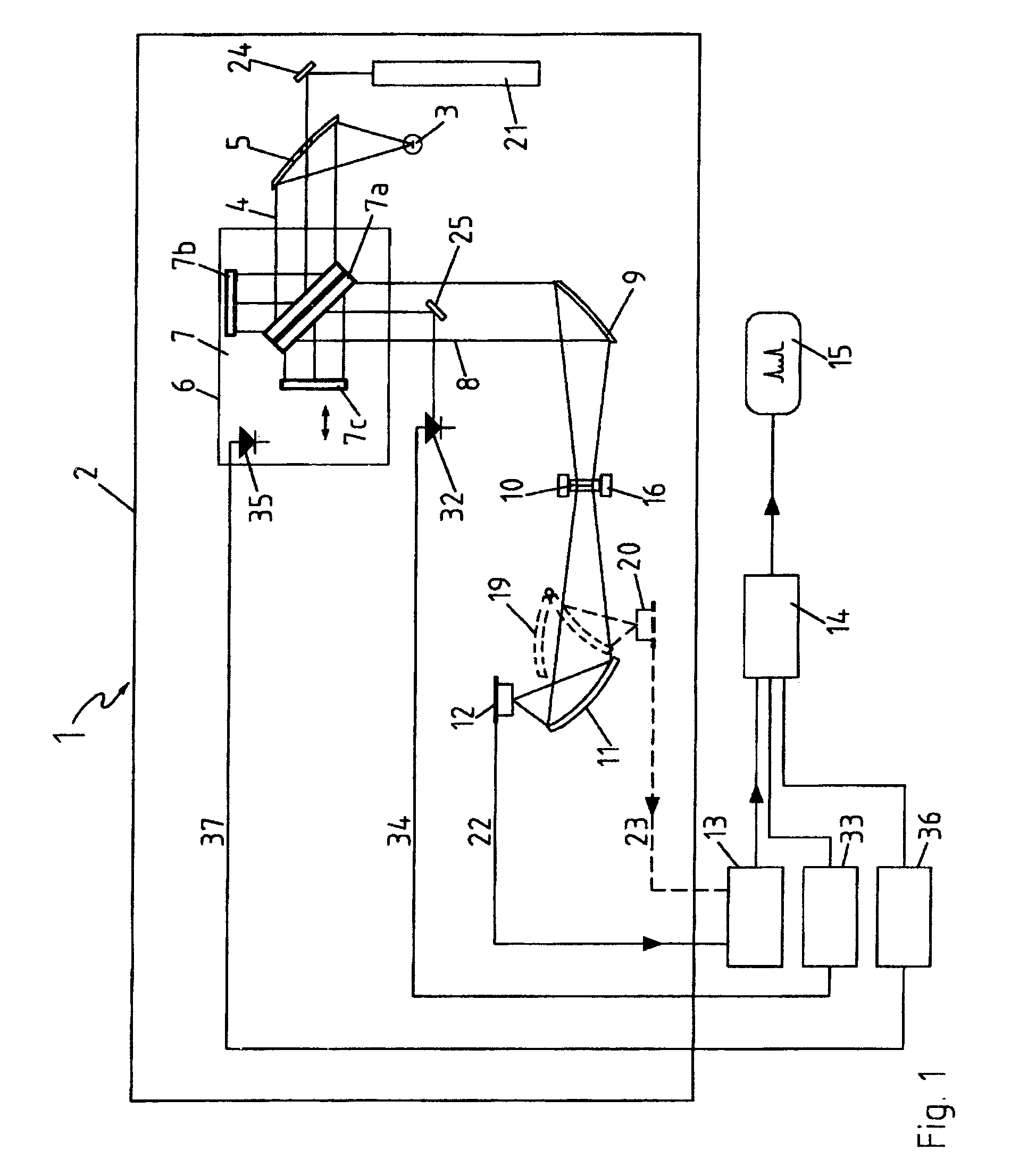

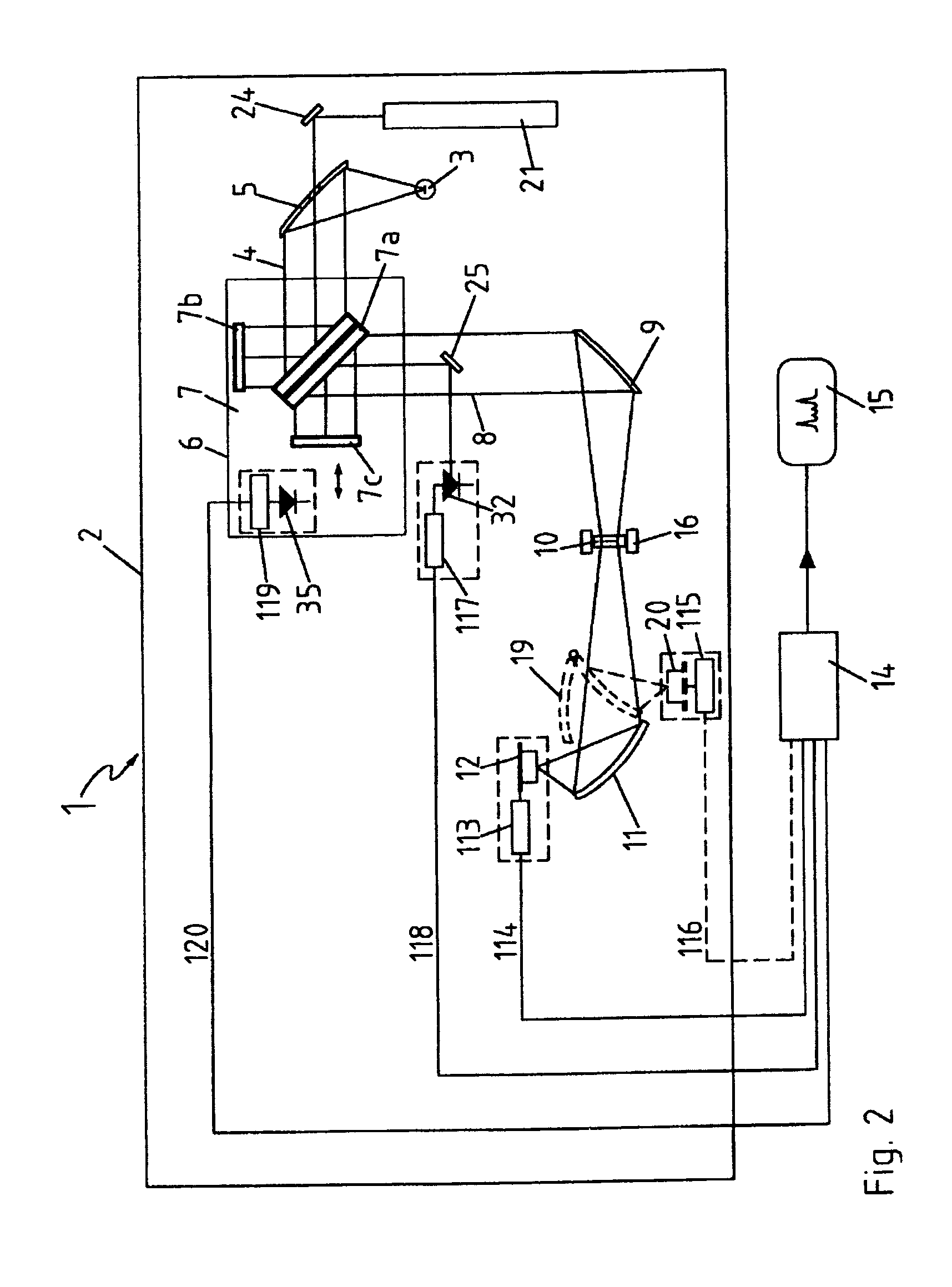

Digital FTIR spectrometer

InactiveUS7034944B2Analogue distanceReduce sensitivityRadiation pyrometryInterferometric spectrometrySingle elementLight beam

The present invention relates to an FTIR spectrometer comprising a single-element detector to analyze a detector light beam emitted by a sample, with a unit to digitize the voltage available at the detector output and with a unit to process the digitized voltage. The single-element detector and the dedicated unit to digitize the detector voltage are located immediately adjacent to each other.

