Method and device for solidifying sludge by virtue of vacuum electric osmosis combined dynamic load

A dynamic load and sludge technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of low dehydration rate, low efficiency of dehydration machinery, and inability to reduce heavy metal content in sludge, so as to reduce operating time and improve sewage Mud dehydration rate, reduce the effect of solidification energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

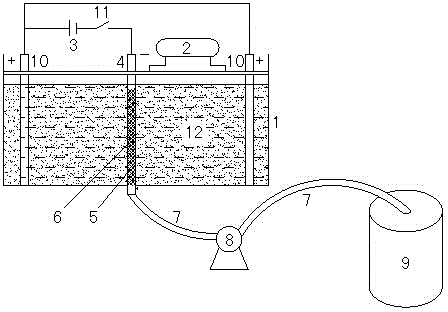

[0024] This example figure 1 As shown, including a plexiglass sludge tank with a size of 600×400mm, the sludge tank 1 has a height of 250mm and a wall thickness of 3mm. There are threaded holes twisted at the bottom of the sludge tank, and the thread diameter is 22mm. Screw in the titanium tube electrode with the same specification in the threaded hole. The titanium tube not only provides a kind of metal electrode that is easy to conduct electricity, but also has good chemical stability, and the local strong acid and strong alkali environment generated during the electroosmosis process is not easy. Electrochemical corrosion occurs, so the titanium tube electrode is an electrode that can be used repeatedly. The surface of the titanium tube is punched with water seepage holes 5, the diameter of the water seepage holes is 3 mm, and holes are punched every 10 mm. The surface of the titanium tube is wrapped with a layer of geotextile 6 with a pore size of 48 μm. The geotextile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com