Multifrequency phased ultrasonic clothes cleaning and dehydration method and device

A technology for washing and dehydrating clothes is applied to washing devices, control devices of washing machines, oscillating washing machines, etc. It can solve the problems of energy dispersion, high power consumption, and high cost of high-power ultrasonic transducers in ultrasonic cleaning, and meet the processing technical requirements. Low, less noise, less wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

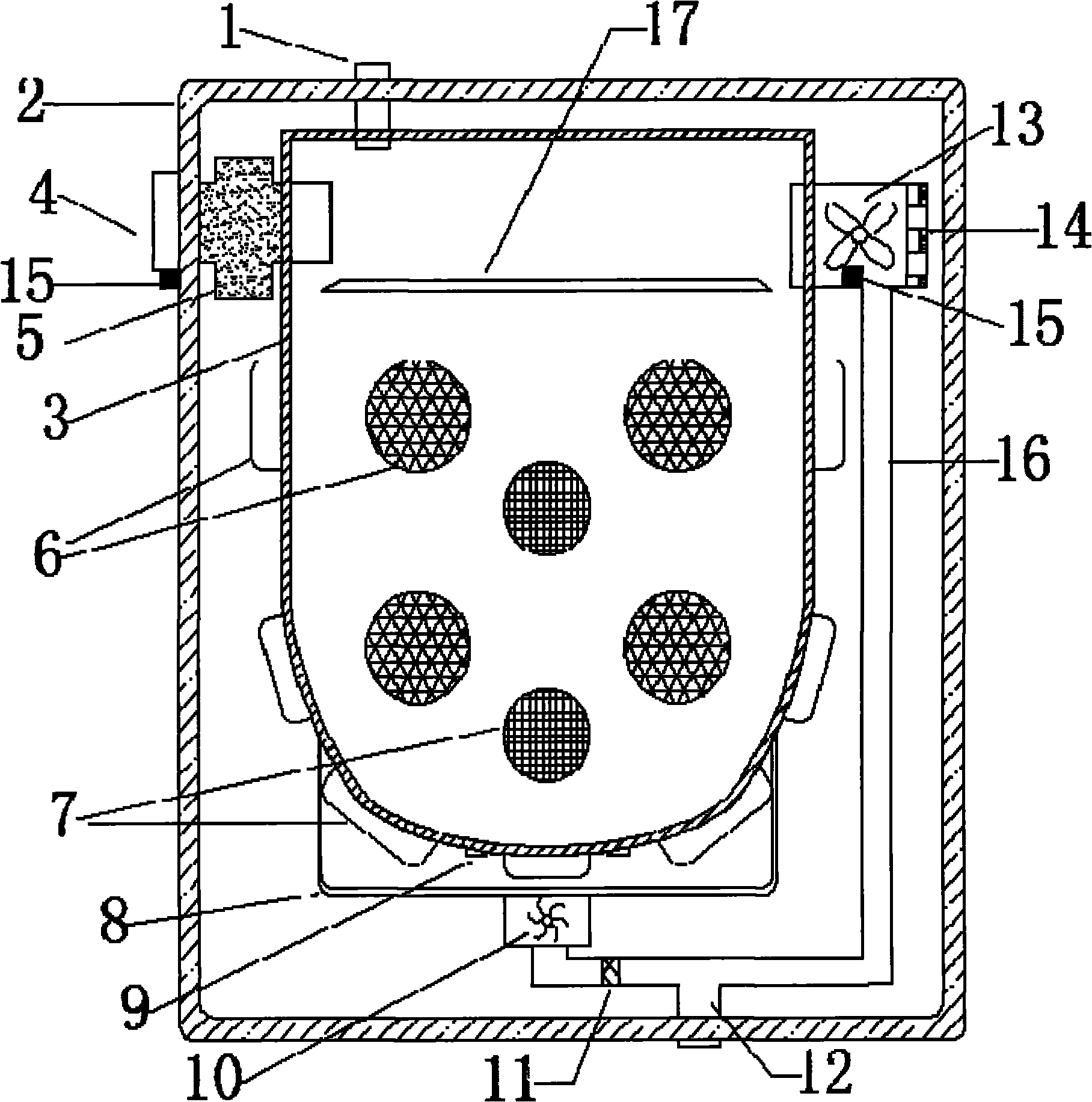

