Patents

Literature

440results about How to "Improve dehydration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

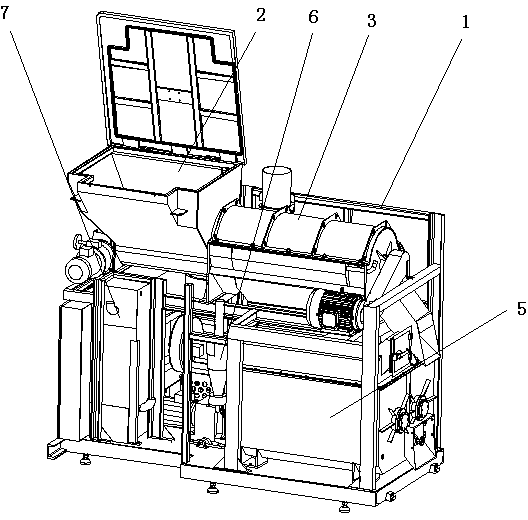

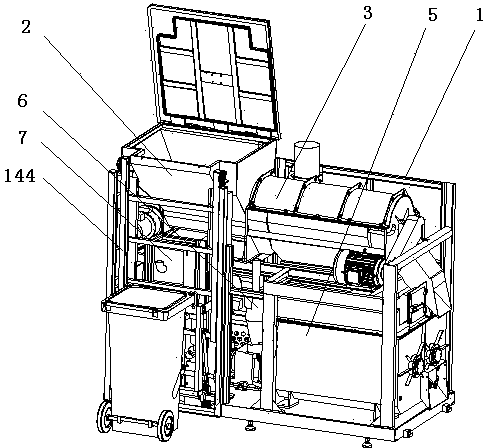

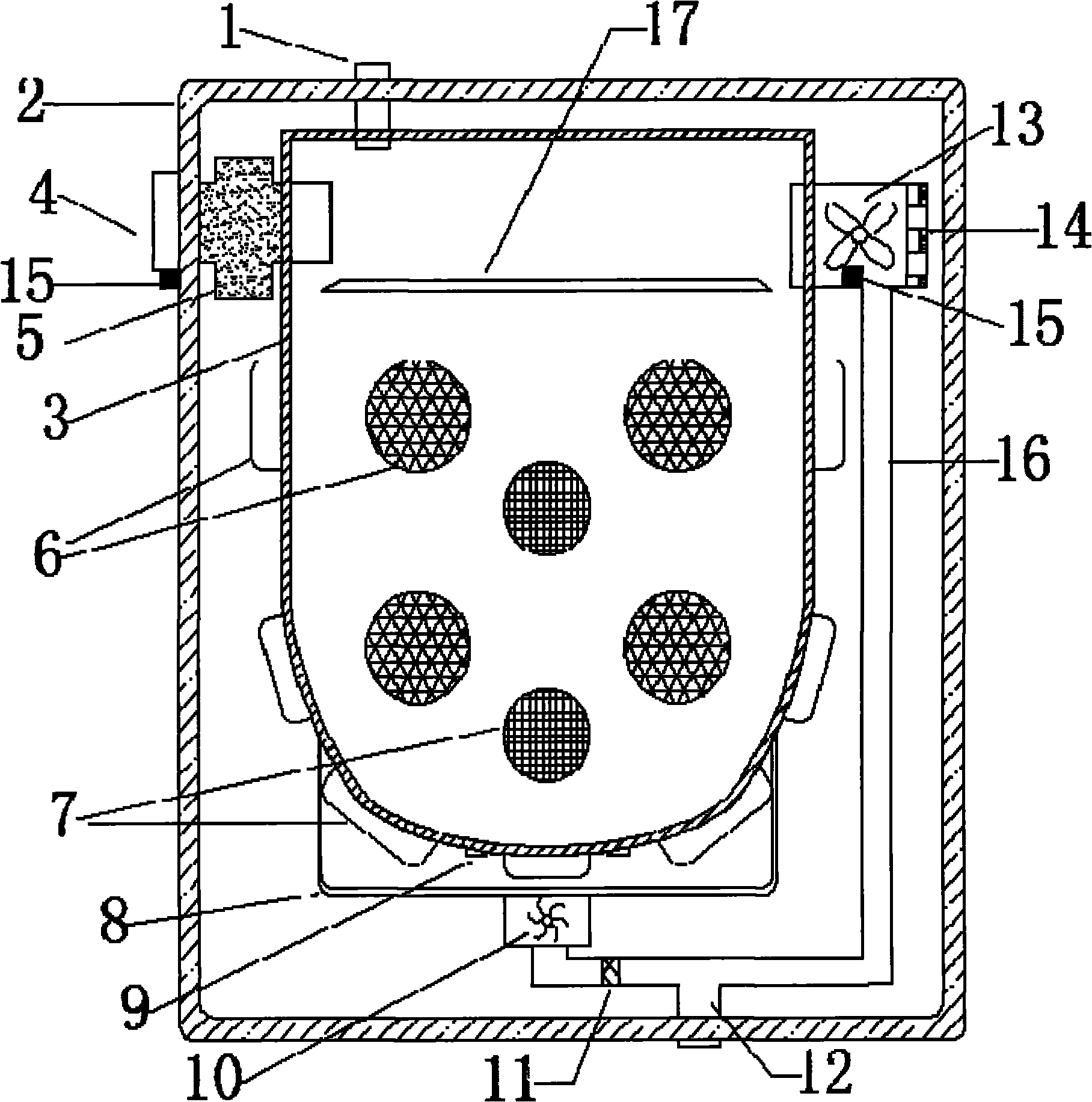

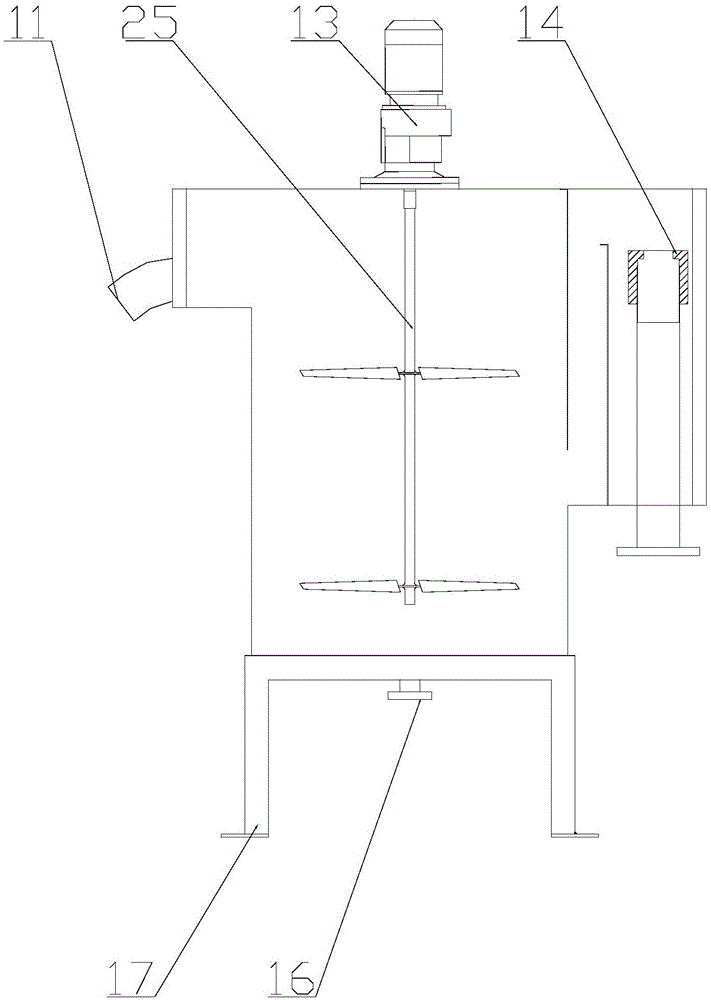

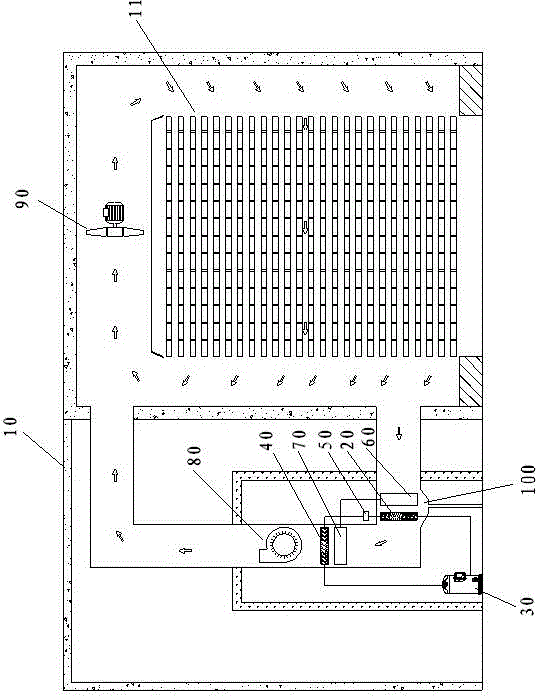

Kitchen waste pretreatment device

ActiveCN103464449ADeodorization up to standardWith automatic sortingSolid waste disposalControl systemOil water

The invention discloses a kitchen waste pretreatment device. The kitchen waste pretreatment device comprises a closed shell and a control system. The kitchen waste pretreatment device is characterized in that the upper end of the shell is provided with a feeding funnel and a feeding motor; the shell is internally provided with an automatic sorting device, a biological fermentation drying device, an oil-water separation device, an ionization deodorization device and a gas condensation device; the feeding funnel is communicated with a kitchen waste charge hole of the automatic sorting device through a discharge hole; the automatic sorting device is communicated with a charge hole of the biological fermentation drying device through a kitchen waste outlet; the automatic sorting device is communicated with the oil-water separation device through a liquid outlet; the biological fermentation drying device is communicated with the gas condensation device through a gas exhaust opening; the gas condensation device is communicated with the ionization deodorization device, so that the effects of automatic sorting, rapid fermentation treatment speed, uniform fermentation, rapid heating speed, capability of oxygenating in fermentation, standard gas deodorization and environment protection and no pollution are achieved.

