Nonmetal internal inflow pore plate type fine grid system

An inflow hole and fine grid technology is applied in the field of non-metal internal inflow orifice plate type fine grid system, which can solve the problem that it is difficult to effectively remove hair flocculent flocculent fibers, and can not effectively remove hair flocculent. It is easy to cause problems such as entanglement or blockage of materials and fluids, so as to ensure long-term stable operation, reduce the entanglement of linear dirt, and reduce the risk of blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the content, features and effects of the present invention, the following examples are given, and detailed descriptions are given below with reference to the accompanying drawings.

[0046] Aiming at the problems existing in the prior art, the present invention provides a non-metallic internal orifice-type fine grid system. The present invention will be described in detail below with reference to the accompanying drawings.

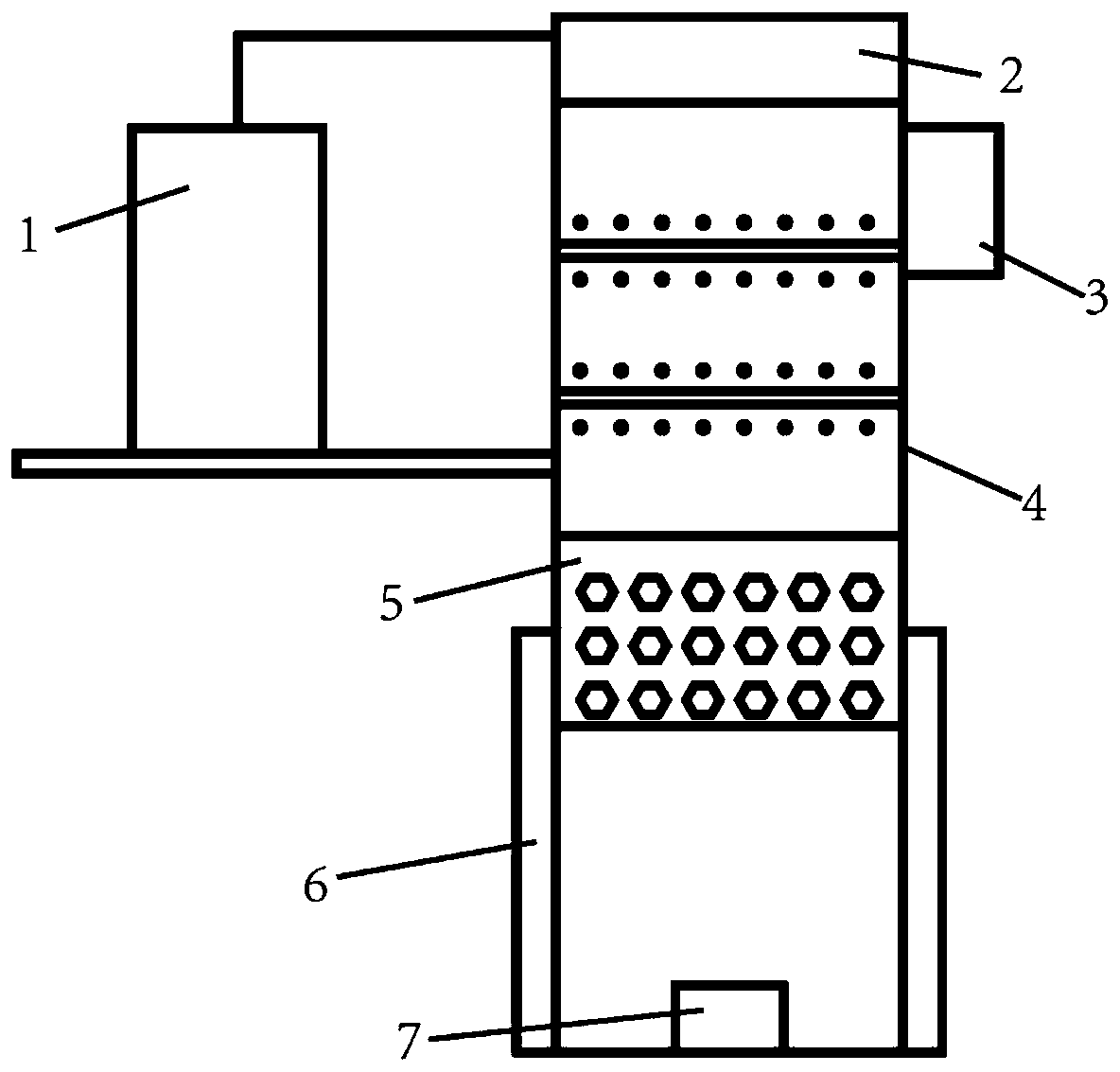

[0047] Such as figure 1 As shown, a non-metallic inflow orifice type fine grid system provided by the present invention includes a frame 4, which is installed in the center of the grid well, and a water inlet hole 7 is opened at the water-facing end of the lower part of the frame 4 , the opposite side is a closed end, guide rails are provided on the front and rear wall panels of the frame 4, and an internal slag collection tank is provided on the upper part, which extends to the outside of the machine, and the two side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com