Method for operating an electric fan motor

A fan motor and electrical technology, applied in engine cooling, coolant flow control, engine components, etc., can solve problems such as unfavorable commutator blades, unclean surface, fan motor failure, etc., to avoid wear and tear run trouble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

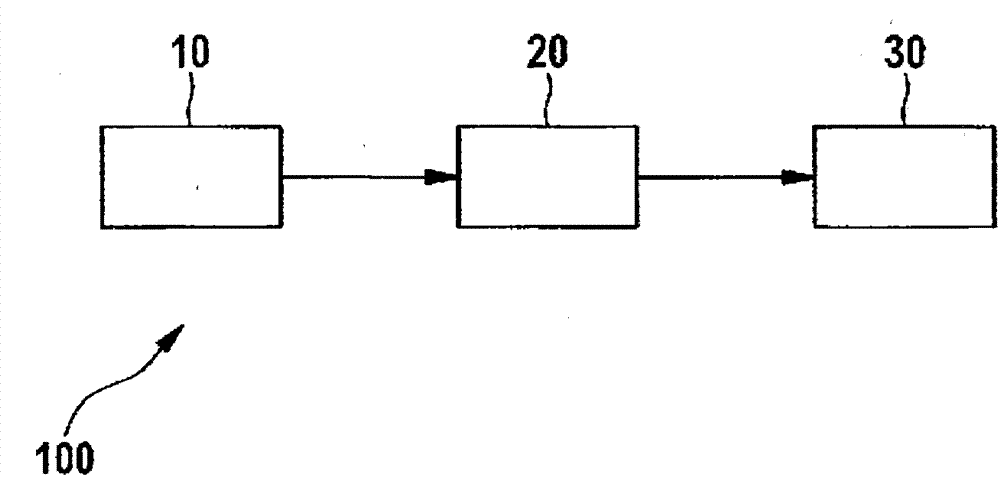

[0023] figure 1 A cooling ventilation device 100 is shown very simplified, which is usually installed in the engine compartment of a motor vehicle (not shown) and serves to cool the coolant of a combustion engine (not shown) of the motor vehicle. For this purpose, the cooling ventilation device 100 generates an air flow which flows through a cooler (not shown) and thereby cools the coolant within the cooler.

[0024] Cooling ventilation device 100 is actuated by a controller 10 , which can be designed, for example, as an electronic controller (ECU, electronic control unit). The controller 10 is electrically connected to a fan controller 20 (fan control module, FCM), which is used to control the electric fan motor 30 of the cooling ventilation device 100 connected to the fan controller 20 . For this purpose, the controller 10 supplies a pulse-width-modulated electrical signal to the fan controller 20 , which converts the signal into a corresponding voltage, thereby actuating t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com