Owner:BRUKER OPTICS GMBH & CO KG

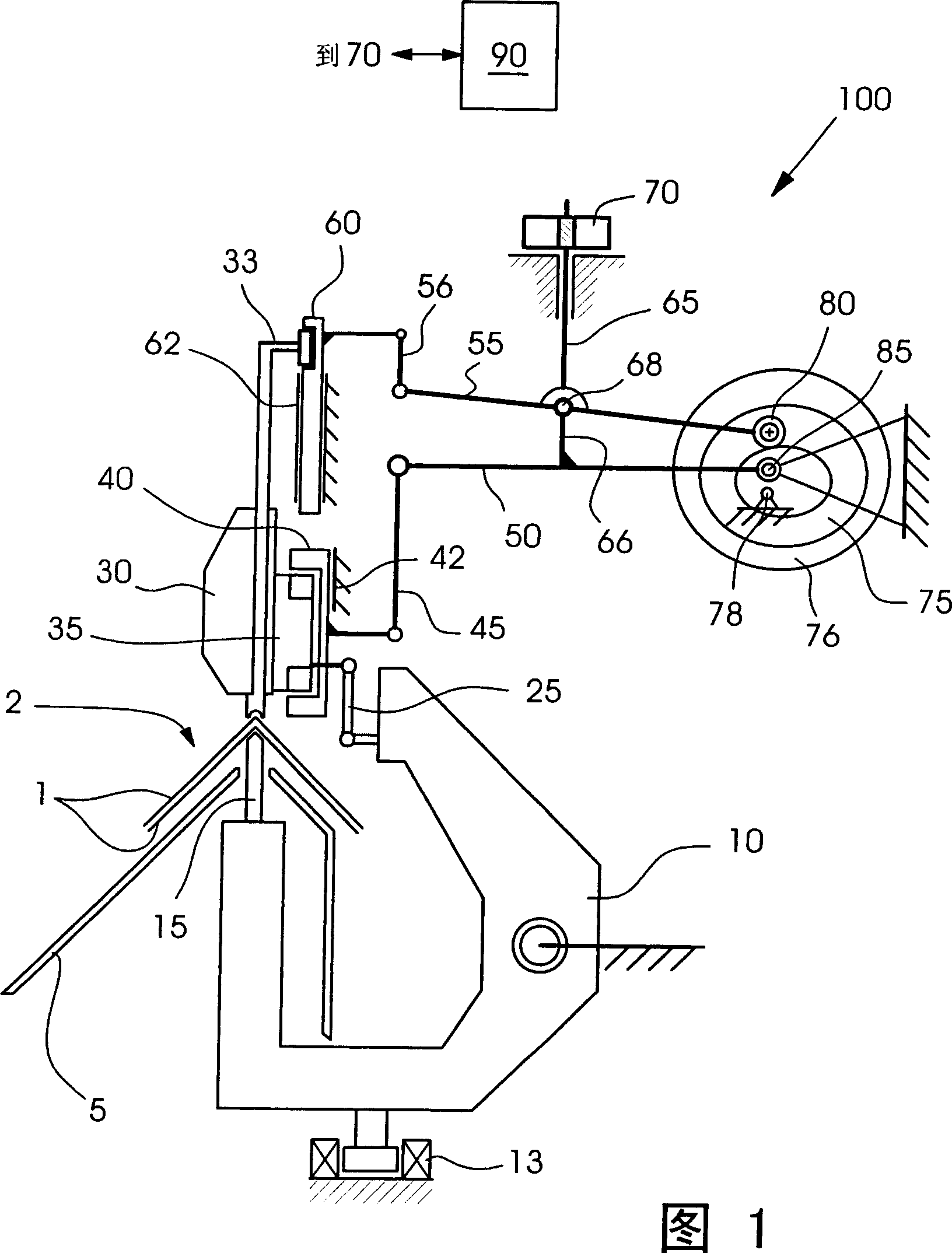

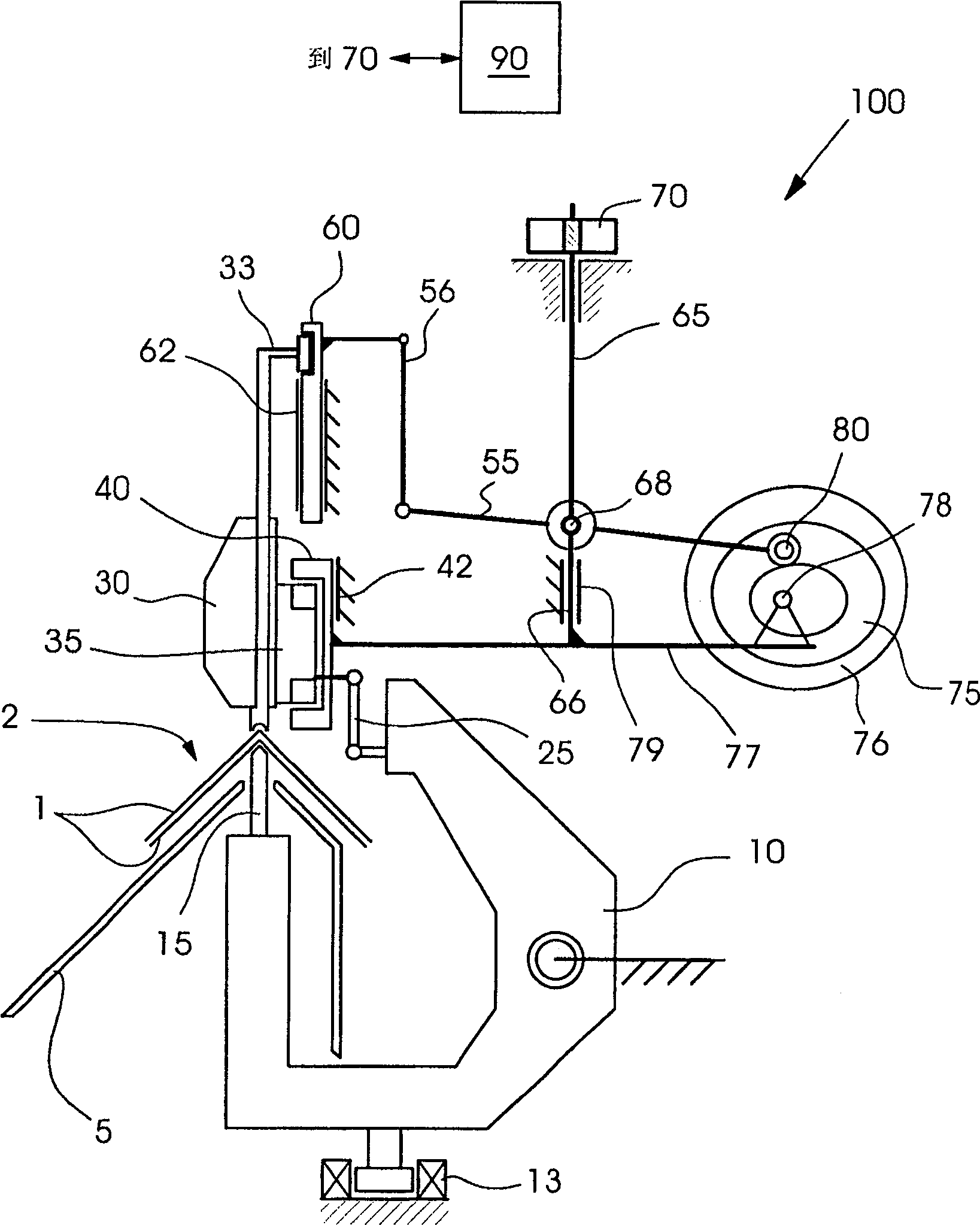

Stitching apparatus

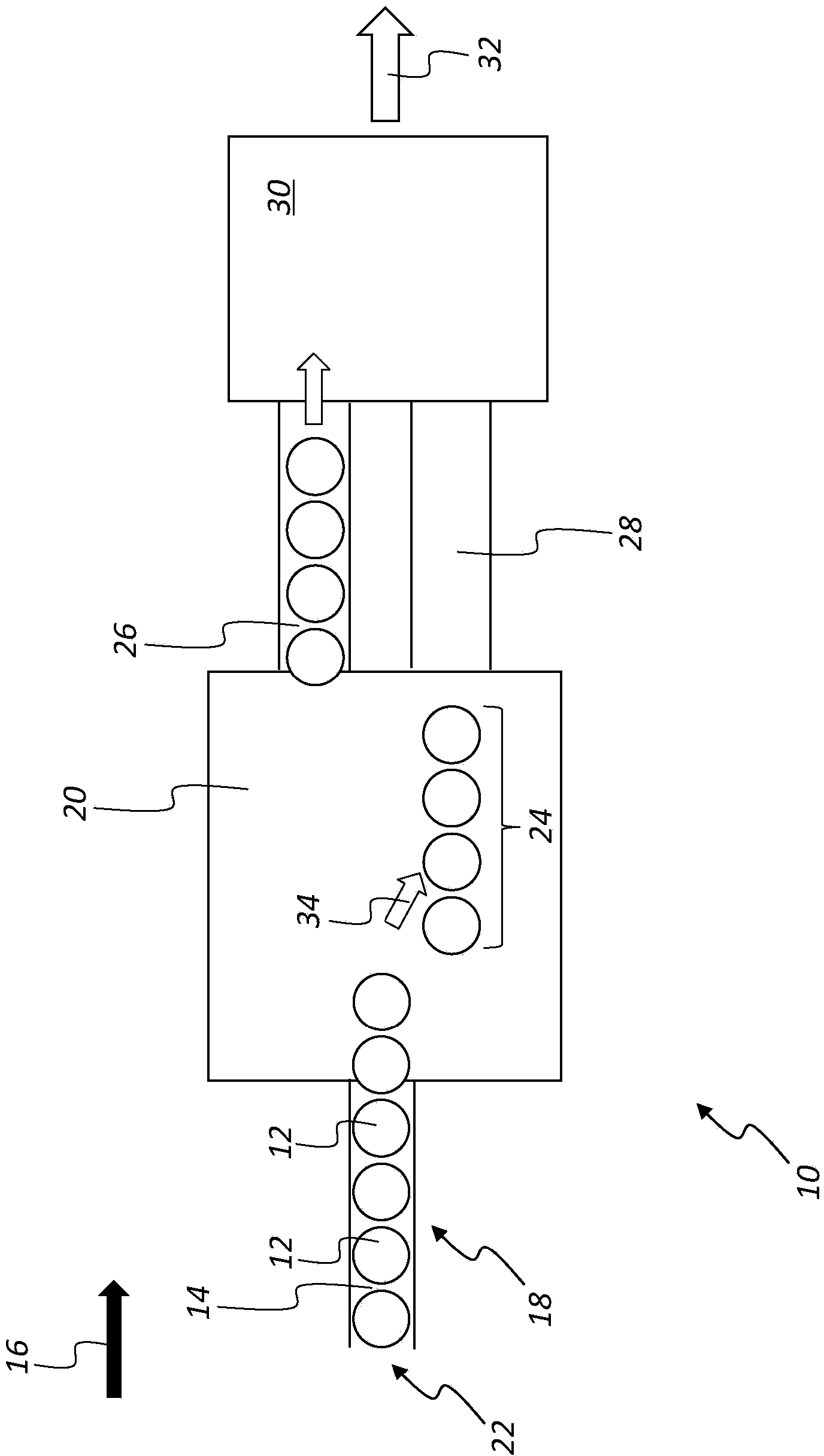

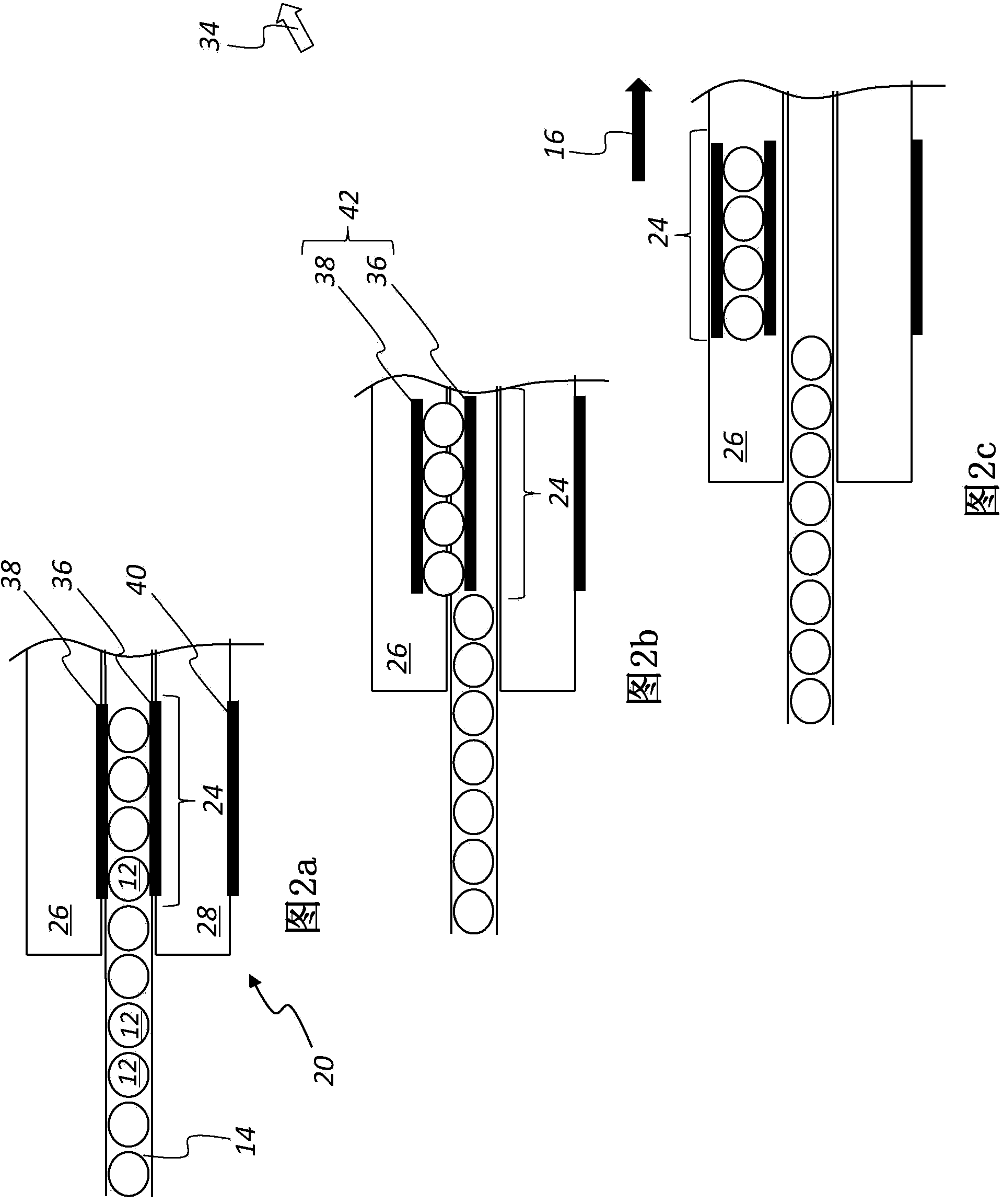

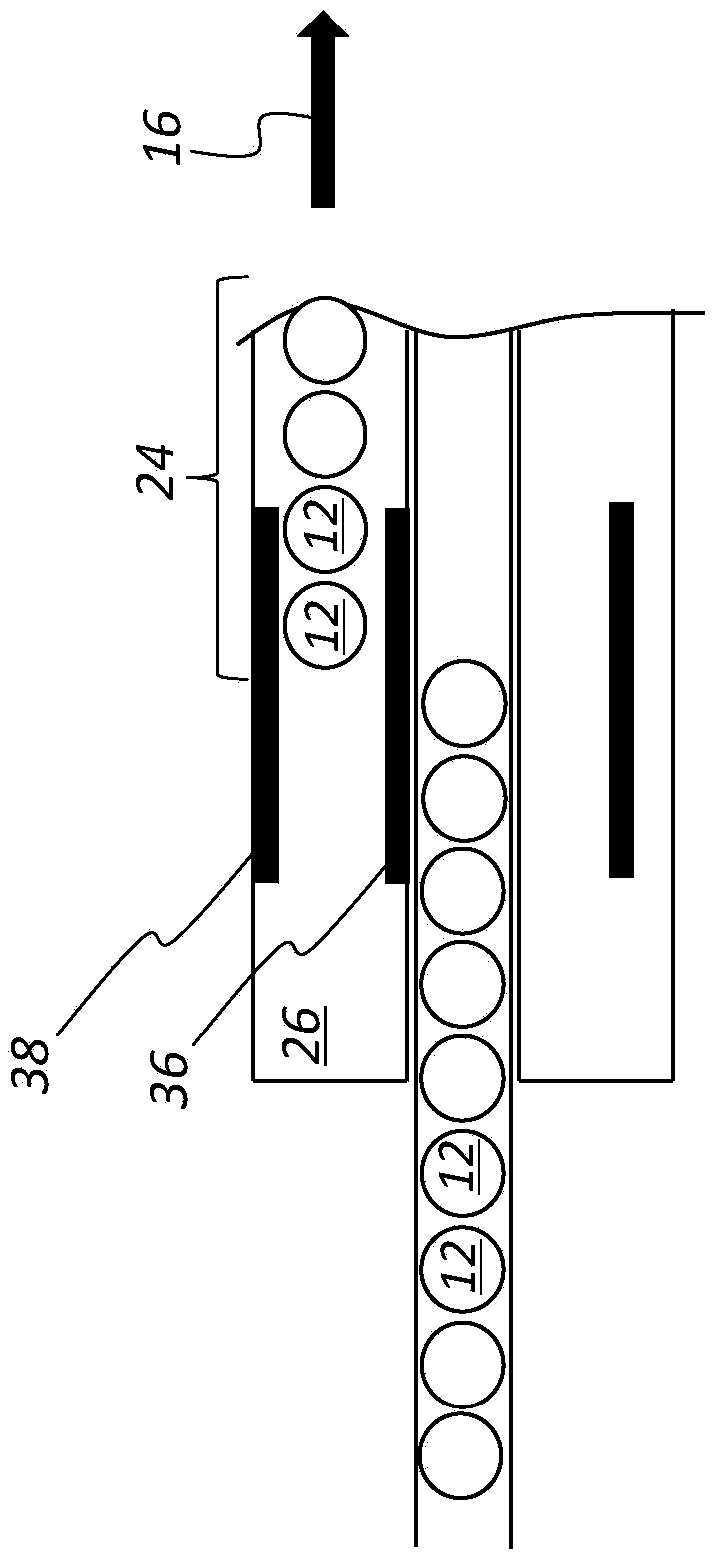

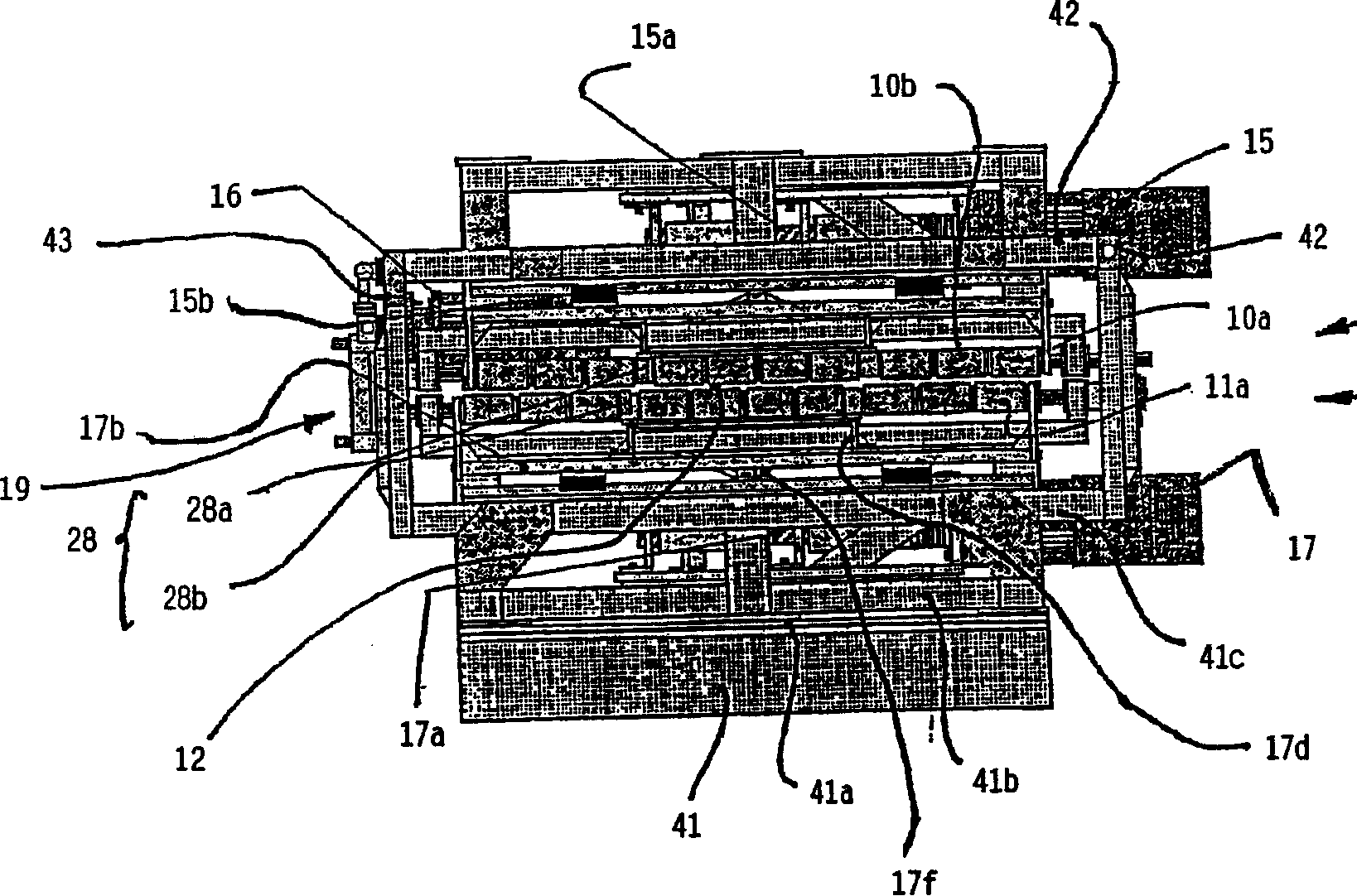

InactiveCN1939754AReduce susceptibility to interferenceRun fastSheet bindingEngineeringMechanical engineering

The present invention relates to a stitching apparatus 100 for manufacturing printed products, in particular in a gathering and stitching linkage machine. The stitching apparatus 100 comprises a stitching sliding carriage 10, at least one stitching head 30 for shaping and driving a staple into a stack 2 of signatures 1, and at least one clinch box 15 for closing the staple driven through the signatures 1, wherein the stitching apparatus 100 comprises adjusting device 45, 50, 55, 56, 65, 66, 70, 77 for vertically moving the stitching head 30 to allow the stitching apparatus 100 to adapted to the thickness of the stack 2 of signatures 1.

Owner:MULLER MARTINI HLDG

Grouping Method And Device

Owner:KRONES AG

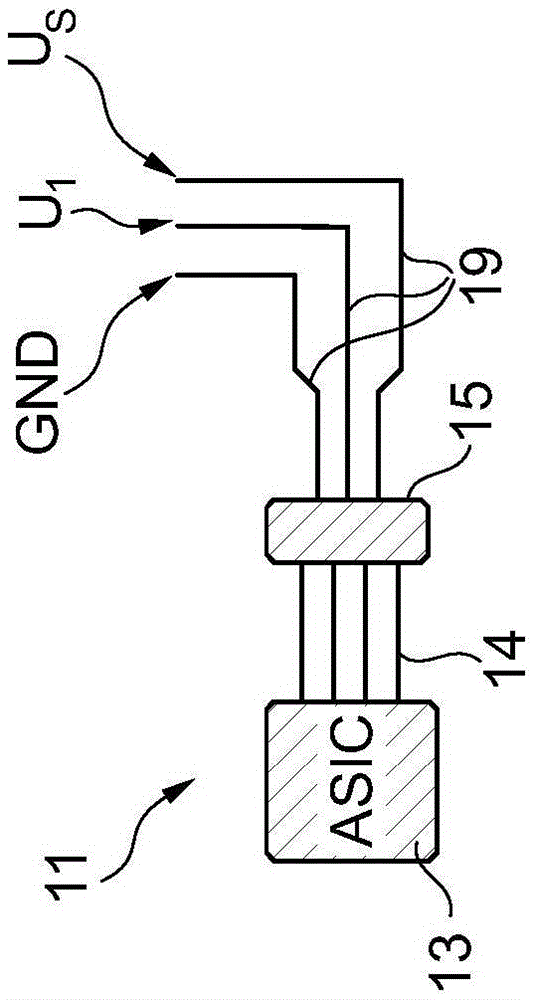

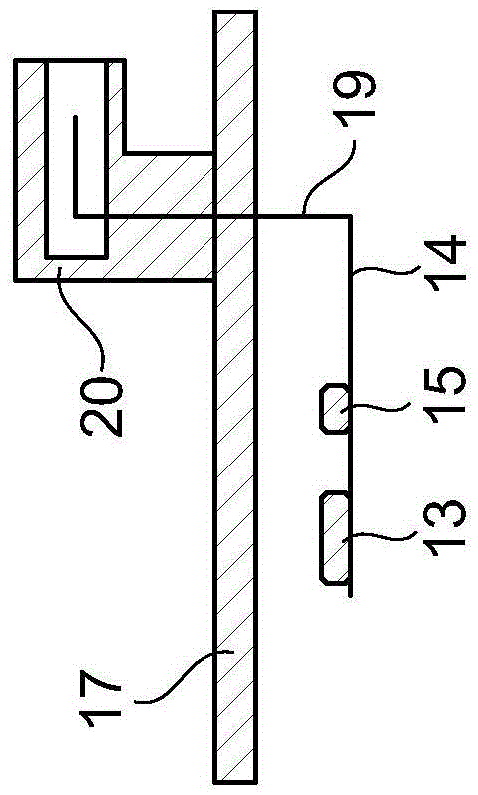

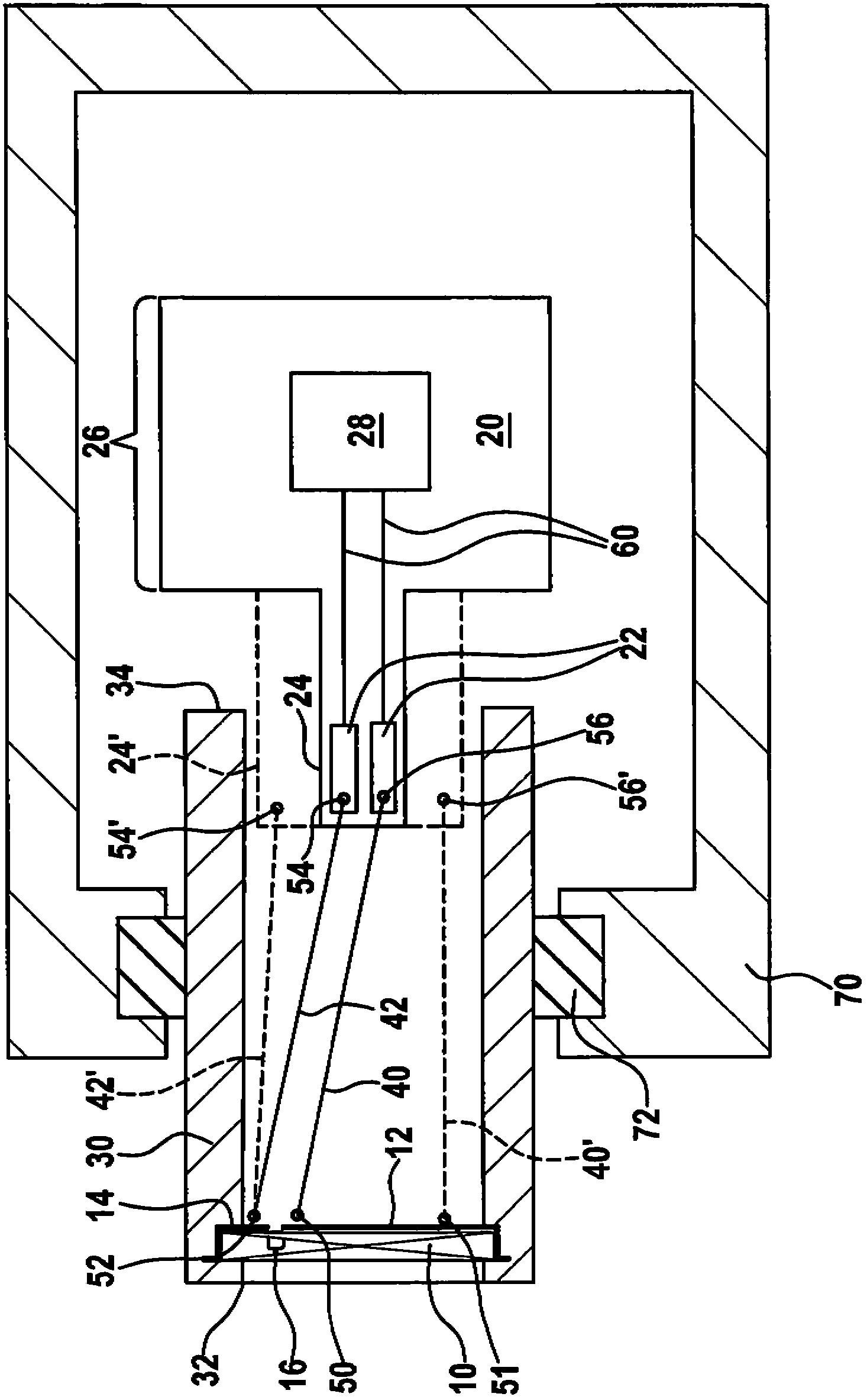

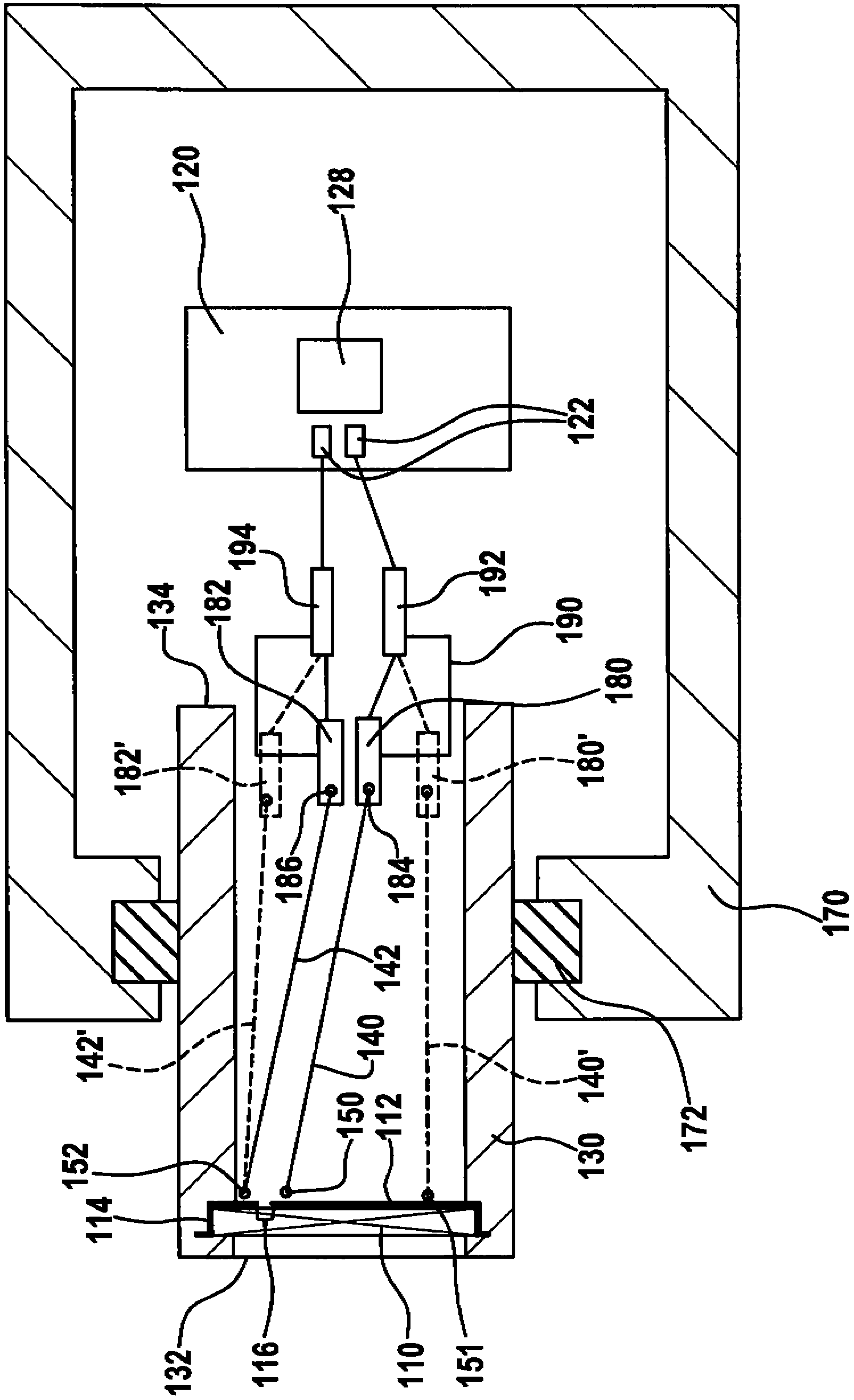

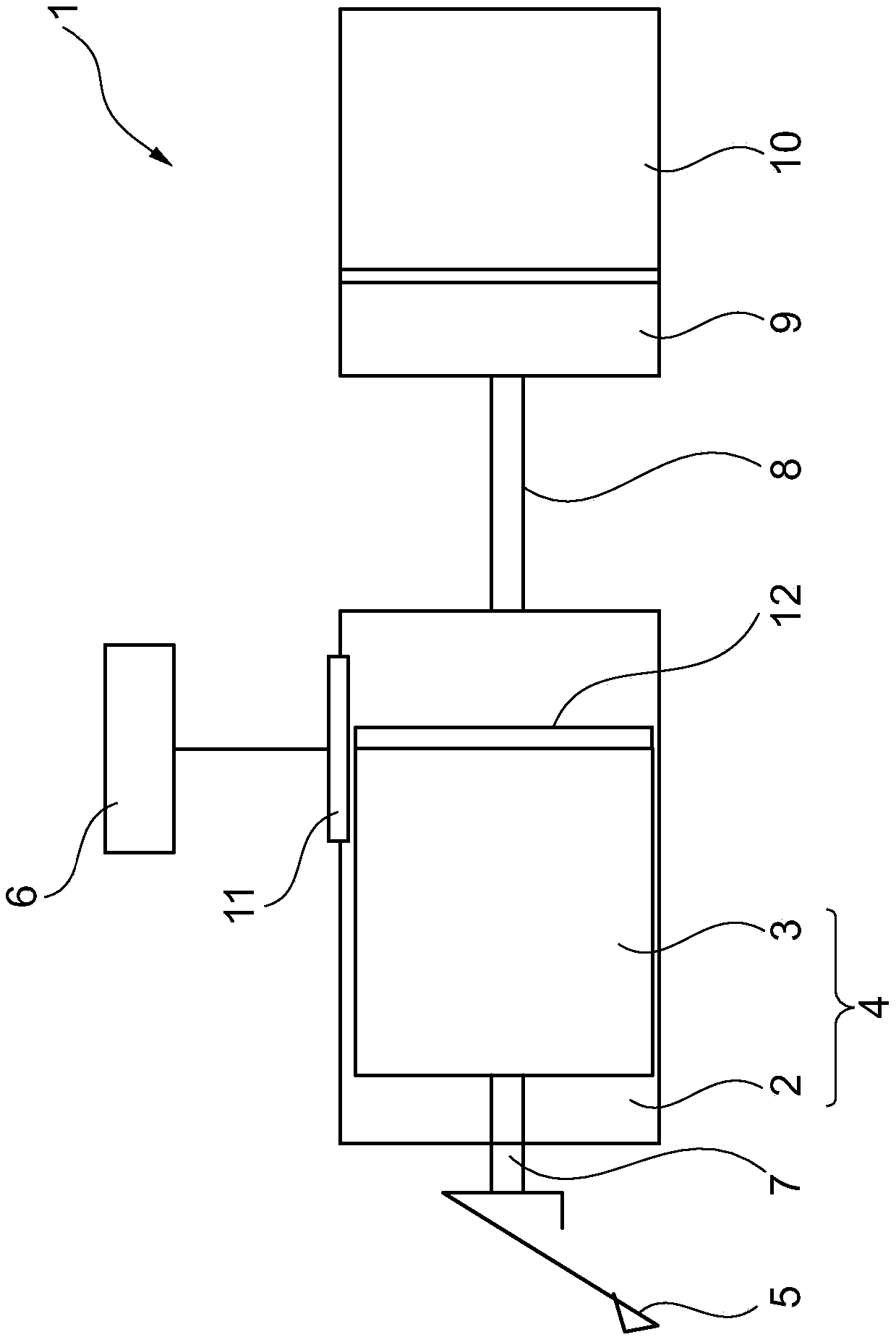

Plunger-cylinder assembly

ActiveCN105593553AEasy to operateFirmly connectedFluid actuated clutchesCouplingsMaster cylinderEngineering

The invention relates to a plunger-cylinder assembly, in particular for a master cylinder of a clutch actuating system in a motor vehicle. The plunger-cylinder assembly comprises a plunger and a sensor system, wherein the plunger is arranged axially movably in a cylinder which is configured as a housing, and the sensor system is arranged on the housing and is operatively connected to a sensor constituent part which is fastened to the plunger. In a plunger-cylinder assembly, in which the assembly is simplified by way of a reduction in the interfaces, the sensor system is positioned on a leadframe assembly which is integrated into the plastic housing.

