Non-sticky electrosurgical instrument electrode

An electrosurgical instrument and electrode technology, applied in the field of medical equipment, can solve the problems of high cost, poor anti-sticking effect of the coating, easy damage of the coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] (2) The preparation of carbon nanotubes also adopts the preparation method of chemical vapor deposition, using 300nm thick silicon dioxide as the growth substrate, using Fe / MgO as the catalyst, the carbon source is acetylene and benzene, the growth temperature is 800 ° C, and the pressure is 1 atm , the growth time is 20-30min.

[0045] (3) Carbon nanofibers are self-assembled from carbon nanotubes. The diameter of the fiber is about 50nm, the length is 1-15 microns, and the density is 2.1g / cm 3 .

[0046] (4) Metal (or alloy) nanoparticles are prepared by high-temperature annealing of thin films. First, a film with a thickness of 10-100 nm is grown by magnetron sputtering, and then annealed at a high temperature of 400-1000 ° C to obtain a metal with a diameter of 50-200 nm ( or alloy) nanoparticles.

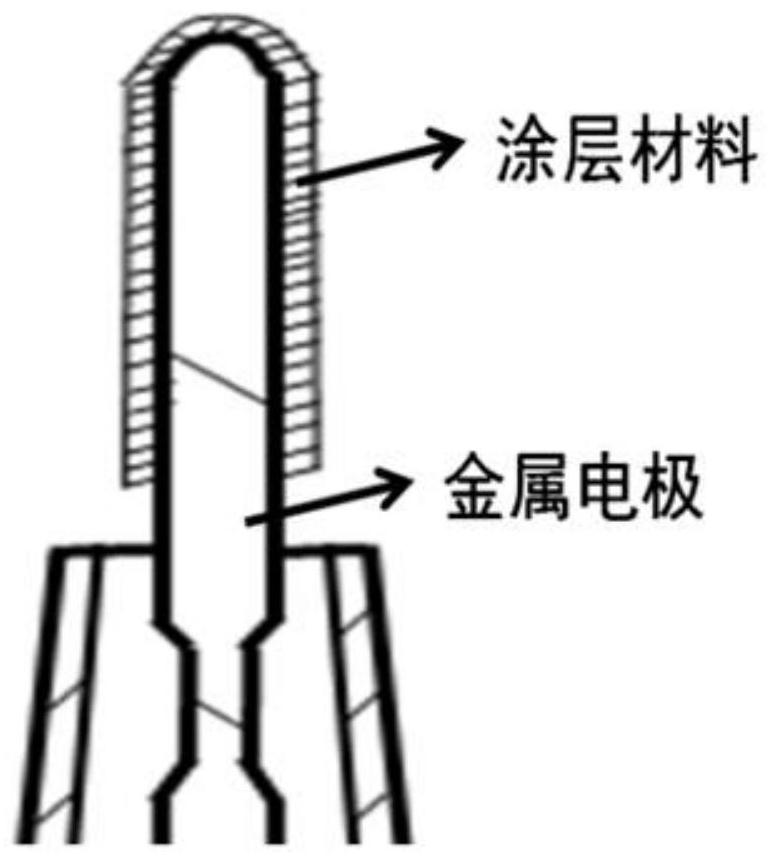

[0047] Finally, the coating material is applied to the cleaned electrode surface by one of thin film wet transfer and deposition to form non-adhesive electrosurgical i...