Owner:SHANDONG MINGLIU KITCHEN WASTE TREATMENT EQUIP CO LTD

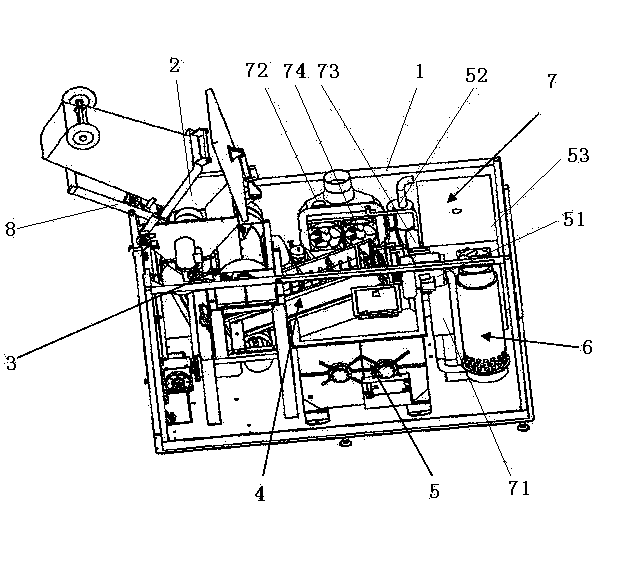

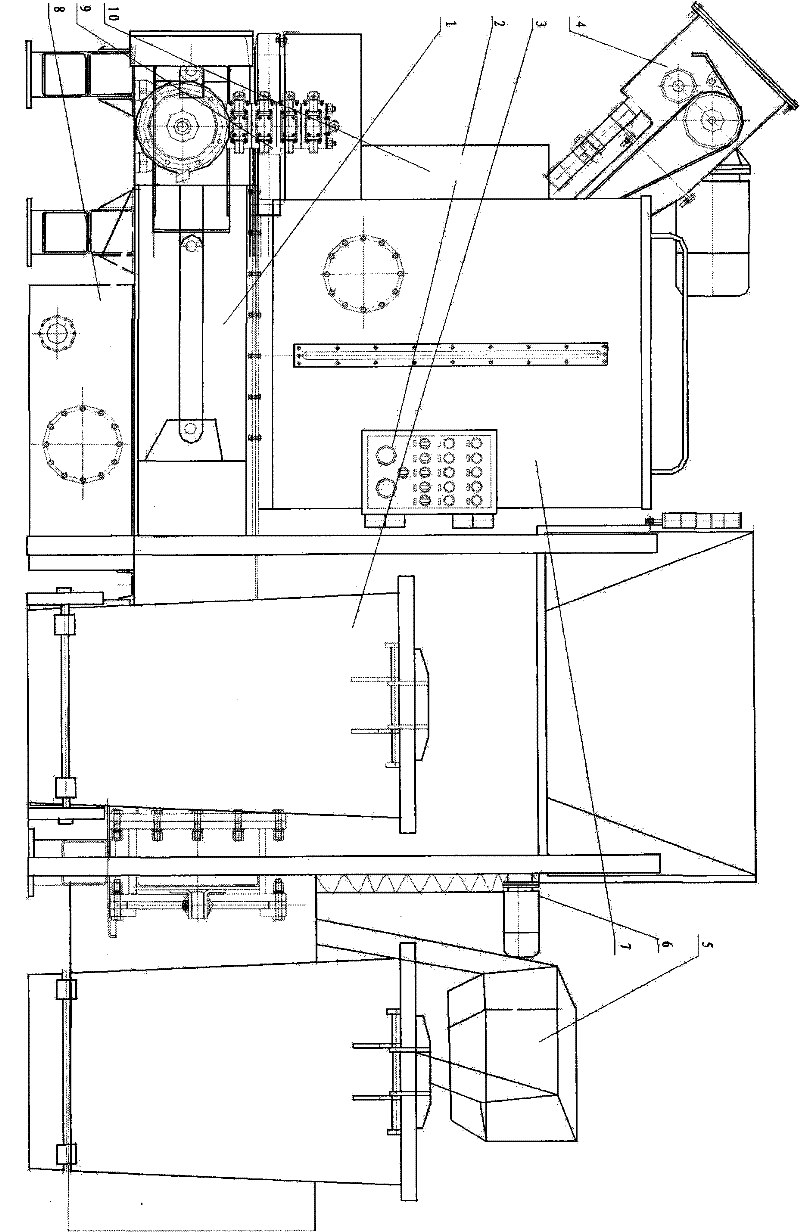

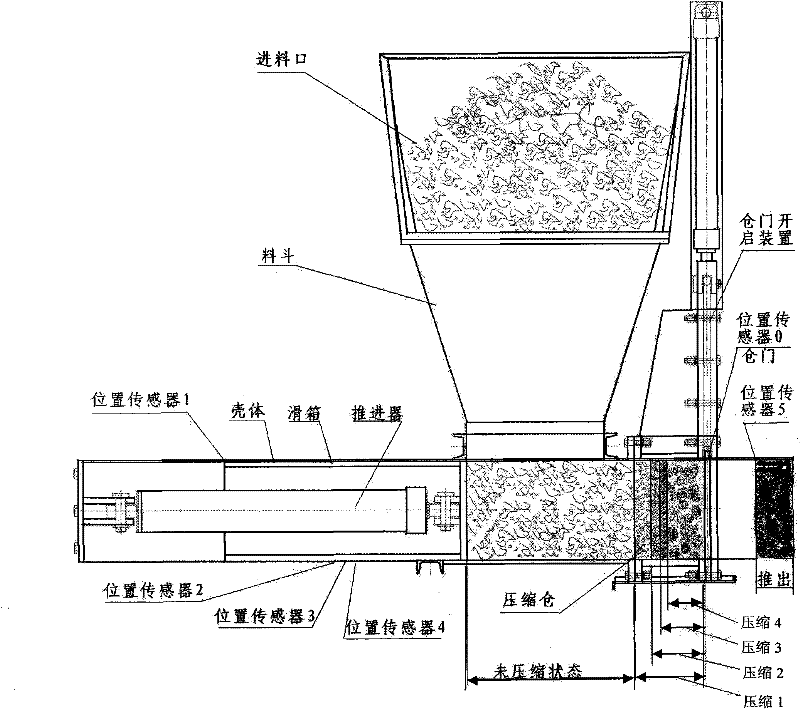

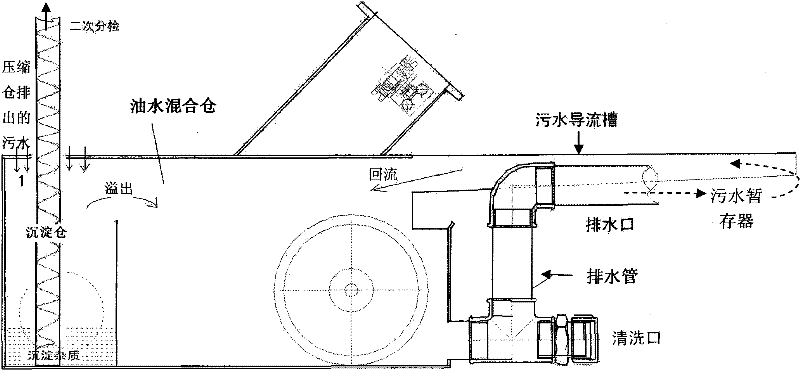

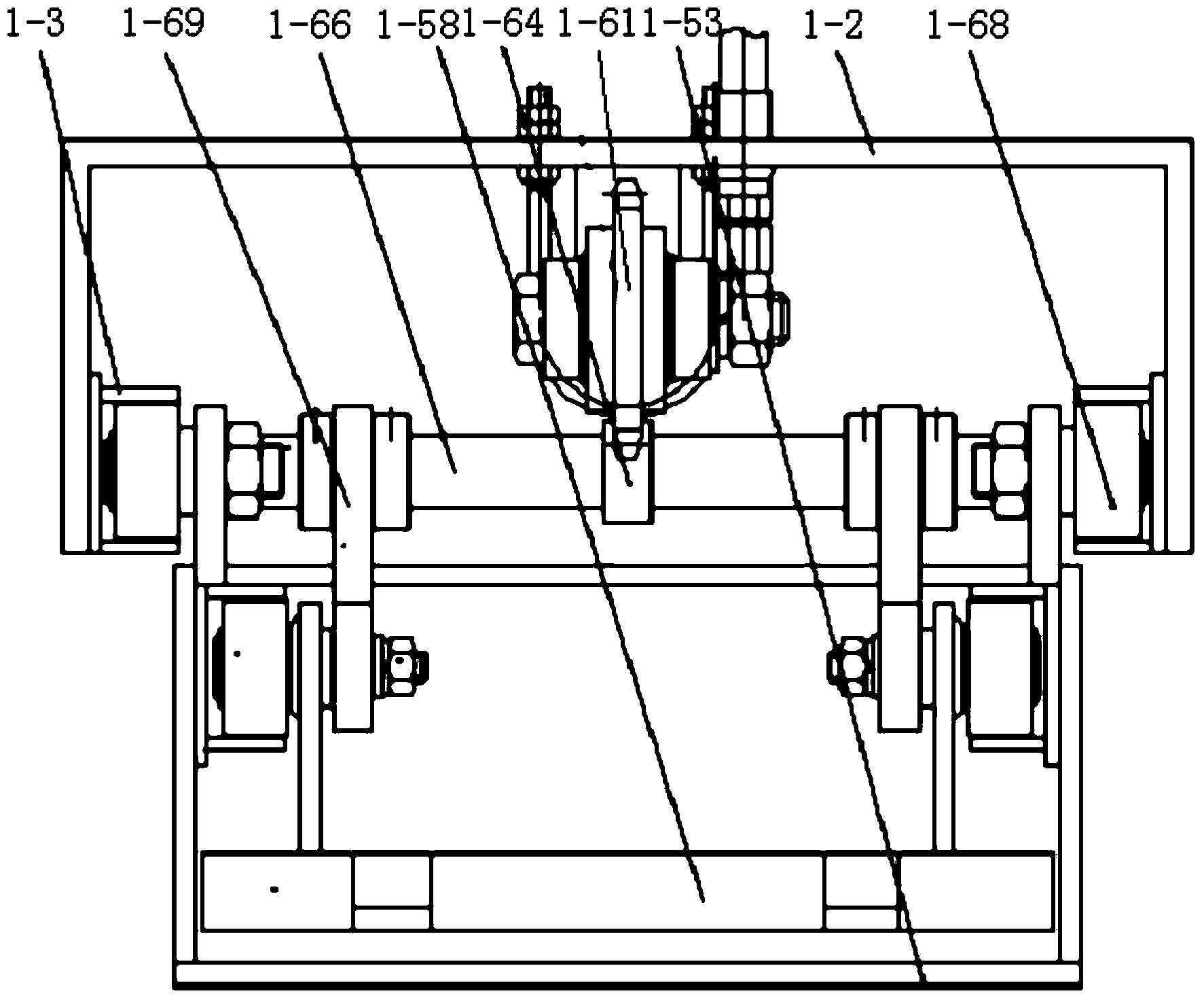

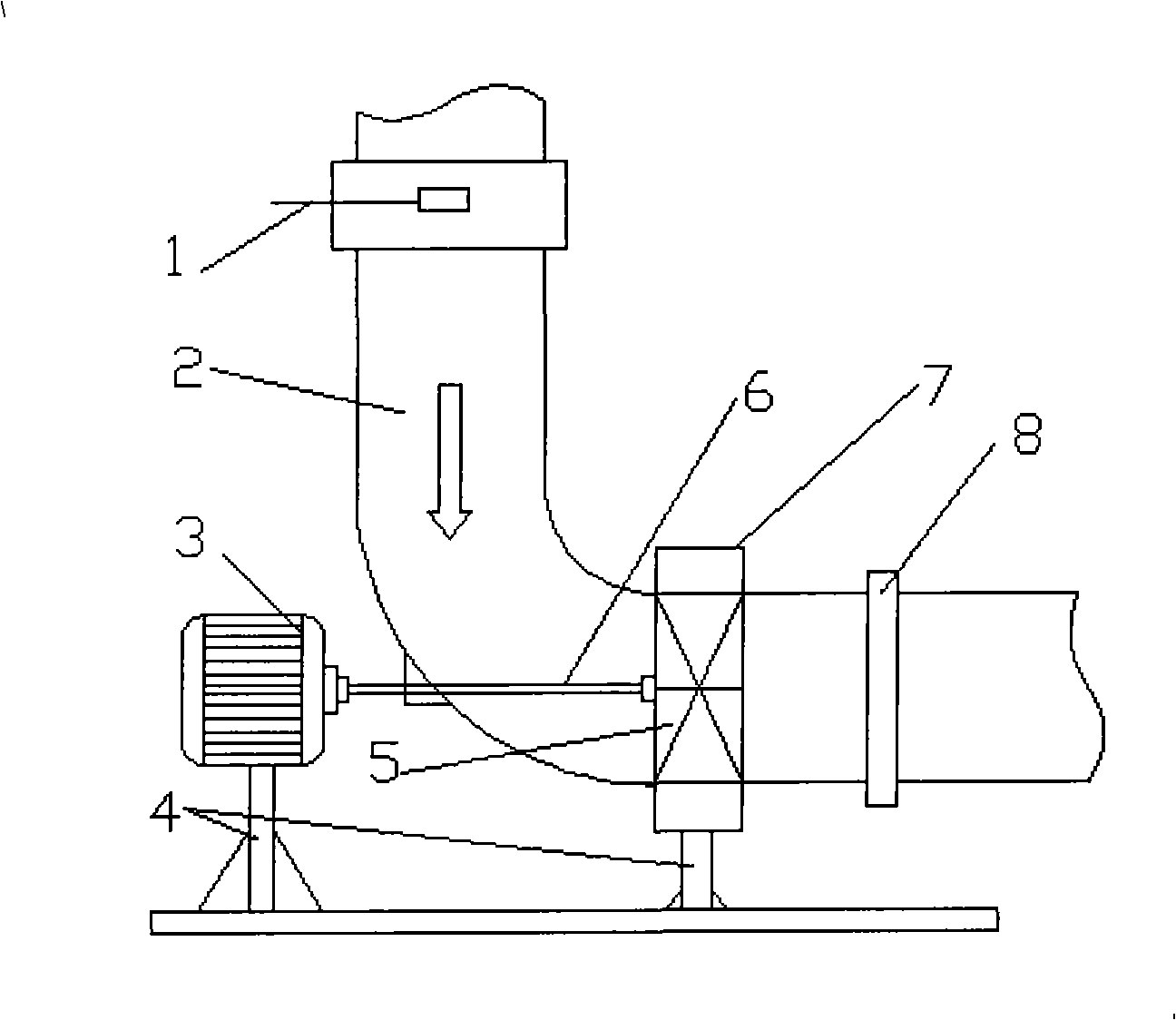

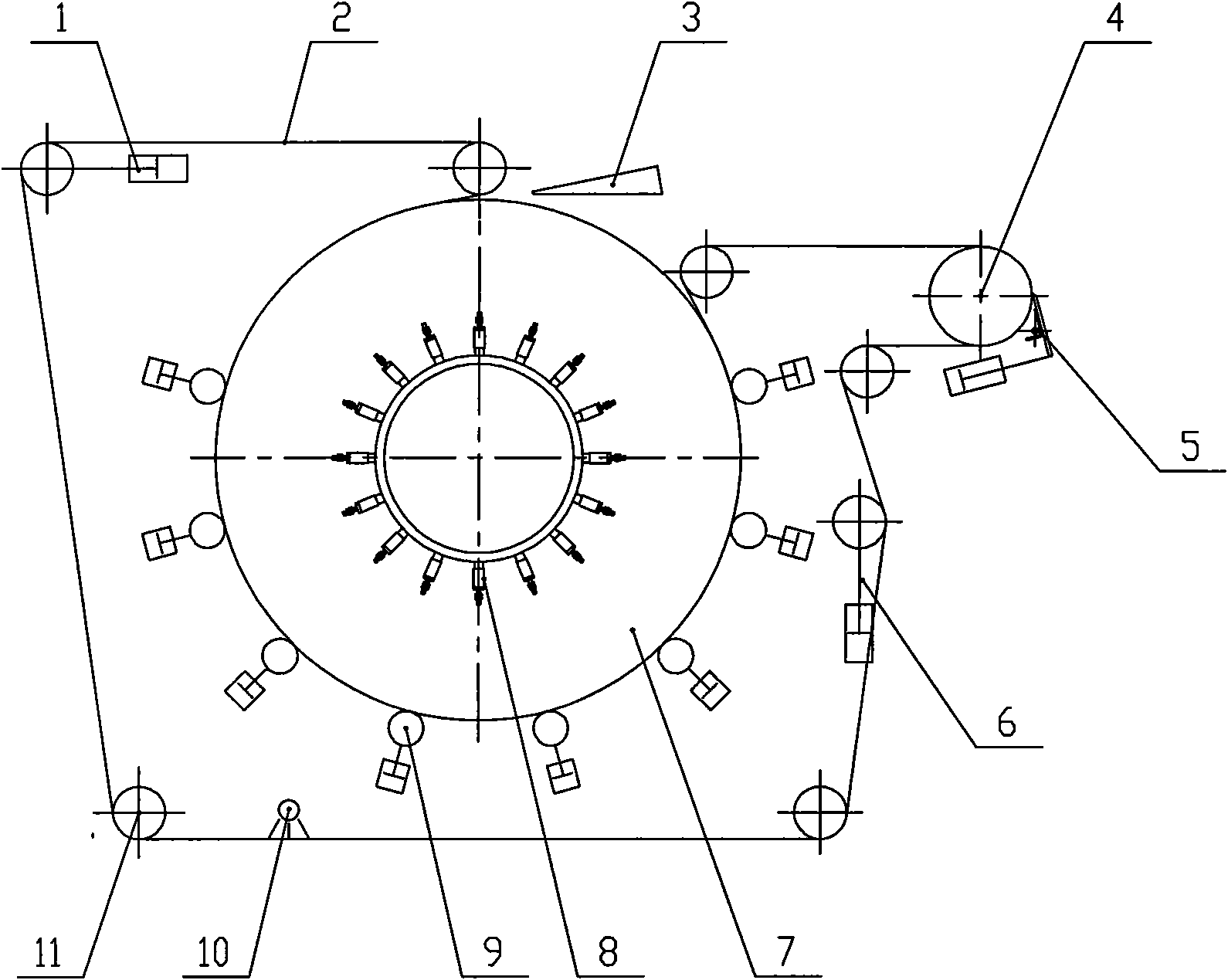

Device for reducing and sorting food waste at the source

InactiveCN102240658AEasy to handleImprove transportation capacitySolid waste disposalDrying solid materials without heatOil and greaseFailure rate

The invention discloses a device for reducing and sorting food waste at the source, and belongs to the technical field of municipal environmental protection machinery. The device is characterized in that: food waste is poured into a feed system and is conveyed into a dehydration system, a sliding box is driven to slide in a housing through a propeller of the dehydration system, a extruding way or a beating way is adopted to complete the food waste dehydrating; the resulting sewage from the dehydration step enters a sewage box from a compression bin to enable a oil and water separation system to extract greases; the solid materials after completing the dehydration are pushed out from the compression bin and enter into a material discharge system; the solid materials are output through the material discharge system and wait for centralized processing. After being processed by the device provided by the present invention, the food waste is divided into three portions comprising the water, the greases and the solid materials so as to conveniently carry out post-treatments such as reuse production of the greases and the solid materials, regeneration treatment of the water source and the like. The device has characteristics of strong processing ability, low failure rate, high automaticity, simple and easy operation and maintenance, no requirement of chemical additives, high dehydration rate, short retention time of the food waste in the device, and the like, and is benefit for improving efficiency of resource reutilization production so as to achieve effect of energy saving and emission reduction.

Owner:曹泽民

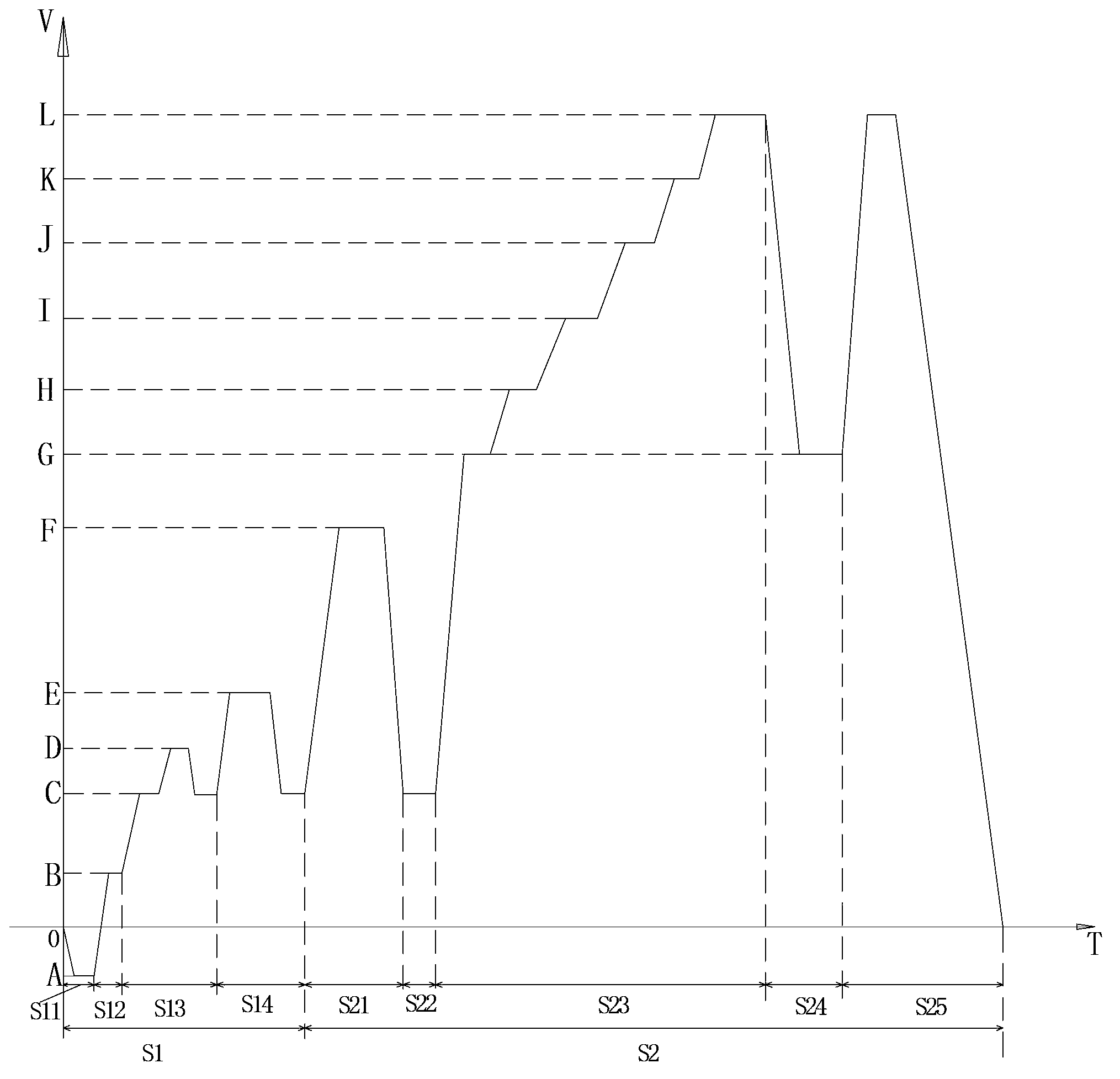

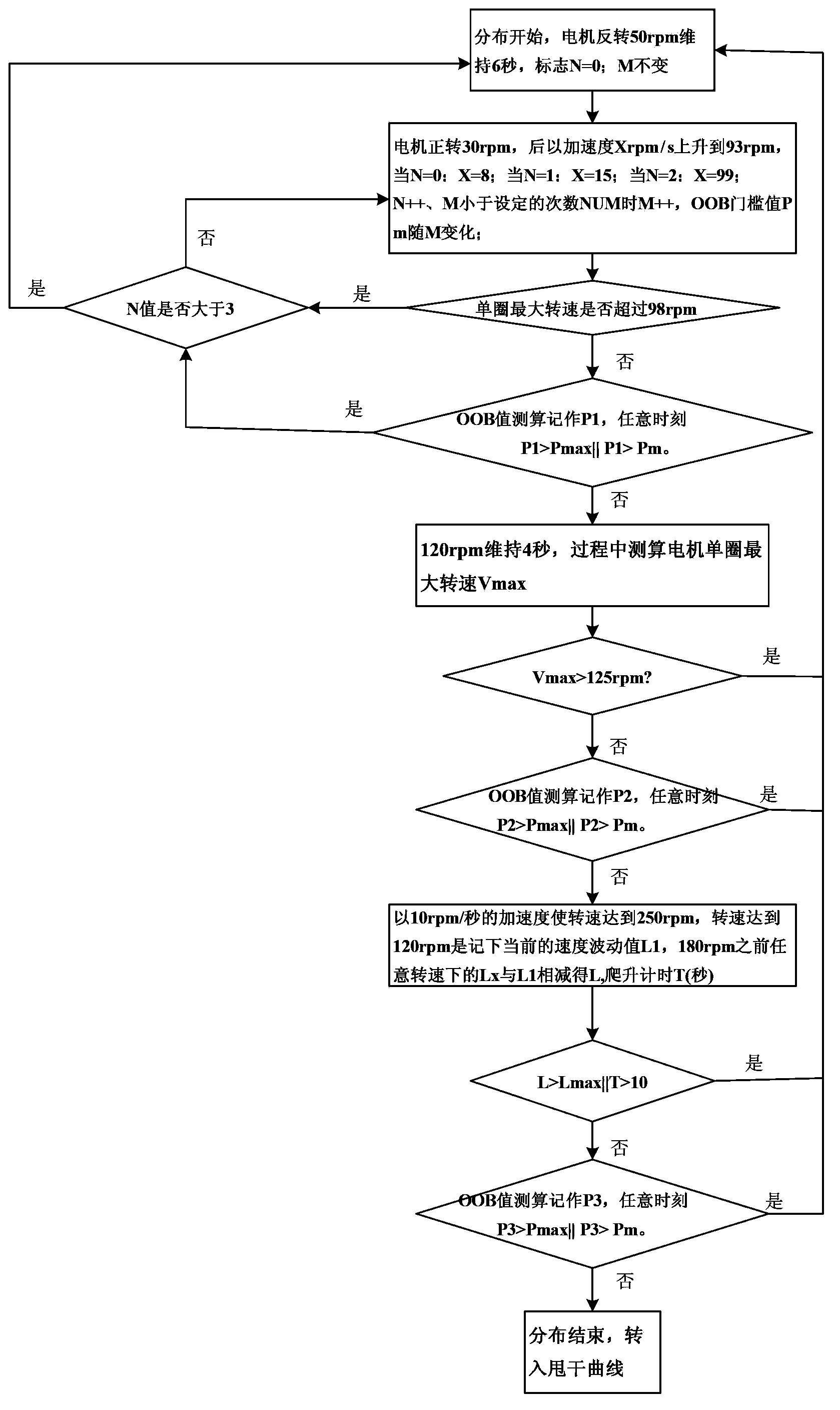

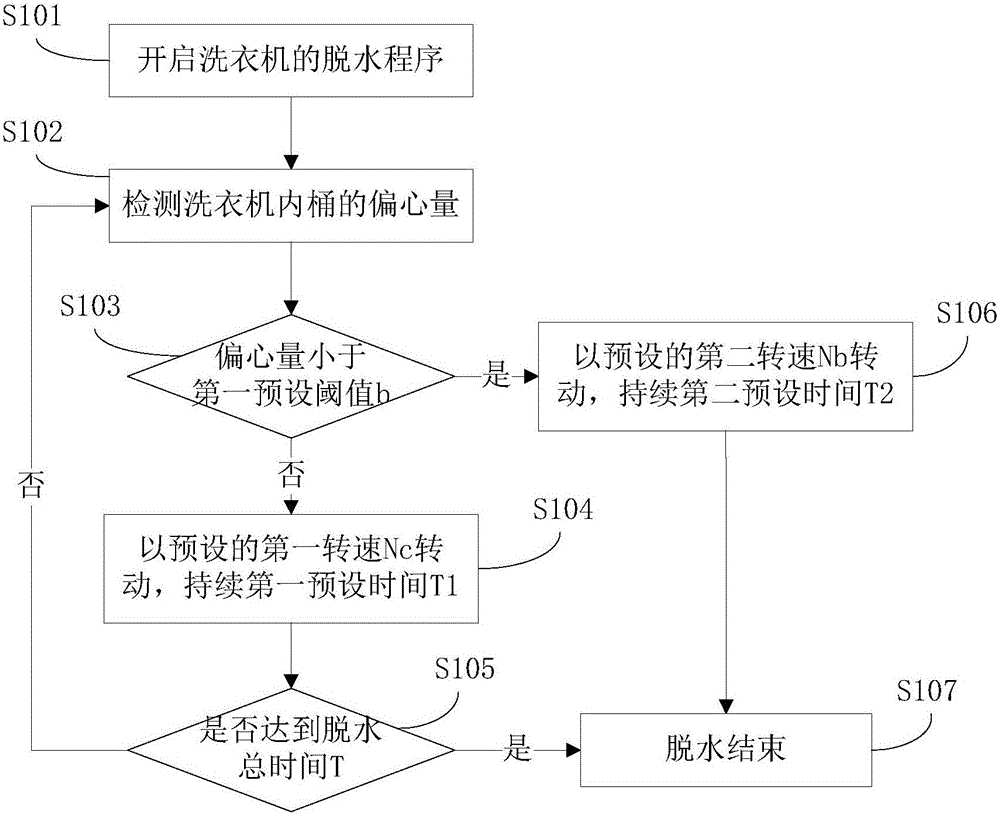

Dehydration distribution control method of washing machine

ActiveCN103911804AImprove stabilityEvenly dehydratedOther washing machinesControl devices for washing apparatusLow noiseDistribution control

