Moulding unit for girder construction by means of quick-assembly systems

a technology of quick assembly and girder, which is applied in the direction of bridges, bridge erection/assembly, forms/shuttering/falseworks, etc., can solve the problems of requiring more concrete consumption, a certain complexity in set-up, and difficulty in disassembly, and none of the formworks described above enable the construction of perforated girders nor double-t girders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

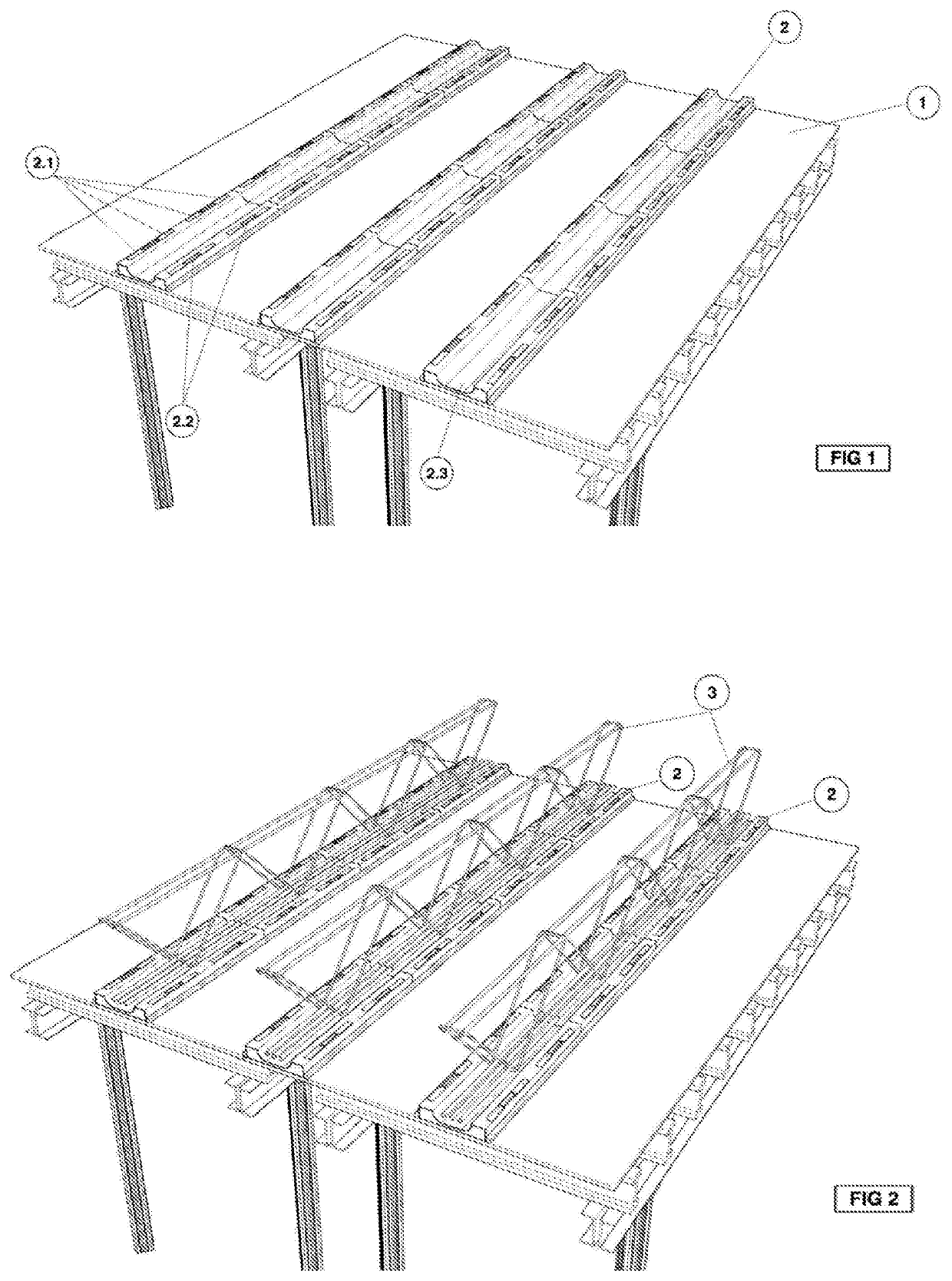

