System for cooling coil

A winding and winding head technology, applied in electric components, electromechanical devices, electrical components, etc., can solve the problems of insufficient cooling of the winding head and low air thermal conductivity, and achieve long service life, enhanced firmness, and low susceptibility to interference. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

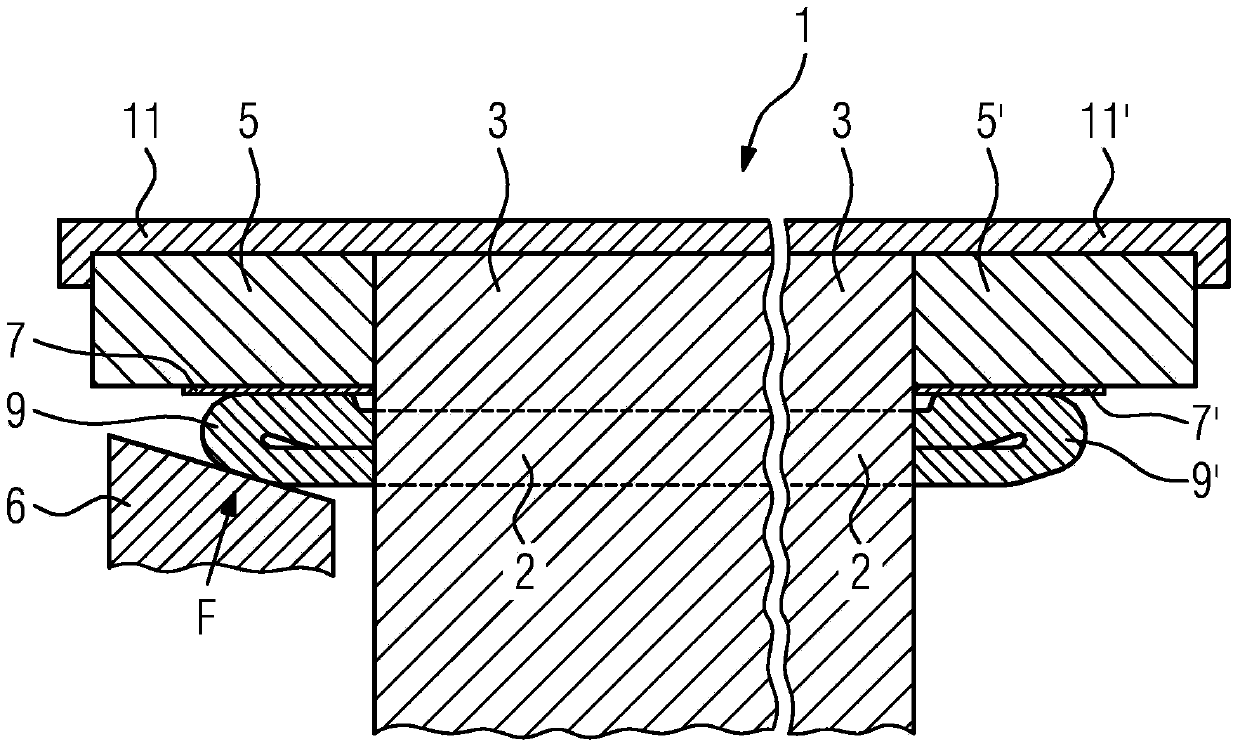

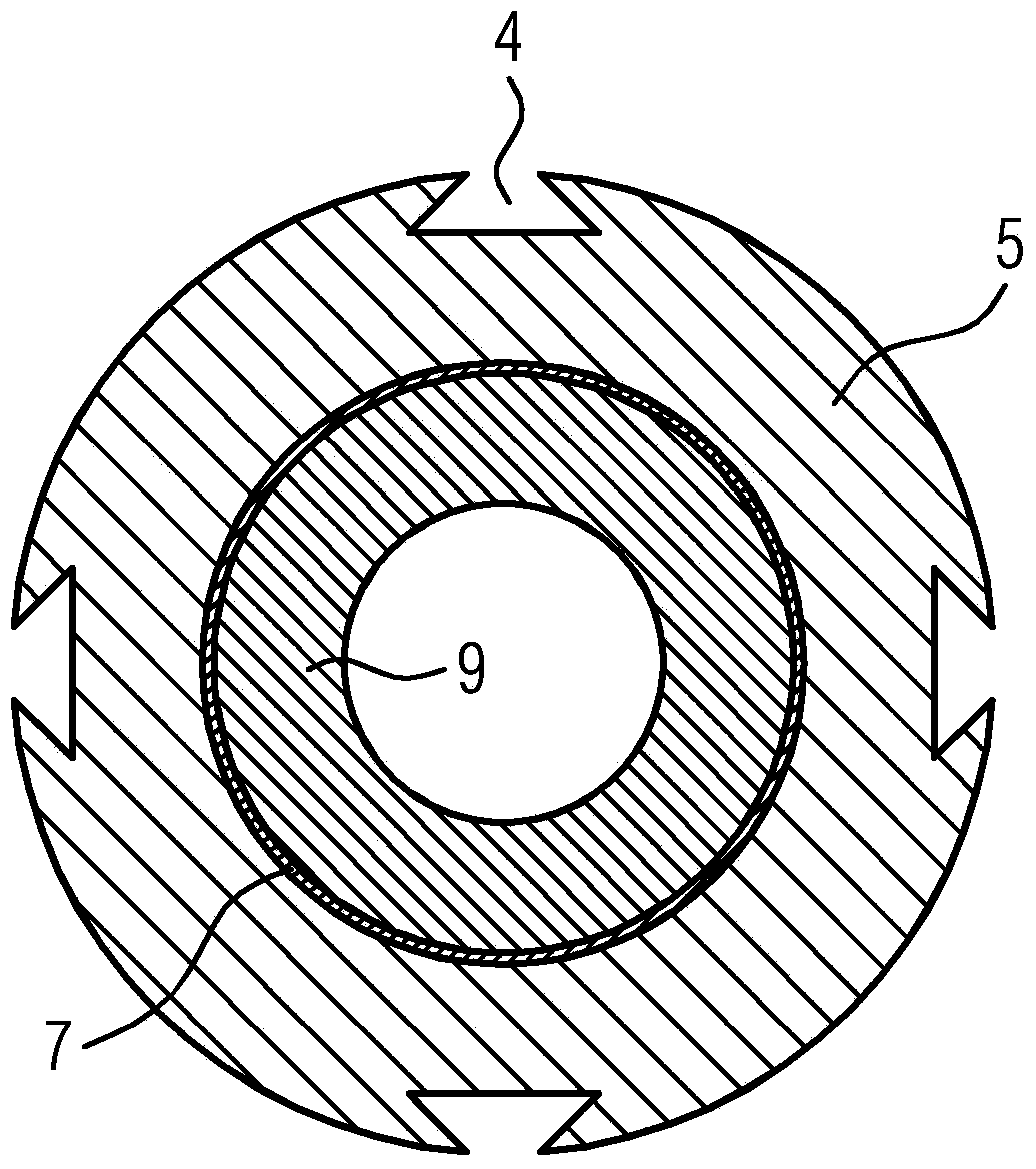

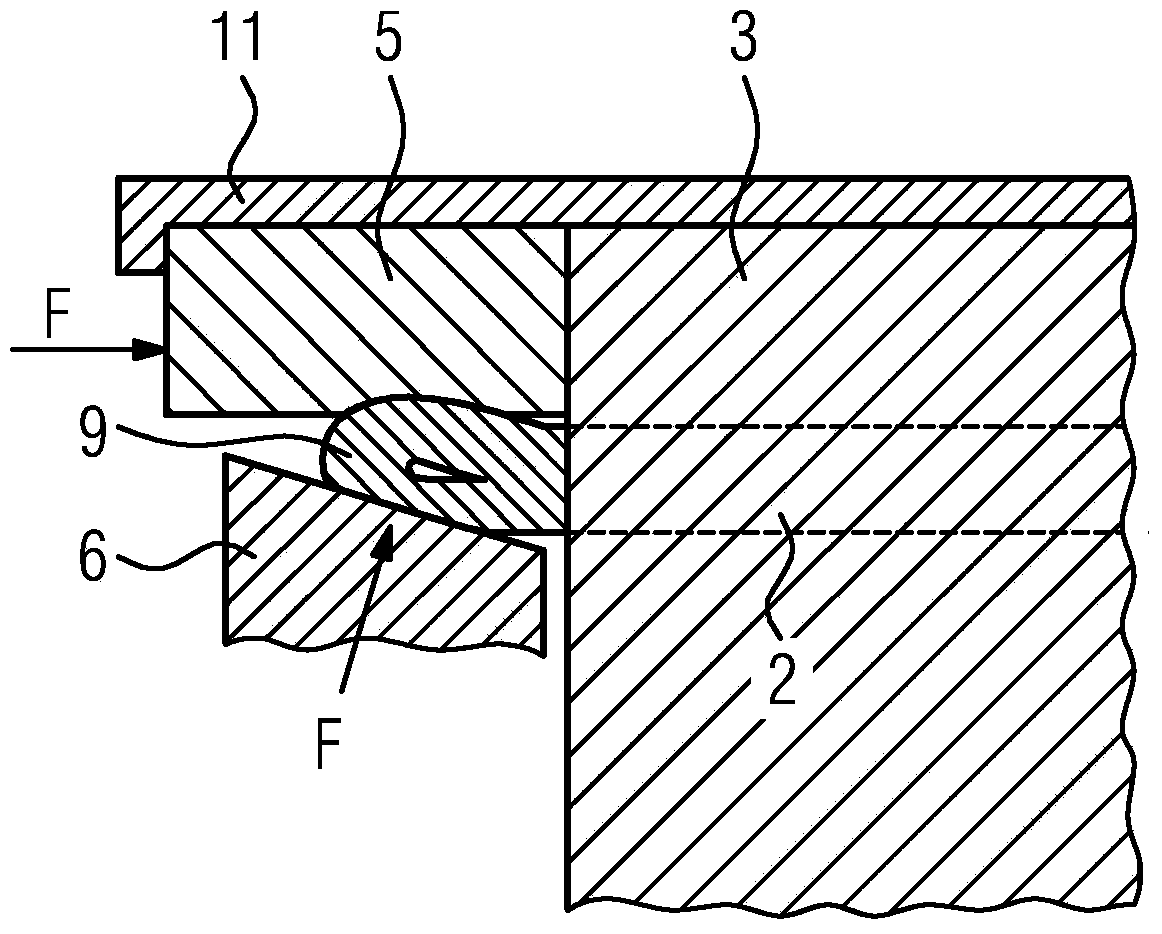

[0029] figure 1A schematic side view of a first exemplary embodiment of a system for cooling a winding is shown. This system consists of a laminated core 3 in which the winding 2 is embedded, and heat-conducting elements 5, 5' which bear against the laminated core 3 at the end sides. The heat conducting parts 5, 5' are fixed together with the lamination stack 3 by means of clips 11, 11'. The clips 11, 11' here extend from one end of the heat-conducting part 5 to the opposite end of the laminated core 3. exist figure 1 In the case of the manner shown in , the clip 11' also surrounds the oppositely arranged second heat conducting part 5'. As shown, the clips 11, 11' can be bent around the outer edges of the heat-conducting parts 5, 5' in order to achieve a non-positive connection of the heat-conducting parts 5, 5' and the laminated core 3. As shown by the thin layer between the winding head 9, 9' and the heat conducting part 5, 5', a thin electrical insulation 7 may be inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com