Owner:SCHAEFFLER TECH AG & CO KG

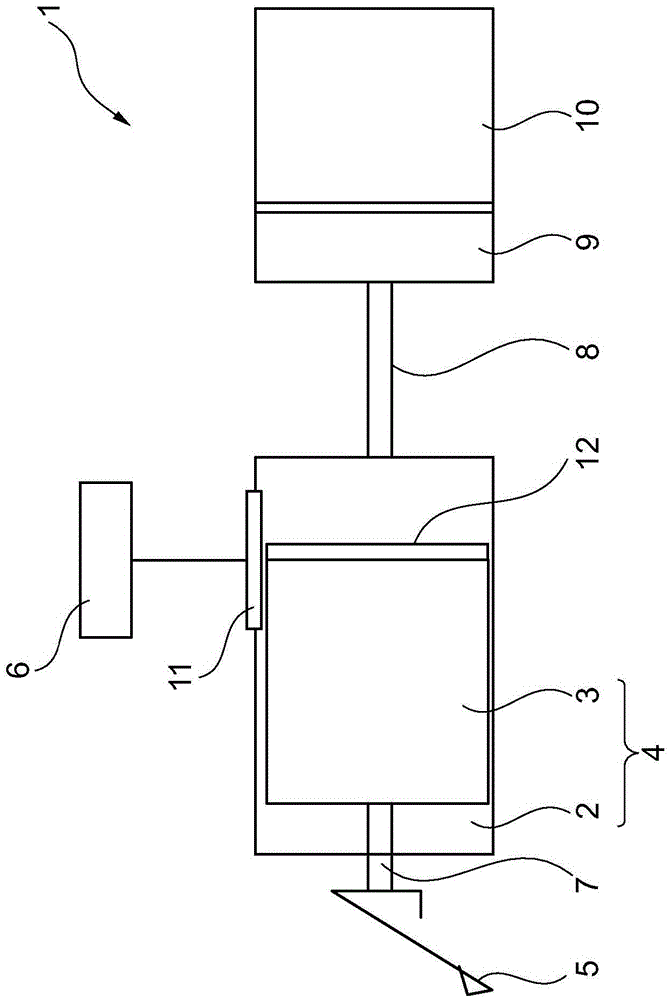

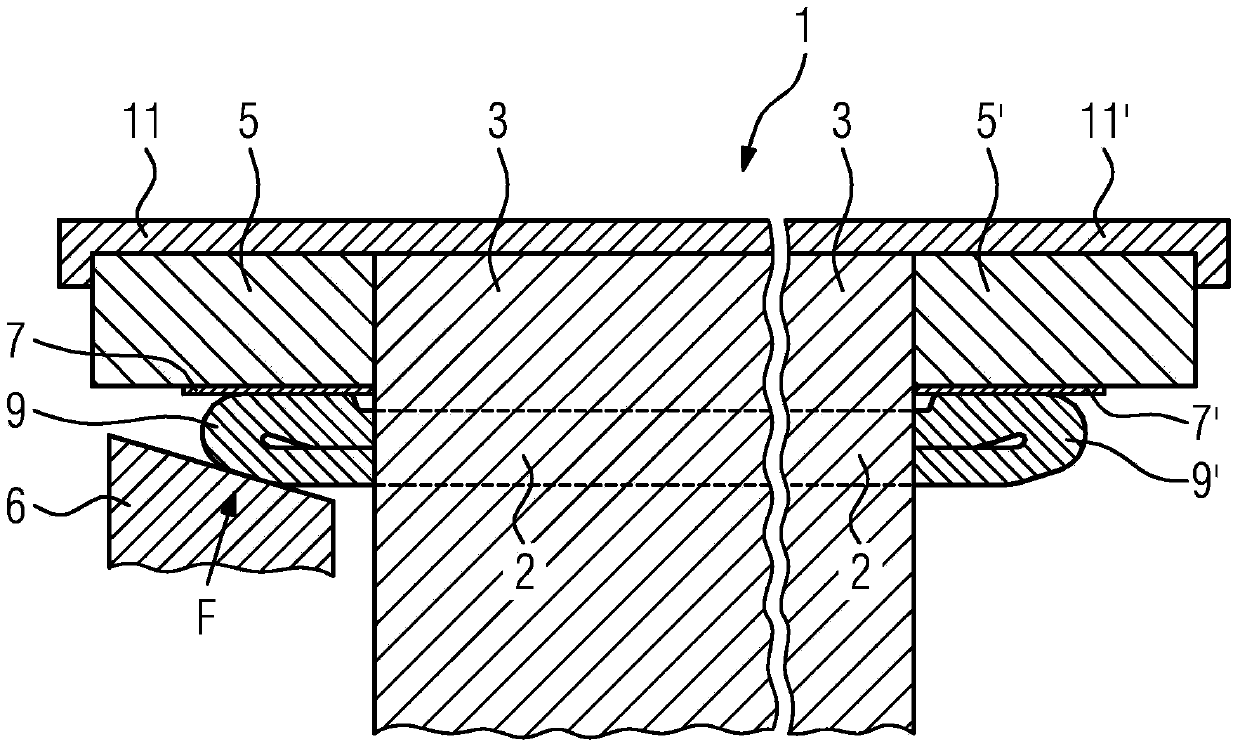

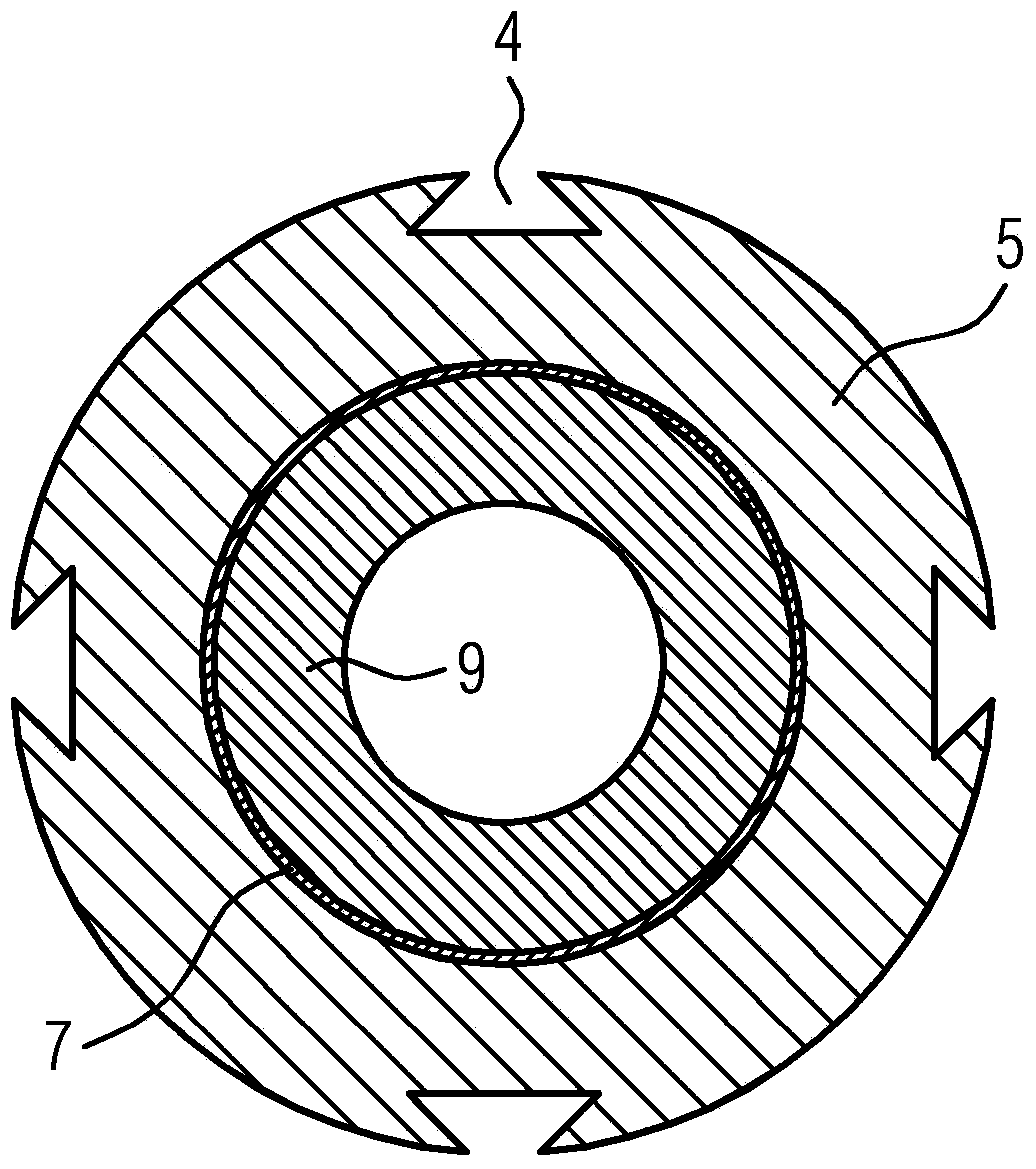

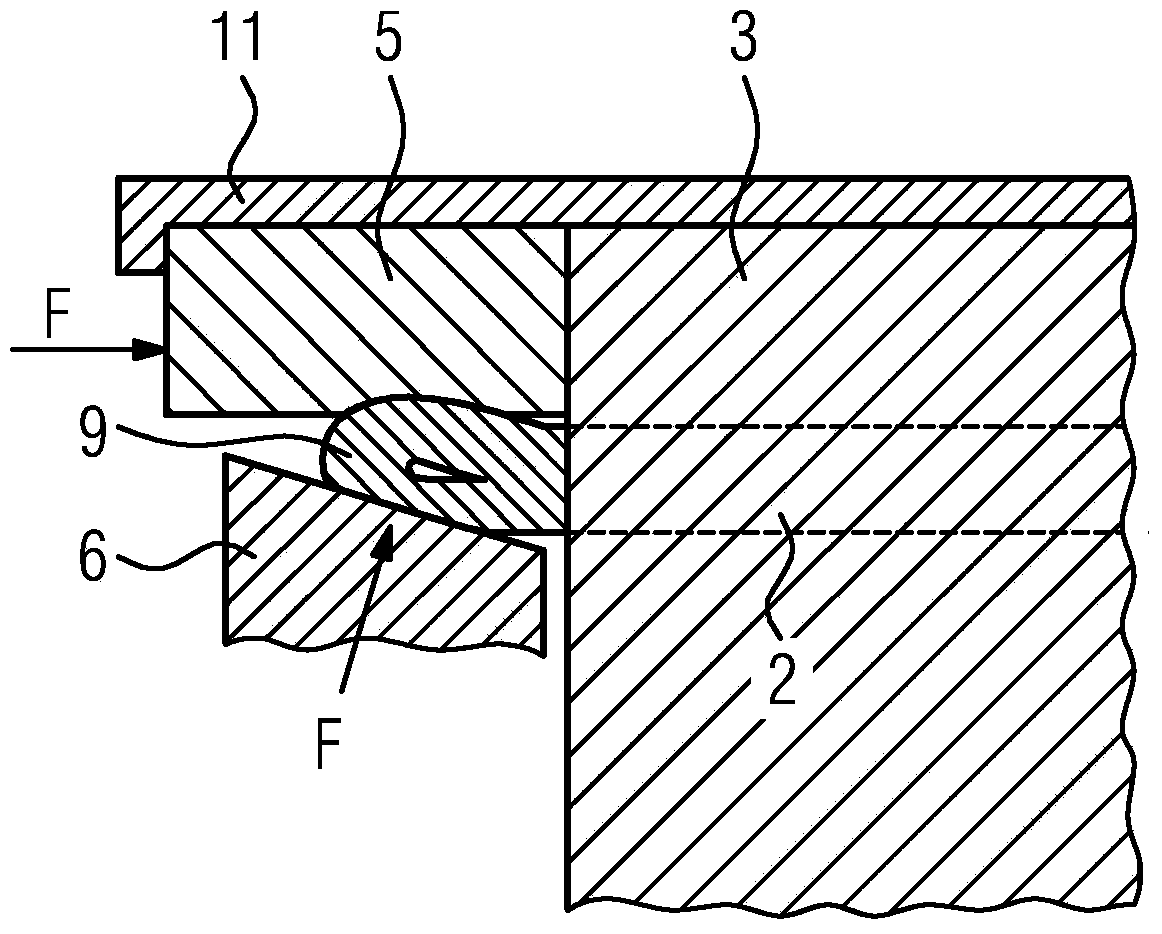

System for cooling coil

InactiveCN103795189APrevent continuous overheatingExtended service lifeManufacturing dynamo-electric machinesWind energy generationCooling coilElectrical and Electronics engineering

The present invention relates to a system for cooling a coil (2), particularly in a rotating motor (1). The system comprises a thermal conductive component (5, 5') having an end side abutting against a lamination group (3) and being in thermal conductive contact with a coil head (9, 9') of the coil (2). The system is characterized in that the thermal conductive contact between the coil head (9, 9') and the thermal conductive component (5, 5') is ensured by the press-fit connection between the coil head (9, 9') and the thermal conductive component (5, 5'), so that the coil head (9, 9') is at least in sections in direct contact with the thermal conductive component (5, 5').

Owner:SIEMENS AG

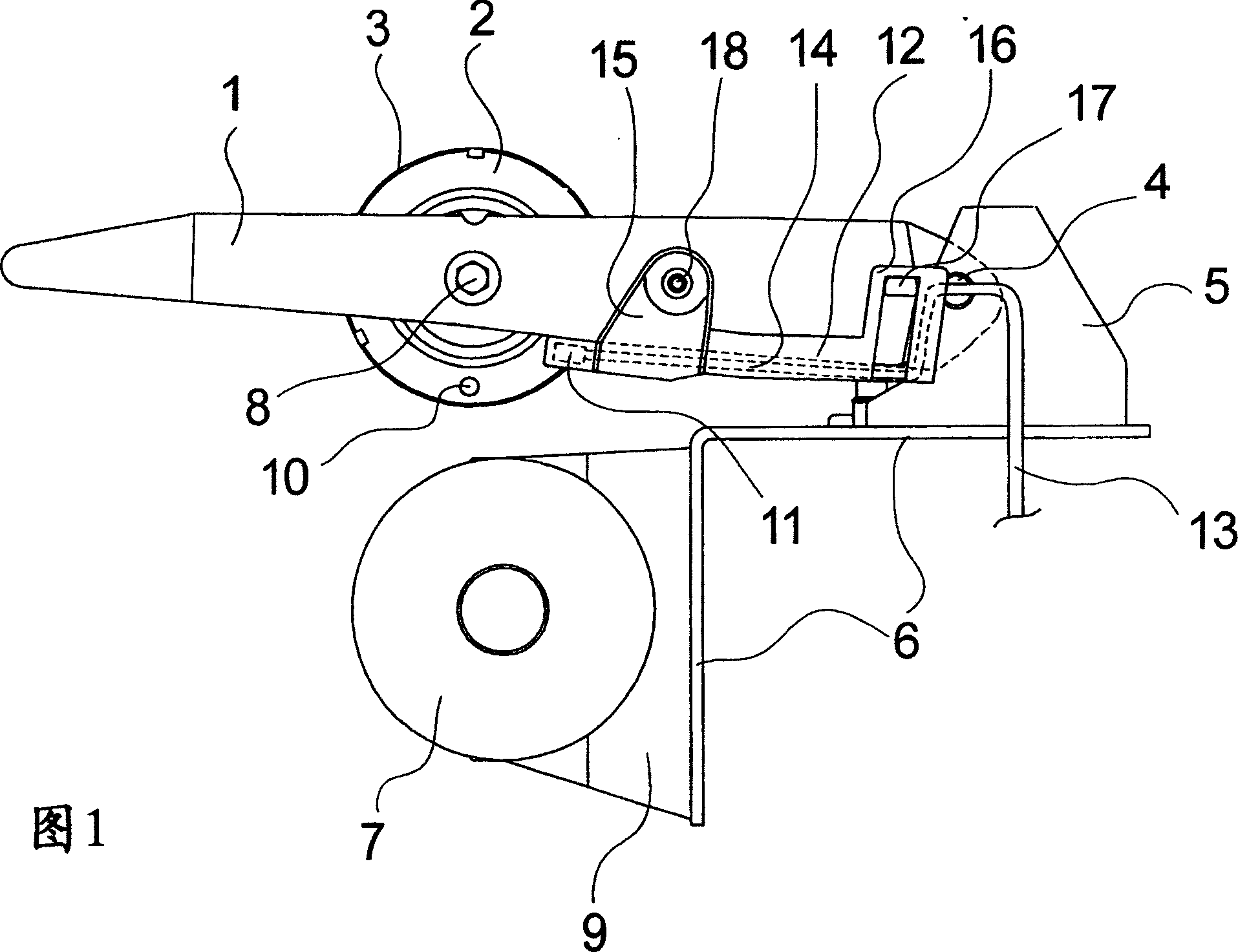

Winding device

The invention relates to a winding device for winding yarns on a bobbin and comprising a double-arm type bobbin frame. The bobbin frame is provided with two tensioning disks which are rotatablely supported relatively, and between which a bobbin of yarns to be winded to a spindle is arranged. The bobbin or spindle is drived by a driven roller, the bobbin is held around the driven roller when being winded. A sensor device is provided for detecting rotate speed setting of the bobbin, the sensor device includes a magnet and a Hall sensor, wherein the magnet is arranged on one tensioning disk, and the Hall sensor is arranged on the bobbin frame and connected with at least a connection wire. In order to ensure a high functional characteristic and a replaceable characteristic of an electronic apparatus component, the Hall sensor of the invention is held by a separated sensor support which is detachablely connected with the bobbin frame and has a cable passage for receiving the connection wires connecting with the Hall sensor.

Owner:SAURER GMBH & CO KG

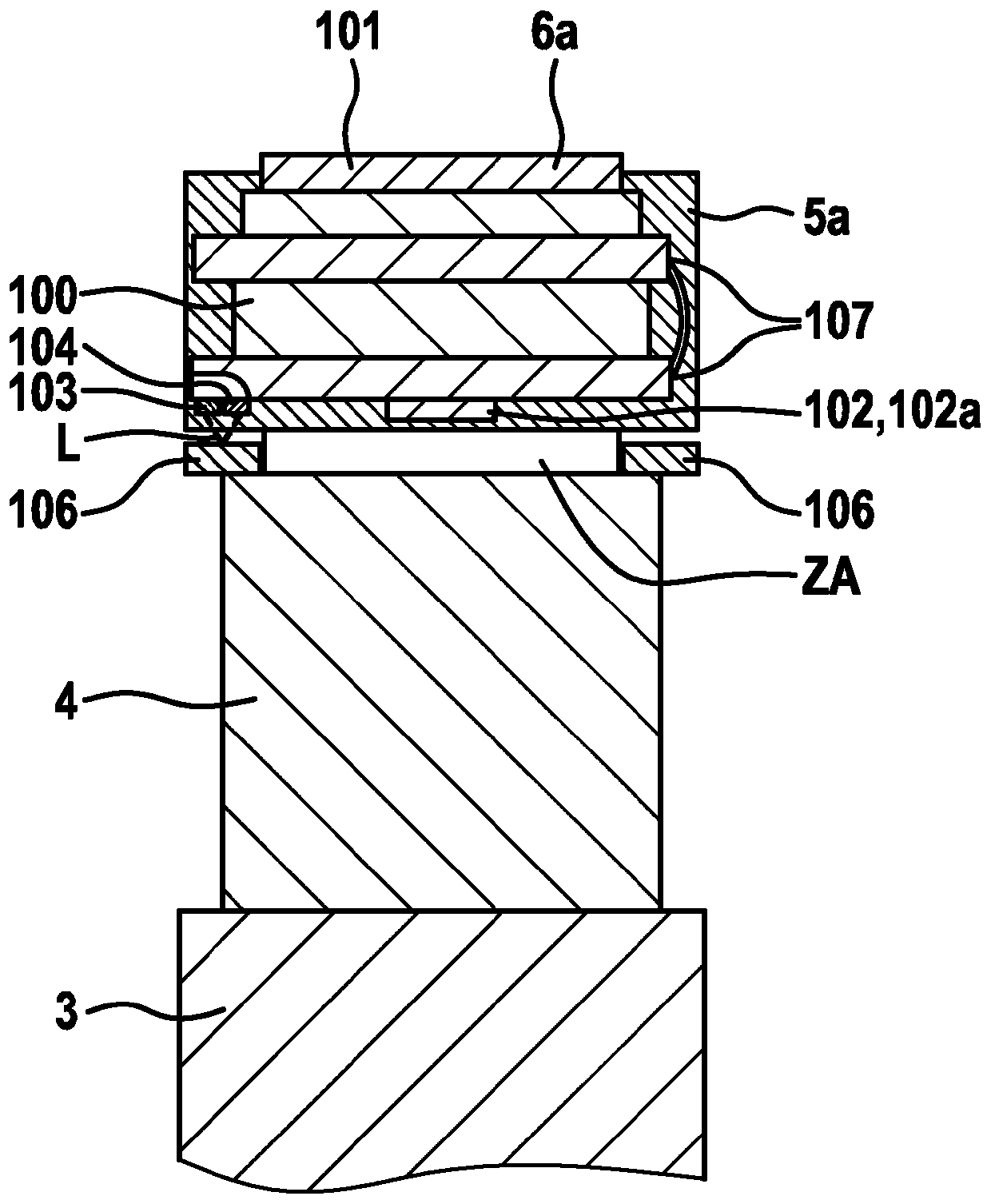

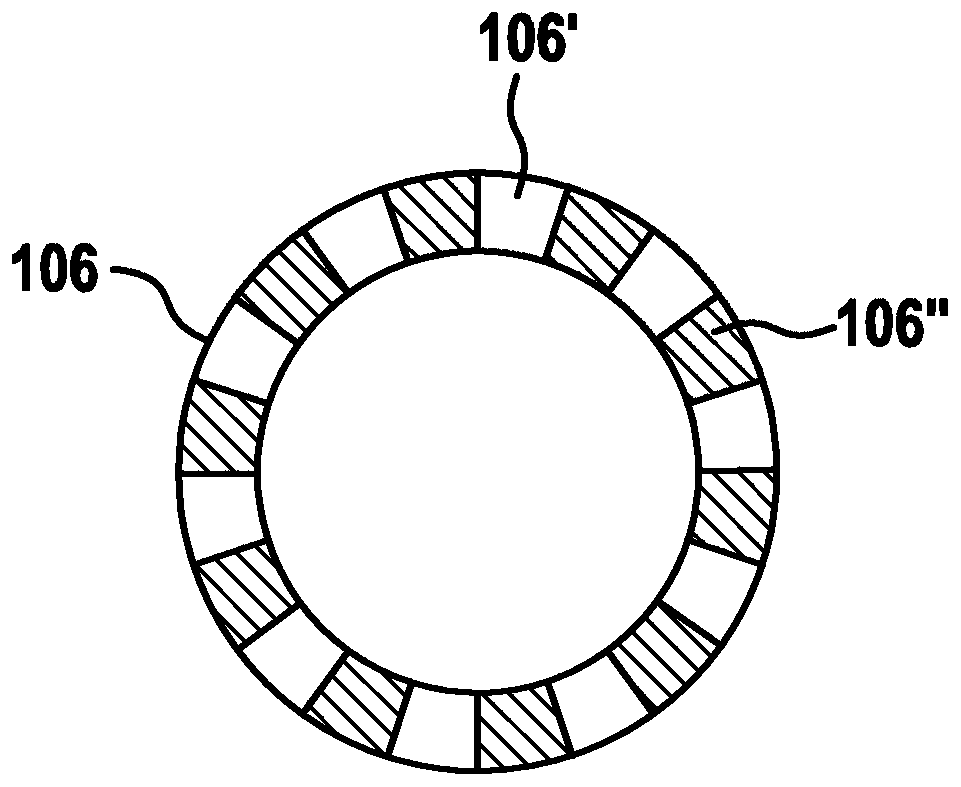

Ultrasonic transducer with piezoelectric element and distance sensor

ActiveCN102833658ALow costReduce susceptibility to interferenceSubsonic/sonic/ultrasonic wave measurementPiezoelectric/electrostrictive transducersPrinted circuit boardElectricity

The invention relates to an ultrasonic transducer, comprising a piezoelectric element, with a printed circuit board and with a diaphragm pot. The piezoelectric element is attached to the front face of the diaphragm pot and connected via at least two leads, to signal connection points of the printed circuit board. In one arrangement a portion of the circuit board projects into the diaphragm pot. The portion of the PCB may be smaller in width than the clear width of the diaphragm pot, and the remainder of the PCB may be arranged outside the pot. Alternatively the leads, (e.g. wires, single core cables) are arranged so that they run with a spacing from one another which is smaller than half the width of the piezoelectric element, preferably no more than the electrode gap width of the element. The transducer may be attached to a panel of a motor vehicle and used as a distance sensor. The distance sensor includes the ultrasonic transducer and also an acoustic damping ring and a housing. A maintaining cover of the ultrasonic transducer is connected with the housing through the damping ring. In addition, the invention relates to a method for manufacturing the ultrasonic transducer.

Owner:ROBERT BOSCH GMBH

Audio shoe contact for a hearing device

ActiveUS7853032B2Easy to assembleReduce susceptibility to interferenceHearing aids housingEngineeringHearing apparatus

Owner:SIVANTOS PTE LTD

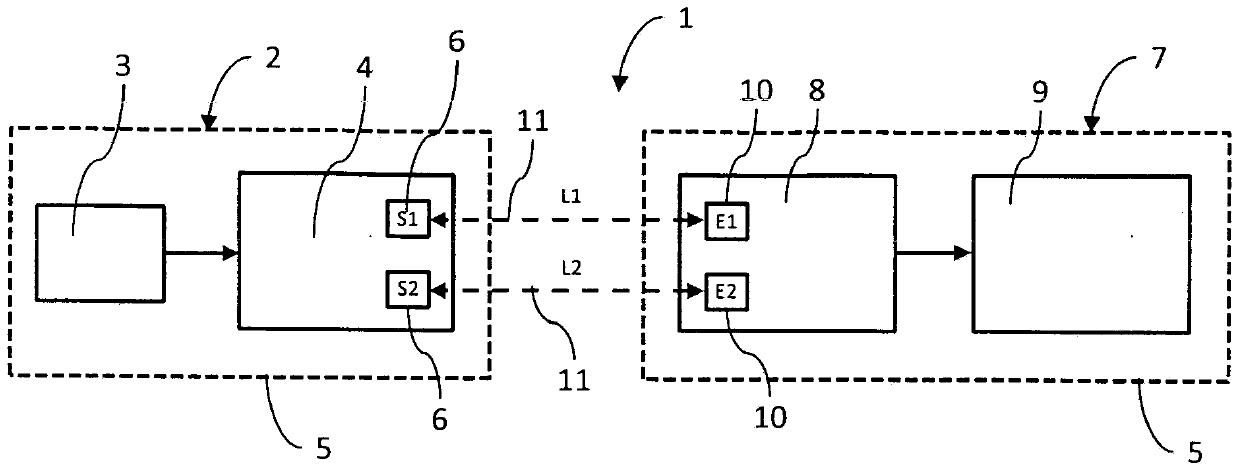

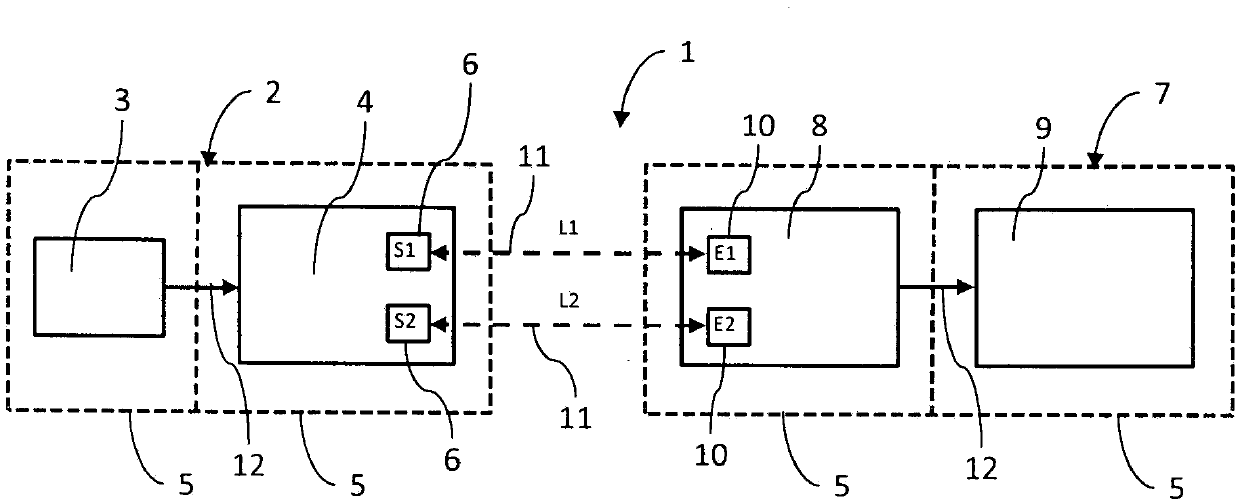

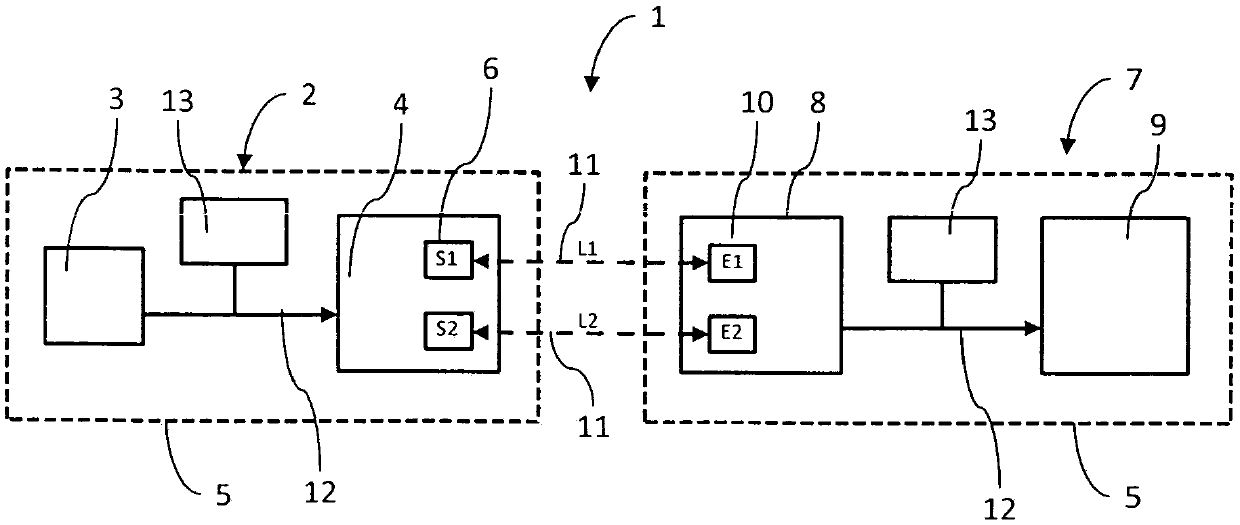

Image transfer arrangement and method for image transfer

ActiveCN109951679AAvoid time lossLower latencyEndoscopesClosed circuit television systemsWireless transmissionInterference (communication)

The invention relates to an image transfer arrangement (1) for the wireless transfer of image information items between a transmitter (4) and a receiver (8), wherein at least two communication channels (11) which are physically independent of one another are formed between the transmitter (4) and the receiver (8) and enable impairment and interference-free communication.

