Method for producing copolymerized polypropylene by using propylene gas phase polymerization device

A technology for copolymerizing polypropylene and gas-phase polymerization, applied in the field of polypropylene preparation, can solve the problems of reducing the partial pressure of monomers effectively participating in the polymerization, increasing the discharge frequency of gas-phase kettles, and the difficulty of dispersing inorganic particles, so as to avoid the reduction of polymerization efficiency and avoid equipment The effect of running fluctuations and stable long-term operation of the device

Inactive Publication Date: 2019-04-30

SINOPEC YANGZI PETROCHEM +1

View PDF8 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] 1) With the addition of a large amount of LPN, a large amount of inert gas accumulates, which reduces the partial pressure of monomers effectively participating in the polymerization, resulting in a decrease in polymerization production efficiency. Roughly estimated, the partial pressure is about 50% when the nitrogen gas is balanced, that is, compared to no nitrogen gas, Polymerization production efficiency drops by at least 50%;

[0007] 2) Excessive nitrogen increases the discharge frequency of the gas phase kettle, increases the amount of post-treatment separation, and increases production costs. If it is directly emptied, the unit consumption of the product will increase significantly

In addition, the application of inorganic particles is mainly in post-processing modification. For example, CN1307074A and CN1150161 propose to use nanoparticles to strengthen and toughen polypropylene materials. This process requires secondary melting of polymers, and the dispersion of inorganic particles is difficult, which increases the cost of product manufacturing.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

