Die-cutting product transferring and pasting device and transferring and pasting process applying die-cutting product transferring and pasting device

A technology for laminating devices and products, applied in the directions of lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of low production efficiency, product yield, high labor intensity, poor transfer accuracy, etc., and achieve high transfer accuracy. , the effect of low labor intensity and lower production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

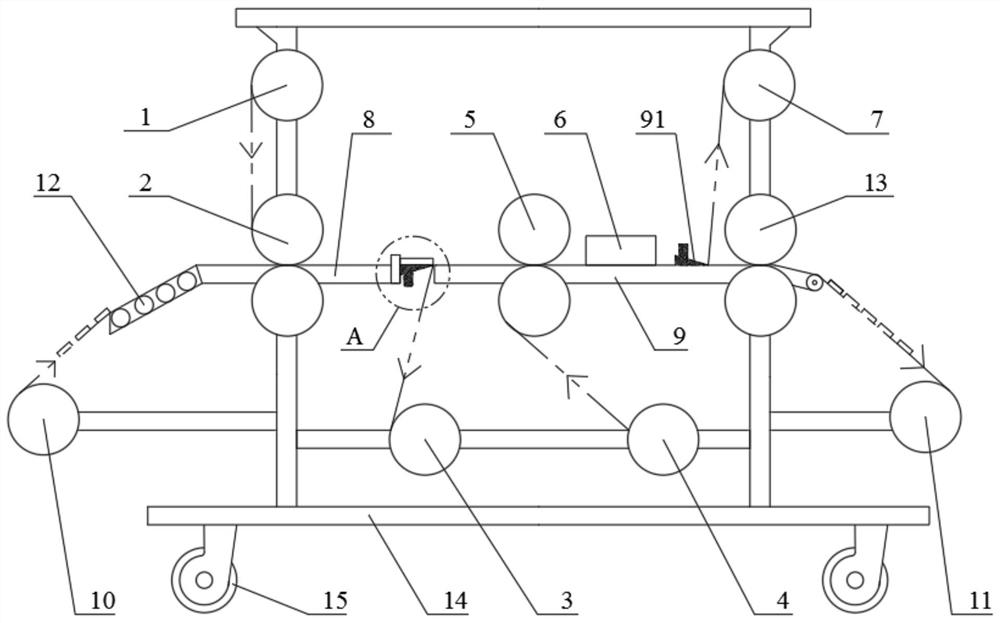

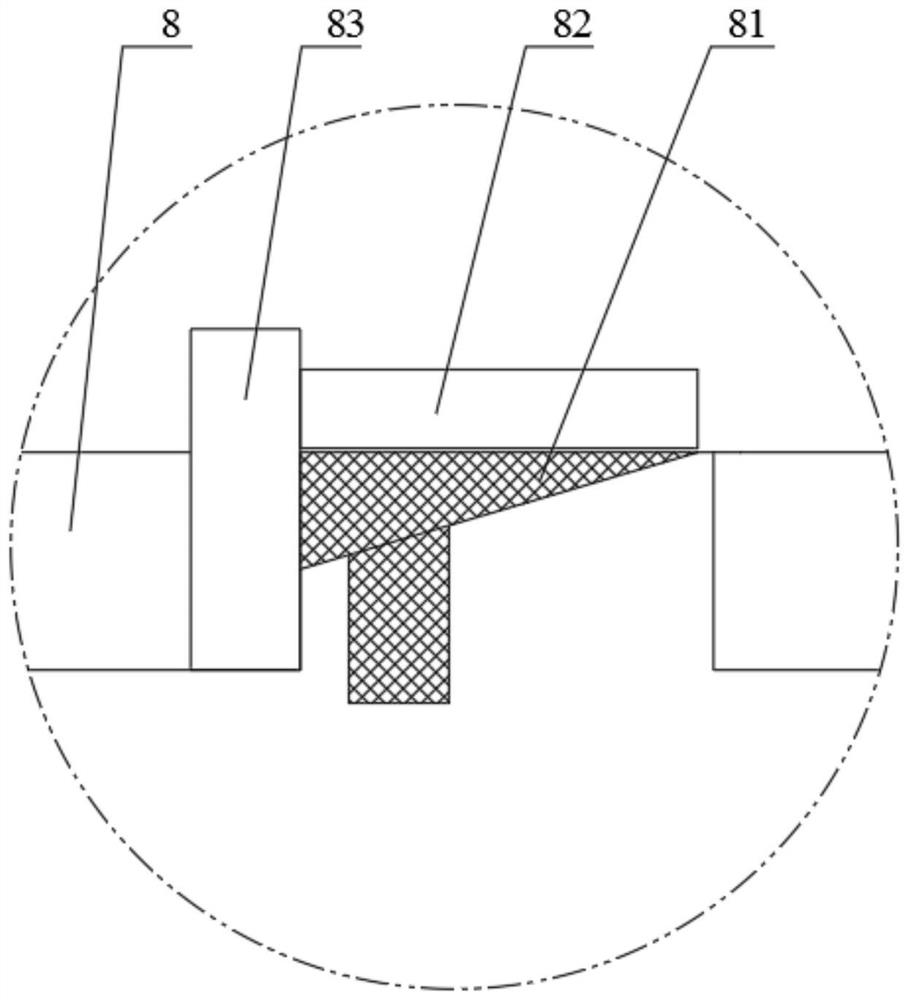

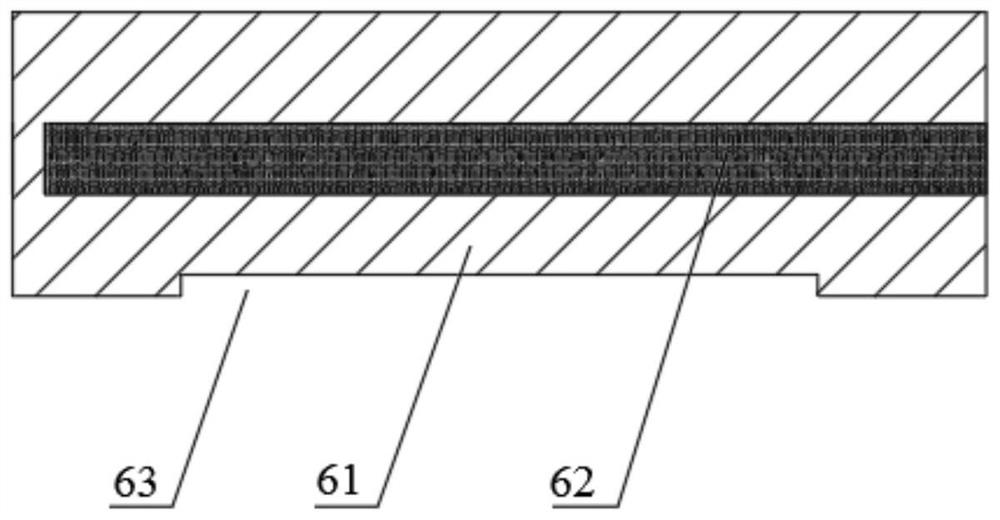

[0031] Such as Figure 1~4 As shown, a die-cut product transfer device according to the present disclosure is schematically shown, including a first discharging mechanism 1, a first laminating device 2, a first receiving mechanism 3, and a second discharging mechanism arranged in sequence 4. The second bonding device 5 , the heating device 6 and the second receiving mechanism 7 . Usually, the first laminating device 2, the second laminating device 5 and the heating device 6 are arranged horizontally in sequence, the first discharging mechanism 1 is located above the first laminating device 2, and the first receiving mechanism 3 is located at the first laminating Below the device 2 , the second discharging mechanism 4 is located below the second bonding device 5 , and the second receiving mechanism 7 is located above the heating device 6 . The pyrolytic adhesive tape is output by the first discharge mechanism 1, and the first laminating device 2 can attach the pyrolytic adhesi...

Embodiment 2

[0042] Such as Figure 1~4 Shown, a kind of reposting technique of applying above-mentioned reposting device, at least comprises the following steps:

[0043] The pyrolytic adhesive tape is output by the first feeding mechanism, and the pyrolytic adhesive tape is pasted on the raw material tape after die-cutting of the product through the first laminating device, and the product is bonded with the pyrolytic adhesive tape at the same time, that is, the product Located between the raw material belt and the thermal debonding material belt;

[0044] Then the first material receiving mechanism rewinds the laminated raw material tape. Since the bonding force between the pyrolytic adhesive tape and the product is greater than the bonding force between the product and the raw material tape, the product remains on the pyrolytic adhesive tape. On, that is, the product is first transferred from the raw material belt to the thermal debonding material belt;

[0045] Then the outgoing mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com