Owner:SCHOLLY FIBEROPTIC

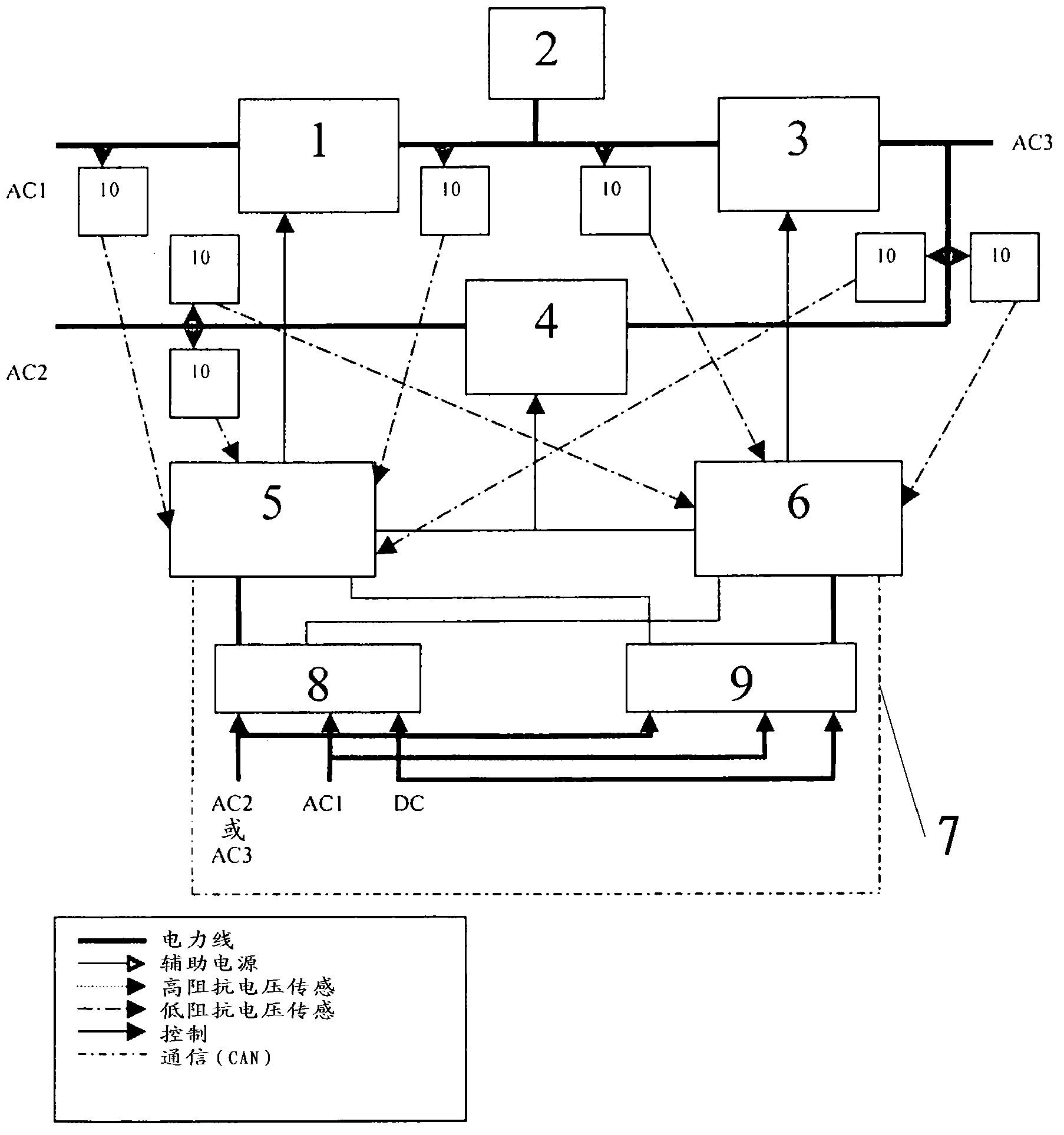

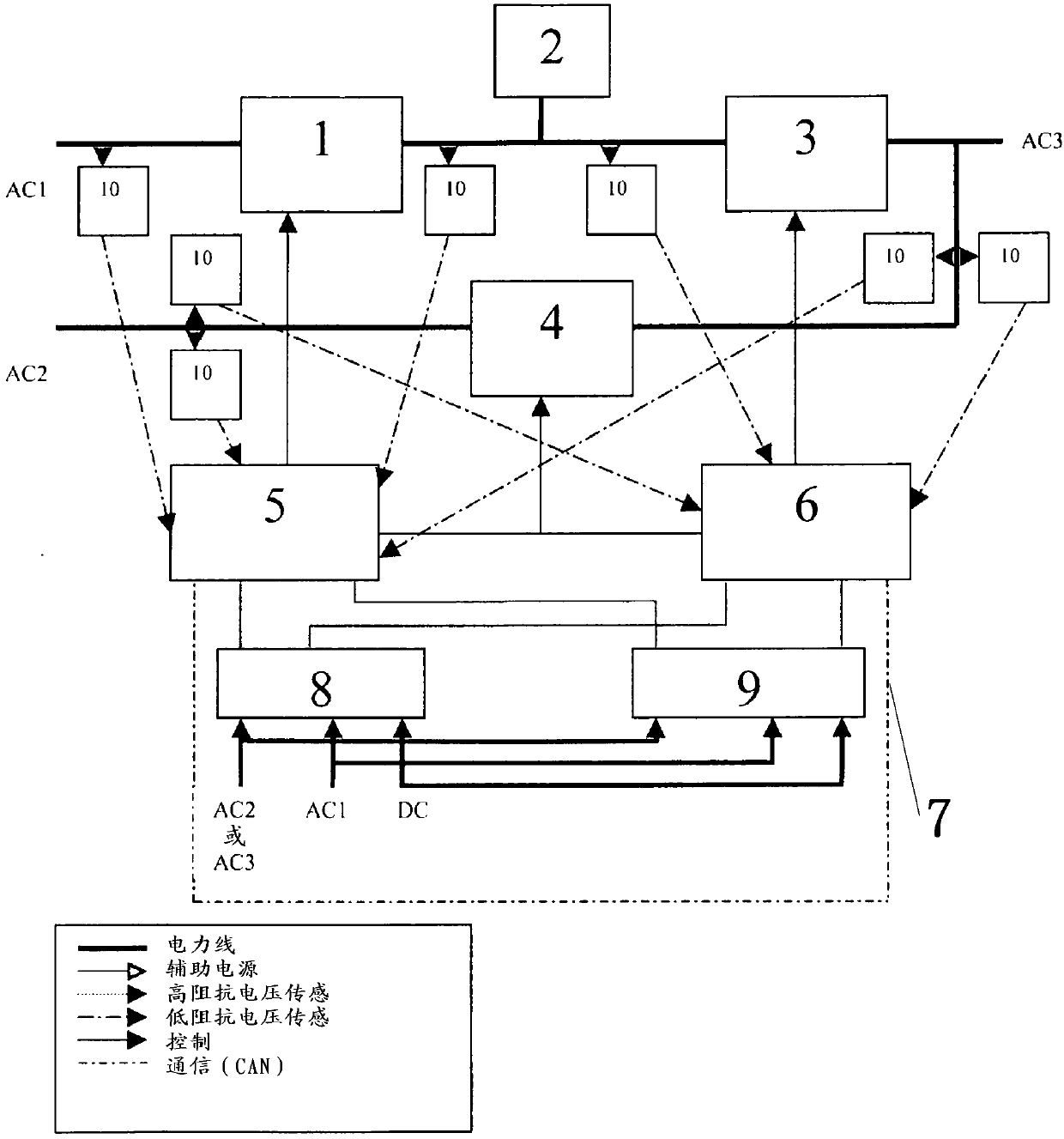

Assembly for an uninterrupted power supply

InactiveCN103138337AReduce susceptibility to interferenceImprove reliabilityBatteries circuit arrangementsElectric powerPower inverterPower flow

An arrangement for uninterruptible power supply comprises a rectifier, an energy store used for storing power, an inverter, a switch and a controller. The rectifier is connected to a rectifier input to a supply grid, the energy store is connected to a rectifier output and to an inverter input. A network to be protected is connected to an inverter output of the inverter. The rectifier input or a supply grid is connected via the switch to the inverter output, wherein the rectifier, the inverter and the switch are controlled by the controller , wherein the arrangement includes sensors for measuring voltages and / or currents. Each sensor is connected via a sensor output to exactly one controller and each sensor is configured to convert a parameter to be measured into a low-voltage signal.

Owner:AEG POWER SOLUTIONS BV

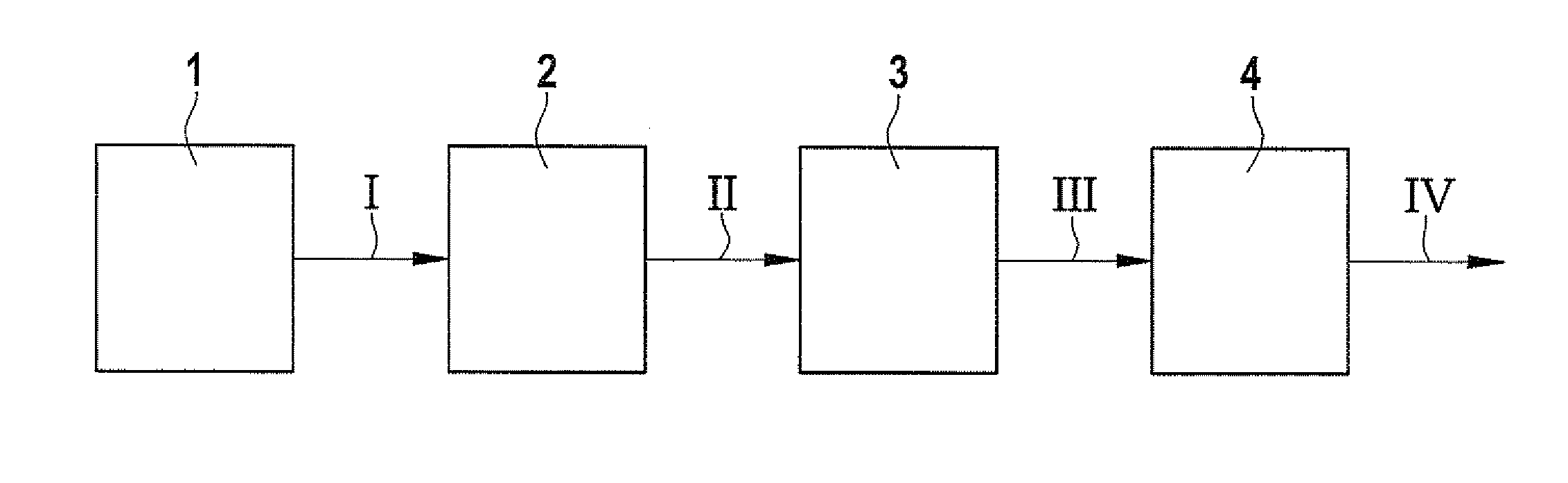

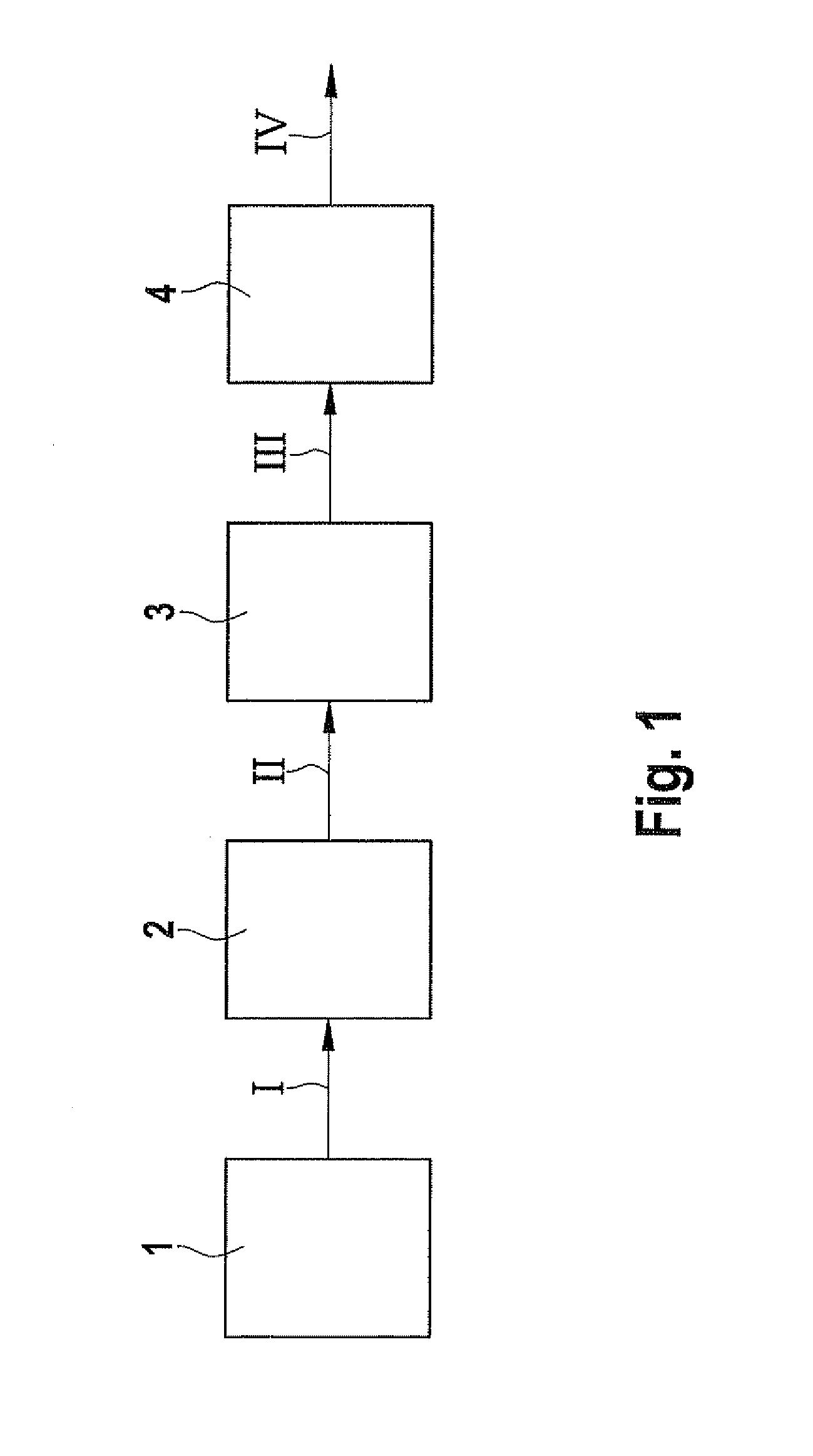

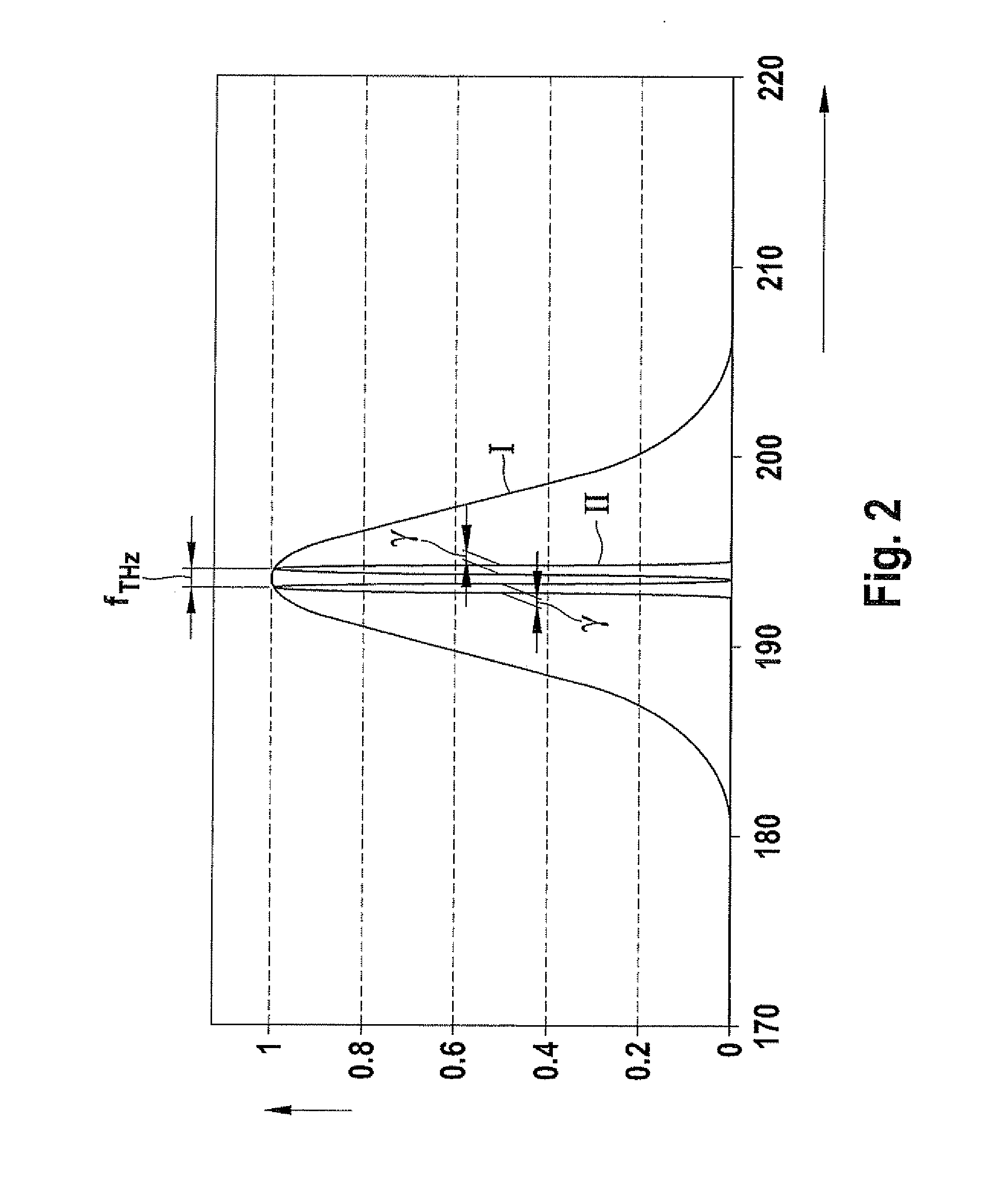

Terahertz radiation source and method for generating terahertz radiation

InactiveUS20110121209A1Reduce susceptibility to interferenceLower unit costGeological detection using milimetre wavesMaterial analysis by optical meansTerahertz radiationPulse shaper

A terahertz radiation source is described which includes a pulsed femtosecond fiber laser, a pulse shaper, an optical amplifier and a nonlinear crystal, wherein the laser, pulse shaper, optical amplifier and nonlinear crystal are configured and / or situated in such a way that a laser pulse I, II, III, IV produced by the laser first passes through the pulse shaper, then the optical amplifier, and then the nonlinear crystal. Also described is a related imaging and / or spectroscopy system, a method for generating terahertz radiation, a method for detecting and / or examining life forms, objects, and materials using a system of this type, and a use of a source and a system of this type.