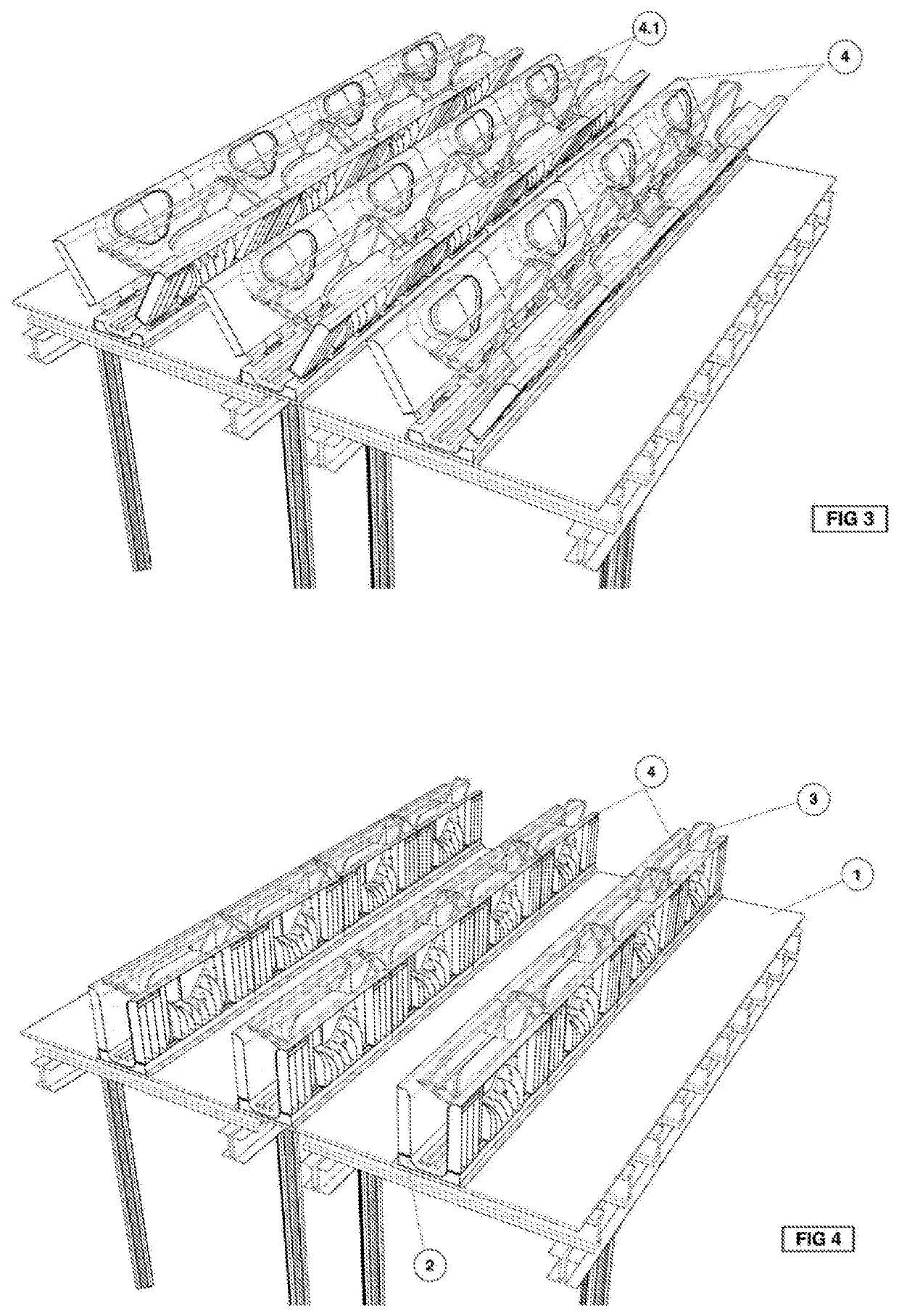

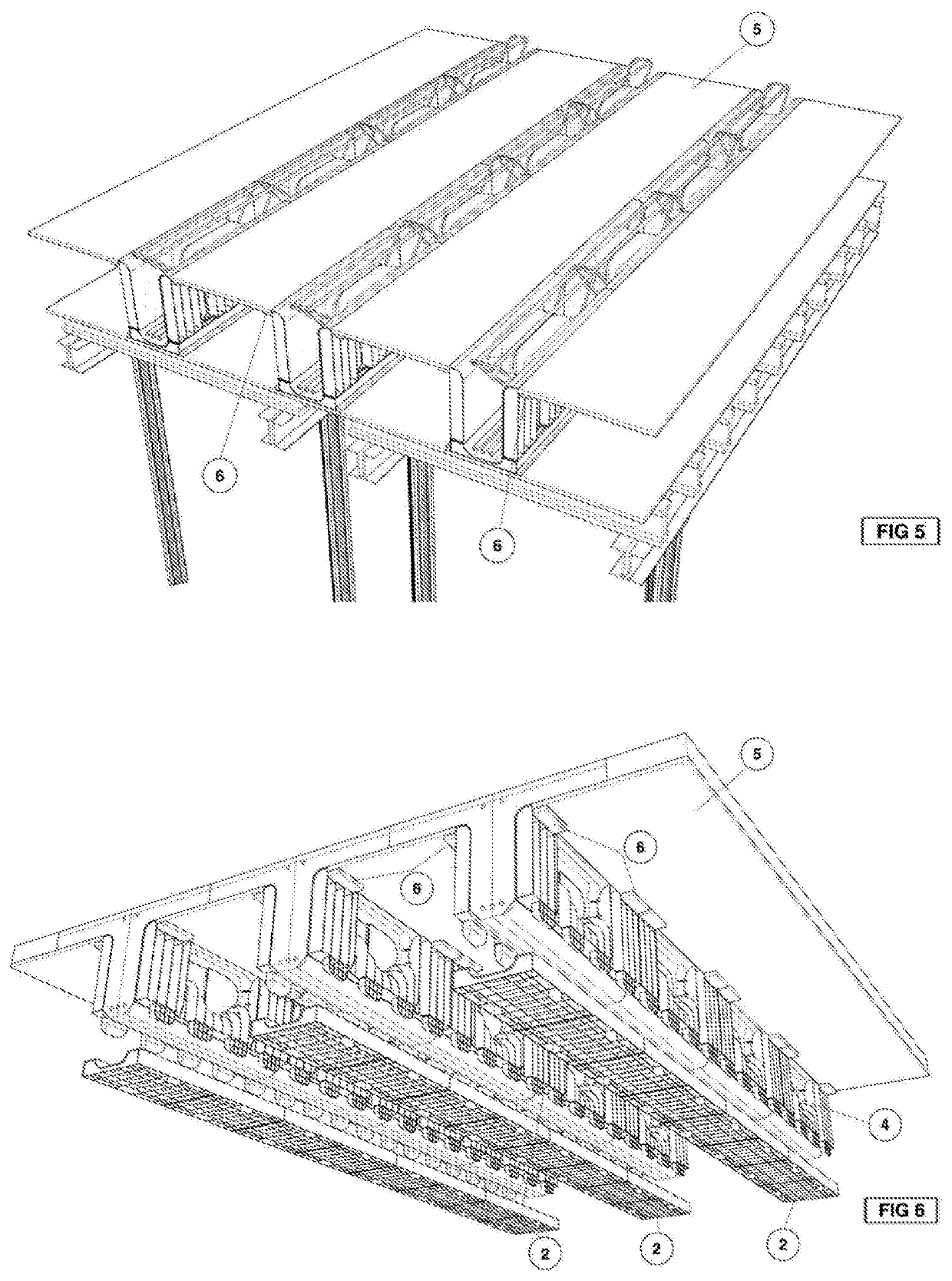

[0010]This invention relates to a moulding unit for girder construction which simplifies the construction of girders directly on site.

[0011]Unlike other girder formwork systems, all the pieces are fitted via clips; the pieces do not require any adjustment before being fitted and they are designed in an easy-to-handle format.

[0012]In the case of building perforated girders, the frameworks can be placed in the first place thanks to the ease of turning of the system.

[0013]The moulding unit comprises a closing piece placed on a horizontal surface onto which side panels are secured, for which purpose the closing piece has side perforations arranged longitudinally and in line with projections that the side panels have on their lower edge.

[0014]The side panels fit together by means of an angular or swinging movement. For this purpose, both the projections and the perforations have a rounded edge on their inner faces.

[0015]The side panels are vertically secured onto the closing piece via cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com