Efficient desulfurization single-tower double-circulation system and method

A circulation system and desulfurization tower technology, which is applied in the field of coal-fired flue gas SO2 pollutant control, can solve the problems of tower series connection occupying a large area, desulfurization single tower height, long construction period, etc., to improve the dehydration rate and improve the purity of gypsum , pH value is easier to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

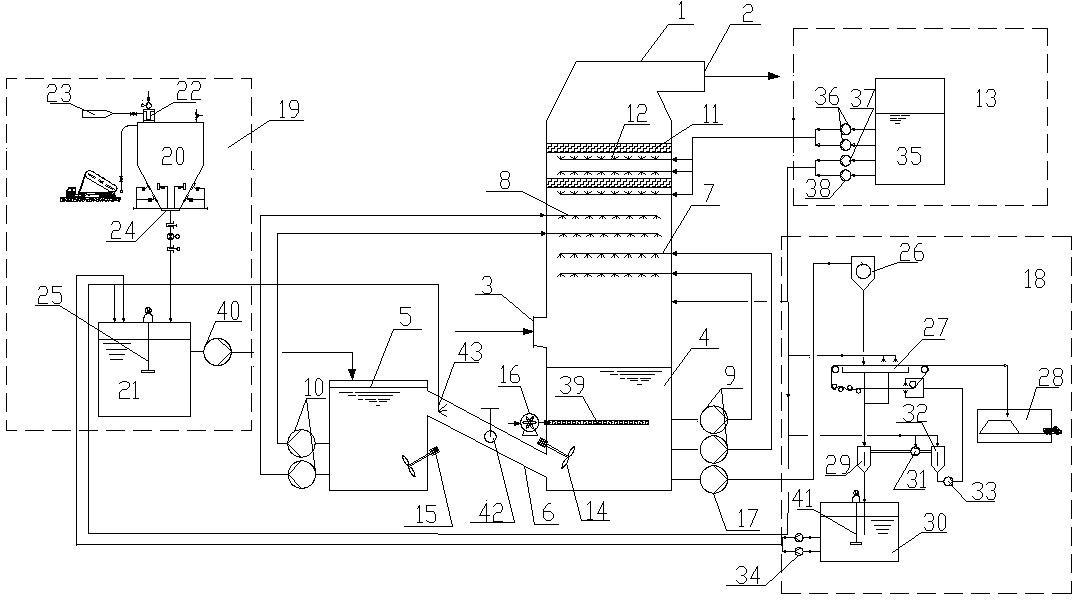

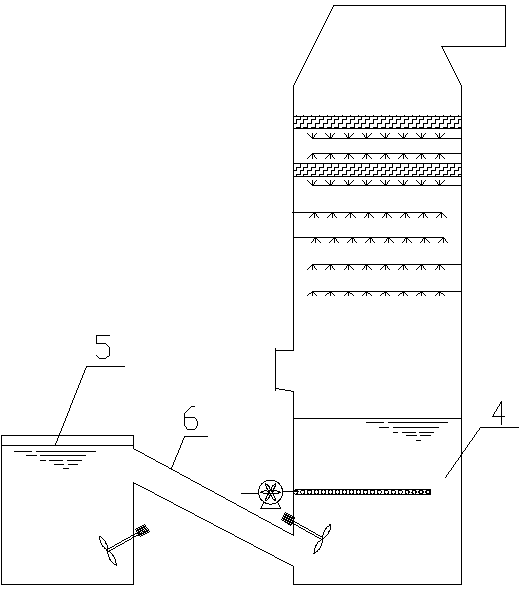

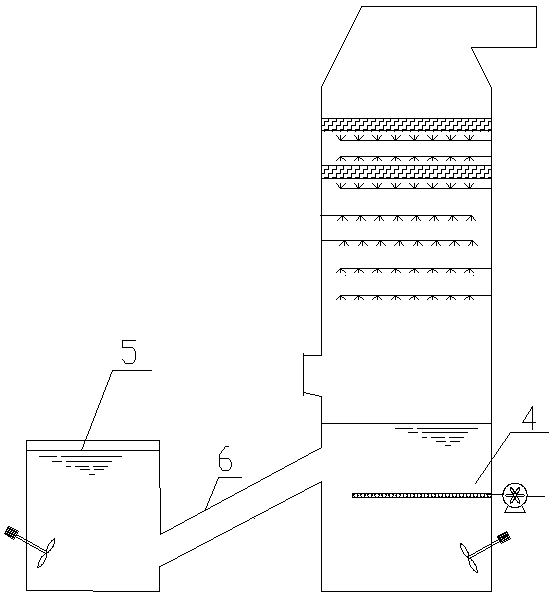

[0039] refer to figure 1 , a high-efficiency desulfurization single-tower dual-cycle system, comprising a desulfurization tower 1, an air inlet 2 is provided on one side of the lower part of the desulfurization tower 1, and an air outlet 3 is provided on the other side of the upper part; the desulfurization single tower 1 is provided with A main slurry pool 4, the main slurry pool 4 is arranged below the air inlet 2, and an auxiliary slurry pool 5 is provided outside the desulfurization tower 1, and the auxiliary slurry pool 5 communicates with the main slurry pool 4 through a pipeline 6, The pipeline 6 is provided with a cut-off valve 42 and a flushing device 43; the upper part of the desulfurization tower 1 is provided with a first spray device 7, and the top of the first spray device 7 is provided with a second spray device 8, so The first spray device 7 includes more than two spray layers, the second spray device 8 includes more than one spray layer, and the first spray de...

Embodiment 2

[0045] refer to figure 1 , a high-efficiency desulfurization single-tower double-cycle method, comprising the steps of:

[0046] (1) The coal-fired flue gas enters the desulfurization tower 1 through the air inlet 2, and is desulfurized by the first spray device 7. The pH of the slurry in the main slurry tank 4 is controlled at 4.5-5.5, and the designed residence time of the slurry in the main slurry tank is not Less than 5 minutes; wherein, the slurry in the main slurry pool 4 enters the desulfurization tower 1 from the spray layer of the first spray device 7 connected to it through the first circulating slurry pump 9; in the main slurry pool, the pH of the slurry is controlled at 4.5 ~5.5, low pH is beneficial to the oxidation of sulfite and the crystallization of gypsum; agitators are radially arranged in the lower part of the main slurry tank, and its function is to make the slurry into a state of suspension and make it diffuse, that is, to maintain the solid in suspension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com