Owner:ROBERT BOSCH GMBH

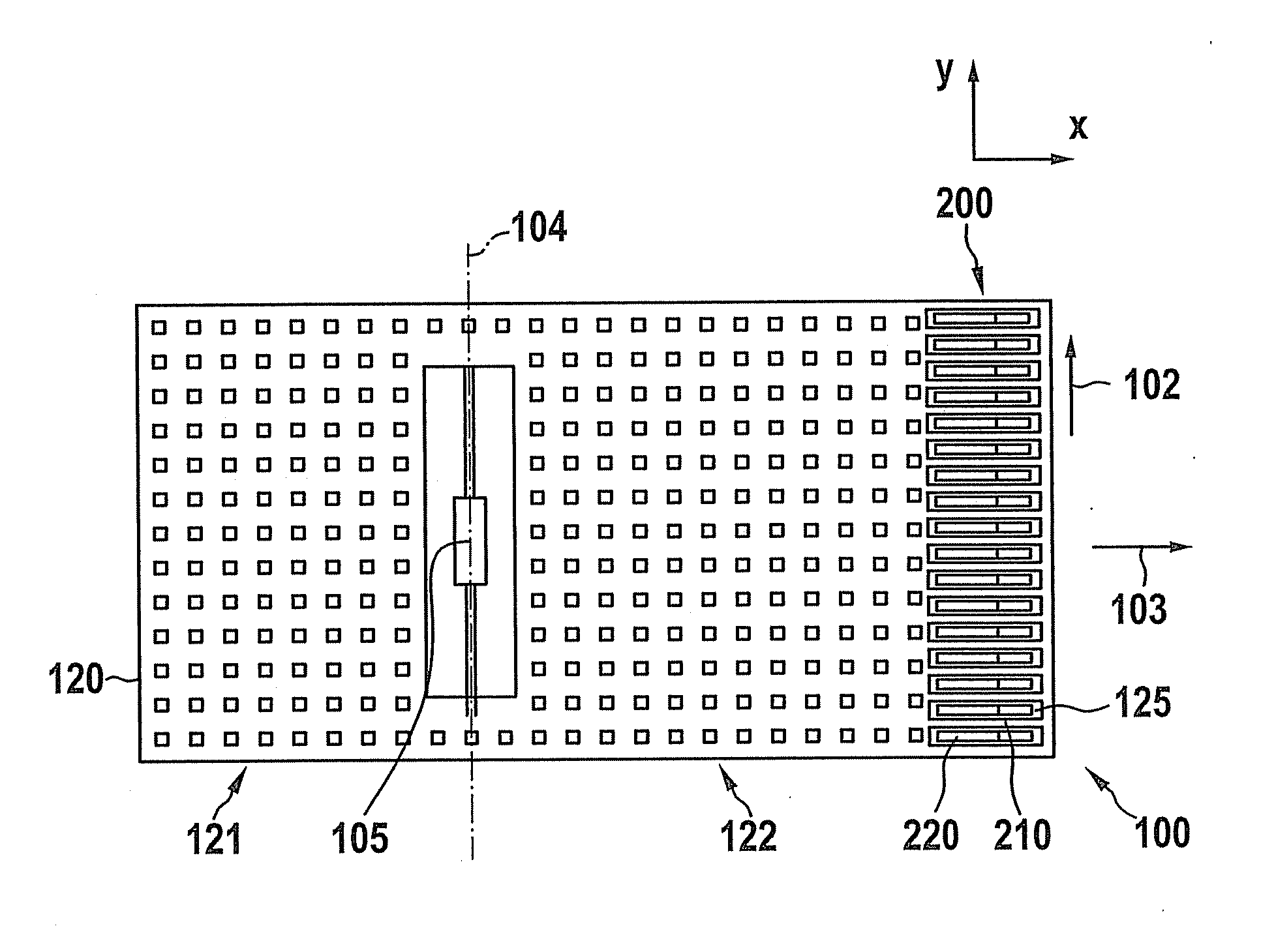

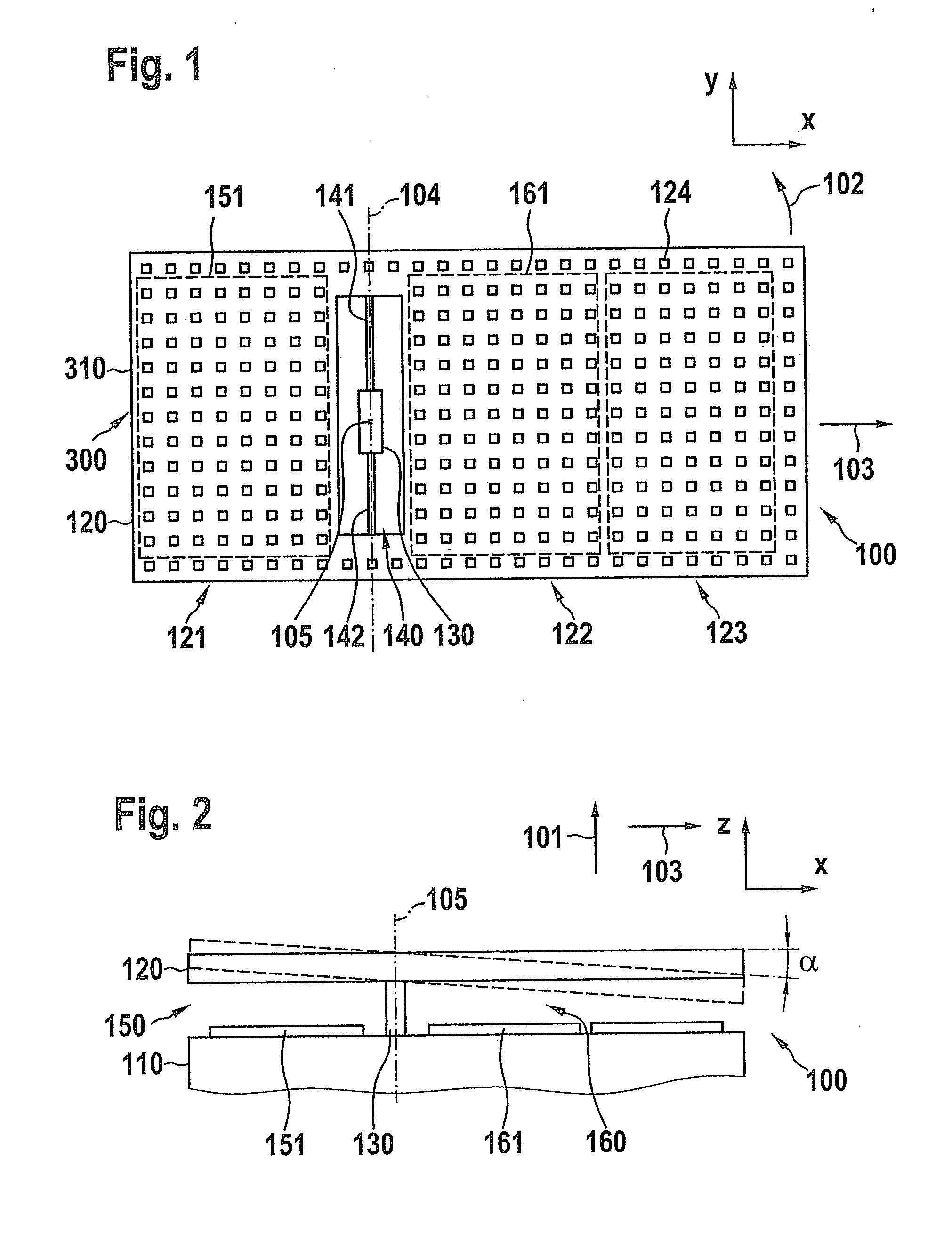

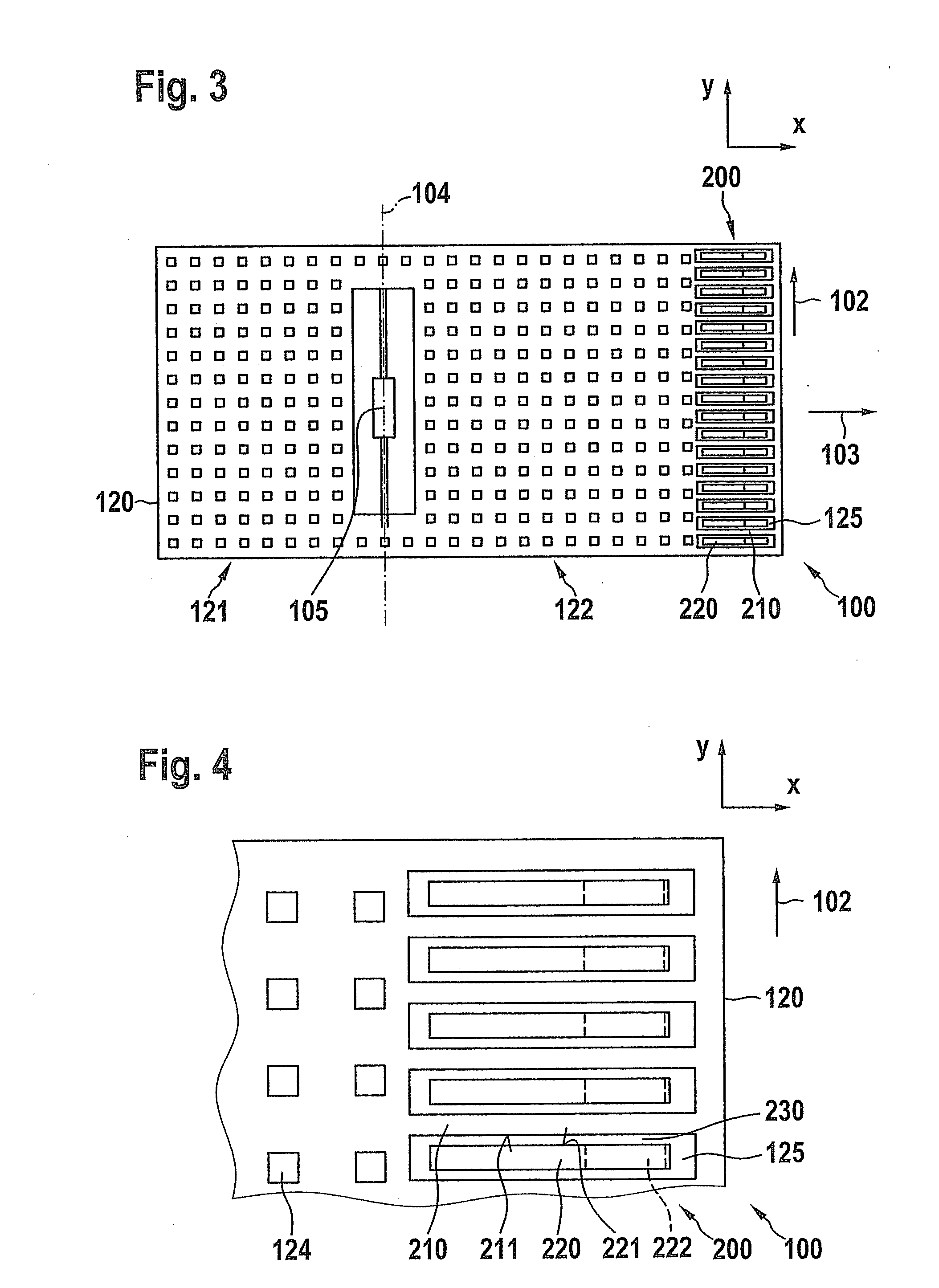

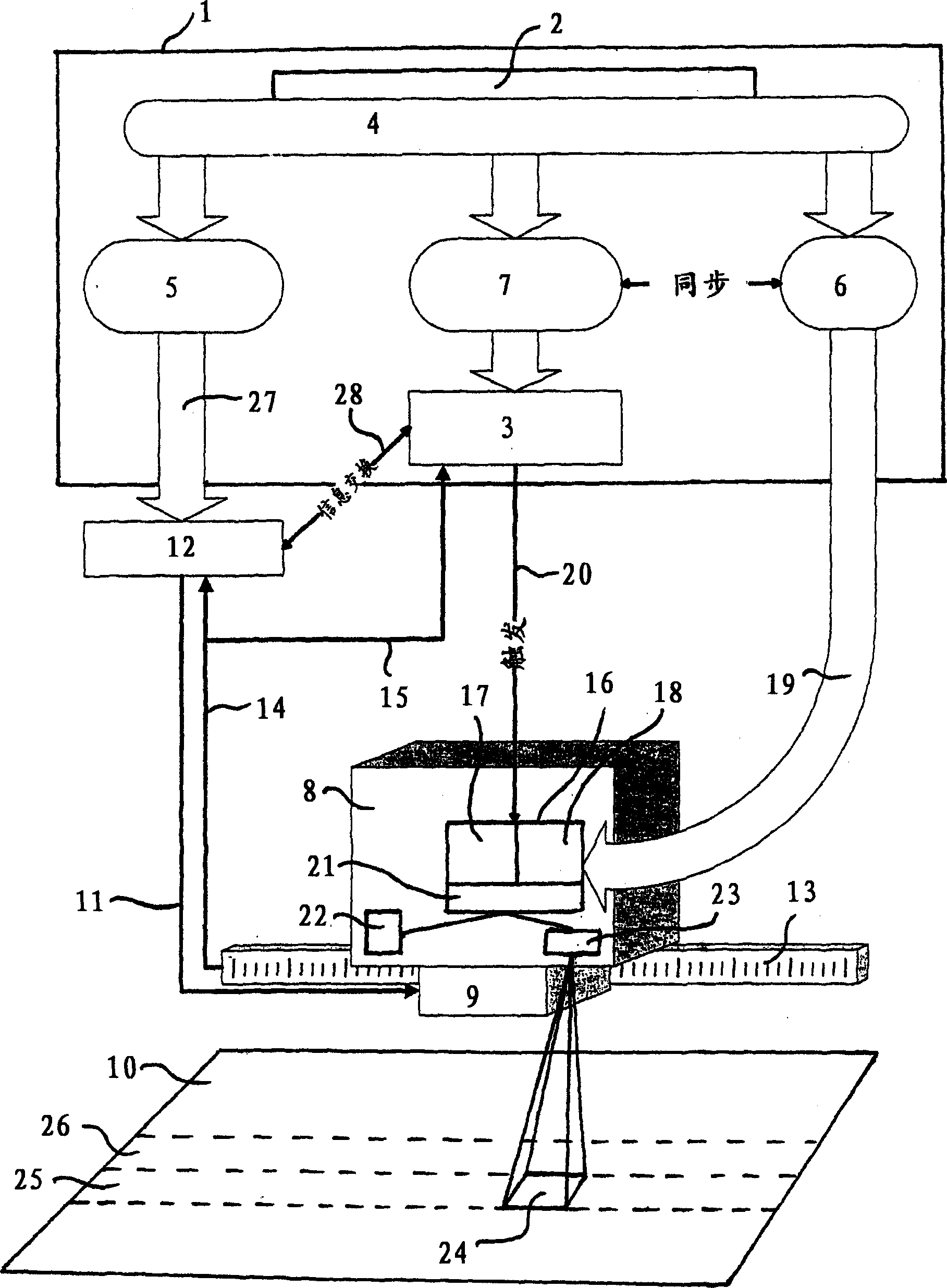

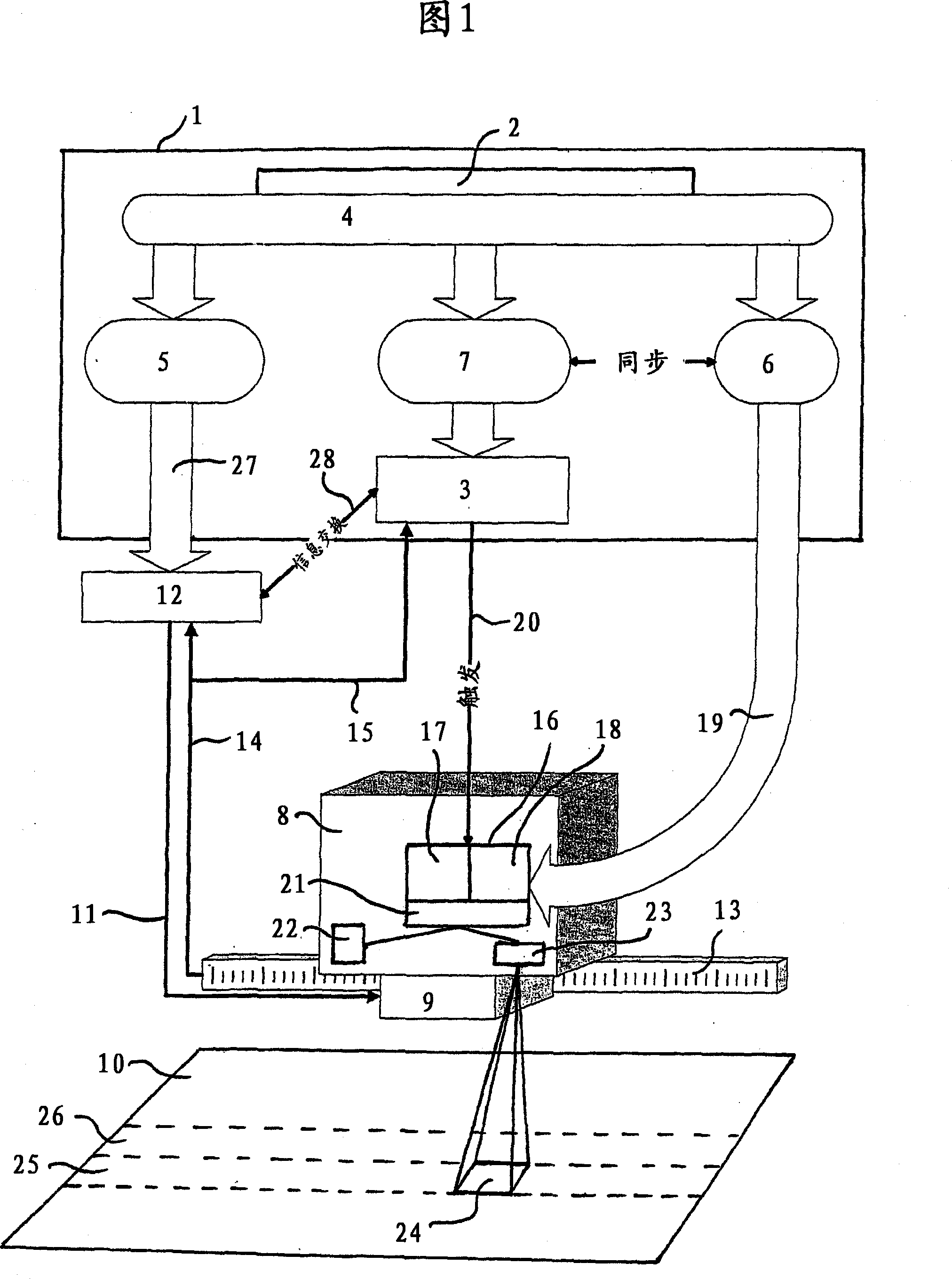

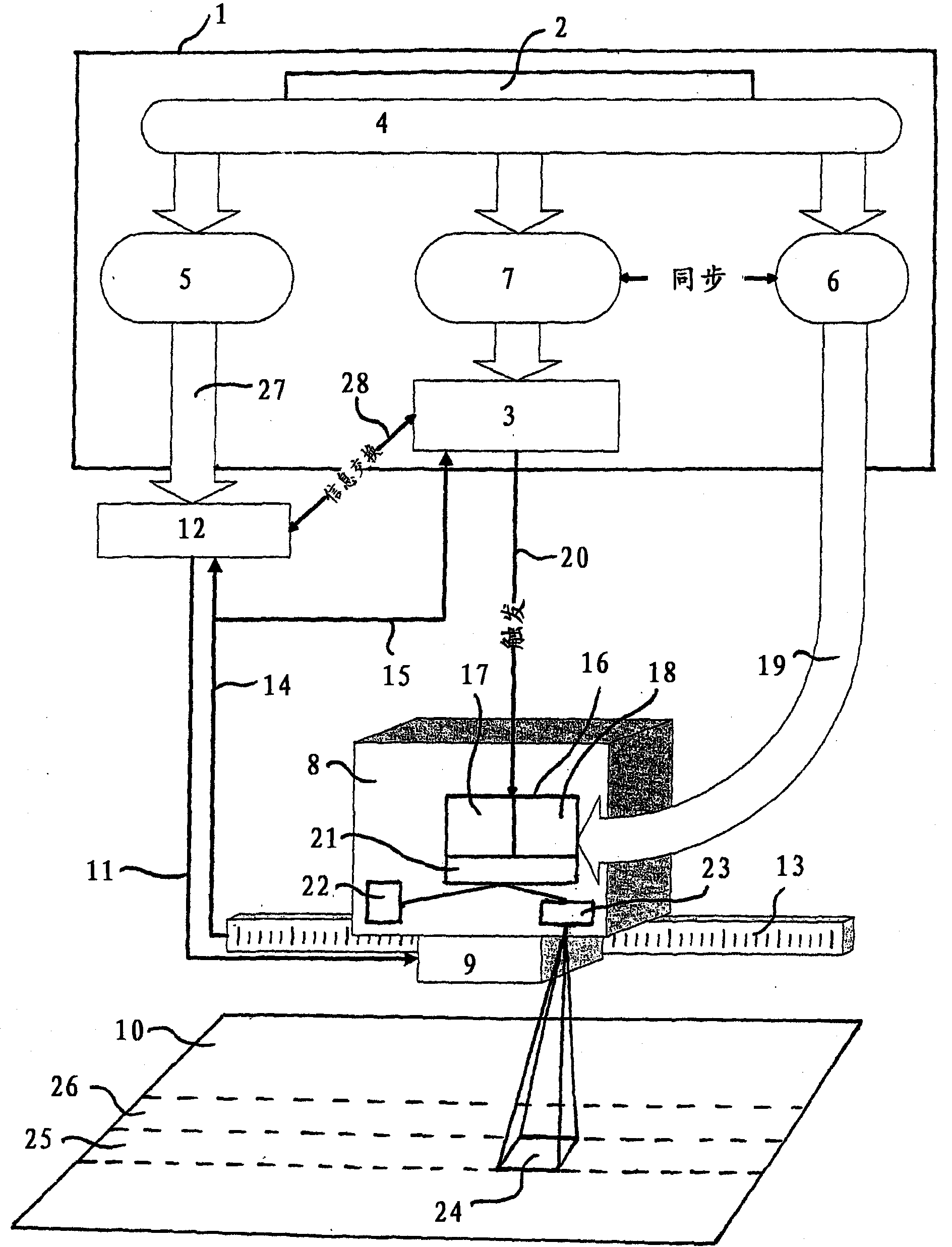

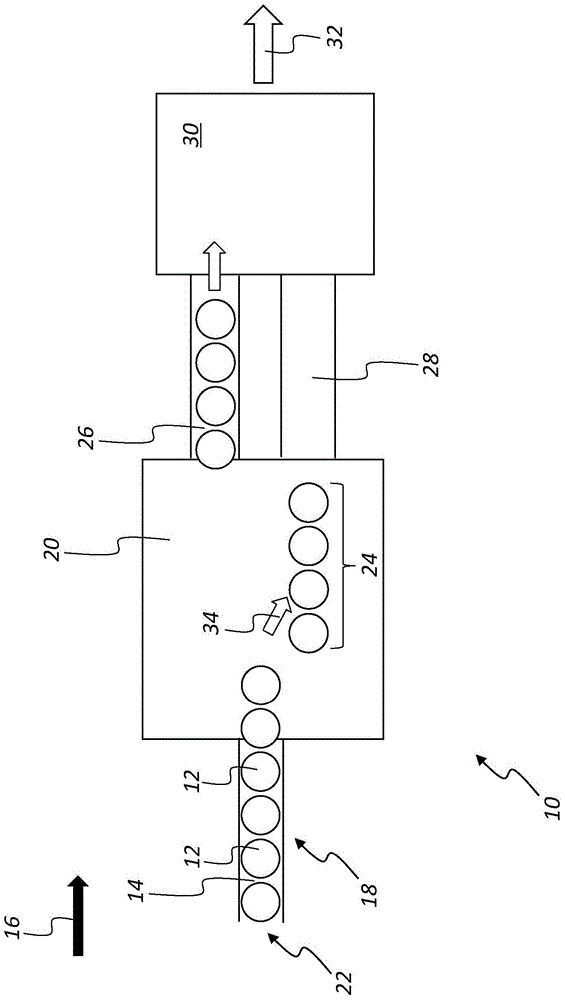

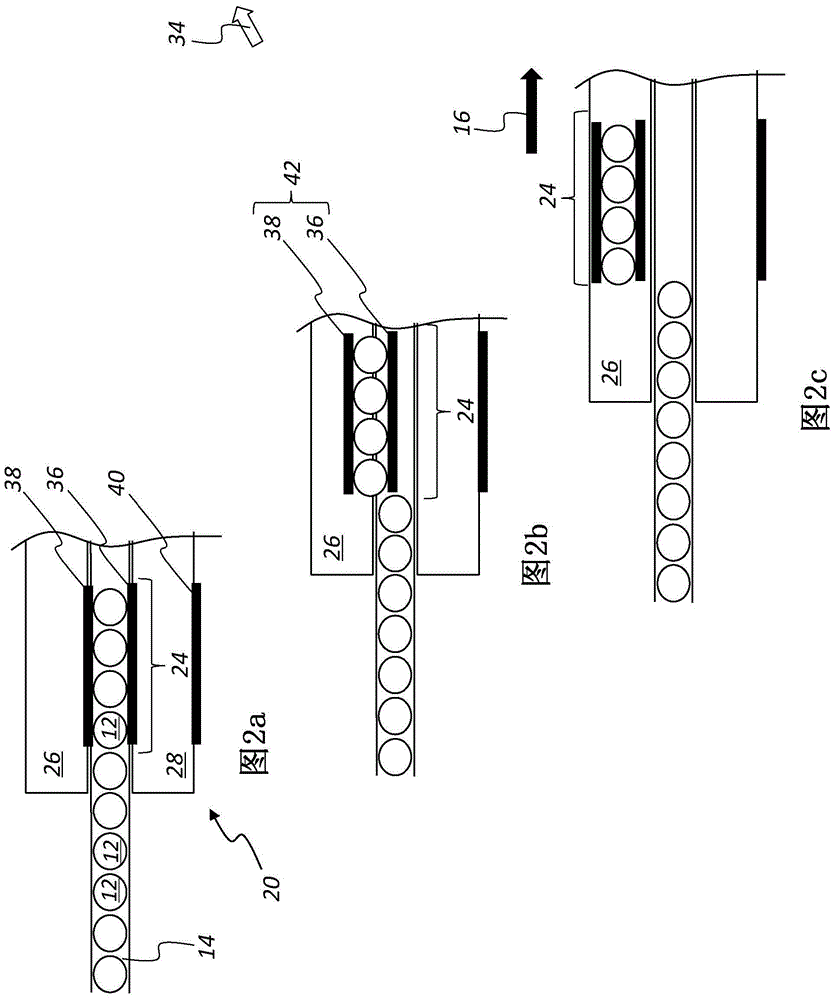

Device and method for digital exposure

InactiveCN1879114ALow costReduce susceptibility to interferenceVisual representatino by photographic printingPicture MemoryMotor control

The invention relates to a device for exposing light-sensitive materials, with an electronic picture memory ( 2 ) for storing a master image, with an exposure unit which comprises a light source ( 22 ), an electronically activatable light modulator ( 21 ) for representing a part picture ( 24 ) of the master image ( 2 ), and imaging optics ( 23 ) for the projection of the part picture ( 24 ) onto the light sensitive material ( 10 ), with a drive device consisting of motors ( 9 ) and of a motor control ( 12 ), for moving the exposure unit ( 8 ) parallel to the surface of the light-sensitive material ( 10 ), with a scroll means ( 7 ) for scrolling a picture strip ( 25, 26 ) of the master image through the light modulator ( 21 ), and with a control device ( 1 ) for synchronising the drive device ( 9, 12 ) with the scroll means ( 7 ). For reducing the processing time for the exposure of the complete printing plate ( 10 ), according to the invention, it is envisaged for a rapid intermediate memory ( 16 ) for storing a strip-like region to be provided, from which the picture data for the part picture ( 24 ) to be exposed, in each case, may be transmitted onto the light modulator ( 21 ) synchronously with the movement of the exposure unit ( 8 ).

