Sludge dewatering device

A sludge dehydration and dehydration device technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of short cathode life, low dehydration efficiency of dehydration device, and small water passing area, so as to achieve high dehydration rate and improve dehydration Efficiency, the effect of ensuring the water passing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

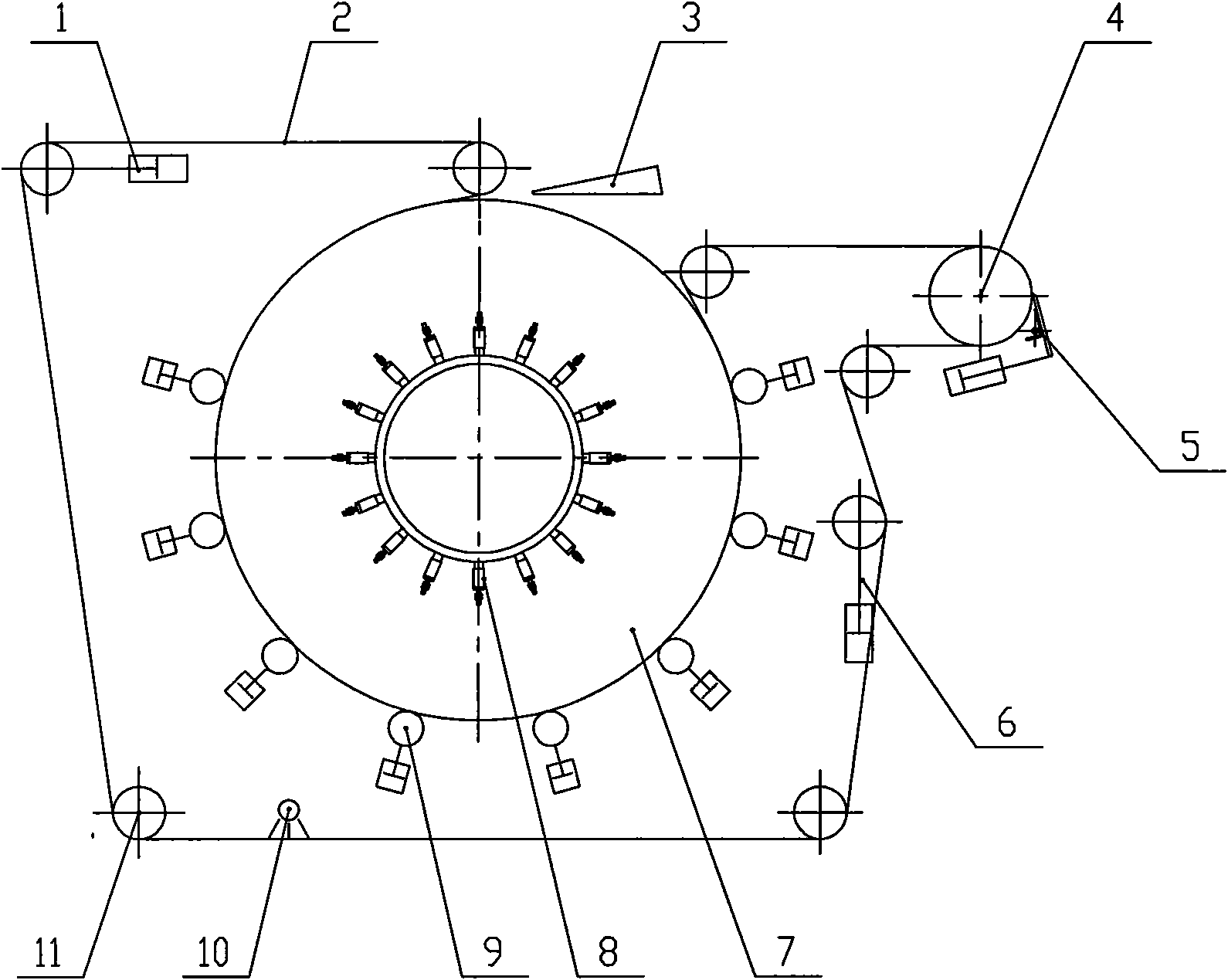

[0027] An embodiment of the present invention provides a sludge dewatering device for dehydrating sludge, such as figure 1 , 2 As shown, the dehydration device includes:

[0028] Frame, anode roller 7, cathode filter screen 2, guide roller 11 and driving roller 4; wherein, the anode roller 7 is a metal roller, arranged in the frame, and electrically connected to the positive pole of the power supply; the metal surface of the anode roller 7 can be covered with special The metal coating can adopt the formula coating containing iridium sintered on the surface of the titanium plate at high temperature. This special metal coating can realize the electric corrosion protection of the surface of the anode drum. Compared with the sacrificial anode protection technology, this technology makes the anode The dimensional stability of the drum is good, and the utilization rate of electric energy is higher;

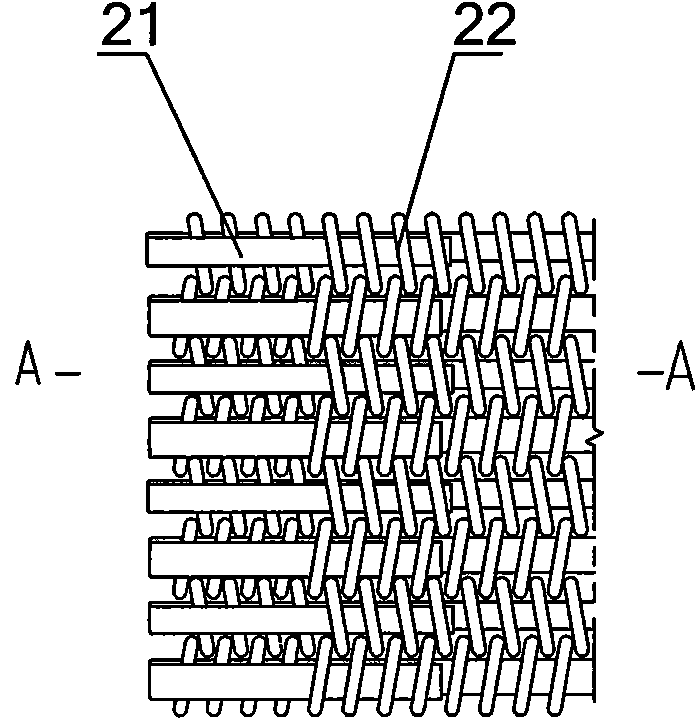

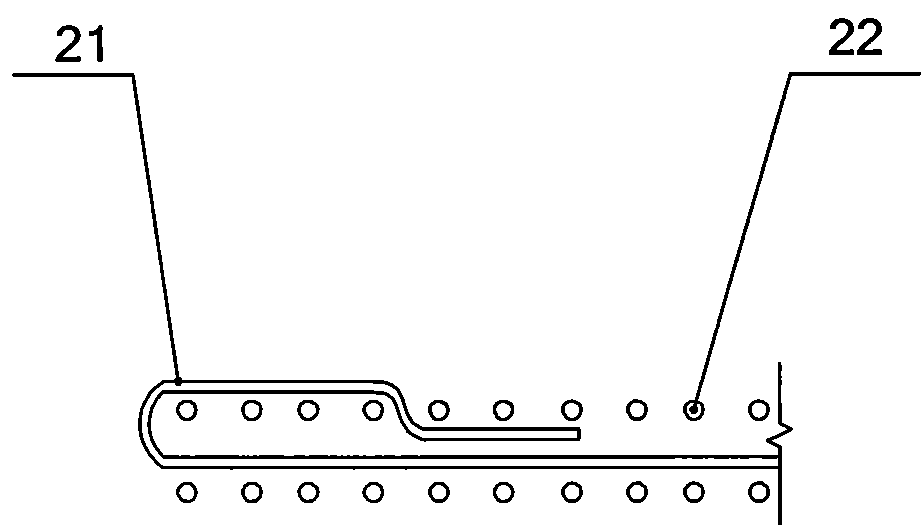

[0029] The cathode filter screen 2 is a non-metal spiral net, and a plurality of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com