Method for purifying acrylic acid b utilizing azeotropic rectification

A technology of azeotropic distillation and acrylic acid, applied in the separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as strong hydrogen bond strength, self-polymerization of acrylic acid, and difficulty in dehydration, so as to reduce polymerization tendency, reduce loss, The effect of extending the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

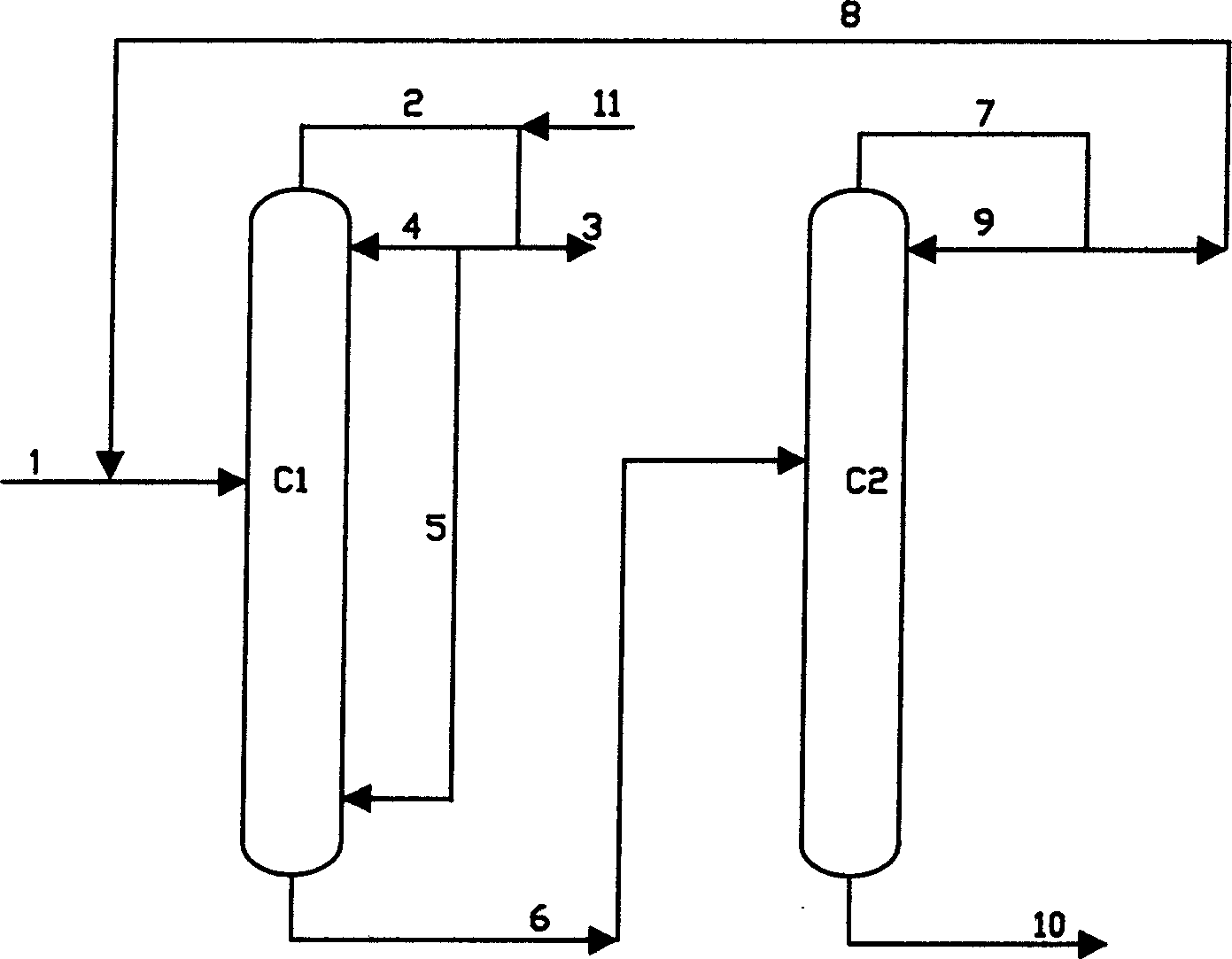

Embodiment 1

[0026] An acrylic acid aqueous solution containing about 48% by weight of water, 4% by weight of acetic acid, and 48% by weight of acrylic acid is introduced into the 15th tray of the light removal tower C1. The tower is equipped with 30 trays and the inner diameter of the tower is 33000mm, among which 12 co-current injection trays are used in the rectification section. A single tetrachlorethylene is used as an entrainer, and the azeotropic rectification operation of the acrylic acid aqueous solution is carried out under this condition. The feeding ratio of tetrachlorethylene solvent and acrylic acid aqueous solution is 2.7:1.

[0027] During the operation of this embodiment, the temperature at the top of C1 is 50°C, the bottom of the tower is 85°C, and the pressure at the top of the tower is 14KPA. The aqueous phase collected from pipeline 3 contains 1.29% by weight of acrylic acid, the extracted liquid from the tower kettle of pipeline 6 contains 0.09% by weight of water an...

Embodiment 2

[0029] An acrylic acid aqueous solution containing about 48% by weight of water, 4% by weight of acetic acid, and 48% by weight of acrylic acid is introduced into the 15th tray of the light removal tower C1. As the entrainer, toluene-tetrachloroethylene complex mixed solvent (combination ratio 20:1) is used, and the azeotropic rectification operation of the acrylic acid aqueous solution is carried out under this condition. The feed ratio of the compounded mixed solvent to the aqueous acrylic acid solution is 3:1.

[0030] During the operation of this example, the temperature at the top of C1 is 45°C, the bottom of the tower is 84.5°C, and the pressure at the top of the tower is 14KPA. The aqueous phase collected from pipeline 3 contains 0.51% by weight of acrylic acid, the extracted liquid from the tower reactor of pipeline 6 contains 0.07% by weight of water and 2.41% by weight of acetic acid, and the extracted liquid from the tower reactor of C2 contains 0.22% by weight of a...

Embodiment 3

[0032] An acrylic acid aqueous solution containing about 48% by weight of water, 4% by weight of acetic acid, and 48% by weight of acrylic acid is introduced into the 15th tray of the light removal tower C1. A toluene-tetrachloroethylene compounded mixed solvent (combined ratio 10:1) is used as an entrainer, and the azeotropic rectification operation of the acrylic acid aqueous solution is carried out under this condition. The feed ratio of the compounded mixed solvent to the aqueous acrylic acid solution is 2.9:1.

[0033] During the operation of this example, the temperature at the top of C1 is 45.5°C, the bottom of the tower is 84.2°C, and the pressure at the top of the tower is 14KPA. The aqueous phase collected from pipeline 3 contains 0.51% by weight of acrylic acid, the extracted liquid from the tower kettle of pipeline 6 contains 0.08% by weight of water and 2.26% by weight of acetic acid, and the extracted liquid from the tower still of C2 contains 0.20% by weight of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com