Owner:赛康预压公司

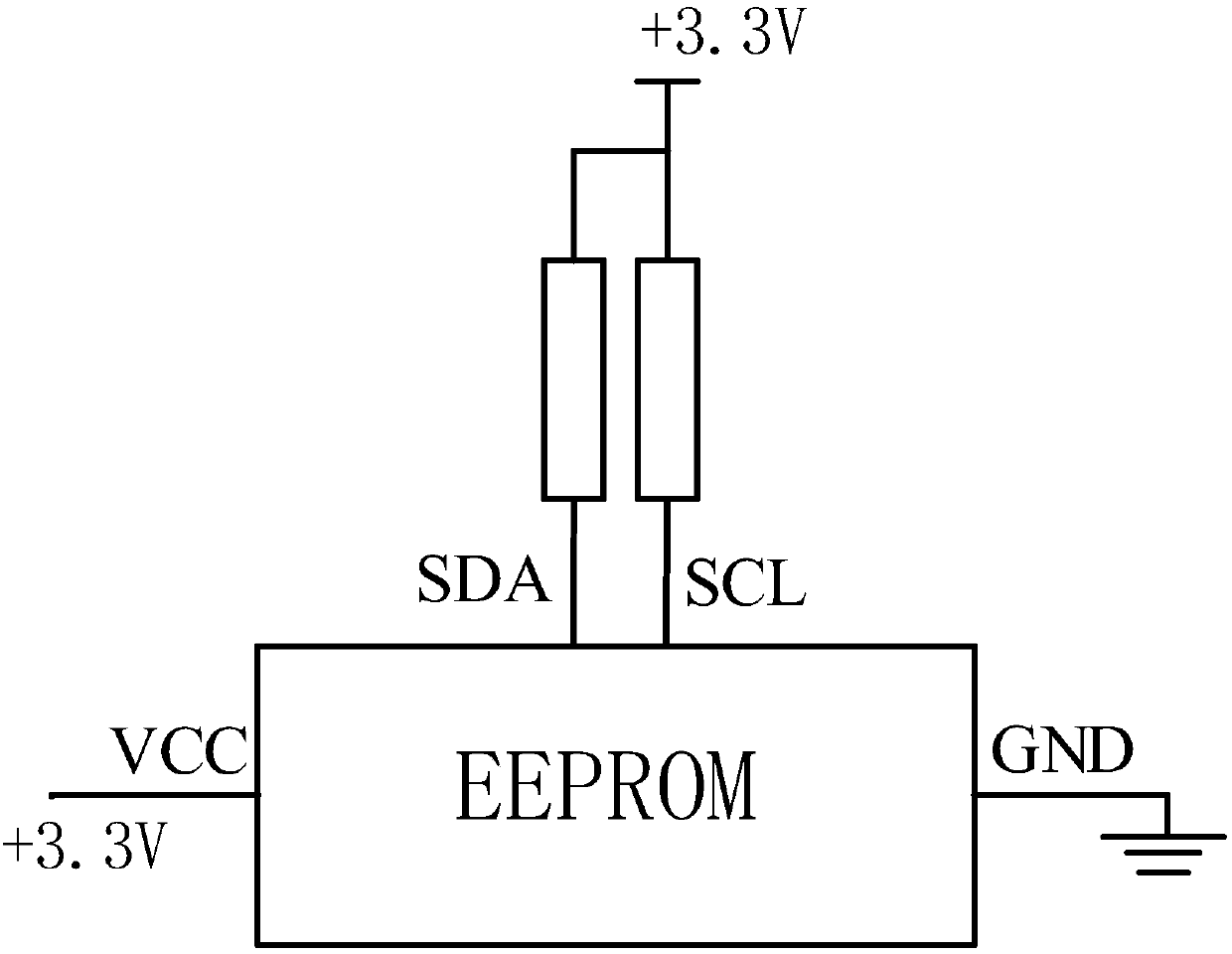

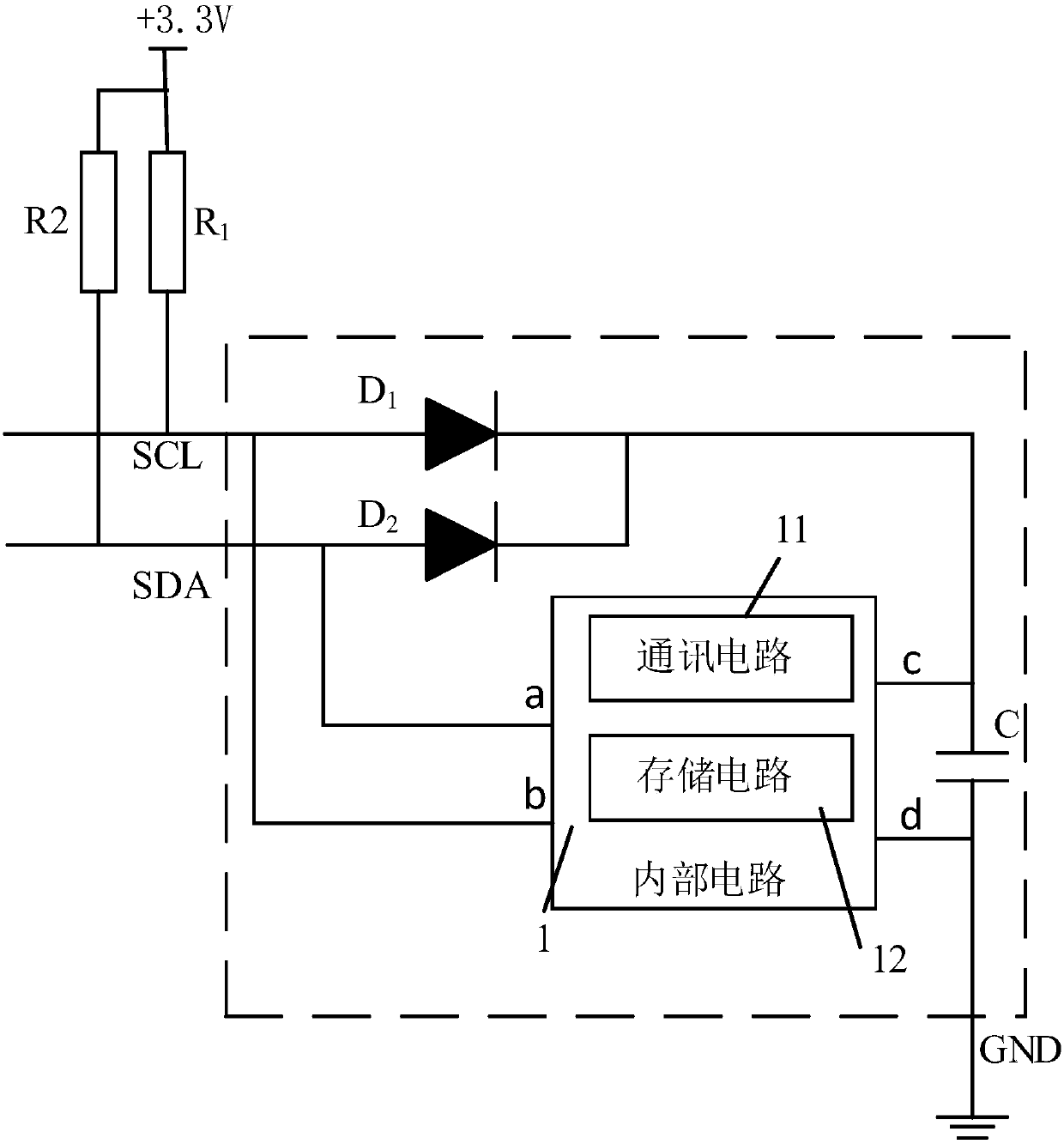

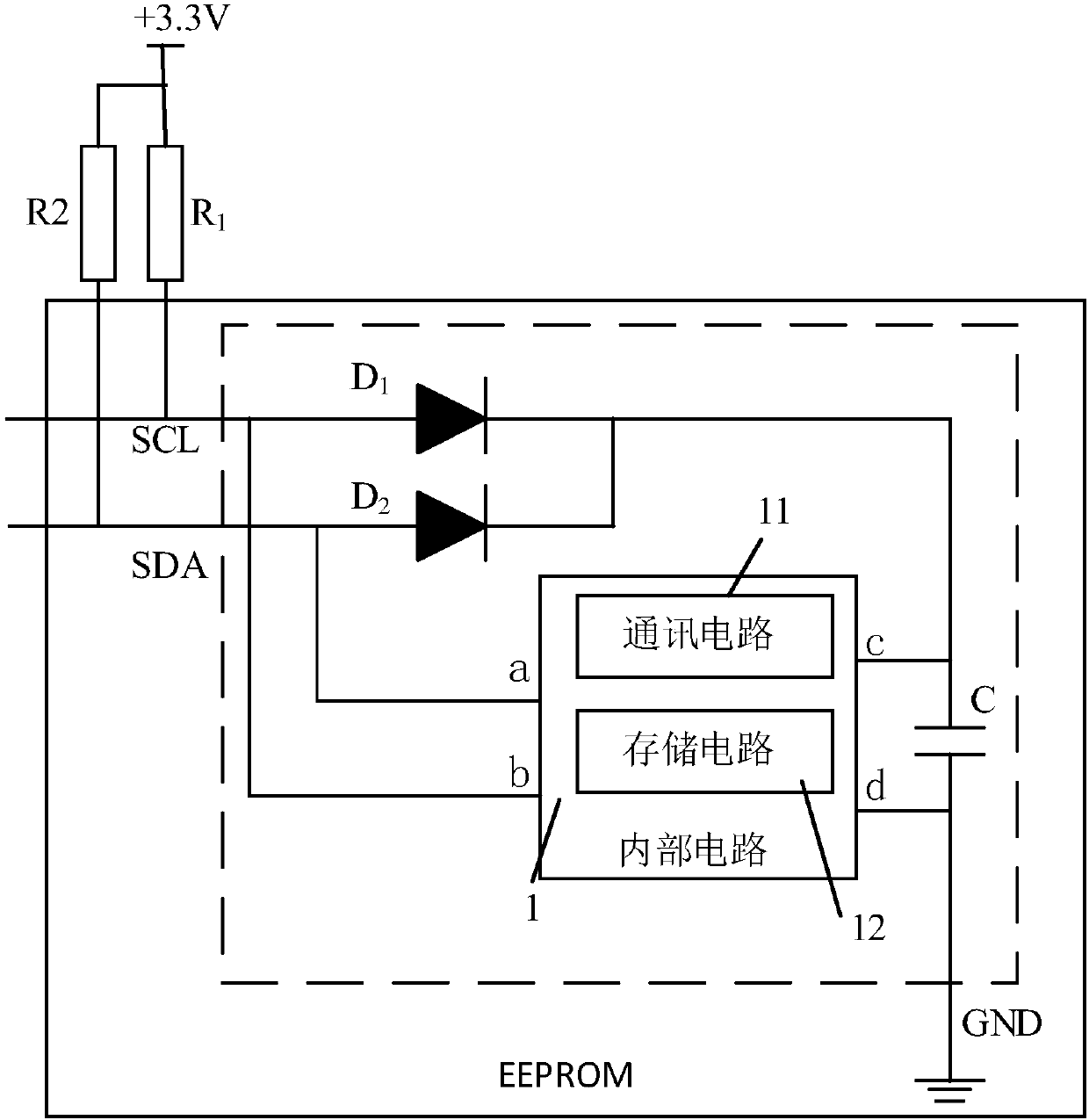

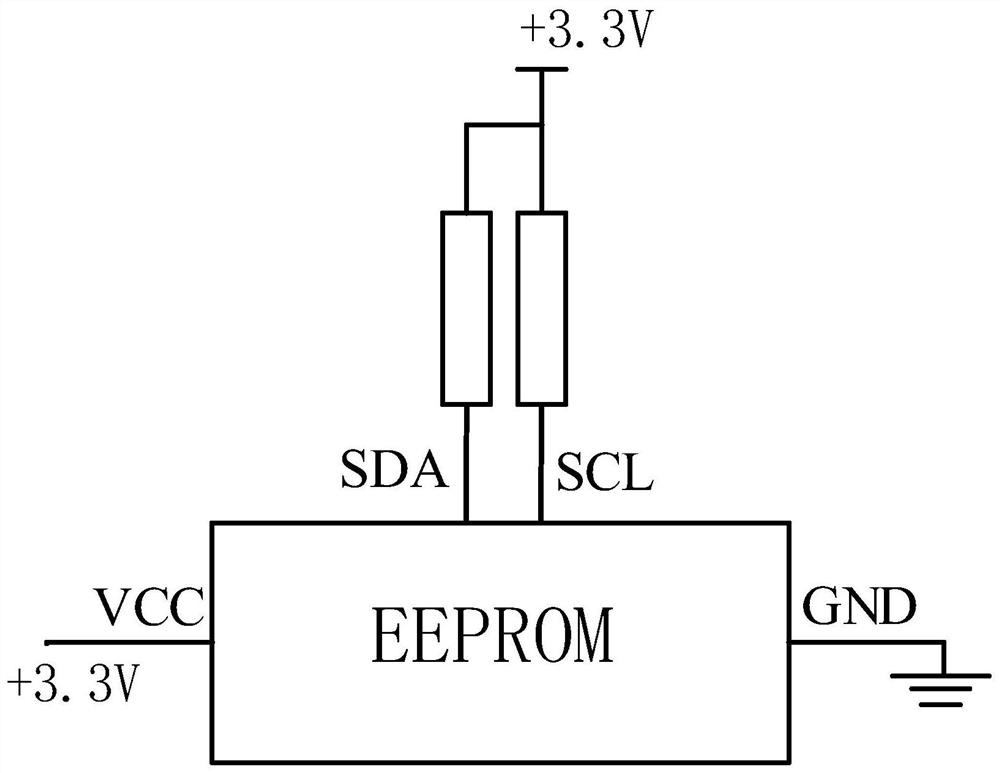

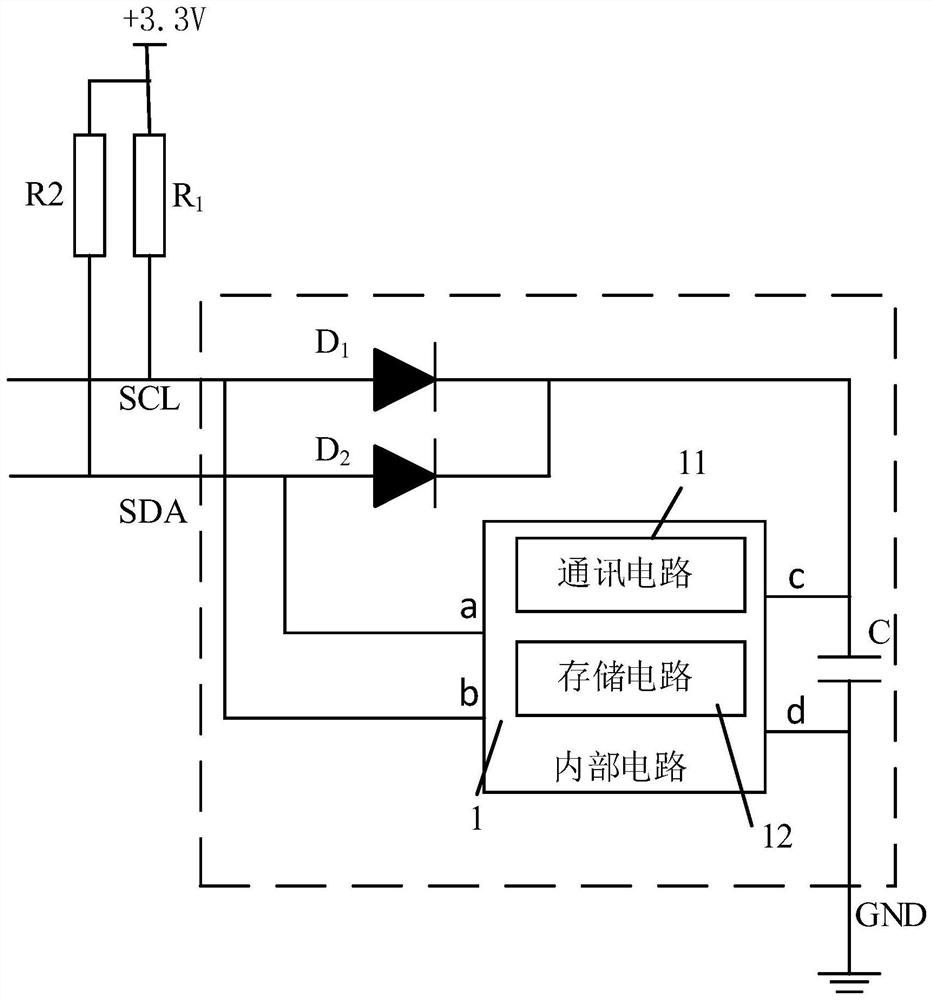

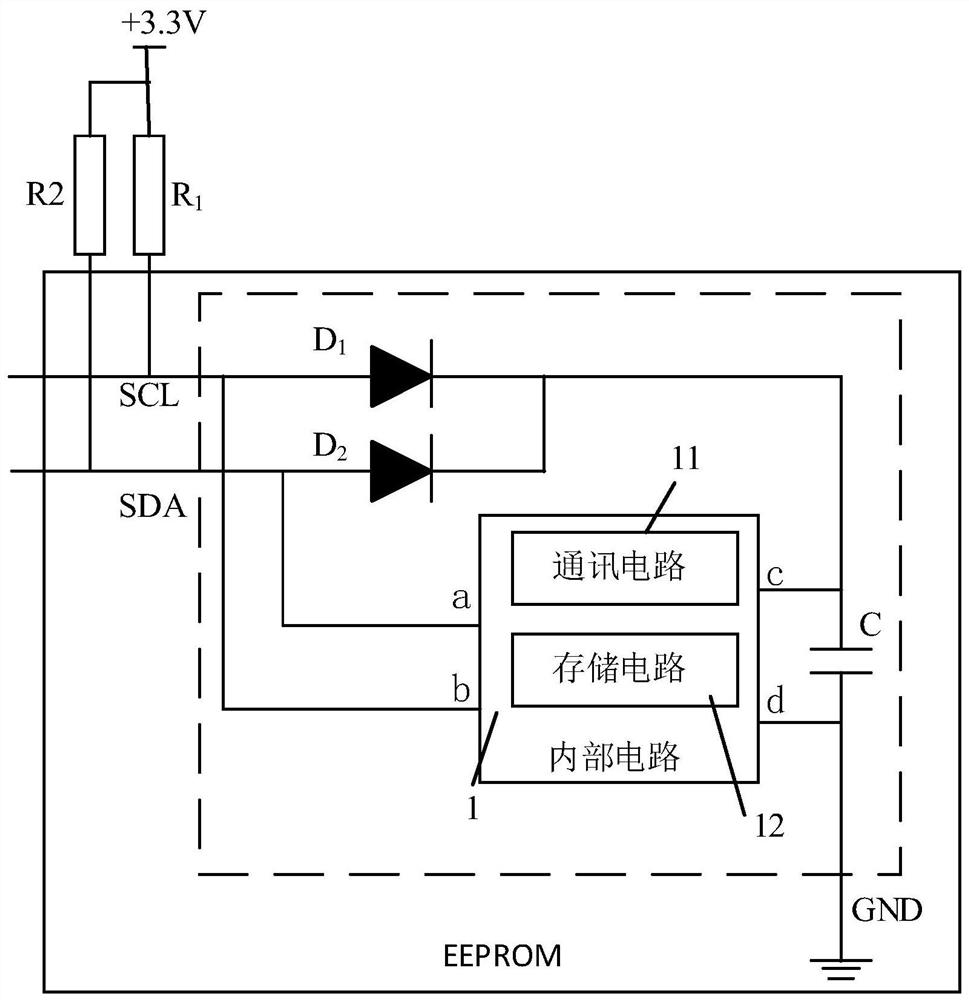

Power supply circuit of EEPROM (electrically erasable programmable read and write memory) and EEPROM

ActiveCN107610734AReduce susceptibility to interferenceEasy wiringRead-only memoriesCapacitanceHemt circuits

The invention discloses a power supply circuit of an EEPROM (electrically erasable programmable read and write memory) and the EEPROM. The EEPROM comprises a clock signal pin, a data signal pin and aground pin, and the power supply circuit comprises a first diode and a capacitor, wherein the clock signal pin is electrically connected with a positive electrode of the first diode and a clock signalinput end of an internal circuit; the data signal pin is electrically connected with a data signal input end of the internal circuit; one end of the capacitor is electrically connected with a negative electrode of the first diode and a power input end of the internal circuit, and the other end of the capacitor is electrically connected with the ground pin and a power output end of the internal circuit. The power supply circuit of the EEPROM and the EEPROM have the advantages that a working power supply is provided for the internal circuit of the EEPROM under the condition that one power supply line is omitted, and accordingly, the risk that the power supply line is easy to interfere due to being too long is avoided, and wiring is facilitated for a user.

Owner:SHANGHAI BEILING

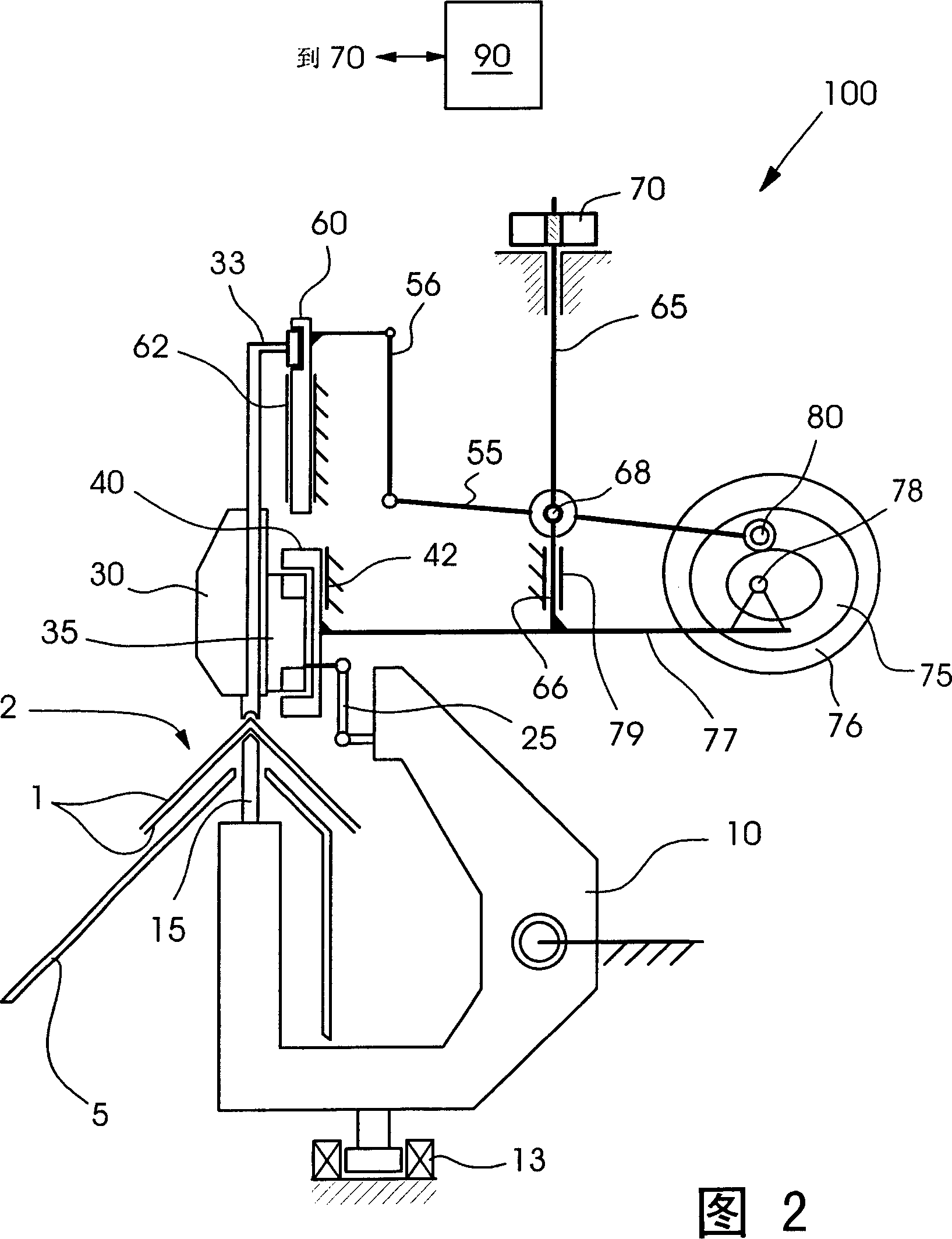

Stitching apparatus

InactiveCN100542921CRun fastReduce susceptibility to interferenceSheet bindingArticle deliveryEngineering

Owner:MULLER MARTINI HLDG

Arrangement for an uninterruptible power supply

InactiveCN103138339AReduce susceptibility to interferenceImprove reliabilityBatteries circuit arrangementsElectric powerUninterruptible power supplyRectifier

An uninterruptible power supply with a rectifier, energy store for storing electrical energy, inverter, switching means and a controller is provided. The rectifier is connected to a rectifier input to a supply grid, wherein the energy store is connected to a rectifier output and to an inverter input of the inverter. A network or load to be protected is connected to an inverter output of the inverter. The rectifier input or a supply grid is connected via the switching means to the inverter output. The rectifier, the inverter and the switching means are controlled by the controller. The arrangement includes means for supplying auxiliary current. Each means for supplying auxiliary current is connected with an input for the supplying auxiliary current to the first control part and an input for supplying auxiliary current to the second control part, for supplying the control parts with electric energy.

