Quick petroleum deemulsifier and preparation method thereof

A crude oil demulsifier, rapid technology, applied in the direction of chemical dehydration/demulsification, etc., to achieve the effect of low process equipment requirements and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

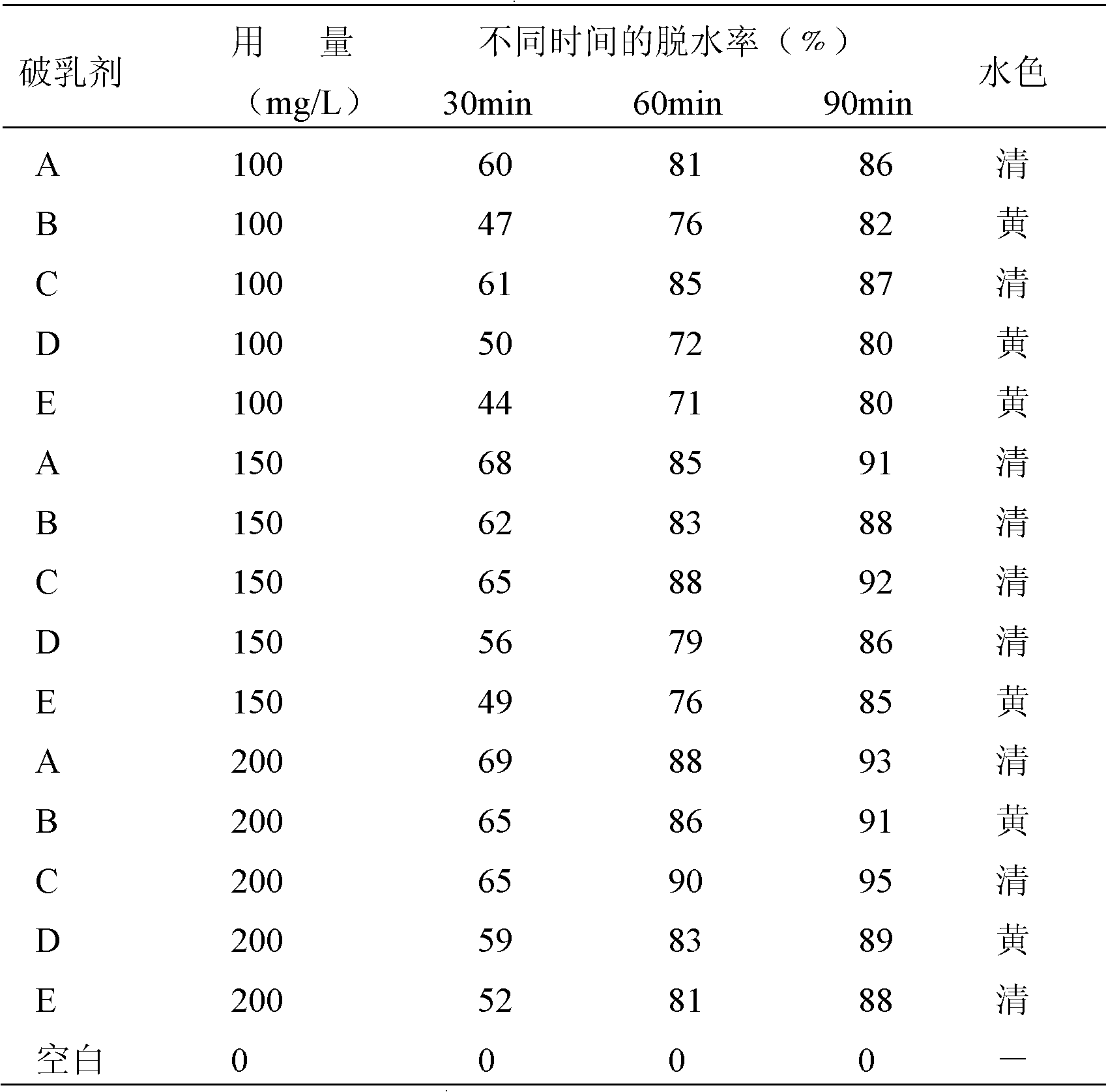

Examples

Embodiment 1

[0026] Embodiment 1, the synthesis of demulsifier A

[0027] (1) Synthesis of polyether

[0028] Using tetraethylenepentamine as the starting agent, the polyether DA01 is obtained by alkoxylation with propylene oxide and ethylene oxide successively under the catalysis of potassium hydroxide; among them, tetraethylenepentamine, potassium hydroxide, The masses of propylene oxide and ethylene oxide are 0.5 gram, 0.5 gram, 150 gram and 50 gram respectively.

[0029] Polyether RF01 is a polyether RF01 obtained by alkoxylation reaction with propylene oxide and ethylene oxide successively with nonylphenol as the initiator under the catalysis of potassium hydroxide; among them, nonylphenol, potassium hydroxide, epoxy The masses of propane and ethylene oxide are 0.5 gram, 0.5 gram, 100 gram and 50 gram respectively.

[0030] Using diethanolamine as the initiator, under the catalysis of potassium hydroxide, polyether CA01 is obtained by alkoxylation reaction with propylene oxide and e...

Embodiment 2

[0037] Embodiment 2, the synthesis of demulsifier B

[0038] Stir 10 grams of polyethylene polyamine polyether acrylate ZDA01, 100 grams of nonylphenol polyether acrylate ZRF01, 50 grams of diethanolamine polyether acrylate ZCA01, 100 grams of methacrylic acid, 40 grams of butyl acrylate and 500 grams of water Mix, use 2 grams of potassium persulfate to initiate free radical polymerization under anaerobic conditions at 80°C, and stop the reaction with 5 grams of ferrous sulfate after 3 hours to obtain demulsifier B.

Embodiment 3

[0039] Embodiment 3, the synthesis of demulsifier C

[0040] Stir 100 grams of polyethylene polyamine polyether acrylate ZDA01, 50 grams of nonylphenol polyether acrylate ZRF01, 50 grams of diethanolamine polyether acrylate ZCA01, 100 grams of methacrylic acid, 10 grams of butyl acrylate and 800 grams of water Mix, use 3 grams of potassium persulfate to initiate free radical polymerization under anaerobic conditions at 80°C, and terminate the reaction with 10 grams of ferrous sulfate after 2 hours to obtain demulsifier C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com