Embodiment 1

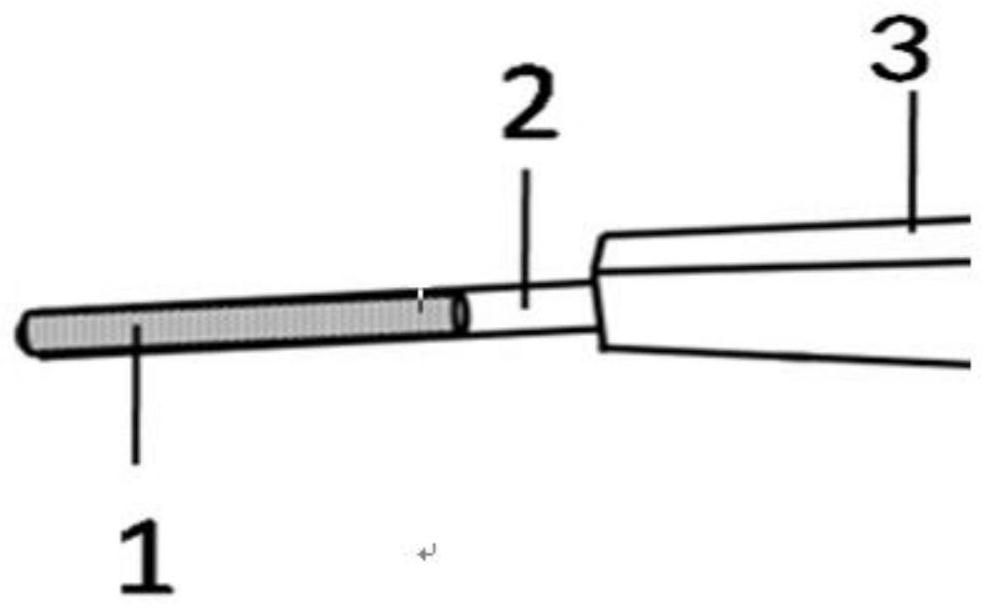

[0051] A non-adhesive high-frequency electrotome electrode based on graphene materials, such as figure 1 , 2 As shown, the highly conductive, non-adhesive graphene coating covers the entire outer surface of the stainless steel electrode tip, and the preparation method of the coating is as follows:

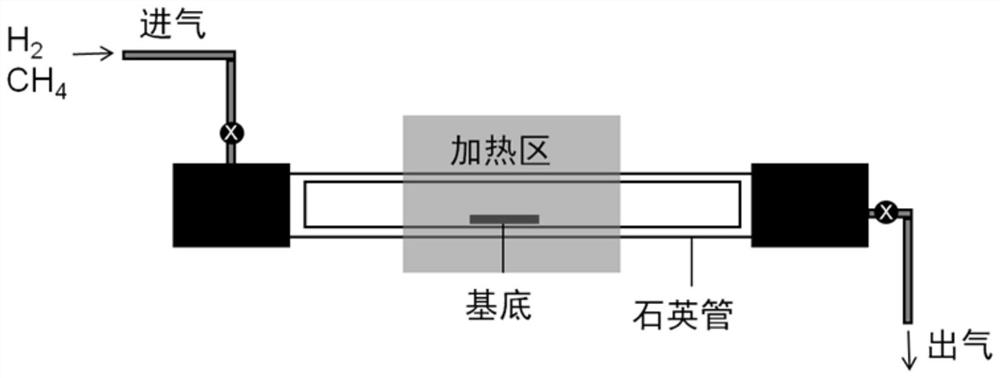

[0052] 1) Use chemical vapor deposition material growth process to grow large-area graphene with a thickness of 100 layers, such as image 3 shown. The selected substrate material is nickel foil with a thickness of 300 nanometers. Put the nickel foil in acetone, isopropanol, ethanol, and deionized water for ultrasonication, place it in dilute nitric acid for 15 minutes, rinse, and dry it with nitrogen; put the nickel foil immediately Into the CVD chamber, and the chamber is evacuated to 500mTorr.

[0053] 2) The growth temperature is 1000°C, the raw material is a mixture of methane and hydrogen, and the gas flow rates are 35 sccm and 2 sccm respectively, and a large area (10 cm ...

Embodiment 2

[0059] A non-adhesive high-frequency electrosurgical electrode based on carbon nanotube materials. The high-conductivity, anti-adhesive carbon nanotube coating covers the entire outer surface of the stainless steel electrode end cutter head. The preparation method of the coating is as follows:

[0060] 1) Using the preparation method of chemical vapor deposition, 300nm thick silicon dioxide is used as the growth substrate, Fe / MgO is used as the catalyst, the carbon source is acetylene and benzene, the growth temperature is 800°C, the pressure is 1atm, and the growth time is 20-30min .

[0061] 2) growing a large-area (5 cm x 5 cm) carbon nanotube film with a clean surface of 50 nm in thickness.

[0062] 3) Use scissors to cut the carbon nanotube film into a rectangular structure with a width slightly wider than the electrode blade. The specific dimensions are: length 1.5 cm, width 0.25 cm (electrode blade length 1.5 cm, width 0.2 cm).

[0063] 4) Through the film wet transfer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com