Owner:AEG POWER SOLUTIONS BV

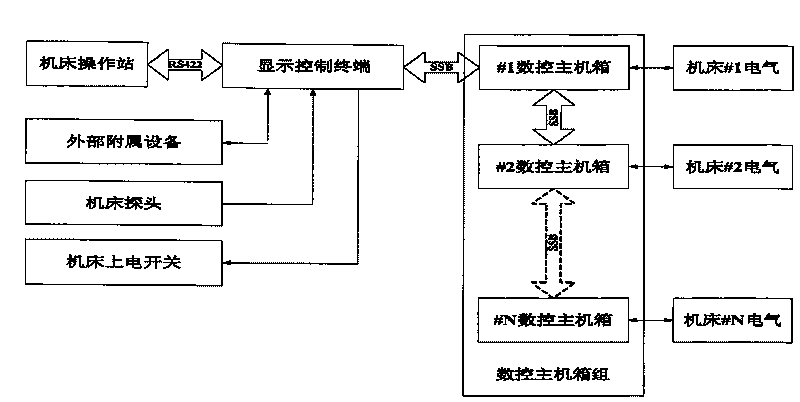

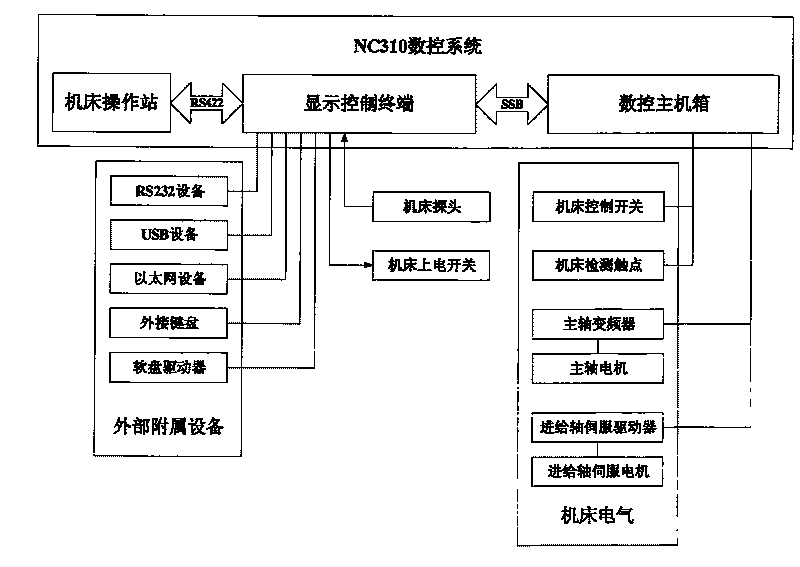

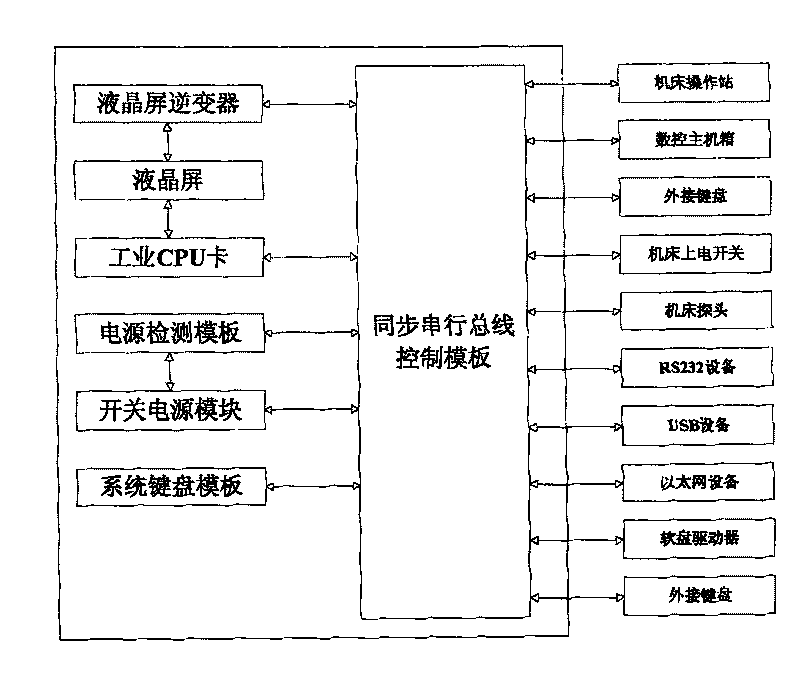

Synchronous serial bus type numerical control system

ActiveCN101329570BCycle times are fast and efficientQuick response cycleNumerical controlAnti jammingControl signal

Owner:SHENYANG GOLDING NC & INTELLIGENCE TECH CO LTD

Device and method for digital exposure

InactiveCN1879114BLow costReduce susceptibility to interferenceVisual representatino by photographic printingPicture MemoryMotor control

The invention relates to a device for exposing light-sensitive materials, with an electronic picture memory ( 2 ) for storing a master image, with an exposure unit which comprises a light source ( 22 ), an electronically activatable light modulator ( 21 ) for representing a part picture ( 24 ) of the master image ( 2 ), and imaging optics ( 23 ) for the projection of the part picture ( 24 ) onto the light sensitive material ( 10 ), with a drive device consisting of motors ( 9 ) and of a motor control ( 12 ), for moving the exposure unit ( 8 ) parallel to the surface of the light-sensitive material ( 10 ), with a scroll means ( 7 ) for scrolling a picture strip ( 25, 26 ) of the master image through the light modulator ( 21 ), and with a control device ( 1 ) for synchronising the drive device ( 9, 12 ) with the scroll means ( 7 ). For reducing the processing time for the exposure of the complete printing plate ( 10 ), according to the invention, it is envisaged for a rapid intermediatememory ( 16 ) for storing a strip-like region to be provided, from which the picture data for the part picture ( 24 ) to be exposed, in each case, may be transmitted onto the light modulator ( 21 ) synchronously with the movement of the exposure unit ( 8 ).

Owner:赛康预压公司

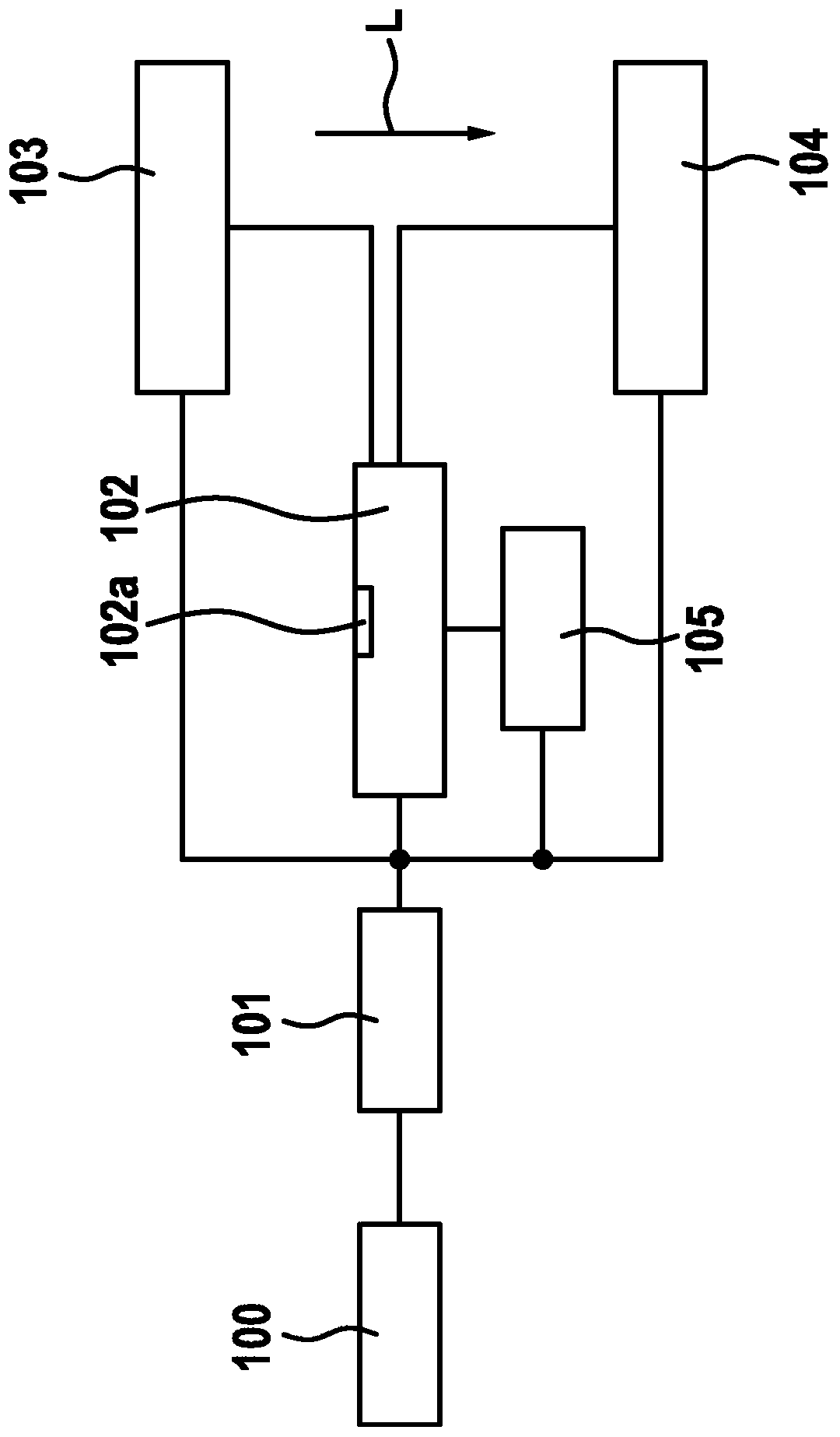

Injection device and corresponding injection measurement method

ActiveCN111032127ASave spaceLow costAmpoule syringesAutomatic syringesInjection equipmentOptical transducers

The invention relates to an injection device and a corresponding injection measurement method. The injection device is equipped with: a pin-like shell (3) for receiving a cartridge holder (2); an injection mechanism, which is provided in the pin-like shell (3) and which has a dosing sleeve (4), by means of which a dosing quantity to be injected can be predefined and which is designed in such a waythat it performs a rotary movement during the injection; a selector apparatus (5a) connected to the dosing sleeve (4) for setting the dosing quantity to be injected; an injection button (6a) connected to the selector apparatus (5a) for applying an injection force; and an optical sensor apparatus (100-105) for detecting the rotary movement of the dosing sleeve (4) during the injection of the dosing quantity, which sensor apparatus has a signal processing apparatus (102) for determining and storing the injected dosing quantity on the basis of the detected rotary movement of the dosing sleeve (4). The injection button (6a) has a switch apparatus (101) sensor apparatus (100-105), by means of which the optical sensor apparatus (100-105) can be activated as the injection force is applied.

Owner:ROBERT BOSCH GMBH

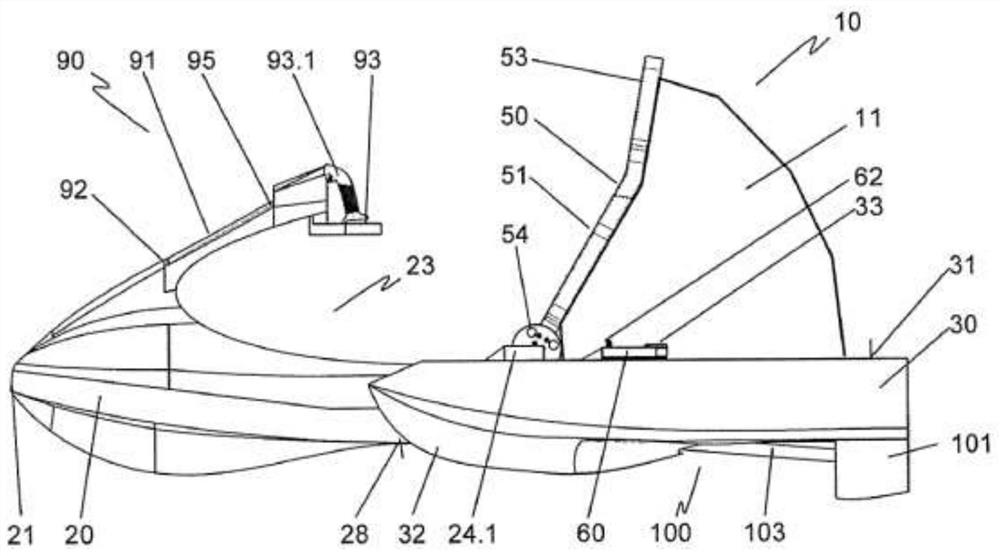

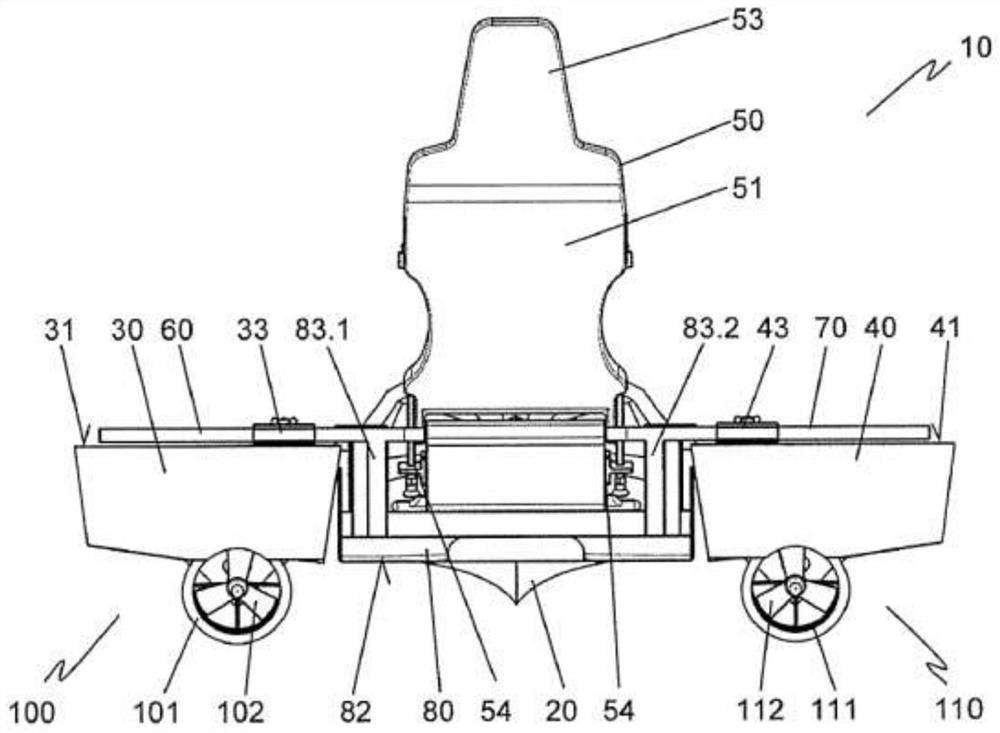

jet ski

ActiveCN108137126BReduce susceptibility to interferenceImprove operational reliabilitySteering ruddersPropulsion power plantsControl signalControl engineering

The invention relates to a jet ski having a hull, at least one seat and two booms arranged on the sides of the hull and connected indirectly or directly to the hull, wherein each boom is assigned a drive power that can be allocated to it. Separately actuated drive units each having at least one propeller driven by a motor, in particular an electric motor. Provision is made for this to connect the controller of the jet ski to the proportional encoder and to feed the control signal of the proportional encoder to the control unit, which indirectly or directly actuates the motor as a function of the control signal of the proportional encoder. A precisely controllable and thus easily dismantled watercraft is thereby provided.

Owner:CAYAGO

Method for operating an electric fan motor

InactiveCN103717852AEliminate stickinessExtended service lifeCoolant flow controlMachines/enginesEngineeringInternal combustion engine

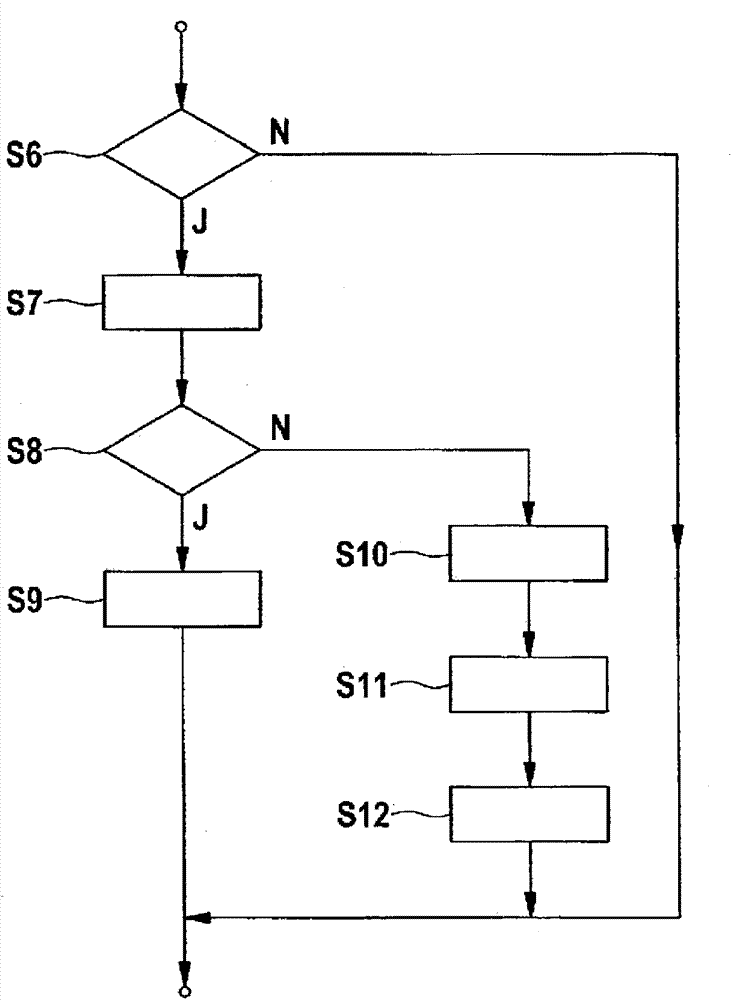

A method for actuating an electric fan motor for an internal combustion engine of a motor vehicle, comprising the steps: - determining an operating duration during which the fan motor is operated below a rotational speed which is critical with regard to pasting; - wherein if the operating duration exceeds a duration which is critical with regard to pasting, the fan motor is operated for a defined time duration at a washing rotational speed which is higher than the rotational speed which is critical with regard to pasting.