The invention discloses a dehydration distribution control method of a washing machine. Before the washing machine is switched to a hydration function, the speed of an inner cylinder is controlled to be increased to a set rotating speed and stabilized at the set rotating speed, next, a process of repeatedly confirming an eccentric value of the load is added; the eccentric value of the load is repeatedly conformed before and after the rotating speed of the inner cylinder is controlled to be increased, and the eccentric value of the load is corrected after conforming that the eccentric value of the load satisfies a set condition; after hydration is began, the eccentric value is detected to determine the maximum dehydration rotating speed, the rotating speed is gradually increased to the hydration rotating speed and the hydration rotating speed is maintained for certain time for dehydration, next, the rotating speed is reduced to a certain rotating speed and maintained at the certain rotating speed for certain time, and then the rotating speed is increased to the hydration rotating speed again; by use of the method, the effects of steady dehydration, low vibration, low noise, low energy consumption and dehydration rate are achieved, and furthermore, the service life of a bearing, a speed reducer and the like of the washing machine is increased.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

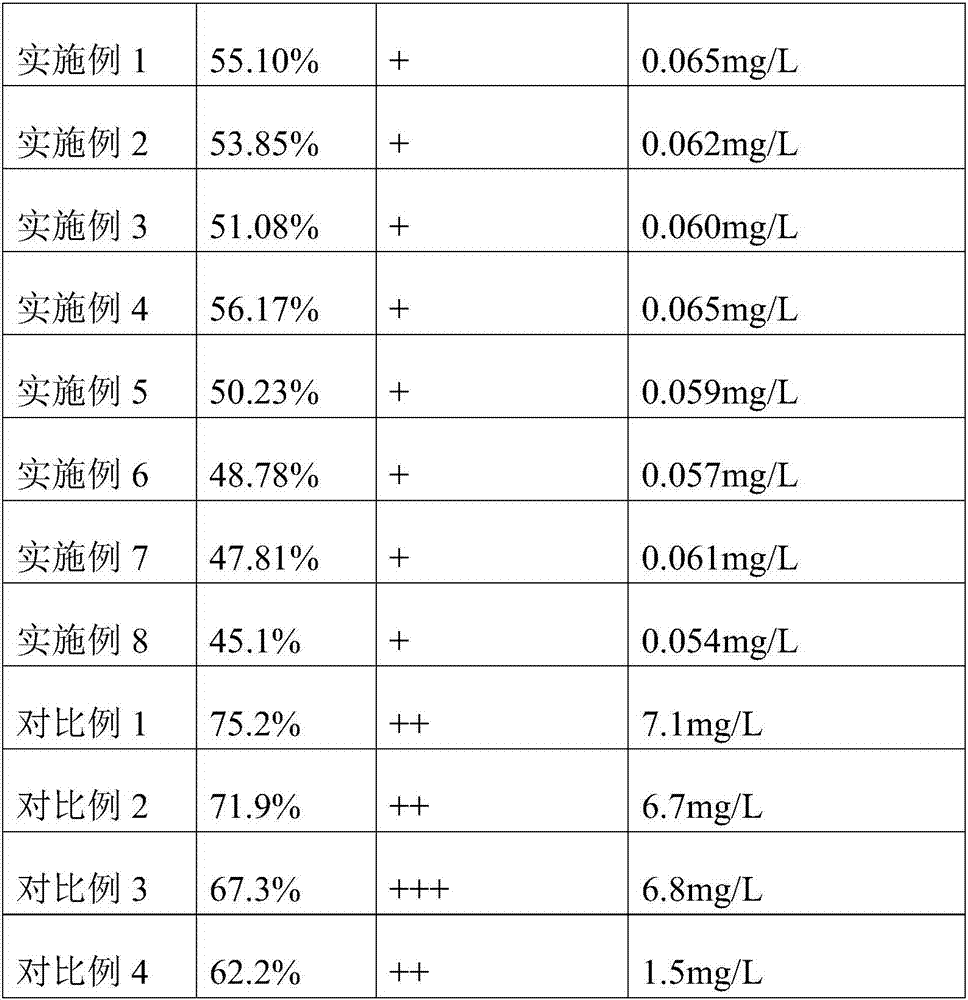

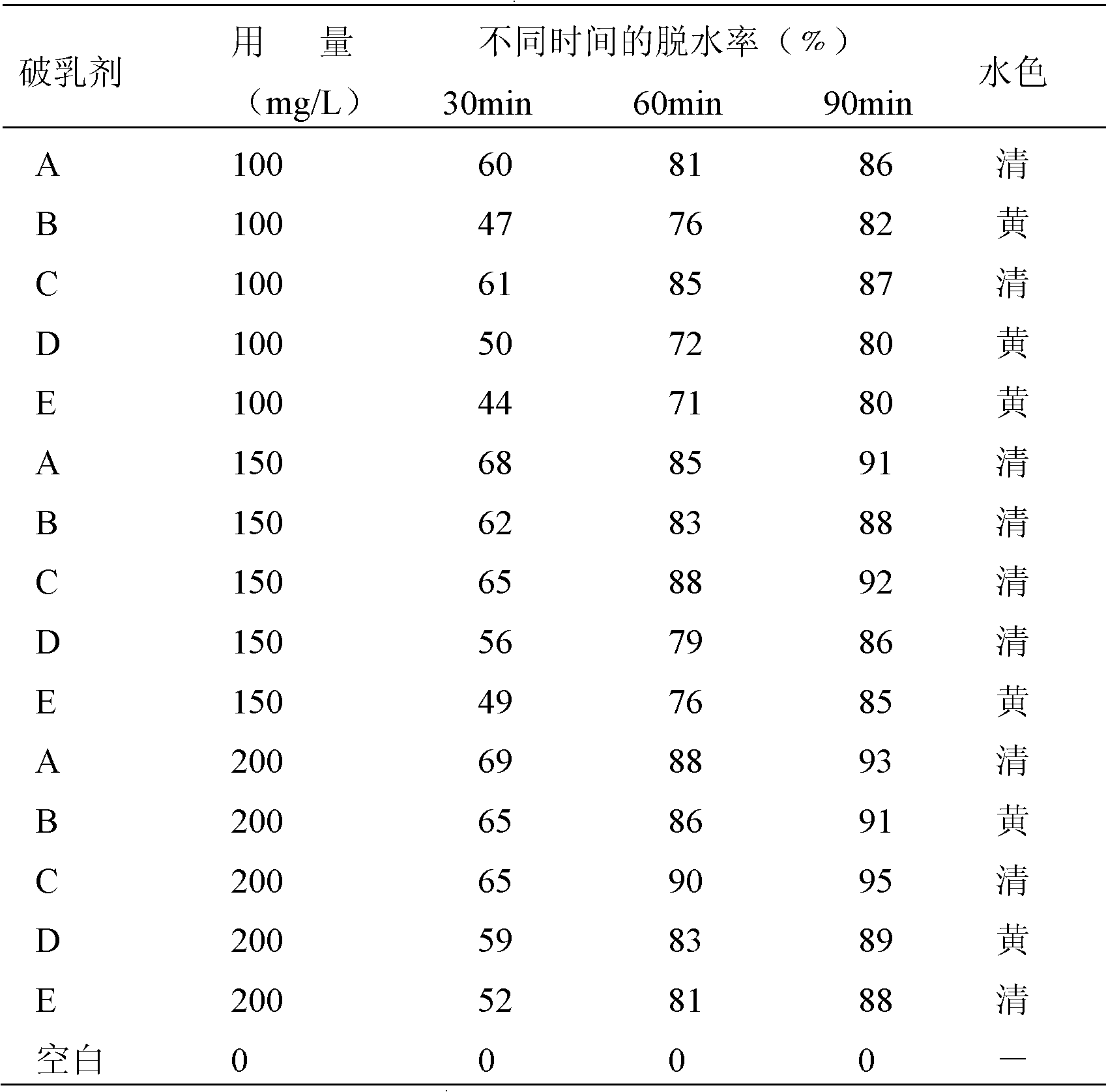

Fast emulsion breaking method

InactiveCN101121898AImprove dehydration rateImprove demulsification efficiencyHydrocarbon oil dewatering/demulsificationNon-miscible liquid separationMass ratioRadiation frequency

The invention relates to a rapid emulsion breaking method, including microwave radiation. Emulsion breaker is added according to the water content of the rolly oil (calculated by weight percent), the mass ratio of the water and emulsion breaker is 1:0.5*10-4 to 5*10-4, and microwave is adopted for emulsion breaking. The emulsion breaker is one or more than two types of mixtures of polyamine polyoxy-propylene polyoxyethylene ether, resin polyoxy-propylene polyoxyethylene ether, higher-alcohol initiator emulsion breaker or propylene glvcol emulsion breaker. The microwave radiation and microwave radiation frequency are 2450MHz or 915MHz. Under the synergistic reaction, water-in-oil emulsion liquid is broken within a relatively short period, a bigger anhydration rate is achieved, and the emulsion-breaking efficiency is improved. In the circumstance of a little emulsion breaker, microwave radiation breaking method can be adopted, and the emulsion breaking speed is increased by 1-2 orders of magnitude compared with the traditional emulsion breaking by heating. The method is easy to implement, energy efficient, rapid in emulsion breaking, and the emulsion breaking effect is good.

Owner:LIAONING UNIVERSITY

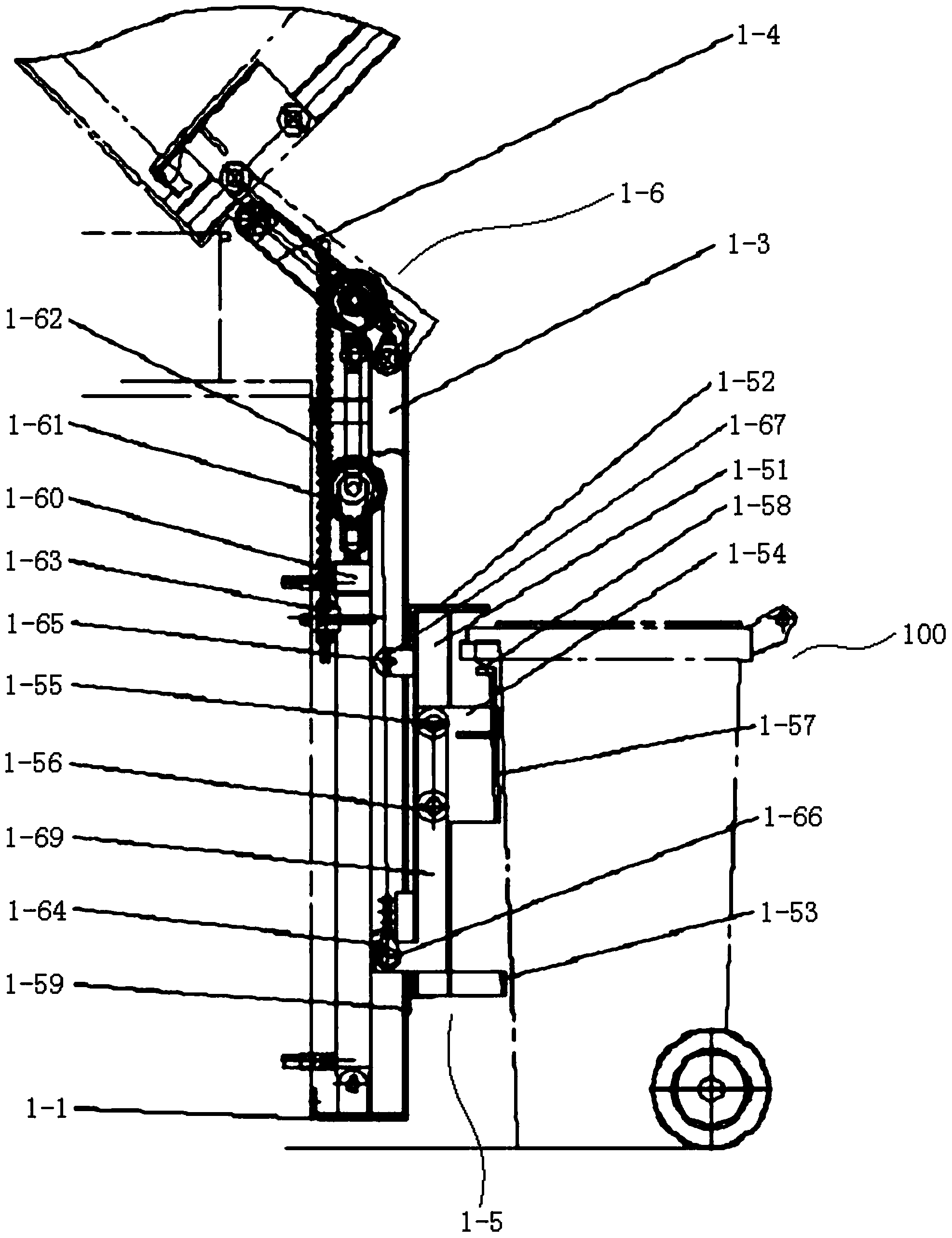

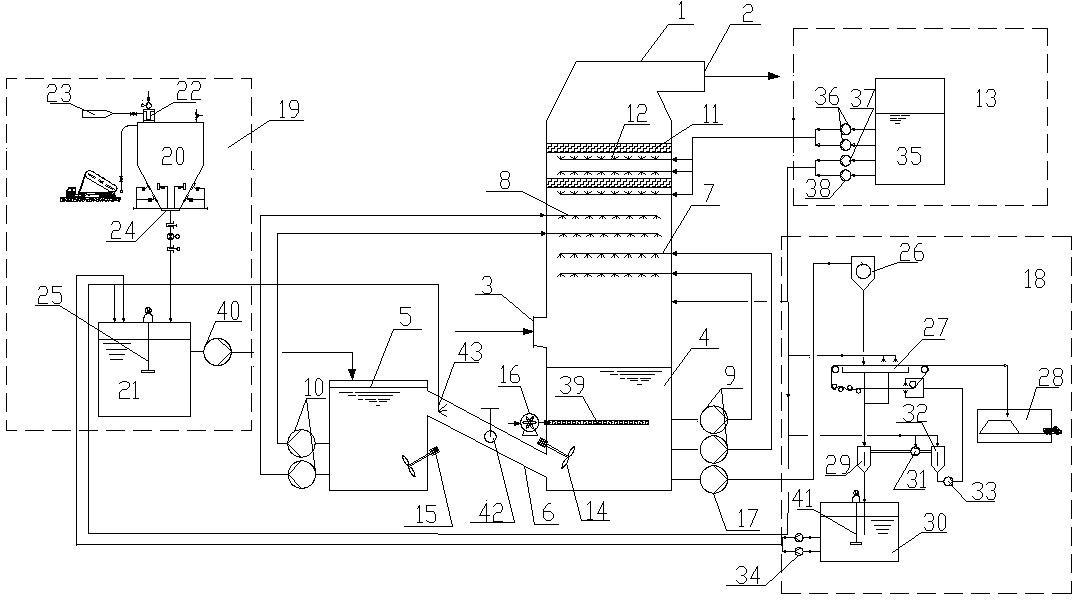

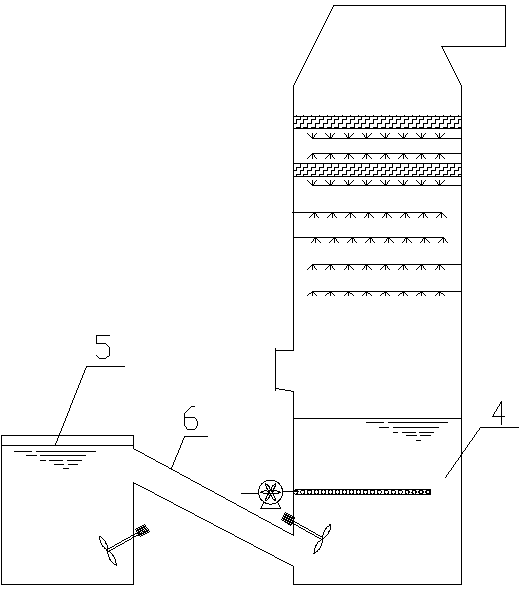

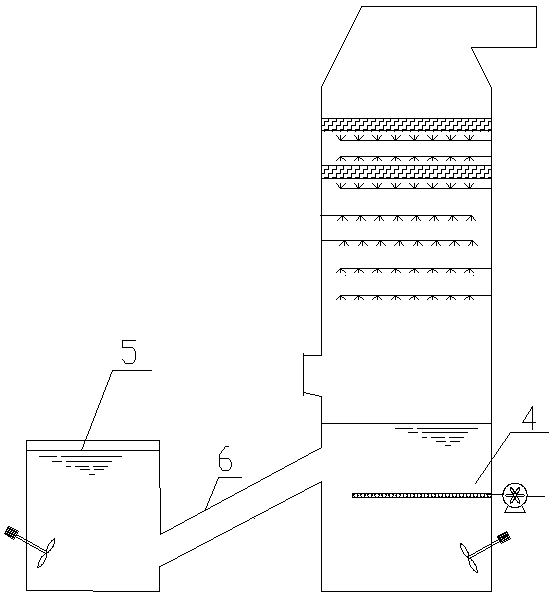

Kitchen waste pretreatment equipment and technology

The invention relates to a kitchen waste pretreatment equipment and technology. The equipment is characterized by comprising a shell body, a garbage can lifting device mounted on one side of the shell body, a feeding device mounted on the upper portion of the shell body, an automatic separation device mounted in the shell body, an extrusion device mounted in the shell body, a smashing device mounted in the shell body, a fermenting and drying device mounted in the shell body and an ionization deodorization device mounted in the shell body. The kitchen waste pretreatment equipment and technology has the advantages of feeding and sorting automatically, being good in solid-liquid separation effect, high in efficiency, high in dehydration rate, high in fermentation treatment speed, even in fermentation, high in heating speed, capable of oxygenating automatically during fermentation, up to standard on gas deodorization, environmentally friendly, free of pollution and convenient to operate, saving manpower and the like, can process the kitchen waste generated by 300 to 500 people in 24 hours, and output 150kg to 200kg organic fertilizer with the moisture content not more than 25%.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

