High-concentration organic sludge treatment method

A technology for sludge treatment and organic matter, applied in sludge treatment, dehydration/drying/concentrated sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of insufficient sludge combustion, high energy consumption, and drying treatment equipment Problems such as large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

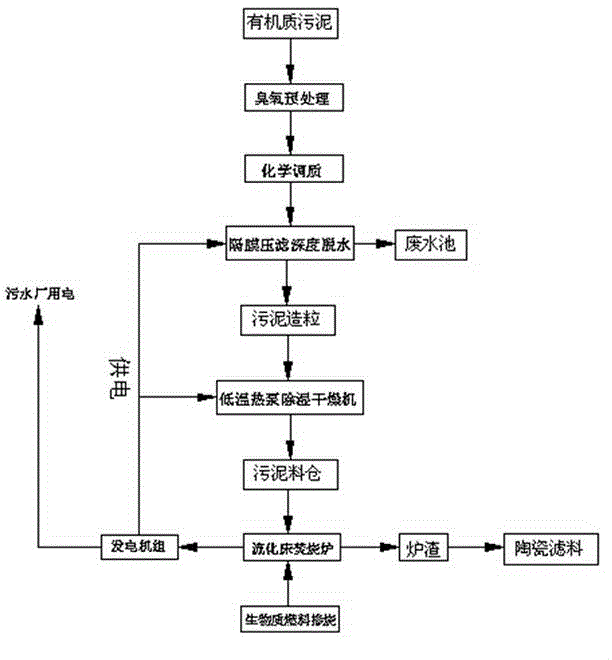

[0044] Please refer to Figure 1 to Figure 4 Shown, it has shown the concrete structure of the embodiment of the present invention; This high-concentration organic matter sludge processing method comprises the following steps:

[0045] (1) Prepare organic sludge: The sludge in the secondary settling tank of the sewage treatment plant has a water content of 95% to 99%.

[0046](2) Ozone pretreatment: transport the sewage in the secondary sedimentation tank to the ozone contactor through the sludge screw pump; pass the ozone into the ozone contactor through the aeration pipe. In this embodiment, the amount of ozone added is 10kg To 15kg / T, of course, it can also be set according to the type of sludge actually treated; ozone aeration makes the sludge fully contact with ozone, and uses the strong oxidative property of ozone to destroy the cell wall and cell membrane in the sludge that are not easily biodegradable. Cause cell death, make cellular substances dissolve in water quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com