Owner:ROBERT BOSCH GMBH

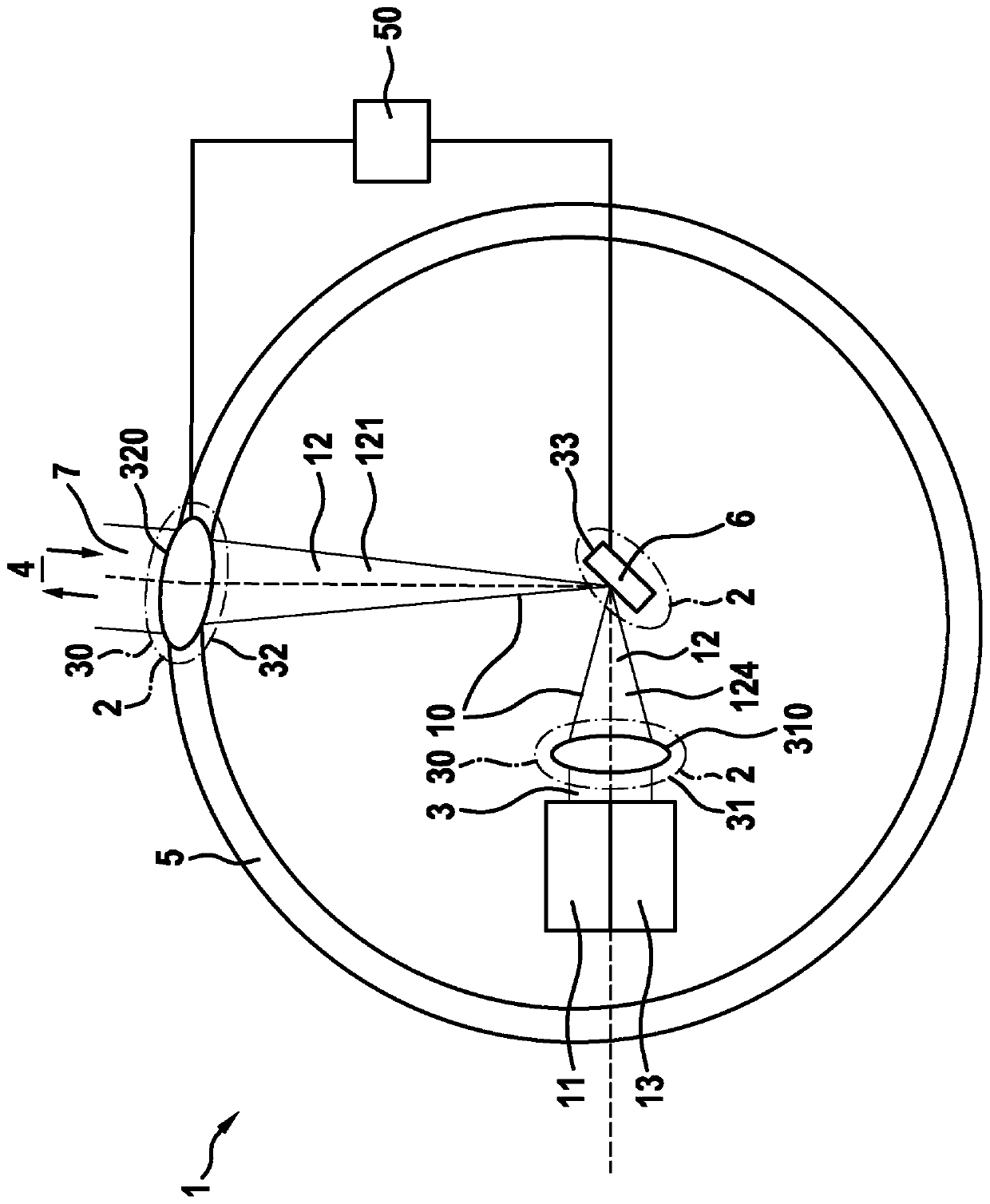

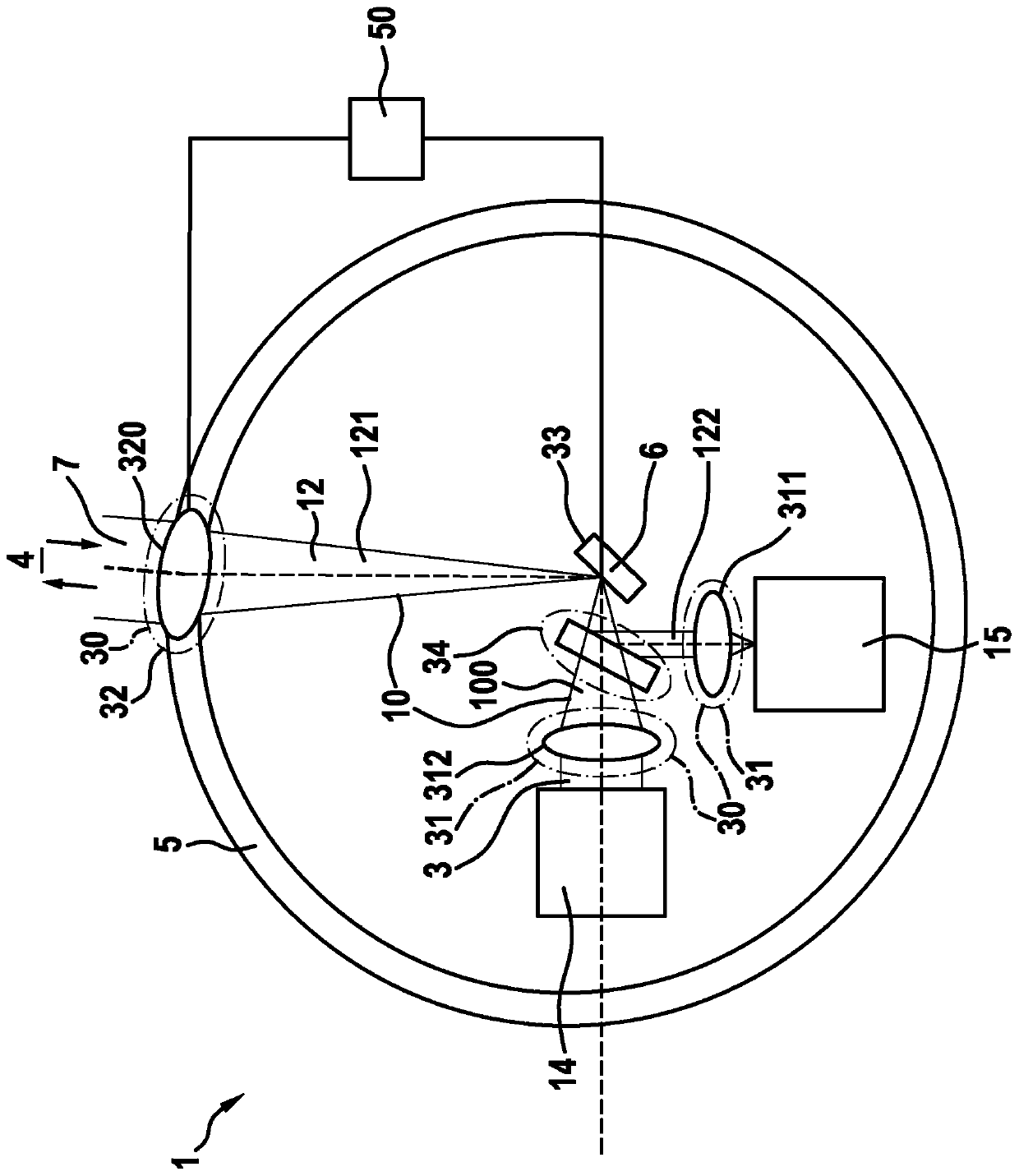

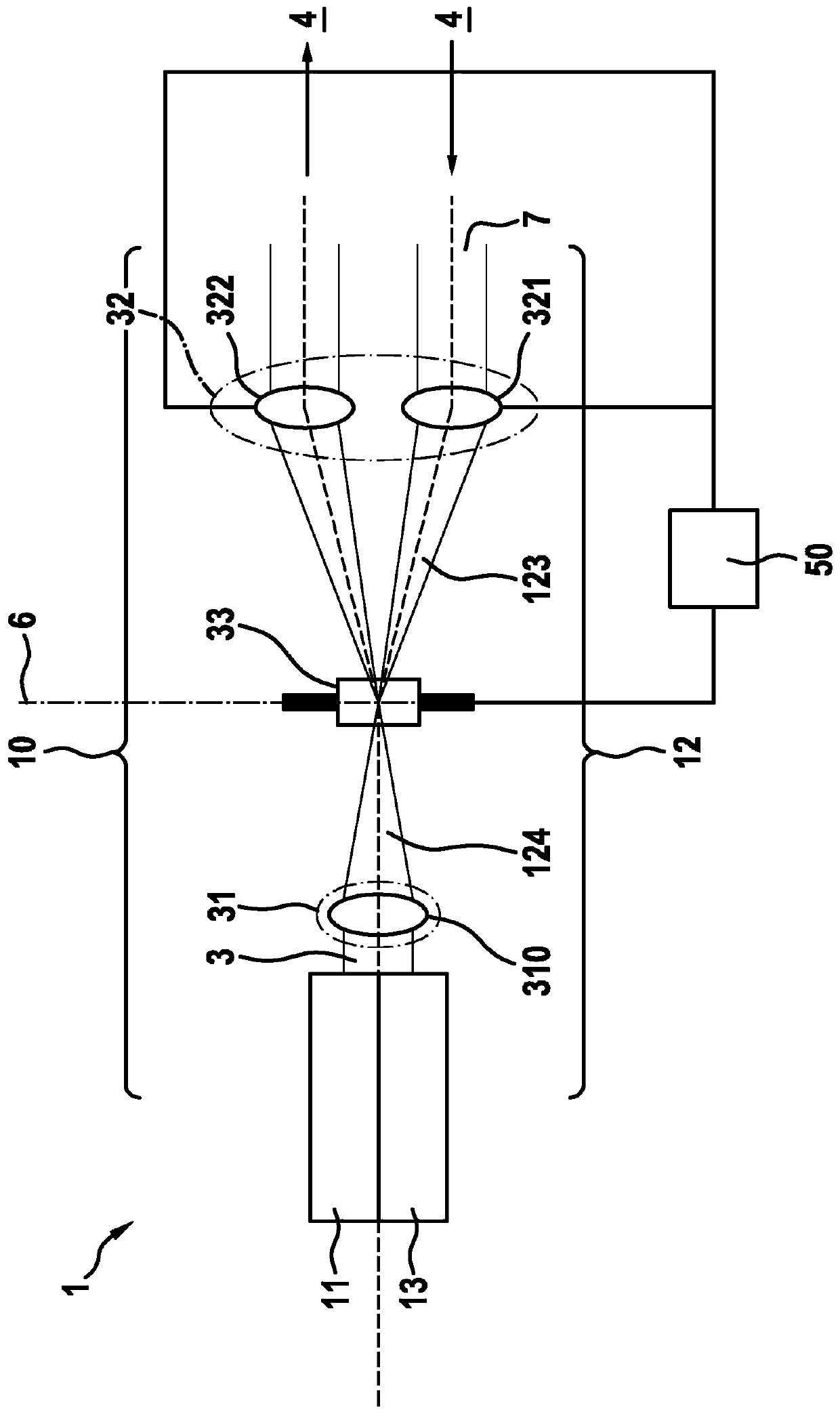

Scanning system and transmitting and receiving device for a scanning system

PendingCN111095019AReduce susceptibility to interferenceImprove reliabilityElectromagnetic wave reradiationOptical axisBeam diameter

The invention relates to a scanning system (1), having a transmitting path (10), a receiving path (12), a transmitter (11), a receiver (13) and a rotating scanning device (2). The transmitter (11) emits radiation (3), which propagates along an optical axis on the transmitting path (10). The radiation (7) received from the target object (4) is detected by the receiver (13) on the receiving path (12). Furthermore, the rotating scanning device (2) comprises an optical unit (30) and a rotating deflecting unit (33), which deflects the radiation of the transmitting path (10) and of the receiving path (12). The optical unit (30) has a first focusing apparatus (31) and a rotating second focusing apparatus (32). The movements of the rotating deflecting unit (33) and of the rotating second focusingapparatus (32) occur synchronously in order to ensure alignment of the deflected radiation with the second focusing apparatus (32). Furthermore, the first focusing apparatus (31) images the radiation(3) emitted by the transmitter (11) onto the rotating deflecting unit (33) in such a way that the beam diameter at the rotating deflecting unit (33) is reduced. In addition, the rotating deflecting unit (33) deflects the radiation (3) onto the rotating second focusing apparatus (32), and the rotating second focusing apparatus (32) collimates the radiation (3) toward the target object (4). The rotating second focusing apparatus (32) images the radiation (7) received from the target object (4) onto the rotating deflecting unit (33) in such a way that the beam diameter at the rotating deflectingunit (33) is reduced, and the rotating deflecting unit (33) deflects the received radiation (7) to the receiver (13).

Owner:ROBERT BOSCH GMBH

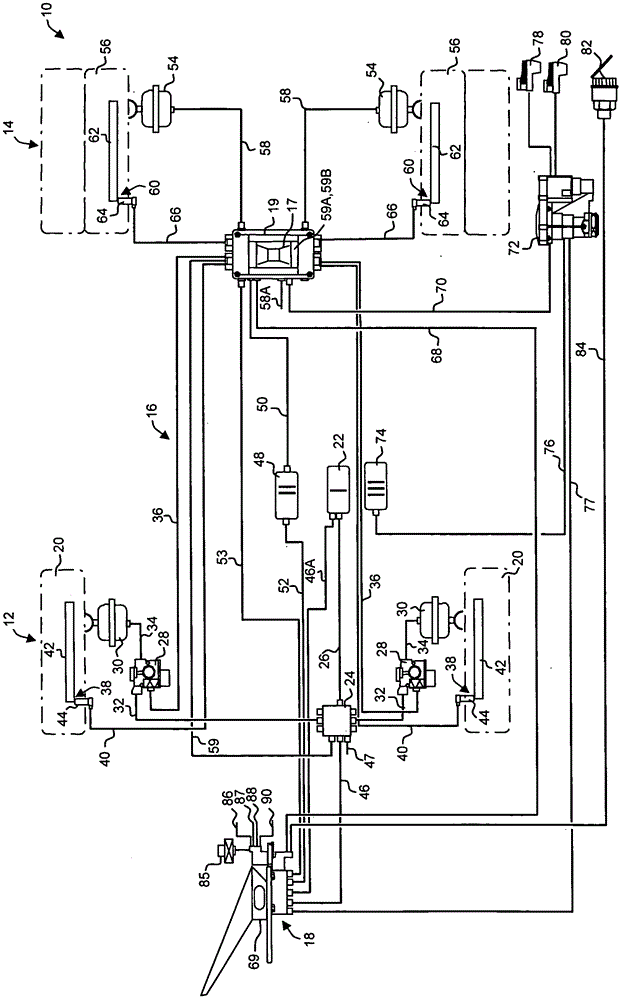

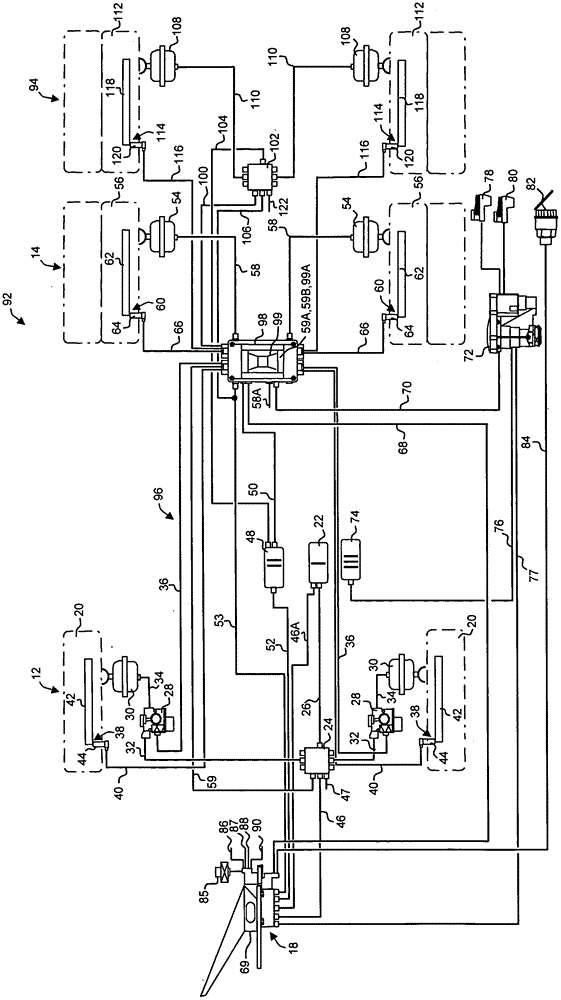

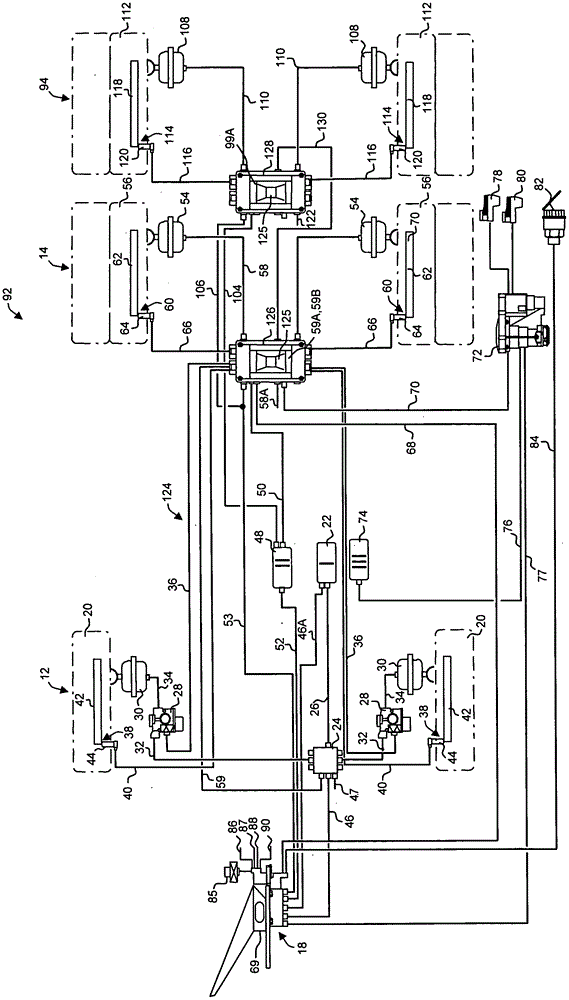

Controller for vehicle braking system and braking system with the same

ActiveCN102470848BReduce the number of linesFlexible sheddingBraking action transmissionAntenna adaptation in movable bodiesAir springBraking system

The invention relates to a controller for a braking system of a vehicle (10; 92; 132; 238), wherein the vehicle (10; 92; 132; 238) has a support structure (222; 240) and consists of the support structure (222; 240) a vehicle cabin (224; 242) supported by at least one driver's seat (226), wherein the controller is arranged outside the vehicle cabin (224; 242) on a support structure (222; 240), The controller has additional functionality for controlling the electronic air spring system.

Owner:ZF CV SYST EURO BV

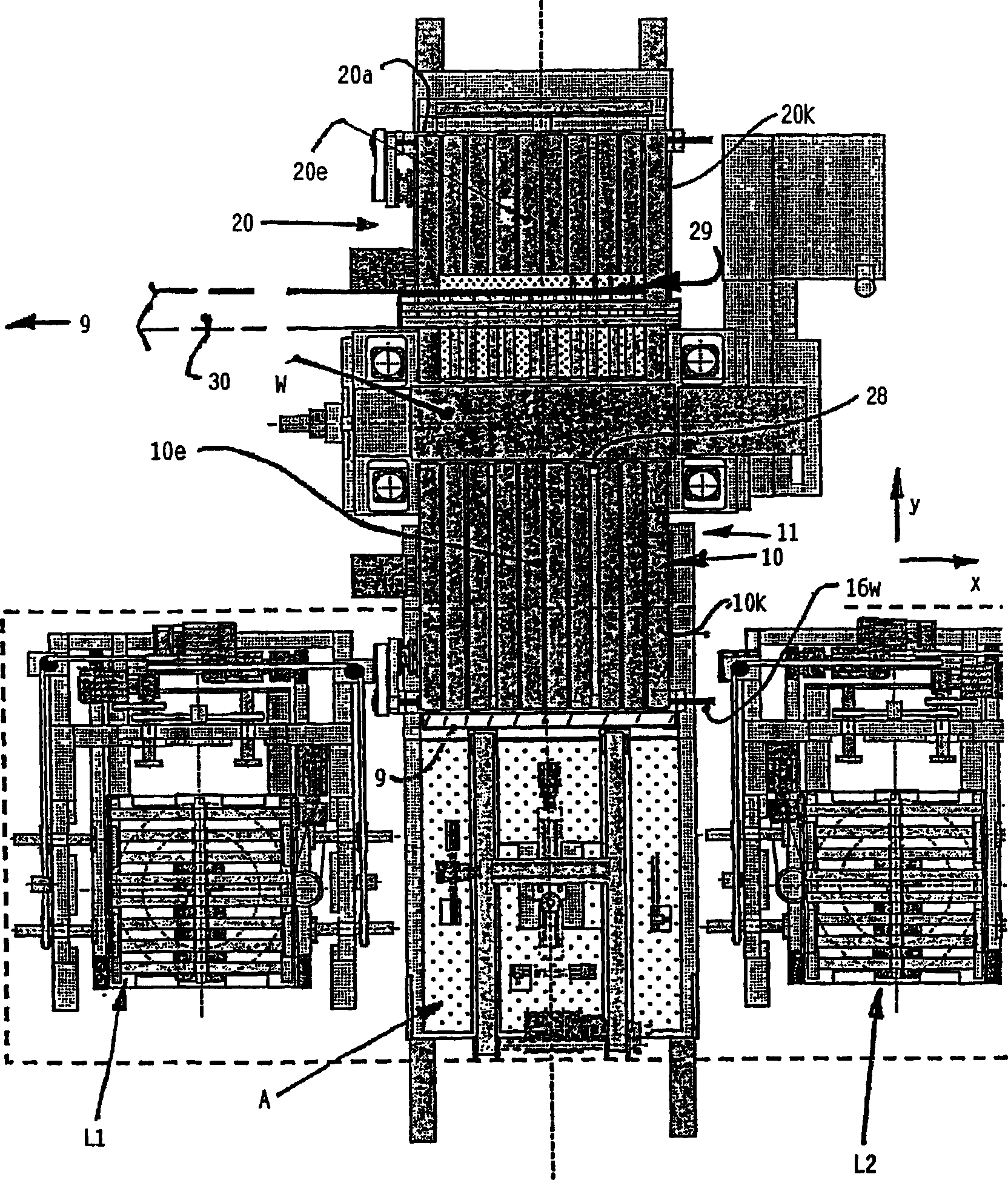

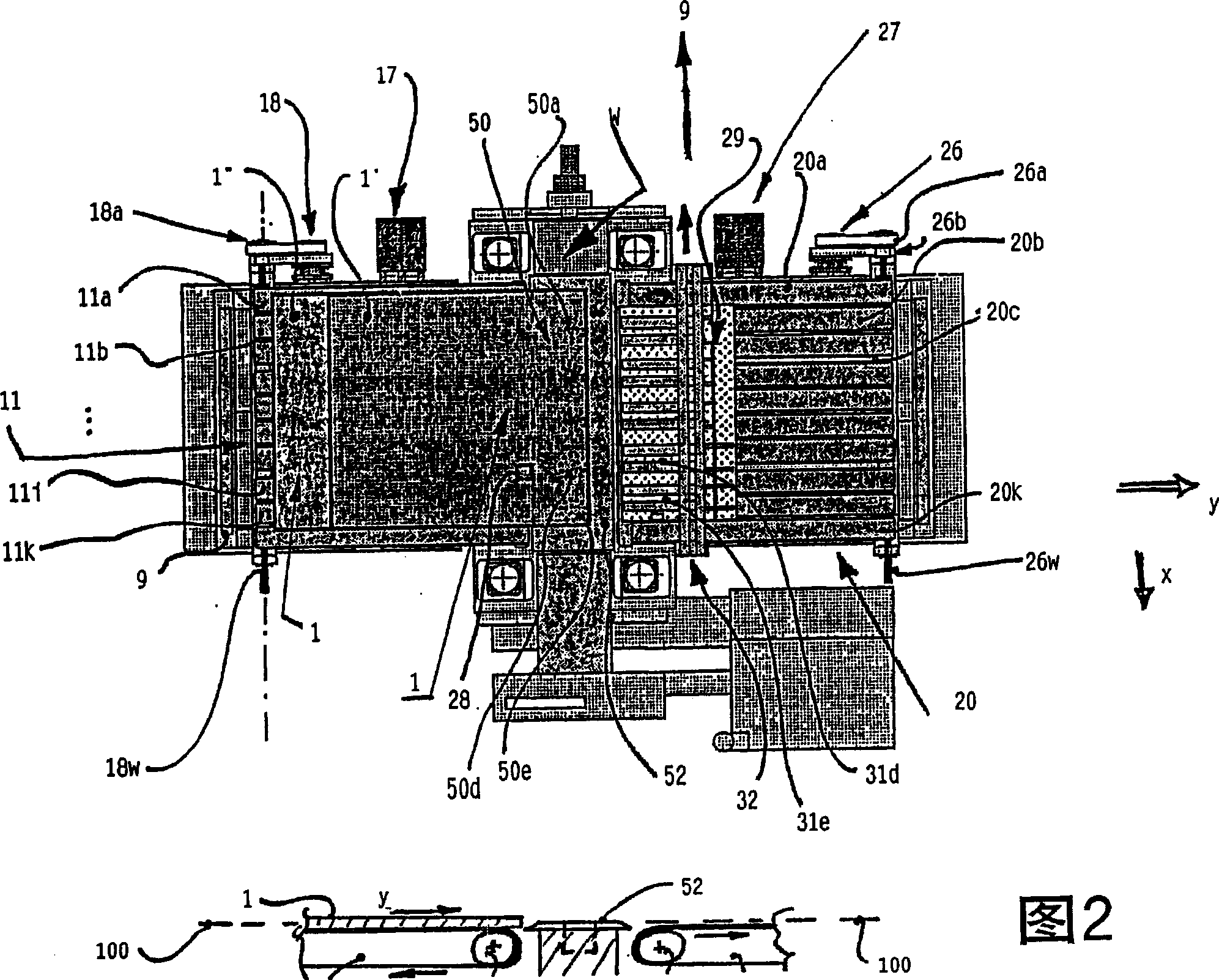

High-speed sheet feeding without grip pliers

InactiveCN1907592AGuaranteed continuous supplyWill not deformConveyorsMetal-working feeding devicesSheet steelControl manner

The invention concerns a conveying device for sheet steel plates and for moving several sheets (1, 1') inside or through a working zone (W; 50) wherein the sheets are machined. The inventive feeding device comprises first and second sheet feeders (10, 11; 20) which feed the sheets in controlled manner to the working zone (W) so that the sheets are machined with positional accuracy. The first sheet feeder (10, 11) is located on an input side of the tool zone and the second sheet feeder (20) is located on an output side of the tool zone. The two sheet feeders (10, 20; 11; 20) are mutually synchronized in their movements (x, y) when feeding forward the sheet (1), the sheet driven by the synchronous movement being maintained by the two sheet feeders. The invention provides the advantages of increased speed and safety. It is possible to increase the speed without the sheet being deformed or losing its flatness.

Owner:EMCO GMBH

Grouping method and grouping device

Owner:KRONES AG

eeprom power supply circuit and eeprom

ActiveCN107610734BReduce susceptibility to interferenceEasy wiringRead-only memoriesCapacitanceElectrical connection

The invention discloses a power supply circuit of an EEPROM (electrically erasable programmable read and write memory) and the EEPROM. The EEPROM comprises a clock signal pin, a data signal pin and aground pin, and the power supply circuit comprises a first diode and a capacitor, wherein the clock signal pin is electrically connected with a positive electrode of the first diode and a clock signalinput end of an internal circuit; the data signal pin is electrically connected with a data signal input end of the internal circuit; one end of the capacitor is electrically connected with a negative electrode of the first diode and a power input end of the internal circuit, and the other end of the capacitor is electrically connected with the ground pin and a power output end of the internal circuit. The power supply circuit of the EEPROM and the EEPROM have the advantages that a working power supply is provided for the internal circuit of the EEPROM under the condition that one power supply line is omitted, and accordingly, the risk that the power supply line is easy to interfere due to being too long is avoided, and wiring is facilitated for a user.

Owner:SHANGHAI BEILING

Piston-Cylinder Assembly

ActiveCN105593553BReduce in quantityReduce susceptibility to interferenceFluid actuated clutchesCouplingsMaster cylinderSensor system

The invention relates to a plunger-cylinder assembly, in particular for a master cylinder of a clutch actuating system in a motor vehicle, having a plunger which is arranged axially movably in a cylinder which is configured as a housing, and having a sensor system which is arranged on the housing and is operatively connected to a sensor constituent part which is fastened to the plunger. In a plunger-cylinder assembly, in which the assembly is simplified by way of a reduction in the interfaces, the sensor system is positioned on a leadframe assembly which is integrated into the plastic housing.

Owner:SCHAEFFLER TECH AG & CO KG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com