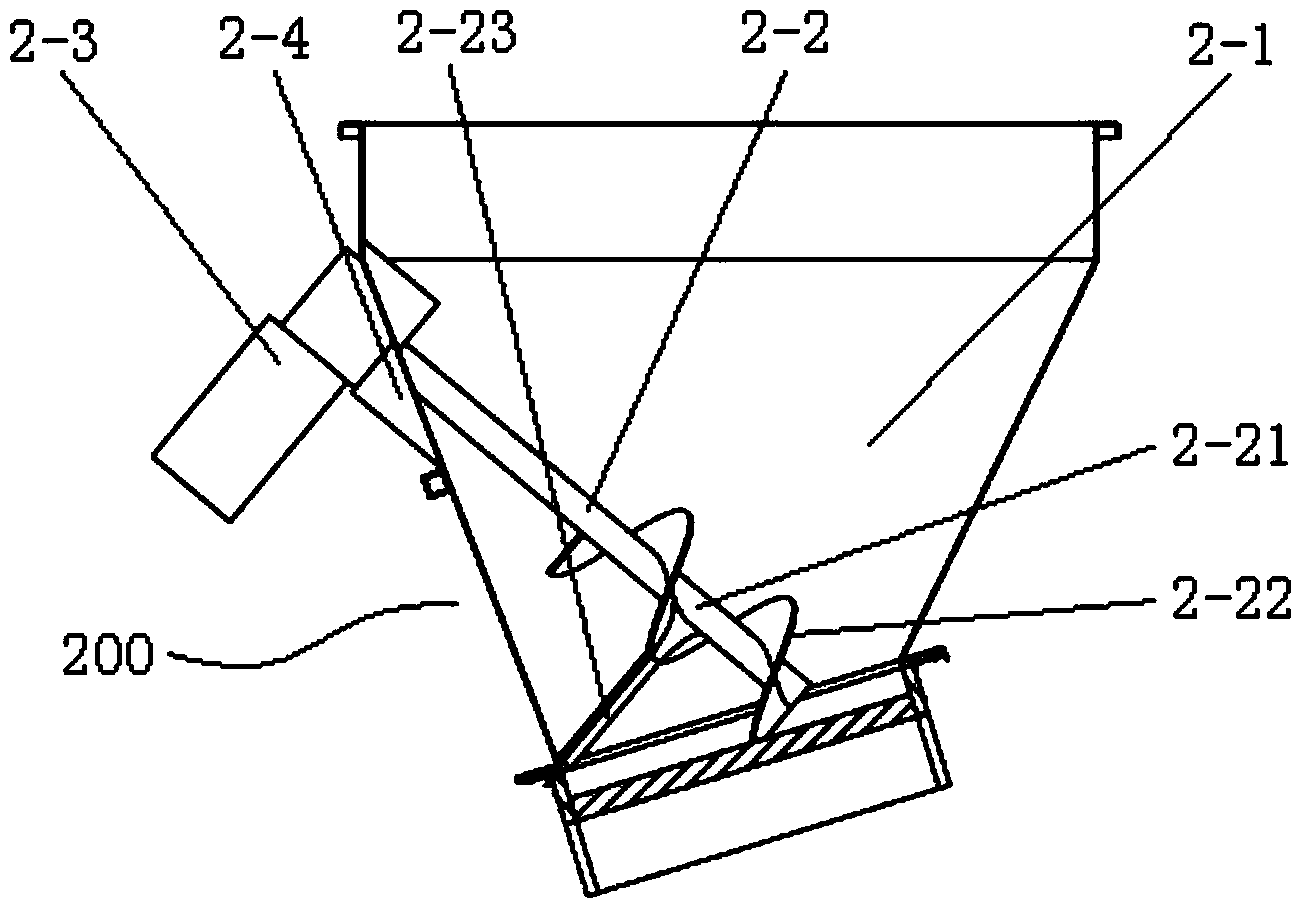

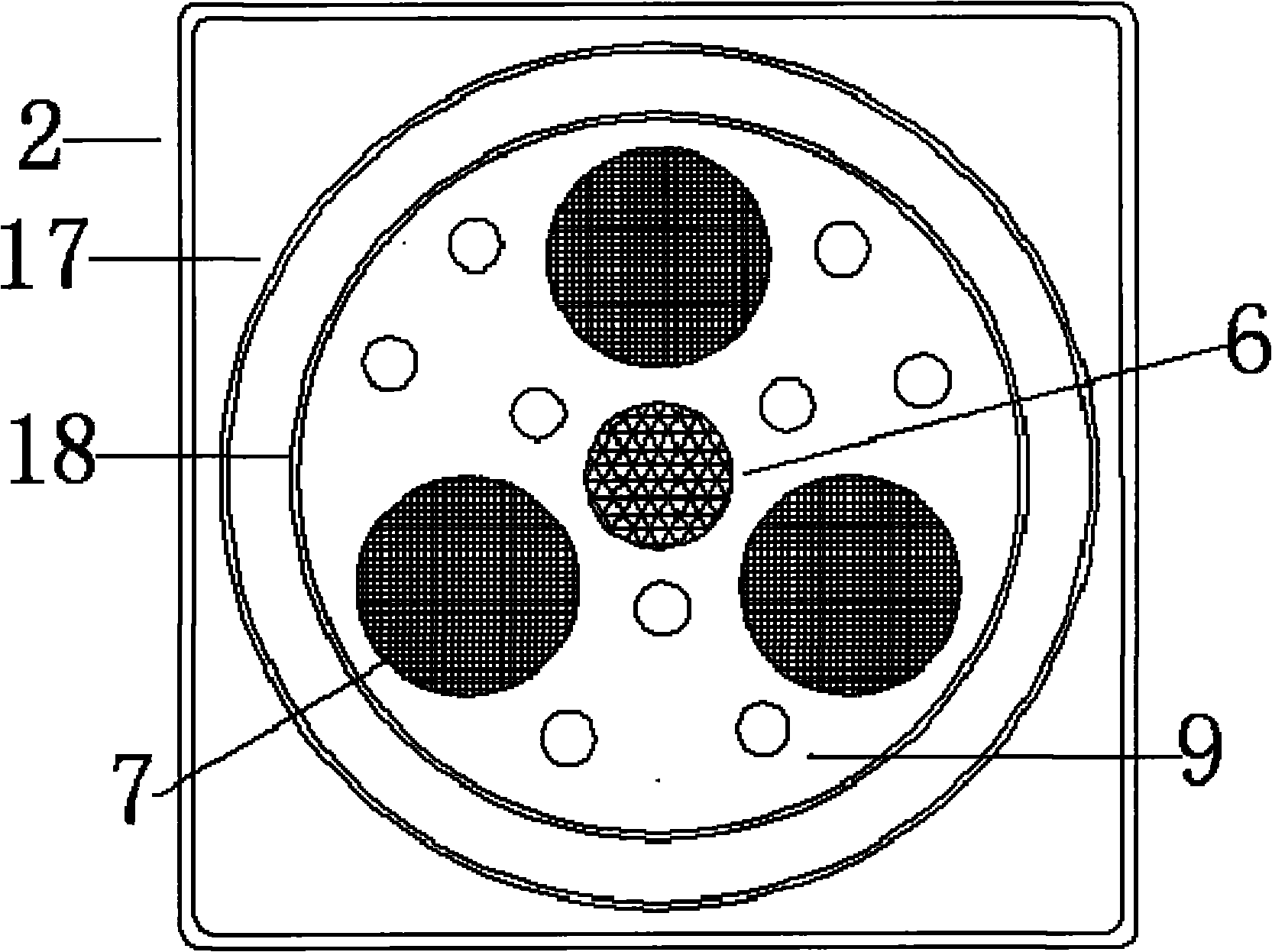

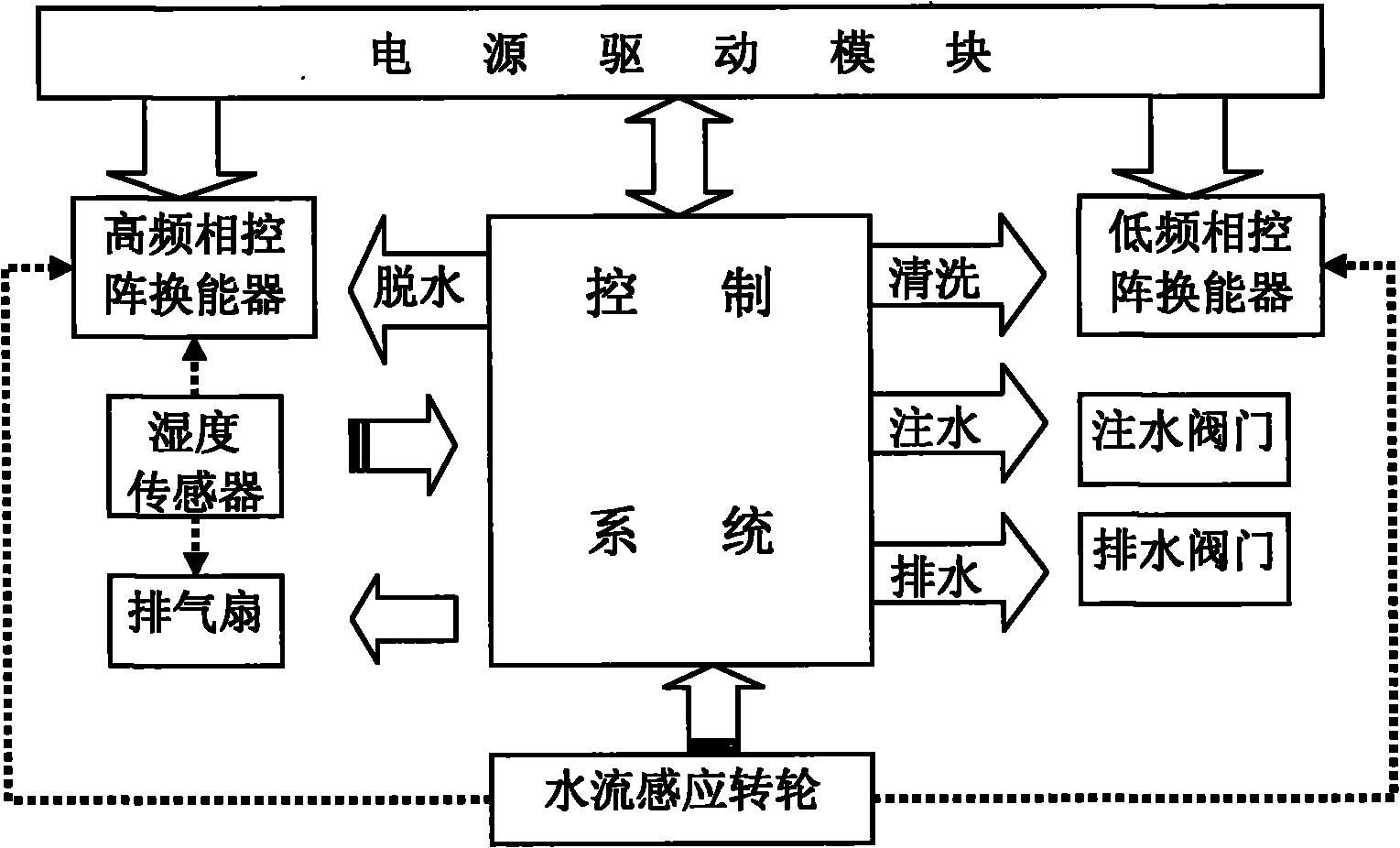

Multifrequency phased ultrasonic clothes cleaning and dehydration method and device

InactiveCN101962898AReduce wearImprove work efficiencyControl devices for washing apparatusVibration washing machinesCavitationEngineering

The invention discloses a multifrequency phased ultrasonic clothes cleaning and dehydration method and device, wherein the device comprises a clothes washing box, a circuit control system, a water inlet and drain device, a display control panel, ultrasonic phased-arrays and an air exchange device, wherein an acoustic wave baffle board is arranged in the clothes washing box, and floats on the liquid surface when working; the ultrasonic phased-arrays are uniformly distributed on the side wall and the bottom part of a barrel; the clothes washing box is provided with a water inlet device at the top part and a drain device at the bottom part; the ultrasonic phased-arrays comprise ultrasonic phased-arrays of different resonant frequencies. The invention finishes full ultrasonic clothes washing by using the method combining high and low frequency ultrasonic according to different characteristics of the cleaning and the dehydration processes in the washing process, that is to say, low frequency ultrasonic is used for cavitation cleaning, and the high frequency ultrasonic is used for atomization dehydration. The invention utilizes the method of scanning with ultrasonic beams so that the energy of the ultrasonic is more concentrative, the penetrating power is stronger, the washing and the dehydration effects are more uniform, and both the cleanness and the dehydration rate are improved.

Owner:SOUTH CHINA UNIV OF TECH

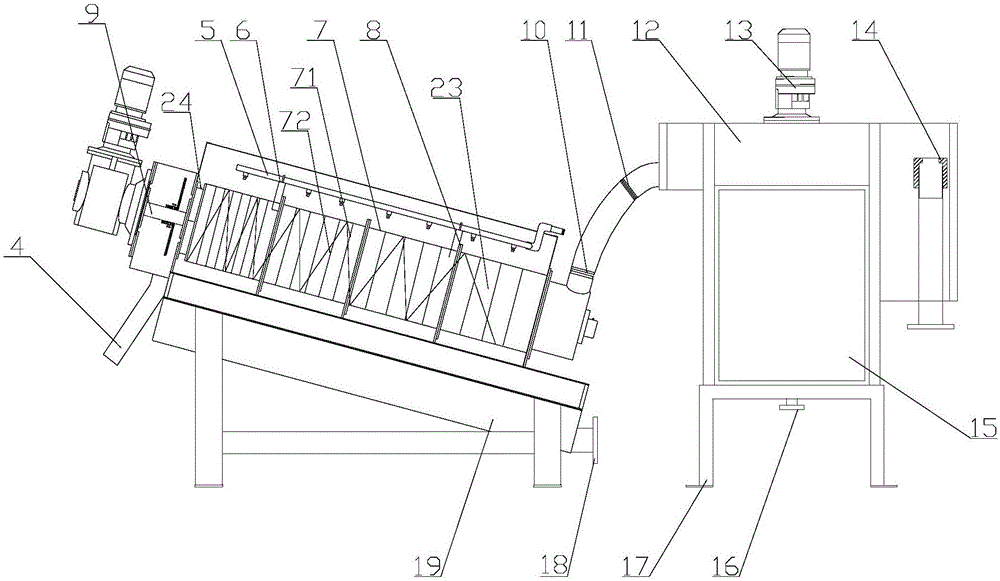

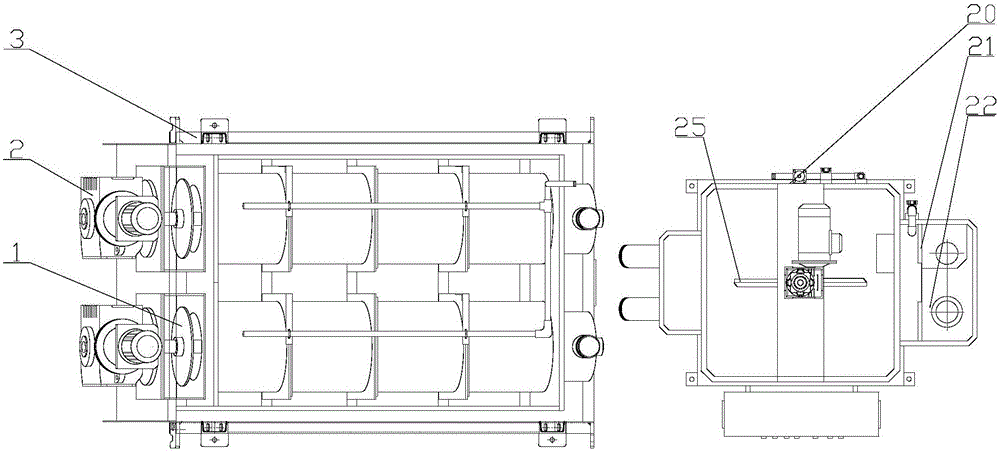

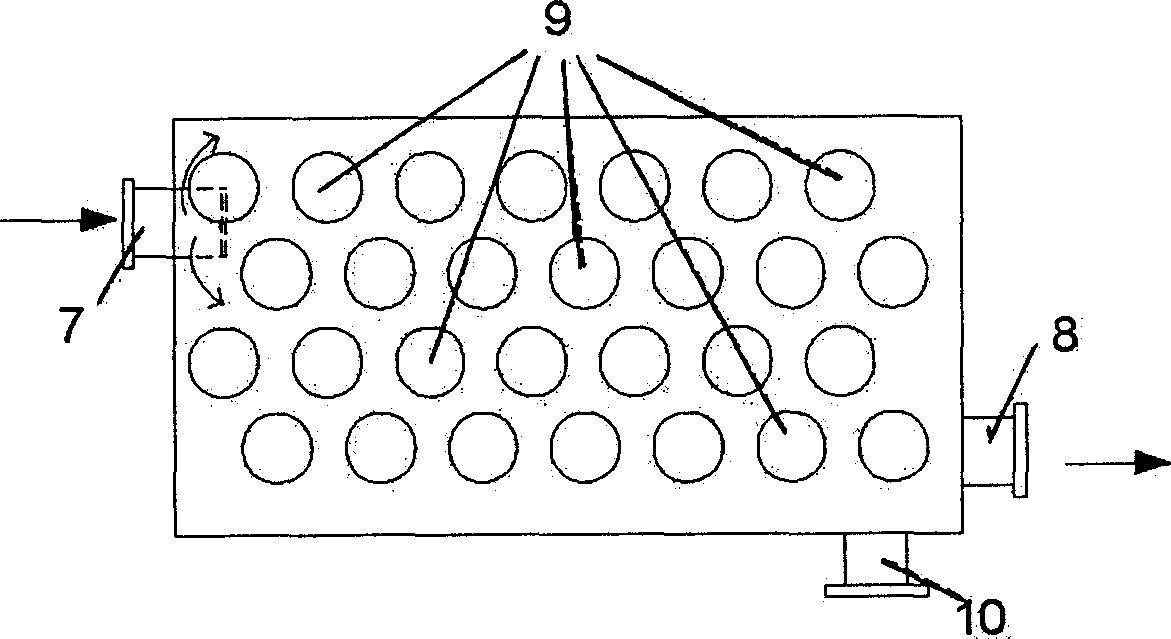

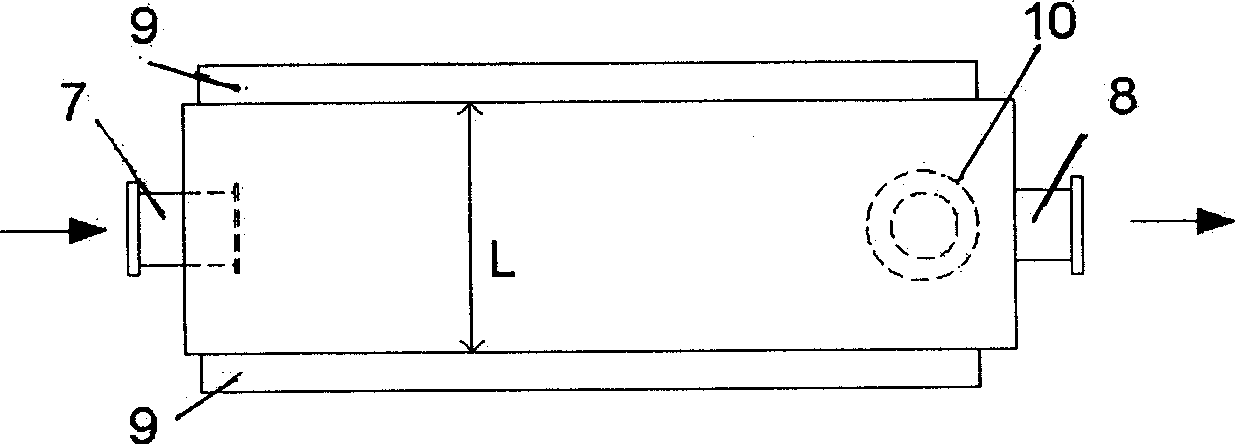

Stacked spiral type sludge dewatering machine

InactiveCN105084709ATurn slowlyImprove dehydration efficiencySludge treatment by de-watering/drying/thickeningFlocculationPulp and paper industry

The invention relates to a sludge dewatering machine, in particular to a stacked spiral type sludge dewatering machine which comprises a stirring flocculation device and a dewatering device. The dewatering device comprises a first sludge inlet, a first sludge outlet, a stacked spiral body, a support plate, a spiral shaft, a rack and a first power device. The stacked spiral body comprises fixed rings and movable rings. The fixed rings are fixedly connected with the support plate. The spiral shaft is located in a cylindrical cavity formed by the fixed rings and the movable rings. The spiral shaft is fixedly connected with the first power device. The support plate and the spiral shaft are fixed to the rack. By the adoption of the structure, the sludge dewatering machine is not prone to being blocked, the dewatering rate is increased, and operation is very convenient.

Owner:江苏清木源环保科技有限公司

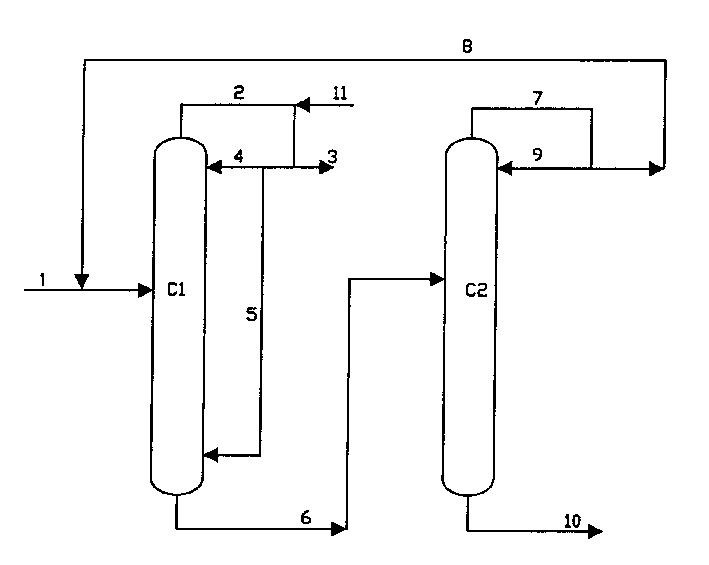

Efficient desulfurization single-tower double-circulation system and method

InactiveCN104226099APromote crystallizationImprove dehydration rateDispersed particle separationPh controlEngineering

The invention discloses an efficient desulfurization single-tower double-circulation system and method. The efficient desulfurization single-tower double-circulation system comprises a primary slurry pool in a desulfurization tower and a secondary slurry pool outside the desulfurization tower, and the two slurry pools are connected by virtue of a pipeline, so as to form a multiregion pH control double-circulation desulfurization system, wherein limestone slurry is supplemented from the secondary slurry pool to the primary slurry pool, and cypsum slurry is discharged from the primary slurry pool of the desulfurization tower. According to the efficient desulfurization single-tower double-circulation system, the region control can be performed on the pH of the two slurry pools, the slurry at different spraying layers is respectively supplied by the two slurry pools, the slurry with a high pH value is favorable for absorbing SO2, so that the desulphurization efficiency of a desulfurization system is more than 99%, and the slurry with a low pH value is favorable for sulfite oxidation and gypsum crystallization, so that the gypsum dehydration rate and the gypsum purity are increased.

