Stacked spiral type sludge dewatering machine

A sludge dewatering machine and screw-stacking technology, which is applied in the direction of dewatering/drying/concentrating sludge treatment, etc., can solve the problems of complex structure, high noise, easy blockage of the network, etc., so as to improve dewatering efficiency, low noise, and dewatering rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

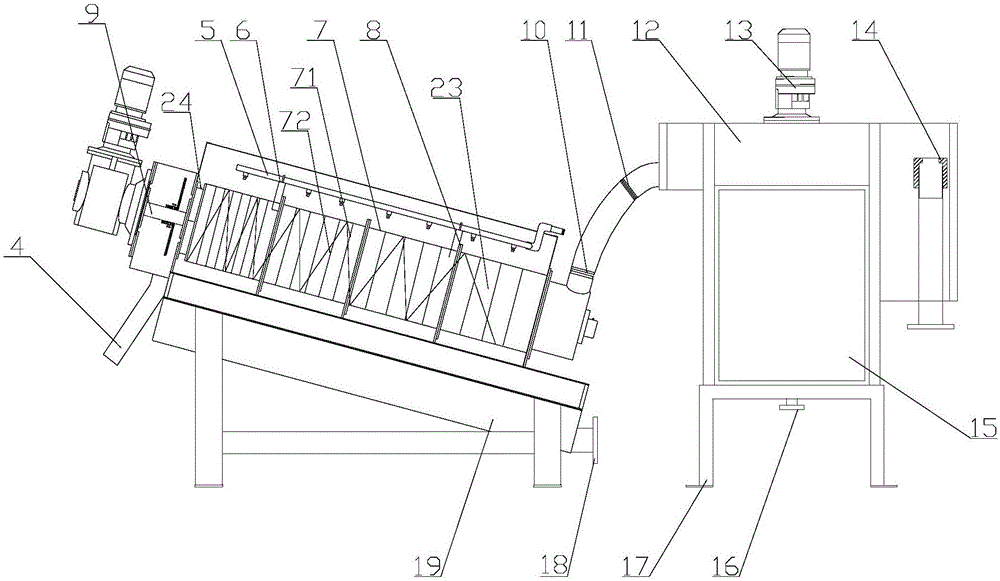

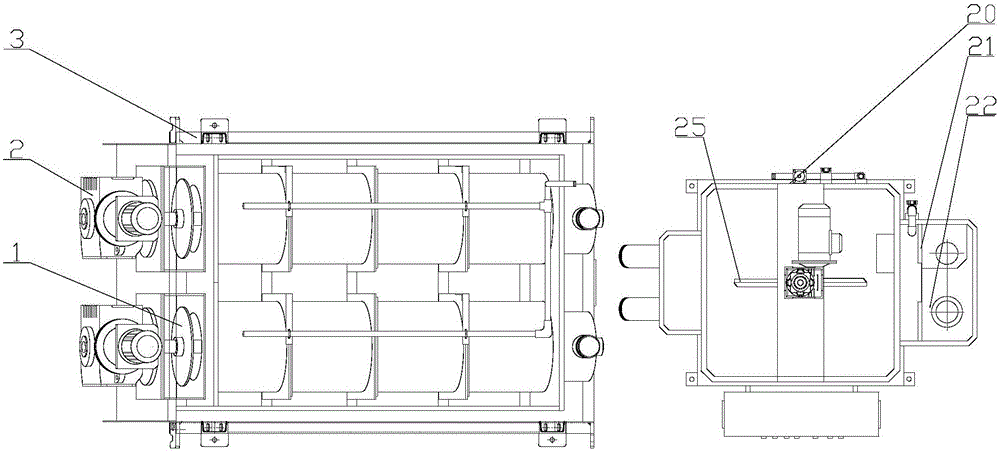

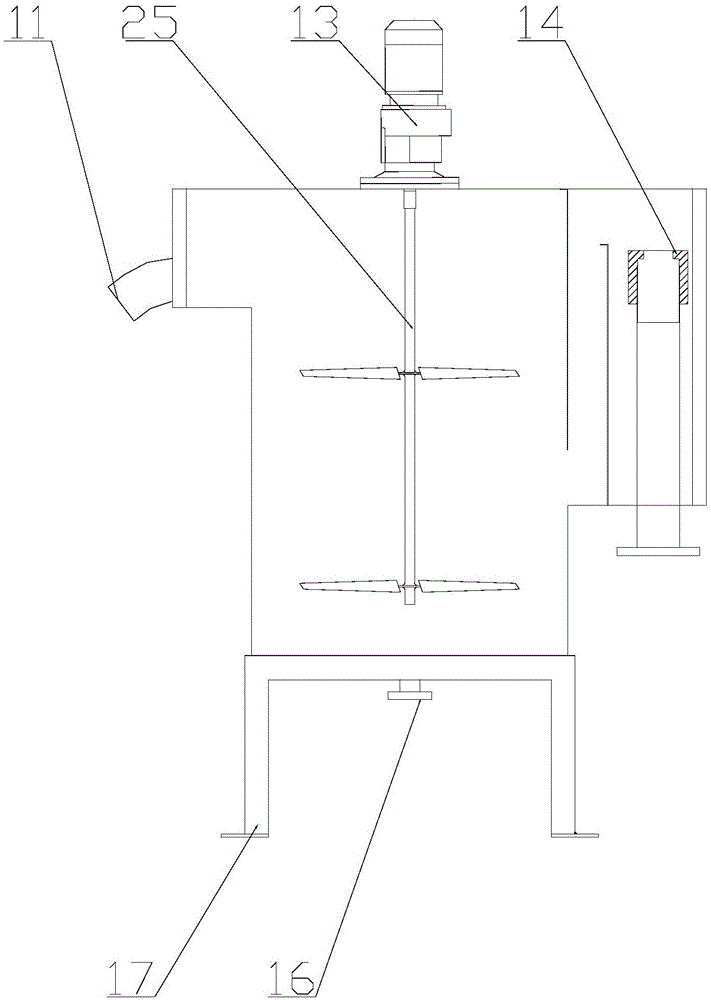

[0015] Such as figure 1 , figure 2 and image 3 As shown, the stacked screw sludge dewatering machine includes a stirring flocculation device and a dehydration device,

[0016] The dewatering device comprises the first mud inlet 10, the first mud outlet 4, the stacked screw body 7, the support plate 8, the screw shaft 9, the frame 3 and the first power unit 2, and the stacked screw body 7 is composed of a fixed ring 71 and a moving The rings 72 are stacked on each other, the fixed ring 71 and the support plate 8 are provided with a number of corresponding through holes, the screw rod 24 is inserted into the through holes, and gaskets are arranged between ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com