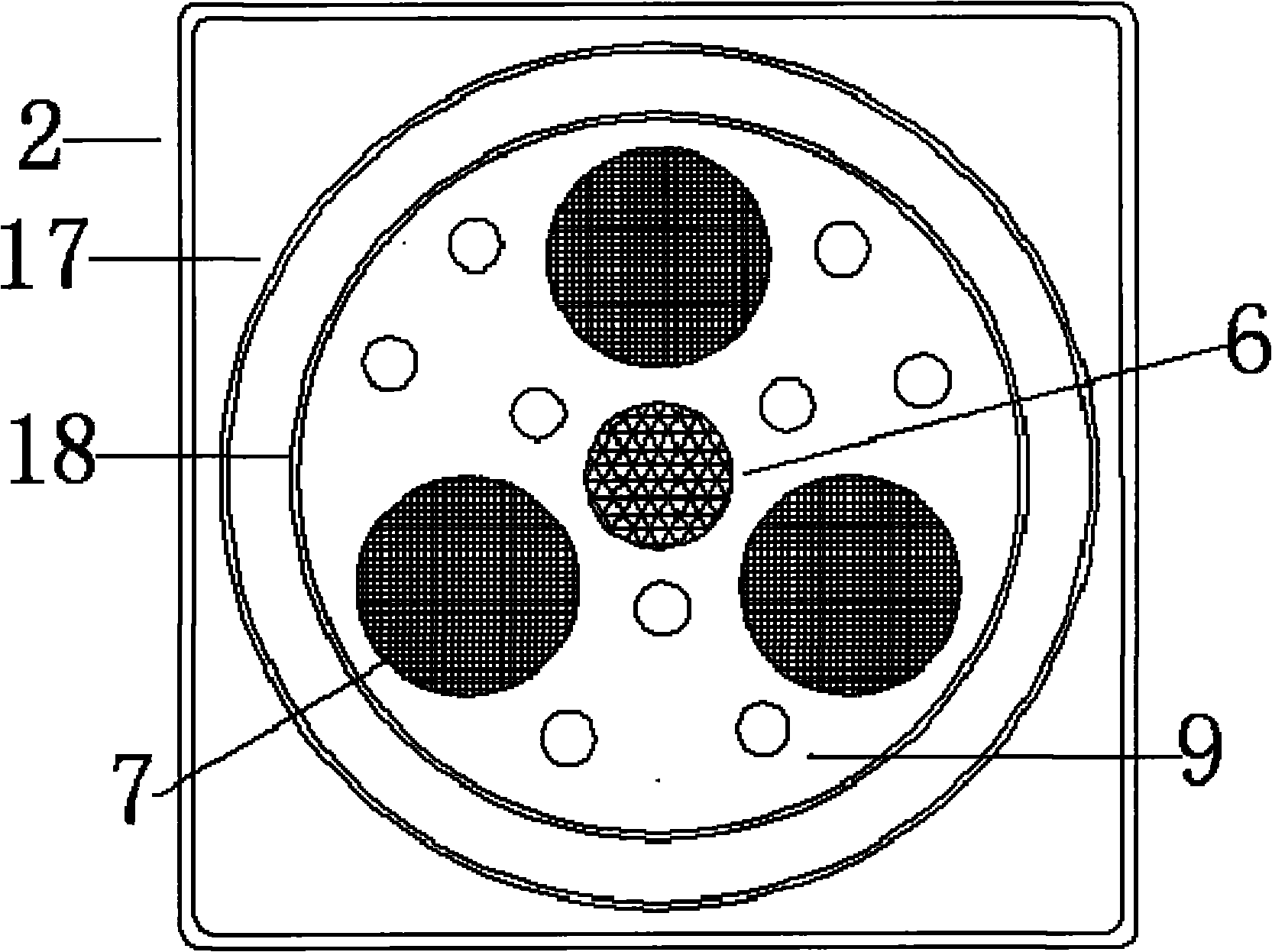

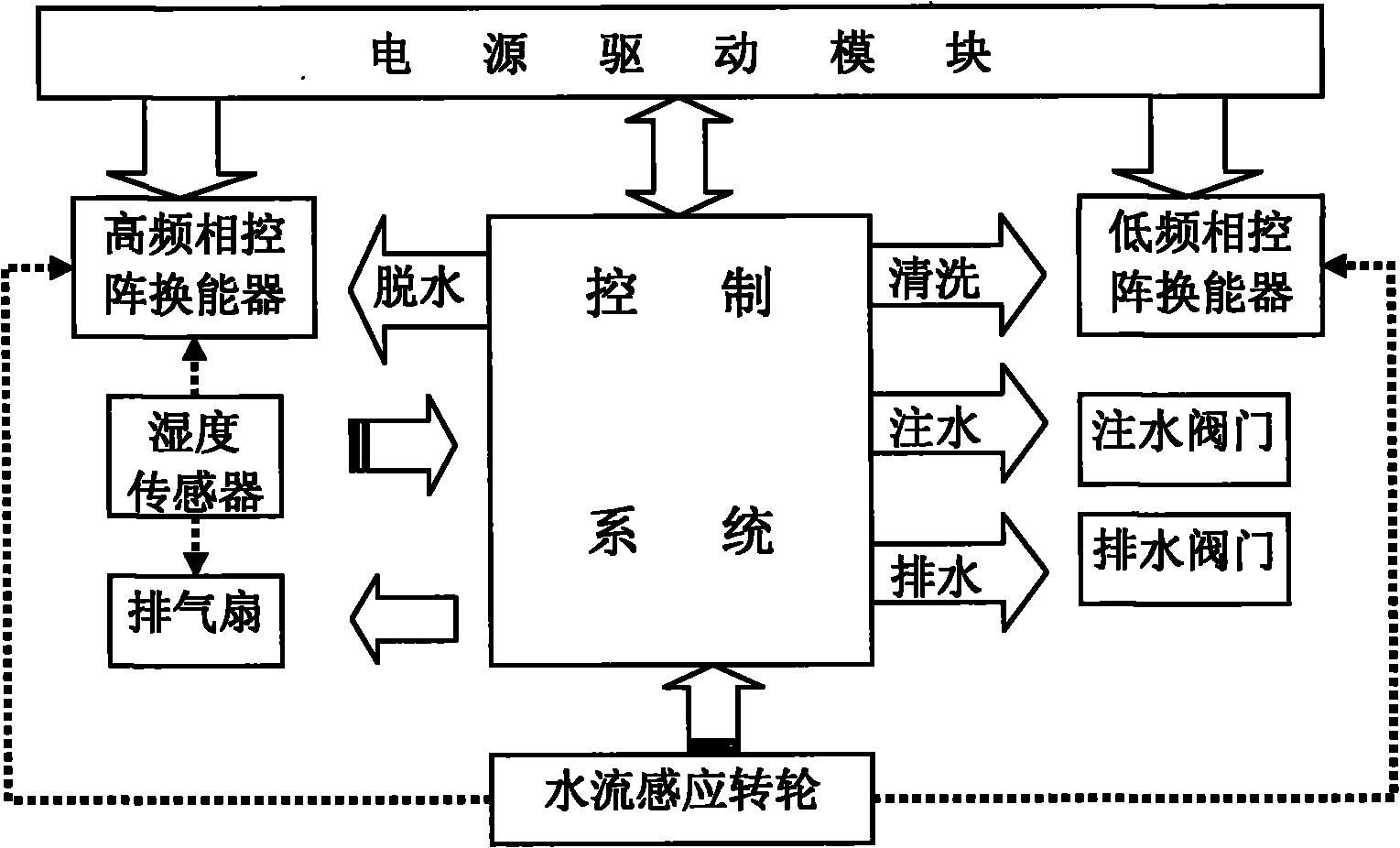

[0042] Such as figure 1 , figure 2 As shown, the present invention mainly includes a water inlet electronic valve 1, an outer cylinder 2, a laundry washing box 3, an air inlet 4, a desiccant storage box 5, a low-frequency ultrasonic phased array generator 6, and a high-frequency ultrasonic phased array generator 7. Isolation tank 8, water leakage hole 9, water flow induction runner 10, drain valve 11, drain port 12, exhaust fan 13, exhaust port 14, humidity sensor 15, mist condensation pipe 16, ultrasonic reflection plate 17.

[0043] The low-frequency ultrasonic phased array generator 6 and the high-frequency ultrasonic phased array generator 7 are distributed on the side wall and bottom surface of the washing box, and the number can be set according to the design requirements. The ultrasonic phased array generators arranged on the side walls are mainly low-frequency ultrasonic phased array generators 6 , and the high-frequency ultrasonic phased array generators 7 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com