Owner:ZHEJIANG UNIV

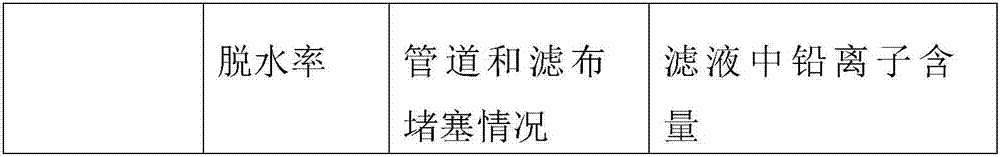

Sludge conditioning agent, application thereof and method for conditioning sludge

InactiveCN106865952ALow costAchieve dehydrationSludge treatment by de-watering/drying/thickeningWater contaminantsFlocculationGeopolymer

The invention provides a sludge conditioning agent, an application thereof and a method for conditioning sludge. The sludge conditioning agent comprises a geopolymer and other conditioning additives. On one hand, the addition of the geopolymer remarkably improves a flocculation reaction of the sludge conditioning agent on the colloidal particles in the sludge conditioning process and improves the sludge dewatering effect, and on the other hand, toxic substances such as metal ions can also be surrounded in a cavity between the geopolymer molecules, so that a detoxification effect is achieved; meanwhile, the geopolymer can remarkably reduce the use of ferric chloride, quicklime and the like, so that the cost can be reduced, the corrosion of the ferric chloride on a pipeline in the mechanical dehydration process and the blockage of the quicklime on the pipeline and a filter cloth can be reduced.

Owner:北京君联合环境科技有限公司

Non-polyether demulsifier and preparation method thereof

ActiveCN105504143AAvoid pollutionMolecular chain lengthDewatering/demulsification with chemical meansHydrophilic monomerCross-link

The invention provides a novel non-polyether demulsifier and its preparation method. The non-polyether demulsifier contains a copolymer prepared by seeded emulsion copolymerization of a hydrophilic monomer, a hydrophobic monomer and an optional cross-linked monomer. The weight ratio of the hydrophilic monomer to the hydrophobic monomer is 3: 97-20: 80. The demulsifier of the invention has advantages as follows: raw materials are easily available; production condition is mild; high temperature and high pressure are not required; operation is convenient; and cost is low. The non-polyether demulsifier of the invention can be used in demulsification of crude oil in an oil field, especially in demulsification of thickened oil. The non-polyether demulsifier has a good demulsification effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Dirty oil dewatering process for refinery and oil field

The present invention relates to dirty oil dewatering process, and is especially ultrasonic treatment process of dewatering dirty oil in refinery and oil field to recover oil. Water containing dirty oil is first ultrasonic treated in ultrasonic treater with ultrasonic field of standing wave and traveling wave before being oil-water separated in a heat deposition tank, or water containing dirty oil is oil-water separated in a heat deposition tank with standing wave and traveling wave ultrasonic treater. The technological process adopts physical demulsifying process to dewater, has high dirty oil adaptability, no influence of dirty oil property, fast oil-water separation, high dewatering rate, and low operation cost. The present invention is significant in dirty oil recovering and reducing environmental pollution.

Owner:NANJING UNIV OF TECH

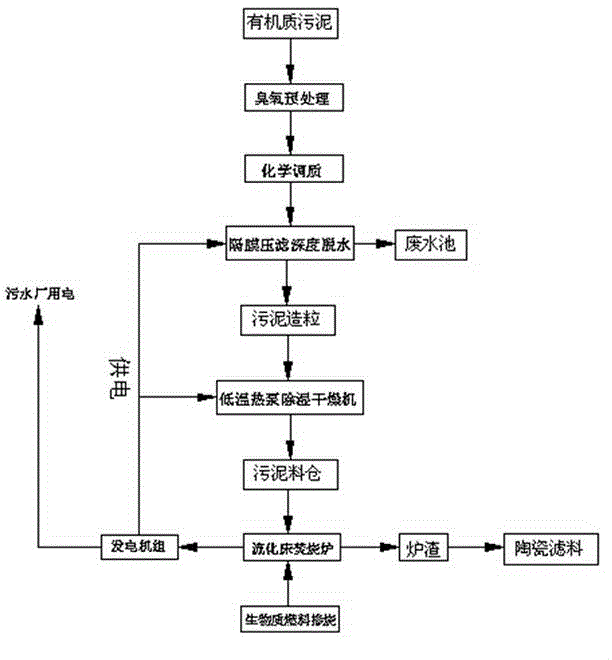

High-concentration organic sludge treatment method

ActiveCN104609693AQuickly soluble inAchieve recyclingSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationHigh concentrationAutomatic control

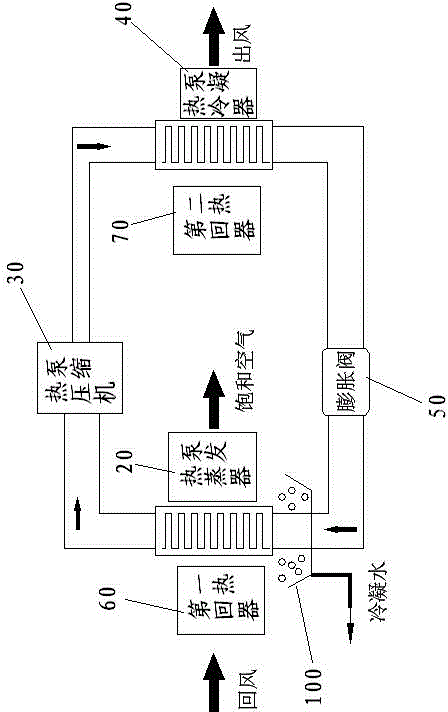

The invention discloses a high-concentration organic sludge treatment method. The high-concentration organic sludge treatment method comprises the following steps: preparing organic sludge, performing ozone pretreatment, chemically tempering, performing diaphragm pressure filtration for deep dewatering, granulating the sludge, drying by using a low-temperature heat-pump dehumidifying drying machine, sending the dried sludge into a sludge bin, doping biomass fuel, performing oxygen-enriched combustion, and converting, recycling and applying combustion heat, steam and slag. The whole treatment method is conveniently matched with a full-automatic control system to enhance convenience in management and operation, and the treatment method has a high sludge-dewatering rate, a high sludge combustion utilization rate and high treatment efficiency; closed treatment is adopted in the steps, so that zero exhaust heat emission and zero noise pollution are ensured and the treatment method is more energy-saving, more environment-friendly and safer; sterilization and harm-removing treatment is performed on the sludge in many links, so that the fact that tail gas emission reaches the standard is ensured; sludge incinerating heat is used for generating electricity which is returned to sludge treatment equipment, so that the operating cost is reduced, economic benefits are improved, and sludge reduction from a source, harmless treatment, resource utilization and sludge recycle are really realized.

Owner:DONGGUAN DONGYUAN ENVIRONMENTAL TECH CO LTD

Nano highly effective amendment for sludge dehydration

InactiveCN1621370AHigh floc strengthLow floc strengthSludge treatment by de-watering/drying/thickeningWater/sewage treatment by flocculation/precipitationSulfateSludge

The present invention discloses one kind of Z's nanometer efficient sewage dewatering amendment. The Z's nanometer efficient sewage dewatering amendment consists of polymerized ferric sulfate 85-98 weight portions, polyacrylamide 0.5-6 weight portions, hydroxymethyl cellulose sodium 0.5-6 weight portions and nanometer material 0.5-3 weight portions. The present invention has powerful neutralizing capacity, bridging capacity and permeating capacity and thus has high sewage dewatering effect.

Owner:曾智勇 +1

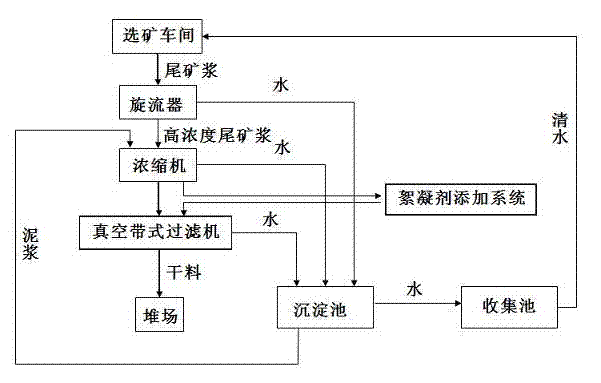

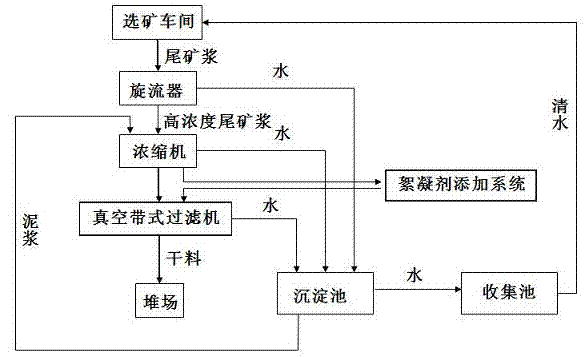

Dehydration method and device of tailings

ActiveCN102228762AEliminate the risk of dehydrationAvoid accidentsFiltration circuitsCycloneTailings dam

The invention relates to a dehydration method and a dehydration device of tailings. The dehydration device mainly comprises a cyclone, a thickener, a vacuum belt filter and a sedimentation basin. A tailing slurry discharged from an ore dressing workshop go through the cyclone, the thickener and the vacuum belt filter in order to form dry materials which are placed in a stock dump. And a flocculating agent adding system is installed between the thickener and the vacuum belt filter. The sedimentation basin is connected to a collection basin used for collecting the clear water overflowing from the sedimentation basin, and then the clear water come into the ore dressing workshop for recycling. With the dehydration method and dehydration device of tailings, risks from dehydration with a tailing dam can be eliminated, so that accidents are effectively avoided. Meanwhile, the device of the invention has low investment, low running cost and high dehydration rate.

Owner:YUNNAN DAHONGSHAN PIPELINE

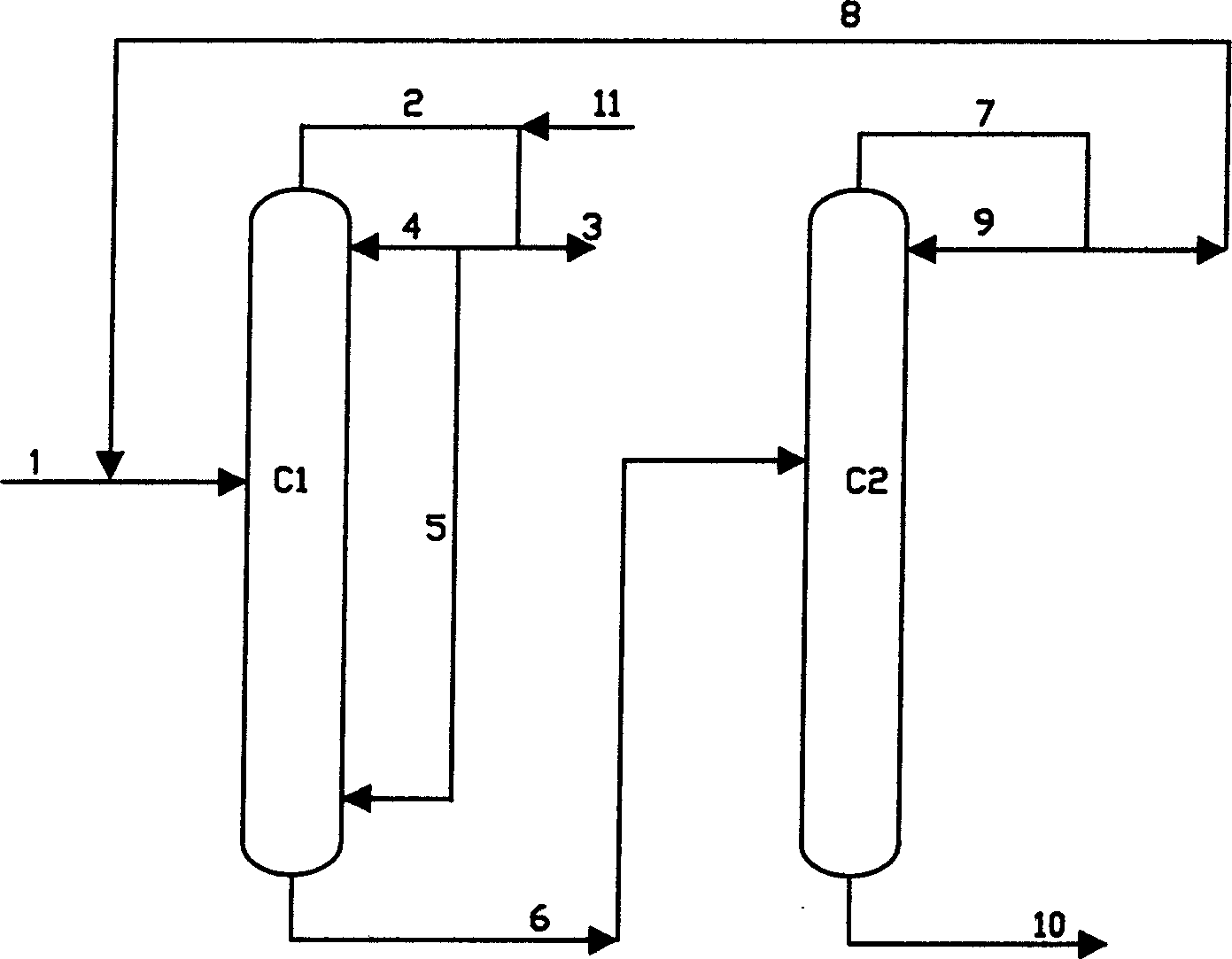

Method for purifying acrylic acid b utilizing azeotropic rectification

InactiveCN1535948AImprove dehydration rateHigh deacetate rateCarboxylic compound separation/purificationAcetic acidTetrafluoroethylene

The present invention relates to a new method for purifying acrylic acid. It uses tetrafluoroethylene single coboiling agent or tetrafluoroethylene and aromatic hydrocarbon compounded cobiling agent, in the light-removing tower adopting parallel-flow jet tray it adopts azeotropic rectification process to remove the water and acetic acid from acrylic acid aqueous solution. Said process method has higher dewatering rate and acrylic acid removing rate and lower acrylic acid carrying-out rate.