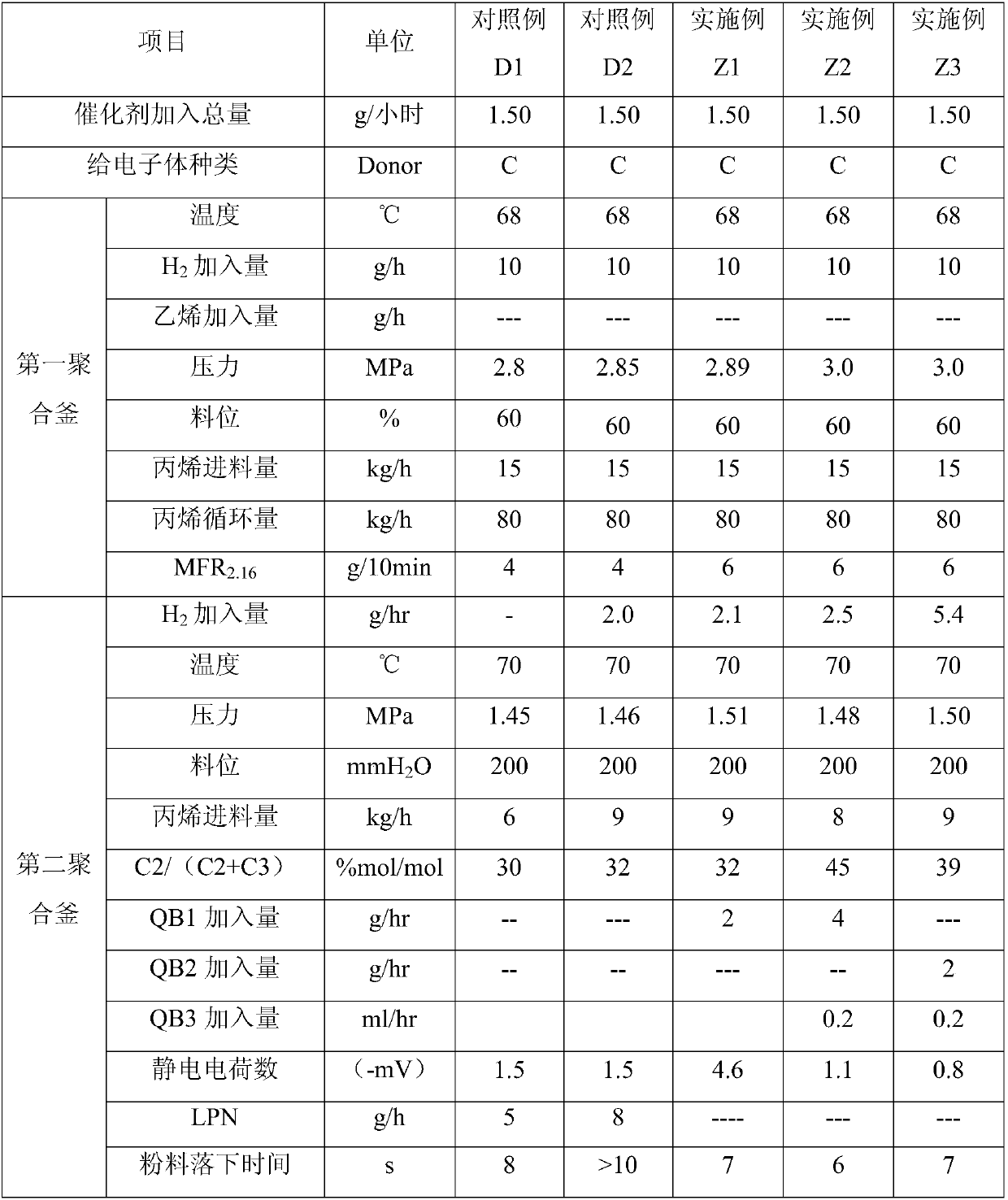

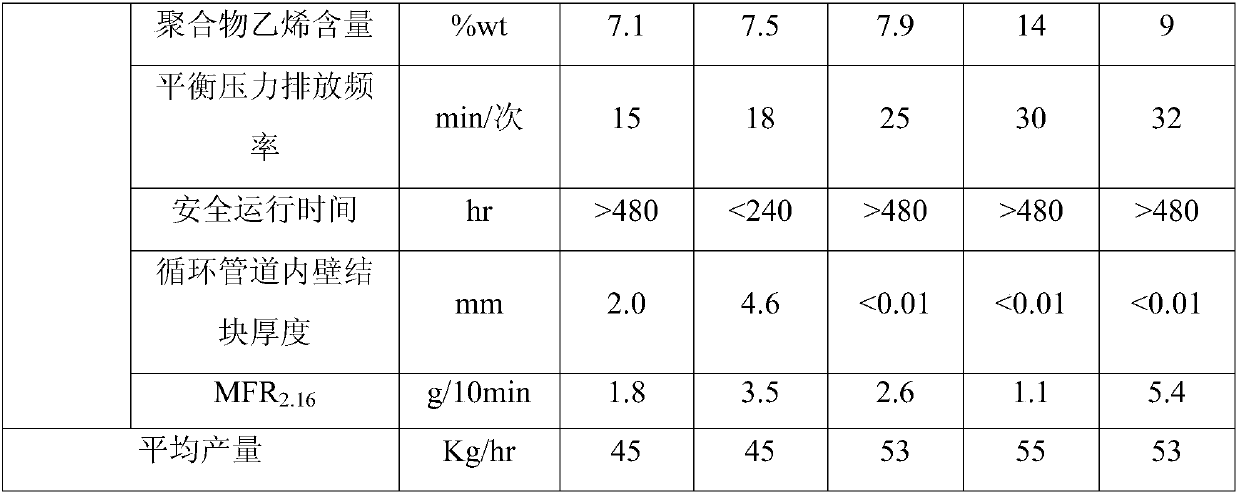

[0029] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, but the content of the present invention is not limited to the following examples.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a method for producing copolymerized polypropylene by using a propylene gas phase polymerization device, wherein a sticking inhibitor is added during the polymerization, and isa refined organic compound. According to the present invention, LPN is replaced with the refined organic compound, such that the component of the inert gas in the reactor can be reduced, the ventingamount can be reduced, the polymerization efficiency of the catalyst can be improved, the smooth operation of the device can be achieved, and the ethylene-propylene impact-resistant product with highethylene content can be obtained; and the sticking probability of the ethylene-propylene copolymer can be reduced after the organic particles are added while the organic particles and the kettle wallare subjected to collision friction to form static electricity, and the alcohol-based substance enters the reaction kettle after being atomized or vaporized through the power of the fan, and can neutralize the static electricity, such that the polymerization can be stably performed for a long time.

Description

technical field [0001] The invention relates to a method for producing copolymerized polypropylene with a propylene gas phase polymerization device, belonging to the field of polypropylene preparation. Background technique [0002] Polypropylene is a typical partially crystalline thermoplastic resin, and its good performance-price ratio determines that it has a wide range of applications. In recent years, with the rapid development of the automobile industry, high-speed trains, construction industry, electronic telecommunications industry and the high performance of polypropylene products, the output and demand of polypropylene have increased significantly, becoming the fastest growing general-purpose plastic in the past ten years. Annual demand growth of up to 8%. With the development and application of production technology and new catalysts, many high-performance polypropylene products appear in the market, mainly in terms of impact resistance, high rigidity, transparenc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08F210/06C08F210/02C08F2/34C08K9/04C08K3/26C08K5/05

CPCC08F210/06C08K3/26C08K5/05C08K9/04C08K2201/003C08K2201/017C08F2/34C08F210/02

Inventor 刘克徐宏彬笪文忠梅利

Owner SINOPEC YANGZI PETROCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com