Non-polyether demulsifier and preparation method thereof

A non-polyether and demulsifier technology, applied in the field of non-polyether type demulsifier and its preparation, can solve the problems of insufficient variety, single structure of polyether products, dangerous environmental pollution, etc., and achieves obvious demulsification effect. High wetting performance and penetration ability, the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

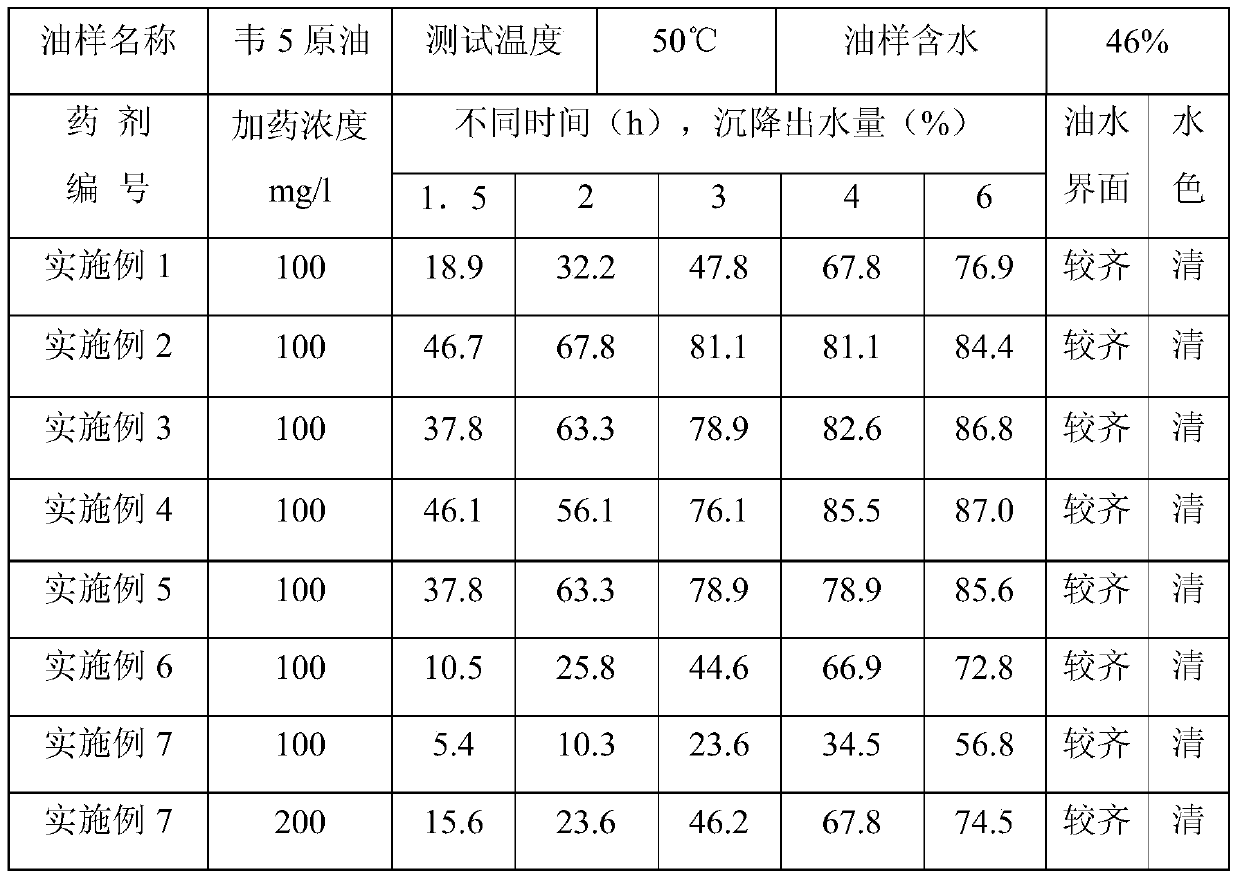

Examples

Embodiment 1

[0028] Add 0.75g of sodium dodecylbenzenesulfonate, 0.375g of alkylphenol polyoxyethylene ether OP-100, and 67g of distilled water into a 500ml reactor. After dissolving, add 6.9g of butyl acrylate and 1.0g of acrylic acid. Stir at room temperature at high speed for 10-60 minutes to obtain a seed emulsion.

[0029] Preparation of the initiator solution: 0.375 g of potassium persulfate was dissolved in 25 g of deionized water, and stirred evenly to obtain the initiator solution.

[0030] Preparation of mixed monomer emulsion: 1.75g sodium dodecylbenzenesulfonate, 100.875g alkylphenol polyoxyethylene ether OP-100.875g, 133g distilled water, after dissolving, add 62.1g butyl acrylate and 7.2g acrylic acid, stir and emulsify 10 to 60 minutes to obtain a mixed monomer emulsion.

[0031] Preparation of demulsifier: keep the reaction device in a nitrogen atmosphere, add 30% initiator solution to the seed emulsion heated to 80°C, and start to add the mixed monomer emulsion and the ...

Embodiment 2

[0033]Add 0.75g of sodium lauryl sulfate, 0.375g of alkylphenol polyoxyethylene ether OP-100, and 67g of distilled water into a 500ml reactor. After dissolving, add 3.5g of butyl acrylate, 3.5g of lauryl acrylate, and 0.5g of acrylic acid. Stir at room temperature at high speed for 10-60 minutes to obtain a seed emulsion.

[0034] Preparation of the initiator solution: 0.225g of 2,2-azo(2-amidinopropane) dihydrochloride (V50) was dissolved in 25g of deionized water and stirred evenly to obtain the initiator solution.

[0035] Preparation of mixed monomer emulsion: 1.75g of sodium lauryl sulfate, 0.875g of OP-100, 133g of distilled water, after dissolving, add 31.5g of butyl acrylate, 31.5g of lauryl acrylate, 4.5g of acrylic acid, diethyl dimethacrylate Glycol ester 0.2g, stirred and emulsified for 10-60min to obtain mixed monomer emulsion.

[0036] Preparation of demulsifier: Keep the reaction device in a nitrogen atmosphere, add 30% initiator solution to the seed emulsion...

Embodiment 3

[0038] Add 0.75g of sodium lauryl sulfate, 0.375g of alkylphenol polyoxyethylene ether OP-100, and 67g of distilled water into a 500ml reactor. After dissolving, add 4.8g of butyl acrylate, 2.3g of octadecyl acrylate, and 0.4g of acrylic acid . Stir at room temperature at high speed for 10-60 minutes to obtain a seed emulsion.

[0039] Preparation of the initiator solution: 0.225g of 2,2-azo(2-amidinopropane) dihydrochloride (V50) was dissolved in 25g of deionized water and stirred evenly to obtain the initiator solution.

[0040] Preparation of mixed monomer emulsion: 1.75g of sodium lauryl sulfate, 0.875g of OP-100, 133g of distilled water, after dissolving, add 43.2g of butyl acrylate, 20.7g of stearyl acrylate, 3.6g of acrylic acid, dimethacrylate Ethylene glycol ester 0.4g, stirred and emulsified for 10-60min to obtain mixed monomer emulsion.

[0041] Preparation of demulsifier: Keep the reaction device in a nitrogen atmosphere, add 30% initiator solution to the seed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com