Owner:SHANGHAI HUAYI NEW MATERIAL

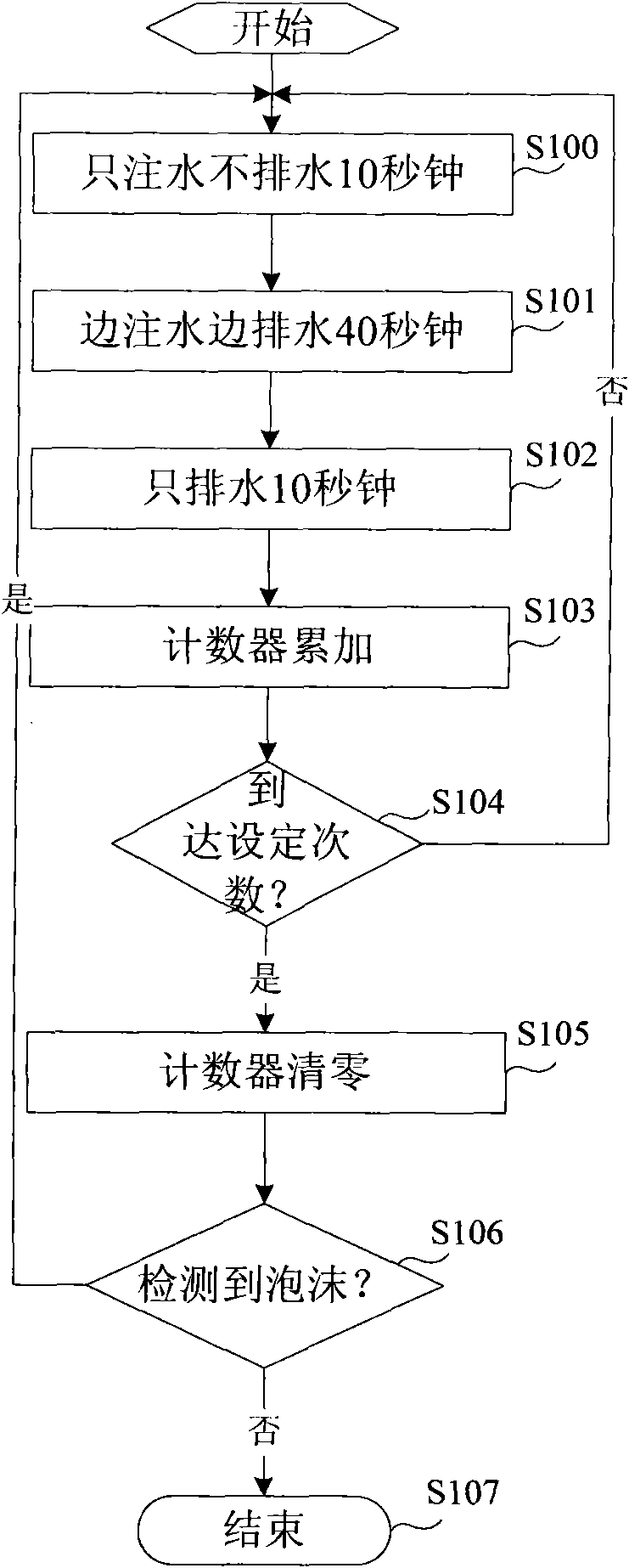

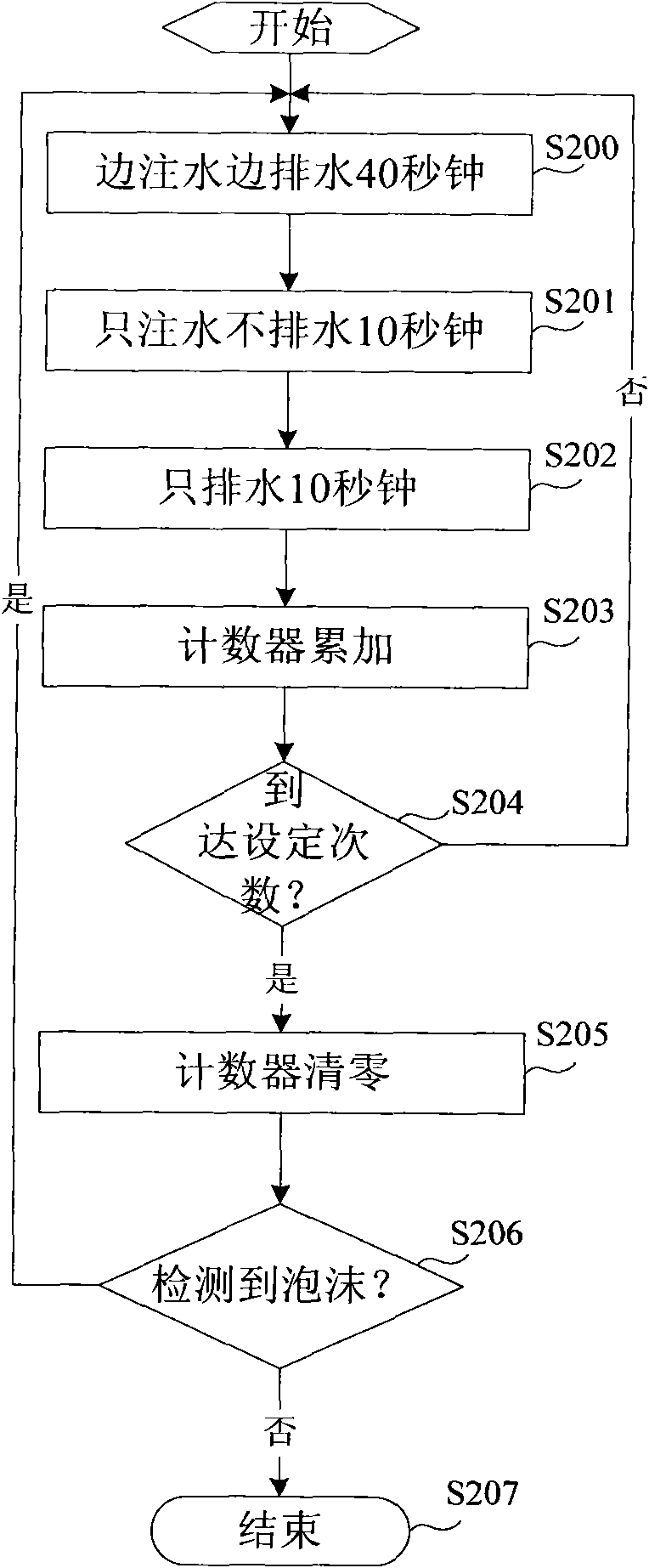

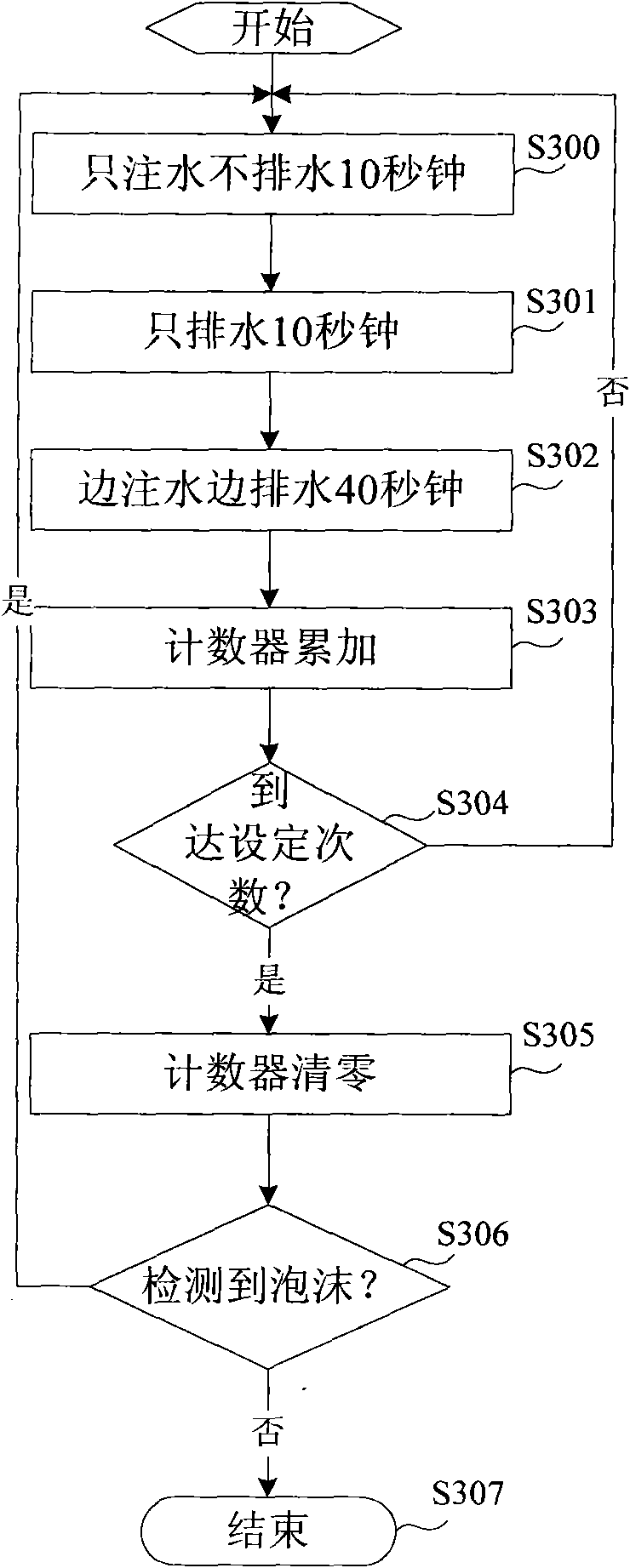

Washing machine defoaming method

InactiveCN101851842AEliminate pollutionEliminate potential safety hazardsOther washing machinesControl devices for washing apparatusEngineering

The invention discloses a washing machine defoaming method, which comprises the following steps of: independently injecting water; performing water injection and drainage simultaneously; and independently draining. In the method, because the steps of independently injecting water, performing water injection and drainage simultaneously, and independently draining are added, the combination effectively removes foams.

Owner:HAIER GRP CORP +1

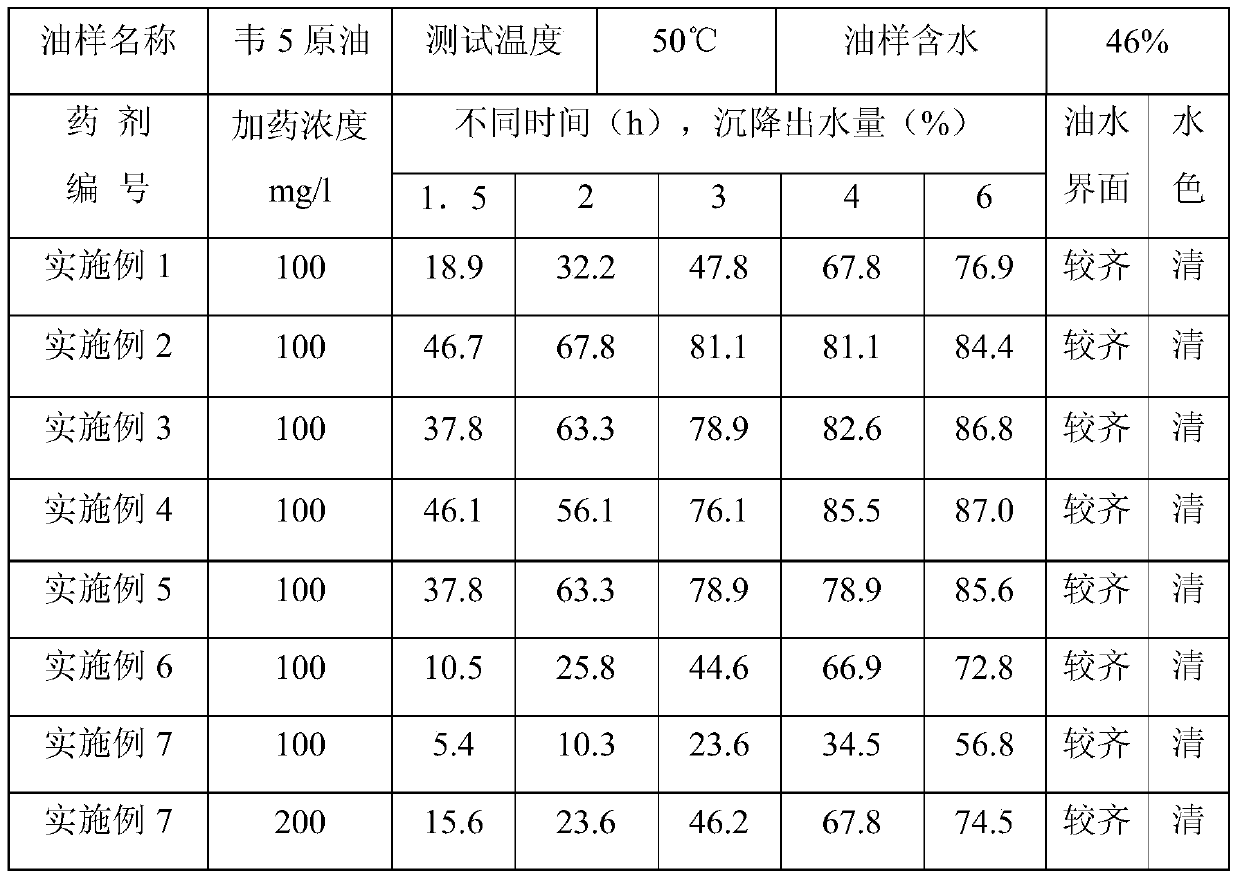

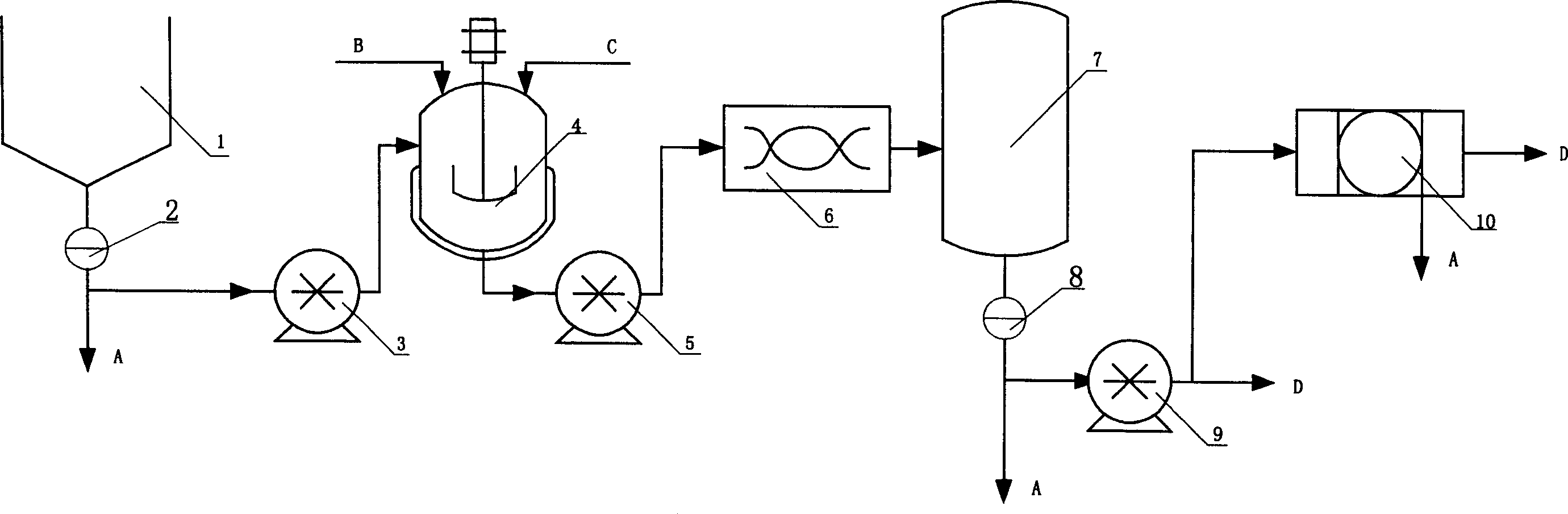

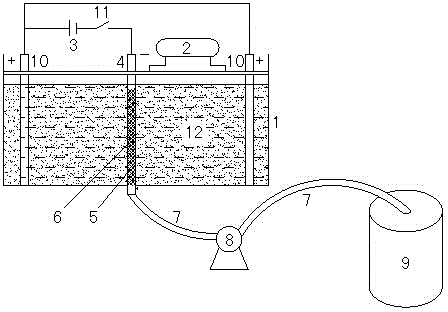

Method and apparatus for high-efficient crude oil desalination / dehydration

InactiveCN102226100AReduce difficultyReduce the water content of crude oilRefining by water treatmentTreatment with plural serial refining stagesChemistryElectric field

The invention belongs to the technical field of petrochemical industry, and particularly relates to a method and an apparatus for high-efficient crude oil desalination / dehydration by a combined filtration-electric field coalescence method. The apparatus for high-efficient crude oil desalination / dehydration of the invention comprises a raw material conveying system, a mixing device, a dehydration filtration device, and an electrical desalting device which are connected in order. The method for high-efficient crude oil desalination / dehydration of the invention is realized by using the apparatus for high-efficient crude oil desalination / dehydration of the invention and through the steps of raw material preheating, mixing, preliminary demulsification, and electrical desalination / dehydration. The invention adopts a combined filtration-electric field coalescence method for crude oil desalination / dehydration, which can overcome respective disadvantages of performing desalination / dehydration process by a filtration method or an electric field coalescence method, decrease running severity of both the two methods, not only improves the adaptability of the crude oil desalination process, the desalination / dehydration rate, and the stable running rate, but also reaches the purposes of energy saving and consumption reduction.

Owner:GUANGZHOU BOXENERGY TECH

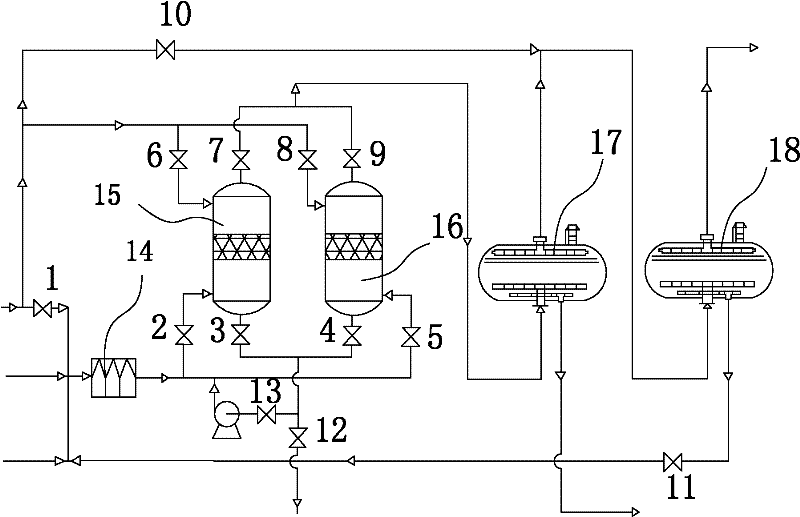

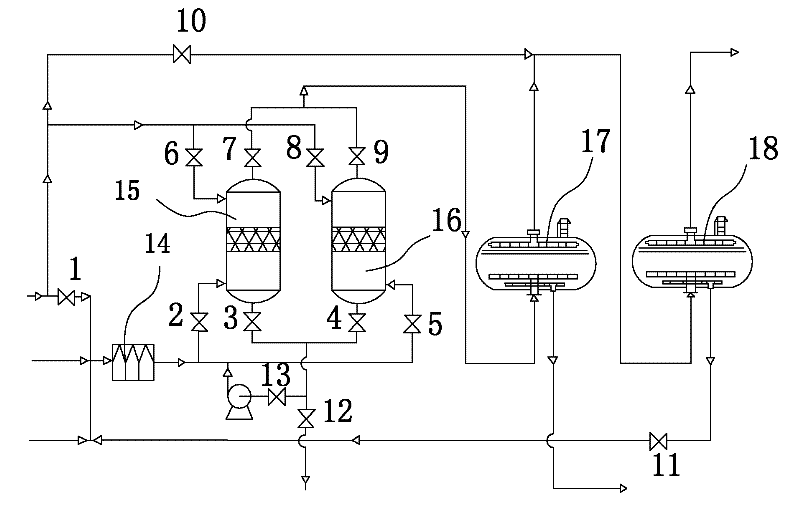

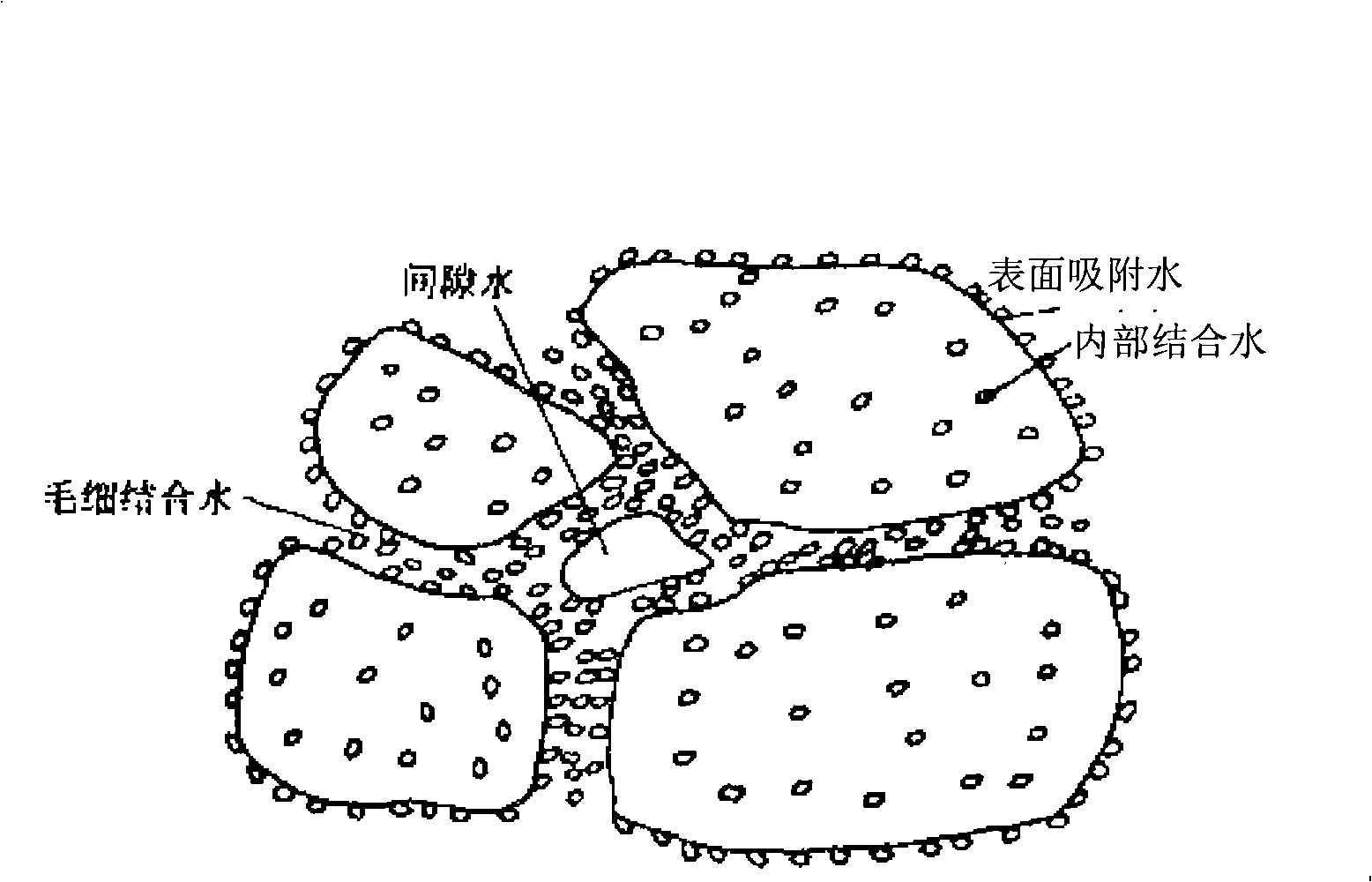

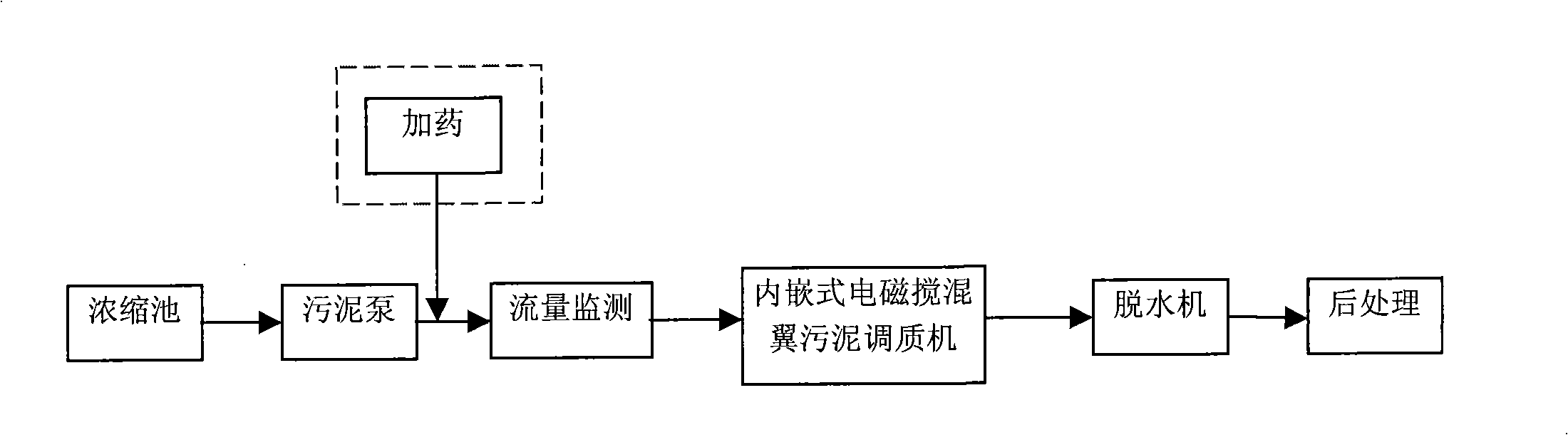

Method and apparatus for improving sludge dehydration

InactiveCN101328002APrecise temperingLower specific resistanceSludge treatment by de-watering/drying/thickeningEnergy expenditureDewatered sludge

The invention discloses a method for improving the dehydrating property of the sludge and equipment thereof. The method is to adopt an inner embedded type electromagnetic swirling wing sludge conditioner arranged in the sludge pipe or an external magnet-rotary sludge conditioner arranged on the sludge pipe to quench and temper the sludge, so as to achieve the purpose of sludge specific resistance reduction and sludge dehydrating property improvement. After the method and the equipment are implemented, the water content of the final dewatered sludge (mud cake) can reach 70-80% which reduces by 2-15% comparing to the technology without conditioner treatment. The work efficiency of the dewaterer is greatly improved, the energy consumption of the dewaterer is reduced by 5-40% and the reagent dosing is reduced by 5-100%. The method and equipment of the invention are not only suitable for the transformation of the old equipment in the prior sludge treatment, but also suitable for the establishment of the new equipment.

