Dehydration method and device of tailings

A dehydration device and tailings technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve problems such as major safety hazards, and achieve the effects of avoiding accidents, low operating costs, and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the present invention will be further described:

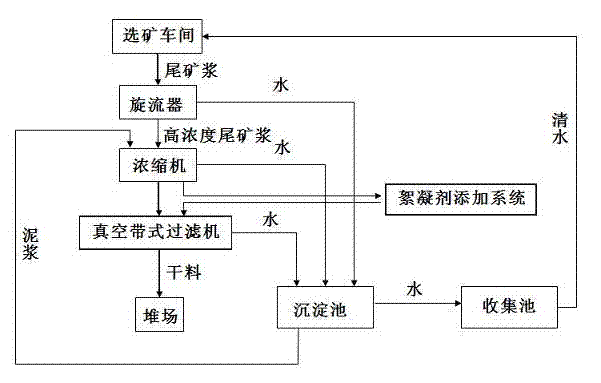

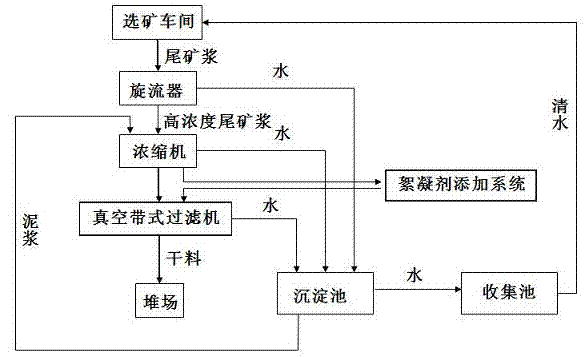

[0025] figure 1 It shows a tailings dehydration device, which mainly includes a cyclone, a thickener, a vacuum belt filter and a sedimentation tank; the tailings slurry discharged from the beneficiation workshop passes through the cyclone, the thickener, and the vacuum belt filter in sequence to form The dry material is placed in the yard. The water collected in the sedimentation tank is the water released by the cyclone, thickener, and vacuum belt filter; the water containing a small amount of tailings deposited in the sedimentation tank enters the thickener for secondary dehydration treatment. There is also a flocculant adding system between the thickener and the vacuum belt filter, so that the fine particles in the tailings slurry and the flocculant in the solution form flocs and settle quickly. The flocculant is polyacrylic acid or polypropylene Amides. The sediment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com