Optical fiber manufacturing method

A manufacturing method and optical fiber technology, applied in the field of optical fiber manufacturing, can solve problems such as complex procedures, low processing efficiency, and long time consumption, and achieve the effect of simplifying the process and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

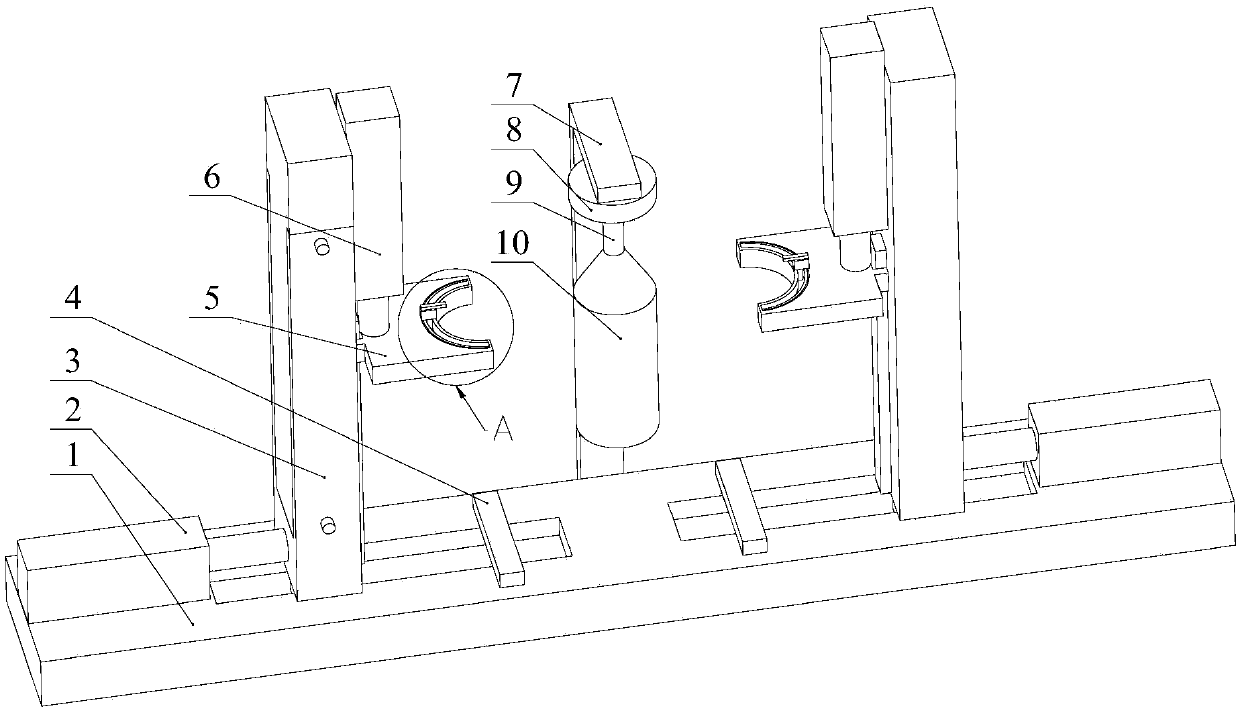

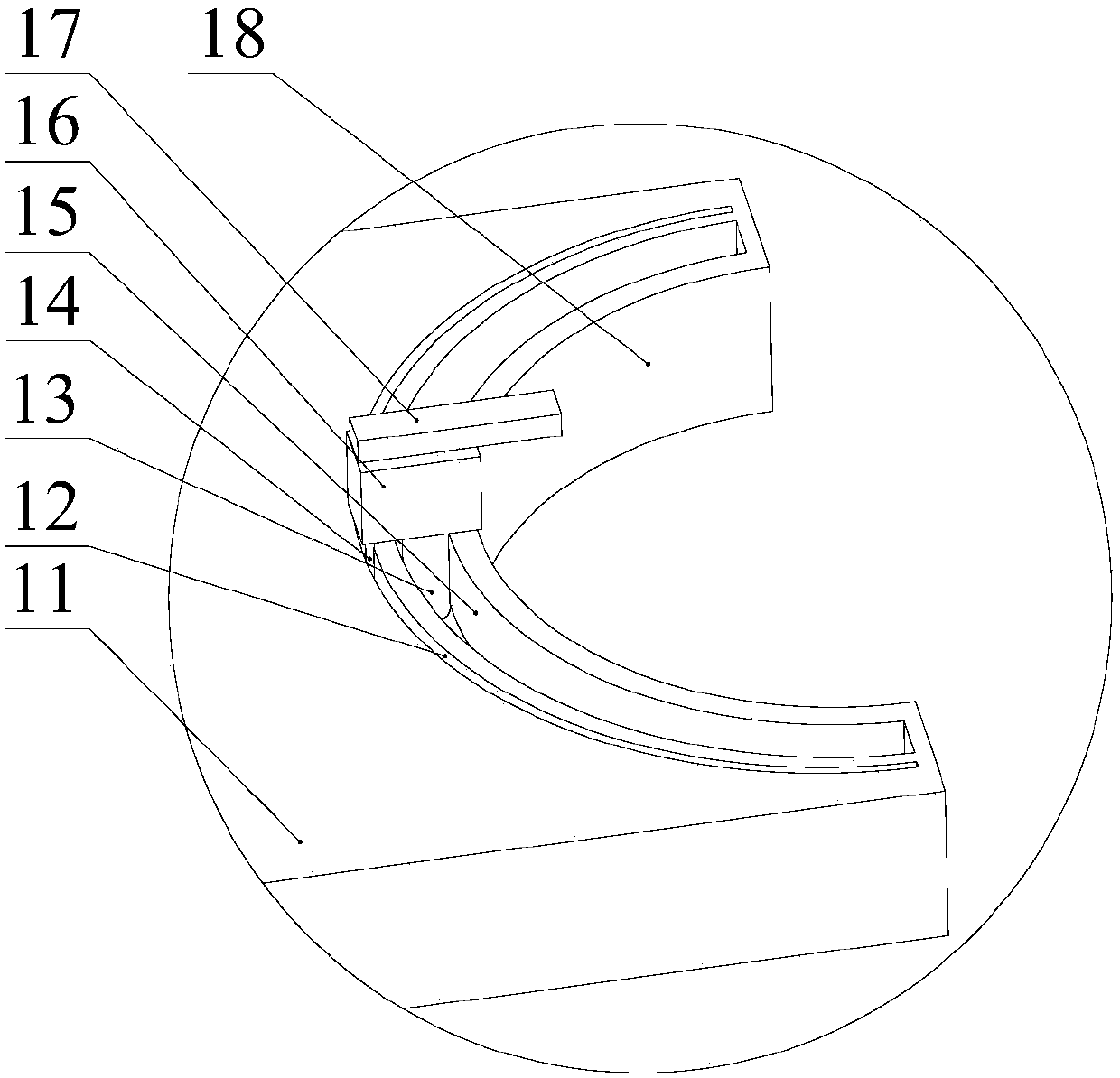

[0037] Below in conjunction with each accompanying drawing, the present invention is described in detail.

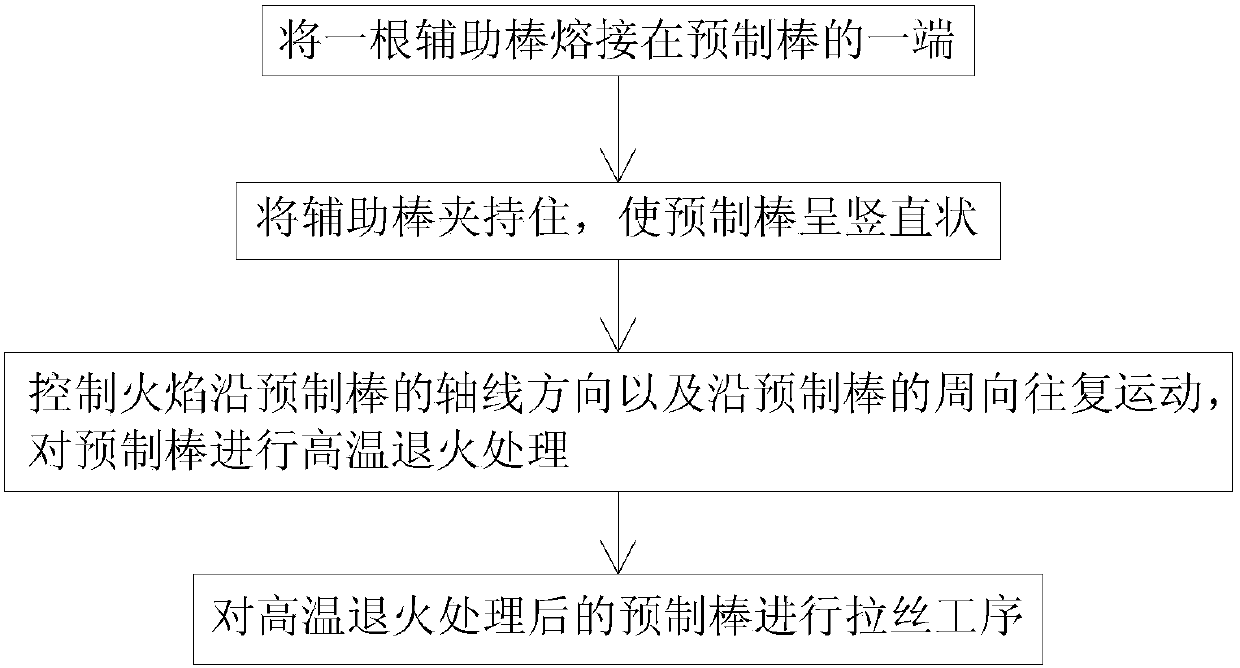

[0038] Such as figure 1 As shown, this embodiment discloses a method for manufacturing an optical fiber, comprising the following steps:

[0039] 1) An auxiliary rod is welded to one end of the prefabricated rod;

[0040] 2) Clamp the auxiliary rod so that the preform is vertical;

[0041] 3) Controlling the reciprocating movement of the flame along the axial direction of the preform rod and along the circumferential direction of the preform rod, and performing high-temperature annealing treatment on the preform rod;

[0042] 4) A wire drawing process is performed on the preform after the high-temperature annealing treatment.

[0043] In the existing manufacturing method, two chucks drive the preform to rotate, and then the blowtorch only needs to reciprocate along the axial direction of the preform to perform high-temperature annealing treatment. Compared with the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com