Owner:上海滨浦水处理设备有限公司

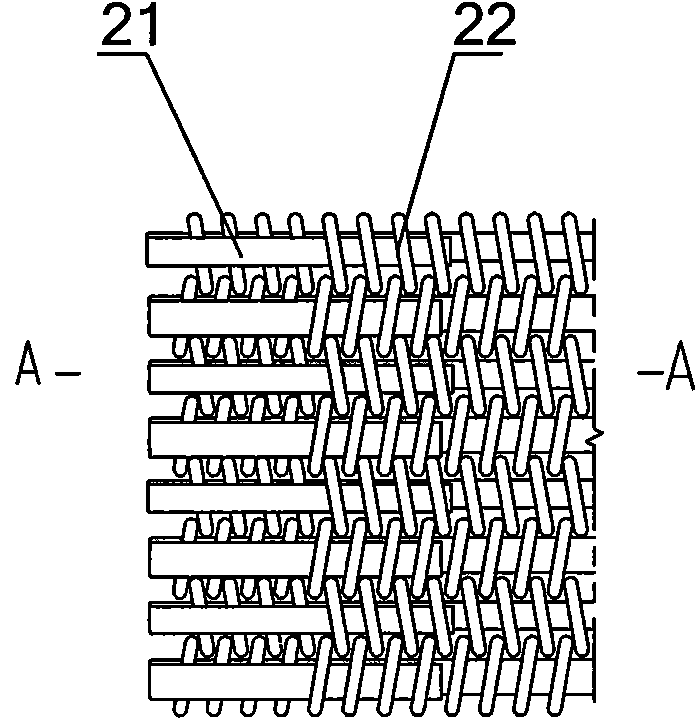

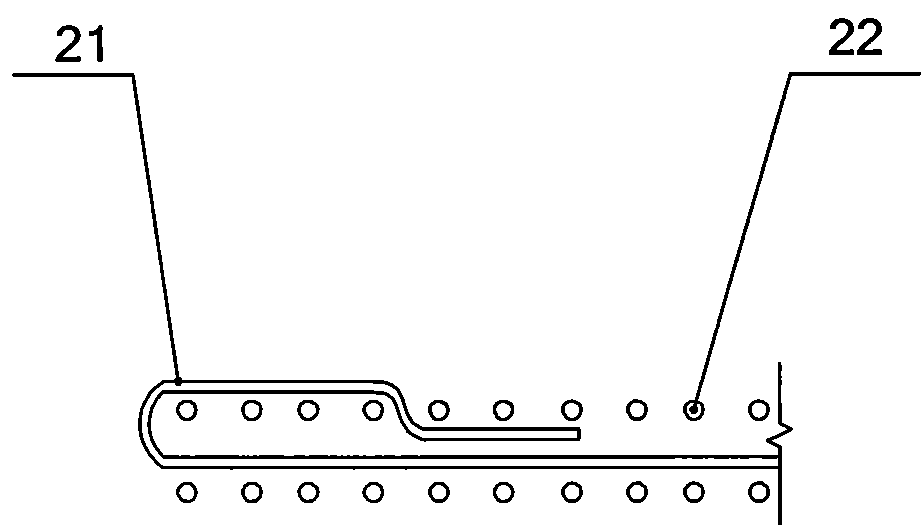

Sludge dewatering device

InactiveCN101993183AGuaranteed water areaExtend your lifeSludge treatment by de-watering/drying/thickeningPulp and paper industryMetal

The embodiment of the invention provides a sludge dewatering device, belonging to the field of sludge processing equipment. The sludge dewatering device comprises a stand, an anode roller, a cathode filter screen, a guide roll and a drive roll. The anode roller is a metal roller, is arranged in the stand, and is electrically connected with an anode of a power supply. The cathode filter screen is a non-metal spiral screen, a plurality of metal wires pass through a spiral cylinder of the non-metal spiral screen to be used as conductive bodies, each metal wire crosswise passes through the non-metal spiral screen, both ends of each metal wire extend outside the non-metal spiral screen, and each metal wire is electrically connected with a cathode of the power supply. The drive roll and the guide roll are arranged on the stand, the cathode filter screen is arranged on the drive roll and the guide roll and driven by the drive roll, and a part of the cathode filter screen surrounds the outside of the anode roller and forms a gap extruding sludge with the anode roller. The flow area of the cathode of the sludge dewatering device is large, the dewatering efficiency is improved, and the service life of the cathode filter screen is prolonged.

Owner:SOUND GLOBAL

Oil-containing dross dehydration process

InactiveCN1803654AReduce dosageReduce operating costsWater/sewage treatment by flocculation/precipitationAluminium chlorohydrateResource recovery

The invention relates to a dewatering technique with chemical regulation and supersonic wave for oil-contained scum. Wherein, after the initial deposition to remove some water, using NaOH or Na2CO3 to regulate the pH value of scum to weak base state; adding flocculant (polyferroaluminium chloride or polyacrylamide) to stir evenly and send to supersonic treatment part for some minutes; then leading into deposition tank or pond to separate scum and water. The treated product can be recovered or send into incinerator for final treatment.

Owner:NANJING UNIV OF TECH

Method for producing adiponitrile with adipic acid liquid-phase method

ActiveCN106146345AImprove dehydration ratePhysical/chemical process catalystsCarboxylic acid nitrile purification/separationSynthesis methodsDiluent

The invention discloses a method for producing adiponitrile with an adipic acid liquid-phase method. A solid phosphoric acid catalyst is adopted, adipic acid and a diluent are added into a reaction still, heating and raw material stirring are conducted during reaction, ammonia gas is supplied after temperature reaches a certain value, and the product is generated after reaction is conducted for a while. A novel environment-friendly adiponitrile synthesis method is adopted. By the adoption of the solid phosphoric acid catalyst, the defects of traditional catalysts are overcome, and catalysis effect is improved.

Owner:PETROCHINA CO LTD

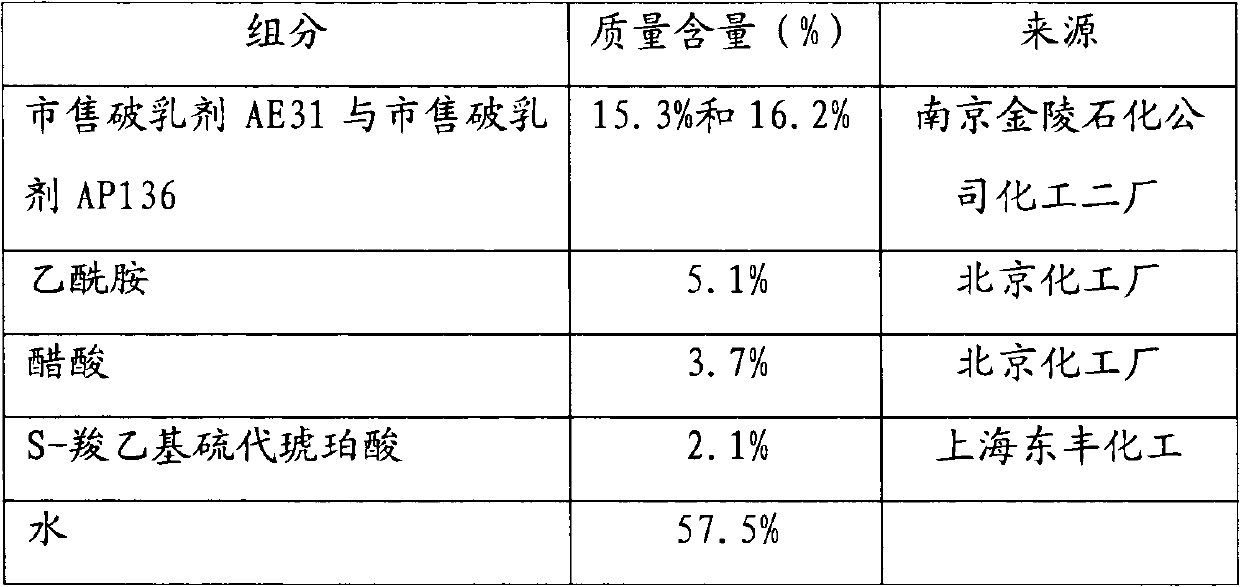

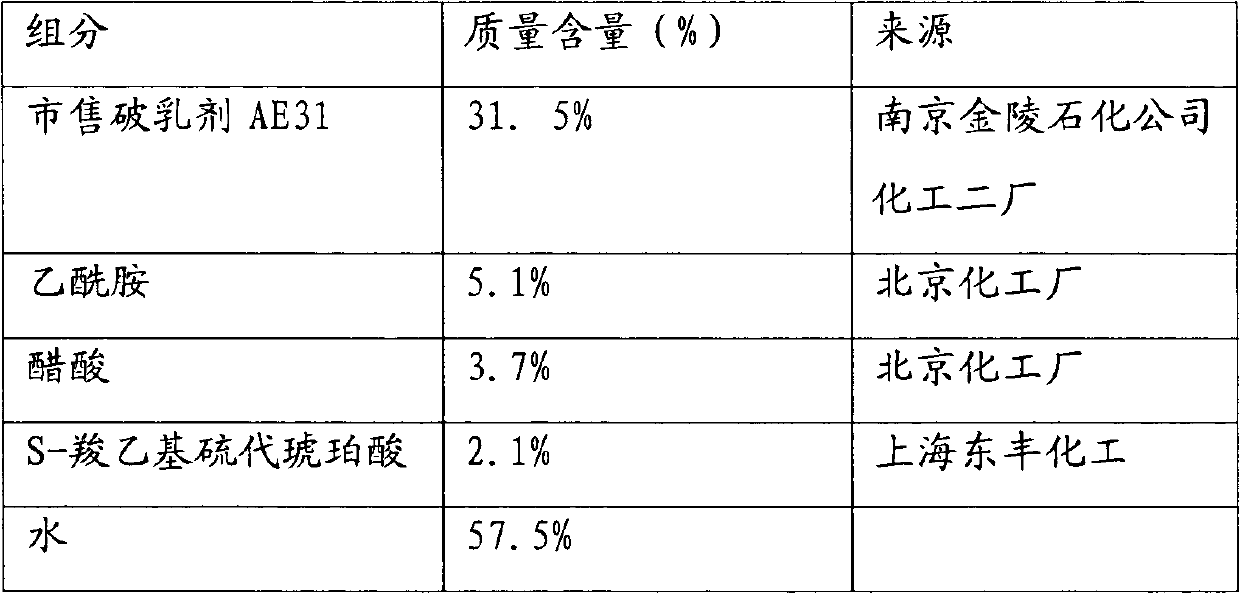

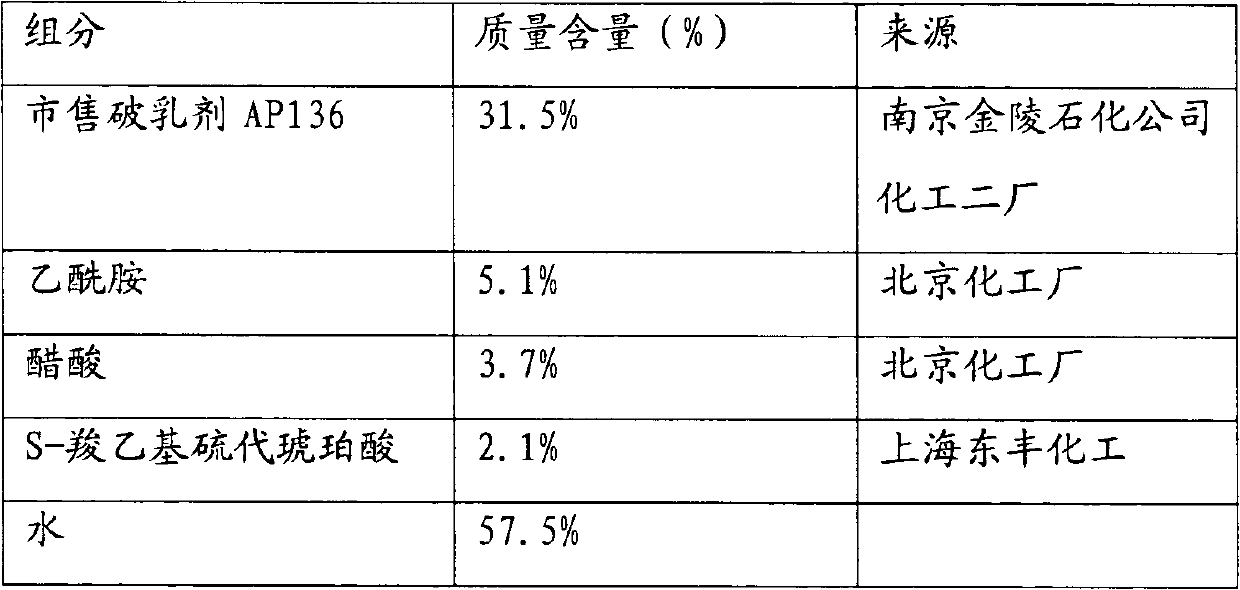

Composite demulsifying agent

ActiveCN103374386AFast dehydrationImprove dehydration rateDewatering/demulsification with chemical meansCarboxylic acidPolypropylene

The invention relates to a composite demulsifying agent. The composite demulsifying agent is a solution which comprises 5-60 parts of polyoxyethylene polypropylene oxide block polyether, 2-10 parts of primary amide, 1-20 parts of C2-C6 carboxylic acids and 20-90 parts of water in parts by mass. When being used for demulsifying high acid crude oil, the composite demulsifying agent has the characteristics of fast dehydration speed, high dehydration rate, low content of water phase and oil and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Quick petroleum deemulsifier and preparation method thereof

ActiveCN102533314AEasy to operateLow process equipment requirementsDewatering/demulsification with chemical meansPolyethylene polyamineChemistry

The invention discloses a quick petroleum deemulsifier and a preparation method thereof. The method comprises the following steps of: (1) performing esterification reaction on polyethylene polyamine, nonylphenol ethoxylates, and diethanol amine polyether with acryloyl chloride respectively to obtain acrylic acid polyethylene polyamine polyether ester, acrylic acid nonylphenol polyether ester, and acrylic acid diethanol amine polyether ester respectively; and (2) performing free radical polymerization reaction on the acrylic acid polyethylene polyamine polyether ester, acrylic acid nonylphenol polyether ester, acrylic acid diethanol amine polyether ester, methacrylic acid, and butyl acrylate in water in presence of initiator under the anaerobic condition, and performing termination reaction by using a terminator to obtain the quick petroleum deemulsifier. The deemulsifier has high dehydration rate in a very short time period, and is suitable for development of offshore oil fields; and the preparation method has the characteristics of low requirement on processing equipment and is easy to operate.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Treatment process of high-slag-content and water-containing sump oil

ActiveCN105419856AHigh recovery rateImprove dehydration rateDewatering/demulsification with chemical meansCavitationSlag

The invention relates to a treatment process of high-slag-content and water-containing sump oil and relates to the technical field of separation and treatment of slag-containing and water-containing sump oil. Firstly, the sump oil is washed with alkali liquor, emulsification systems of a W / O type and an O / W / O type in the sump oil are subjected to phase inversion to form emulsion of an O / W type, the viscosity of the high-slag-content and water-containing sump oil and the interfacial tension of the emulsion systems can be effectively reduced due to formation of the emulsion of the O / W type, and therefore mass transfer of a subsequent demulsifying agent is facilitated, and the demulsifying effect of the subsequent demulsifying agent fully acts. Then, sulfuric acid is added and made to react with sodium naphthenate, sodium naphthenate is reduced into naphthenic acid without the emulsifying effect, and therefore the emulsifying effect of sodium naphthenate is eliminated. Next, a demulsifying agent of a compound type and a flocculating agent are sequentially added, and further flocculating setting separation happens to part of dross remaining in an oil layer. Finally, the sump oil is treated through the acoustic cavitation effect of ultrasonic waves, the mechanical vibration effect and the heat treatment effect, water and slag are further removed, and crude oil is recycled.

Owner:YANGZHOU UNIV

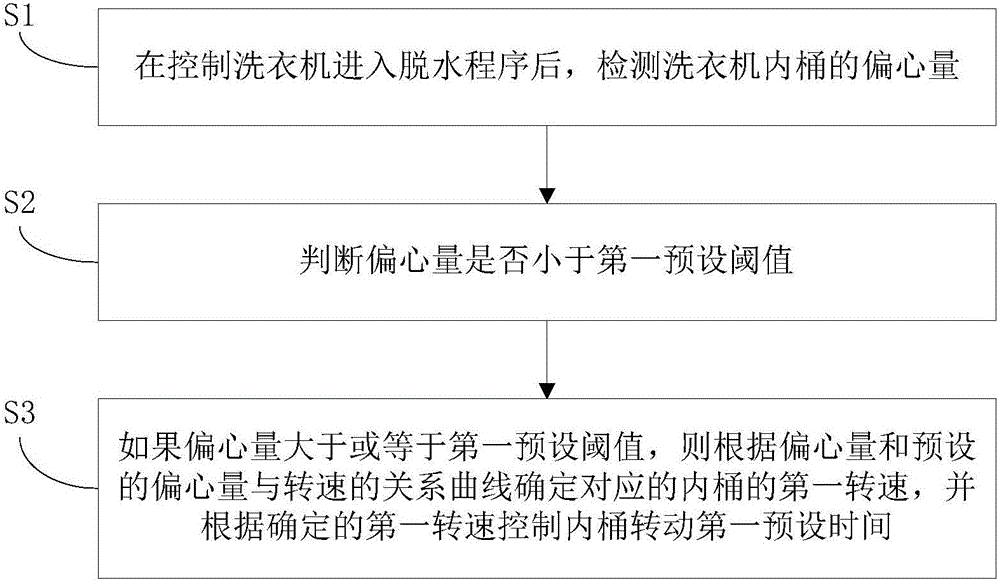

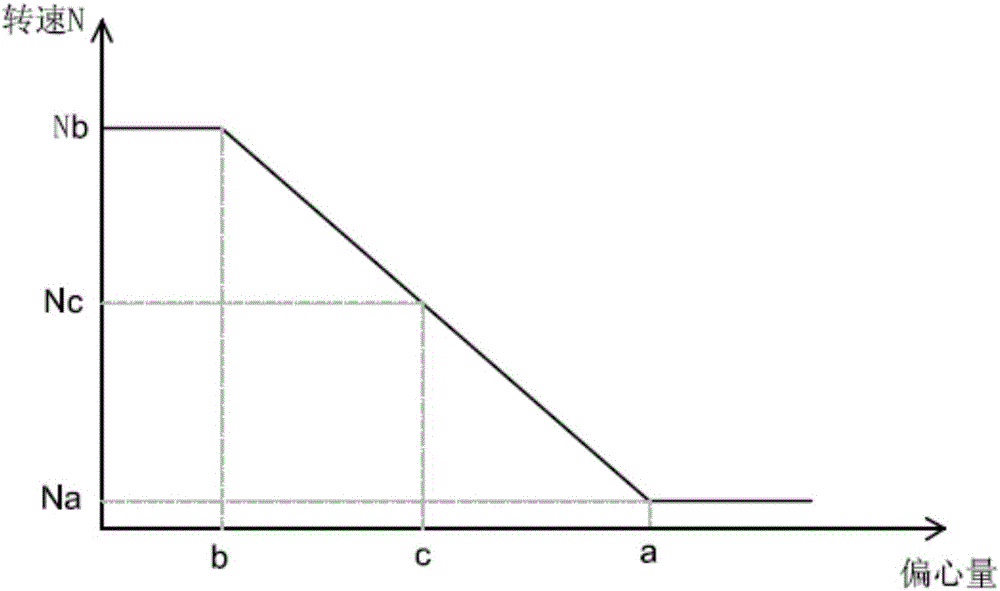

Washing machine and dewatering control method and device thereof

ActiveCN106400386AImprove dehydration rateImprove dehydration effectControl devices for washing apparatusTextiles and paperProcess engineeringNegative relationship

The invention discloses a washing machine and a dewatering control method and a device thereof. The method comprises the following steps of when the washing machine is controlled to enter a dewatering program, detecting the eccentricity of an inner bucket of the washing machine; judging whether the eccentricity is smaller than a first preset threshold value or not; when the eccentricity is greater than or equal to the first preset threshold value, determining a first rotation speed of the inner bucket according to the eccentricity and the relationship curve of preset eccentricity and rotation speed, and controlling the inner bucket to rotate with a first presetting time according to the determined first rotation speed, wherein the rotation speed is in a negative relationship with the eccentricity in the relationship curve. The method disclosed by the invention has the advantages that the dewatering probability of the washing machine is effectively increased, the time consumption of dewatering is decreased, and the dewatering effect is improved.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Method and device for solidifying sludge by virtue of vacuum electric osmosis combined dynamic load

InactiveCN105036508AReduce running timeReduce moisture contentSludge treatment by de-watering/drying/thickeningWater storageWater storage tank

The invention discloses a method and device for solidifying sludge by virtue of a vacuum electric osmosis combined dynamic load. The method comprises the steps of placing sludge to be solidified into a sludge tank of a solidifying device, arranging a cathode tube passing through the bottom of the tank in the center of the sludge tank, sealing the top end of the cathode tube, forming a group of uniformly-distributed water seepage holes in the middle section of the cathode tube, coating a layer of geotechnical cloth outside the cathode tube, connecting the bottom end of the cathode tube and an air inlet of a vacuum pump through a hose, and connecting an air outlet of the vacuum pump and a water storage tank through a hose; inserting a group of uniformly-distributed anode bars at the periphery of the sludge tank; arranging a vibrator at the top of the sludge to be solidified; and when the sludge to be solidified is needed to be solidified, turning on a switch of a direct-current power source, starting the vibrator, meanwhile, starting the vacuum pump to generate negative pressure in the cathode tube, and pumping water permeating into the cathode tube into the water storage tank. By using the method and device, heavy metals in sludge can be driven to be migrated into the cathode tube along with water under the action of an electric field so as to be discharged; and the vacuum pump operates at different intervals, so that the energy consumption can be reduced.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

Manufacturing method of flavor grapefruit peel dish

InactiveCN106722546AImprove permeabilityReduce churnFruit and vegetables preservationYeast food ingredientsDiseaseHuman body

The invention relates to a flavor grapefruit peel dish, which has the advantages that the grapefruit peel can be effectively recovered and reused; the economic benefits are improved; the shelf life of the grapefruit peel is prolonged; meanwhile; the salt content of a finished product is reduced through a low-temperature dehydration process; through the dehydration treatment, 90-percent of nitrite is effectively removed. Rich saccharides, mineral substances and vitamin are contained in the finished product; the nutrition values and the health care functions of the grapefruit peel are combined; the effects of clearing away heat and toxic materials, diminishing inflammation, promoting urination, softening and expanding blood vessels and the like are achieved; the human body disease-resistant capability is favorably improved; the occurrence of the cardiovascular system diseases can be prevented. The added value of the grapefruit peels is greatly mined; further, the industrialization system of the grapefruit processing is completed; a great number of grapefruit peels can be recovered and utilized; the resource waste is reduced; the rich paths are also provided for the human diet nutrition and health.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

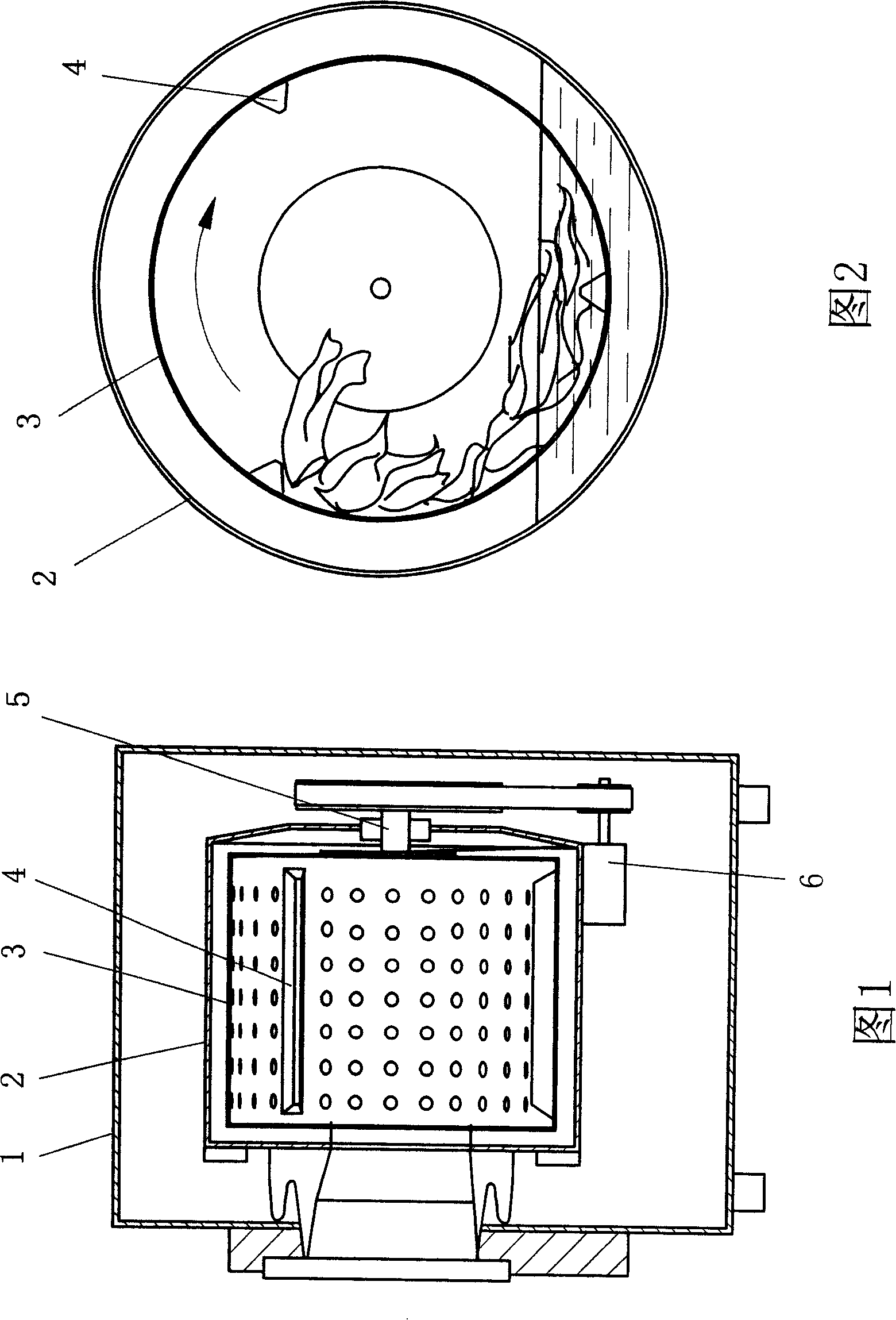

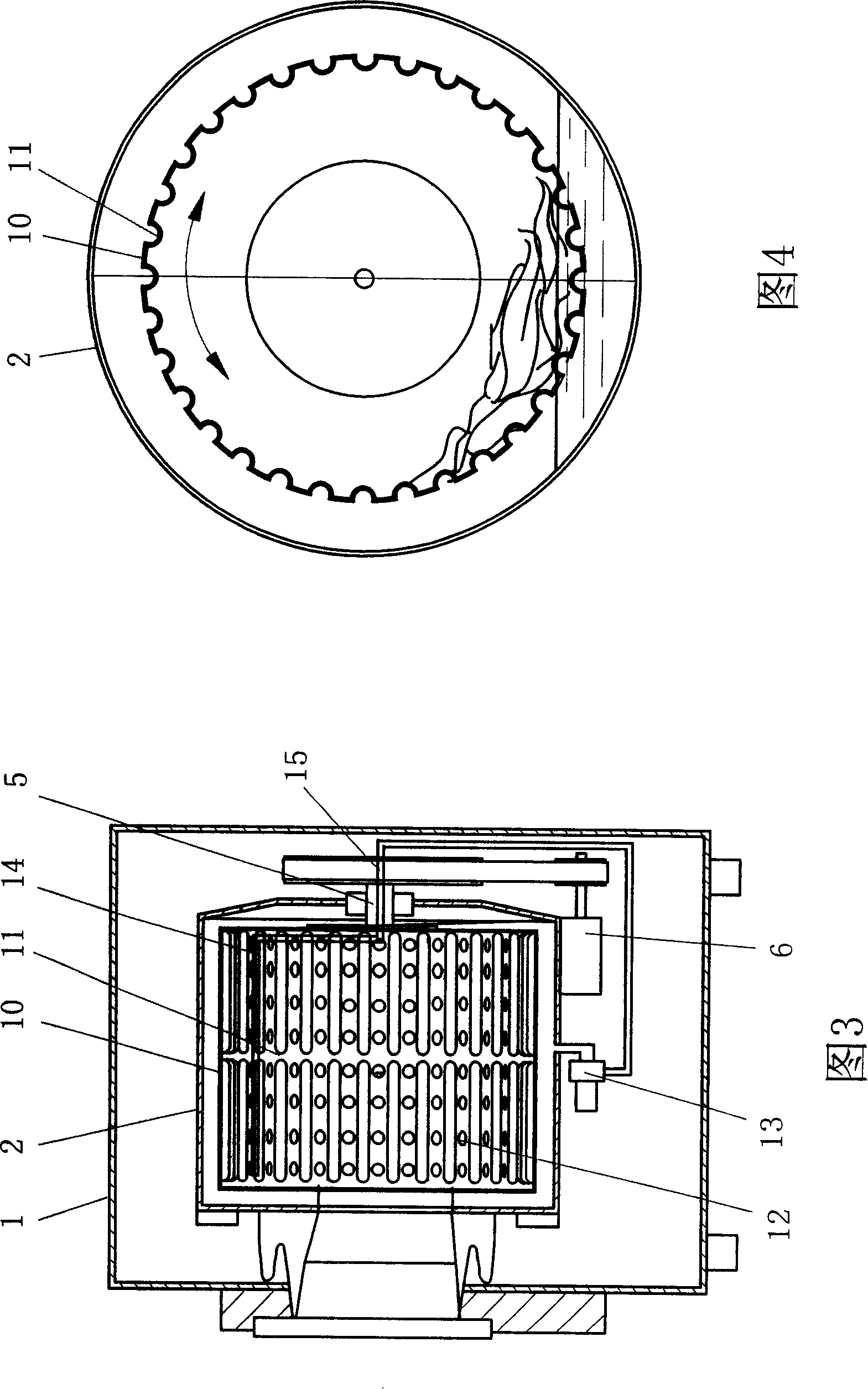

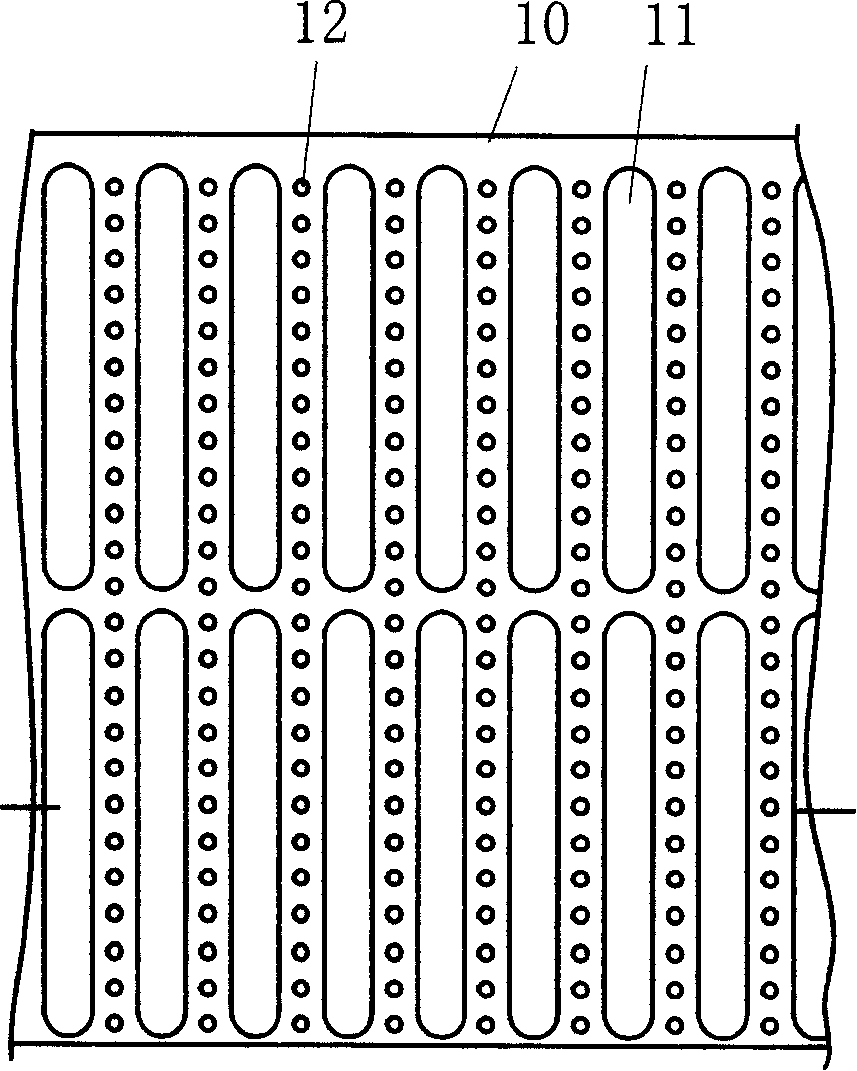

Washboard type roller washing method and washing machine applying the same method

ActiveCN101210369AConserve waterImprove cleaning ratioOther washing machinesWashing machine with receptaclesWater savingDrive motor

A washboard-type drum washer comprises a housing, a water tank and a drum arranged in the housing, a rotation shaft arranged at the bottom of the drum and a drive motor connected with the rotation shaft. The drum washer is characterized in that a plurality of axial densely-arranged ribs are provided on the inner wall of the drum, and water drain holes are provided among the ribs. The washing method provided by the invention can repeatedly scrub the clothes by using the ribs provided on the drum, and the clothes can be further scrubbed after rotating to change the position, so that the clothes can be washed like hand washing on a washboard by scrubbing and rotating the clothes by multiple times, thus saving water and improving the cleaning ratio. High dewatering rate can be obtained by high-speed drying by arranging the water drain holes among the ribs. The ribs stamped on the drum can improve the strength and the rigidity of the drum, thus improving the service life of the washing machine.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Lignocellulose material for road and method for making same

InactiveCN101096835AReduce manufacturing costImprove hydrophobicityIn situ pavingsTextile disintegration and recoveryCelluloseCardboard

The invention discloses a road wood fibre, which comprises the following steps: choosing waste newspaper as raw material; proceeding high concentration fluff; screening; deslagging; purifying slurry; stirring with mixed filling evenly; pasting; forming paper web; squeezing; drying with drying cylinder and infrared; proceeding flicking course; adding into caoline (talcum powder), active calcium carbonate filler and NaCl with dry method; getting the wood fiber product.

Owner:NANJING FORESTRY UNIV

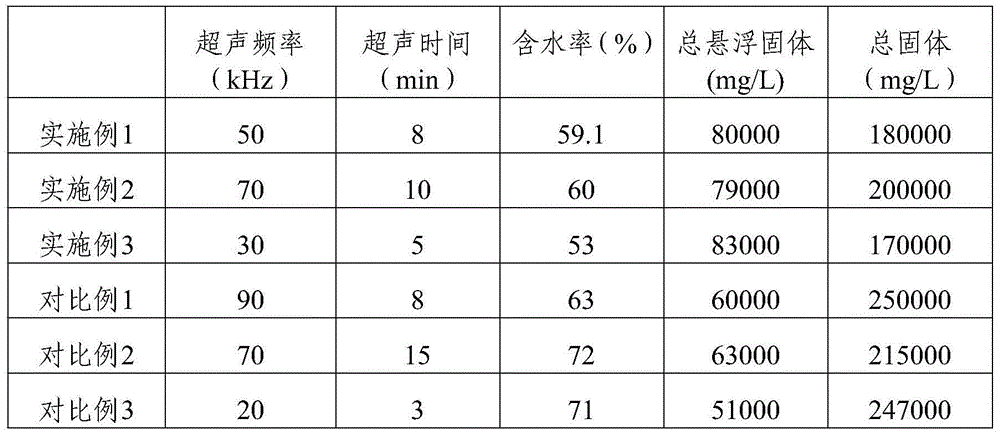

Method for treating sludge by use of polyaluminum chloride and ultrasonic combining technology

InactiveCN104891774AImprove dehydration rateImprove drynessSludge treatment by de-watering/drying/thickeningAluminium chlorohydrateEnergy consumption

The invention relates to the technical field of sludge dehydration property improvement and particularly relates to a method for treating sludge by use of a polyaluminum chloride and ultrasonic combining technology. The method comprises the following steps: adjusting the pH value by use of sodium hydroxide, adding polyaluminum chloride and stirring uniformly with a stirrer; treating for 5-10min with a frequency of 26-70kHz; and performing centrifugal filtration treatment with a centrifuge. By adopting the method, the dehydration property of sludge is improved, and the sludge storage capacity is reduced; and moreover, the energy consumption of treatment is relatively low, the removal rate of water is not less than 38.7%, the water content of sludge is reduced to be not higher than 60%, and the sludge dehydration property is improved by 5-9% over the traditional sludge dehydration property.

Owner:ZUNYI NORMAL COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com